Bastl tromso User manual

last update: 9. 9. 2016

TROMSØ v1.0 - Assembly Guide

bastl-instruments.com

INTRODUCTION

This guide is for building Tromsø module from Bastl Instruments. It is good to have basic soldering skills

and to be able to identify electronic components before starting this kit. However if you have never

soldered before, check out this tutorial first . We even included some of the best quality solder to help

1

you solder everything faster and better.

The Tromsø kit consists of two boards. All the parts comes in three bags separated for Top board,

Bottom board and Assembly parts. See Bill of Materials (BOM) for detailed list.

1 http://www.instructables.com/id/How-to-solder/

1

Before starting this kit, prepare the following tools:

● Soldering iron (15-20W)

● Multi-meter

● Flush cutters

● n2. hex screwdriver or allen key (enclosed with kit)

● Phillips screwdriver

● Wrench No. 8

● Protective eyewear

After the Tromsø is built it should be calibrated. You can use your mobile device with installed tuner

application for this purpose. For details see the Calibration part below.

We suggest that you work in a clean and a well lit and ventilated environment to avoid accidents or

losing any of the small components.

Also briefly go through this guide and make sure that you understand all the steps.

BOTTOM BOARD

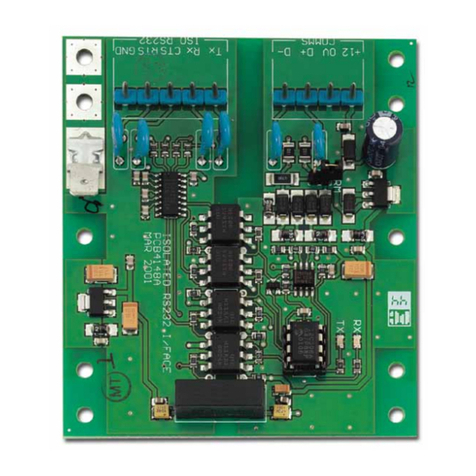

You will start with the bottom board PCB. Before you will start soldering, take your time and find all the

resistors values using a multimeter (or you can check the color codes if you are seasoned enough):

2

-470R (1x), 1k (4x), 10k (3x), 15k (1x), 30k (1x), 33k (1x), 100k (8x), 150k (1x), 220k (1x).

Be careful to insert these resistors on the right place and solder them. Then snip the leads close to the

PCB (be sure to make this step on all remaining leads in the course of this guide).

After that solder the diodes. There are four of them (2x 1N4148, 2x 1N4007). Be careful, diodes are

polarized! Make sure that the marking ring on the diode body matches the marking on the circuit board.

2 https://learn.sparkfun.com/tutorials/how-to-use-a-multimeter/measuring-resistance

2

Now you can move to soldering the IC sockets (be aware of the right direction, there is a notch on the

sockets that has to match with the sign on PCB):

-8 pin DIL (1x)

-14 pin DIL (2x)

-16 pin DIL (1x)

Now let’s do some capacitors. According to the size insert and solder them in the following order:

-100nF ceramic capacitors (11x, marked “104” on itself)

-100pF ceramic capacitors (2x, marked “101” on itself)

-47nF/63V WIMA polyester capacitor (1x)

-560pF ceramic capacitor (1x, marked “561” on itself)

-10uF electrolytic capacitor (2x, there is a plus (+) sign on the PCB that has to match the longer

lead of the electrolytic capacitors)

Turn around the PCB to solder the 2x5 pin

male header and solder it. Be careful to solder

the headers straight. You may first solder one of

the pin, take the board in your hand and re-heat

that pin while you are adjusting the header

straight. Add also the trimmer.

3

Then you can solder the fuses. There are just

two of them. They look quite similar to a

ceramic capacitors. Place them in the “PTC”

rectangular).

To finish soldering of the bottom board you

have to connect the female headers with the

male headers from the Top board bag. Use

your flush cutters to get two pieces of 1x9

female pinheaders (you will always lose one

pin when cutting the female headers, so be sure

to cut it always after the last required pin).

Then take the Top PCB and mount the hex

spacers on it: nut-screw spacer on the top

connected with the nut-nut spacer from the

bottom. Place the headers on the bottom board

facing the female parts downwards. Now connect the boards together and secure them with the

screw from the bottom. Finally you are ready to solder all the male and female headers.

Disconnect the boards. Don’t forget to place the ICs into the sockets (2x TL074, 1x V2164D, 1x LF398).

There is a notch on each IC that has to match with the notch on the socket.

4

Great, you are done now with the bottom board! Before moving to the next one make the last check that

all parts are on the right place and every joint is properly soldered.

TOP BOARD

Now let’s do the top PCB. Again, start with the resistors:

-1k (2x), 33k (1x), 39k (1x), 100k (3x)

Then insert and solder some other parts (capacitor and transistor):

-470nF ceramic capacitor (marked “474” on itself)

-2N3906 transistor (the flat side has to match with the printing on the PCB)

Insert now all the other parts (jack connectors, potentiometers, switches and LED) but do not

solder them yet:

-100k linear potentiometers (2x, marked “B100k” on the PCB and on itself)

-200k linear potentiometer (1x, marked “B200k” on the PCB and on itself)

-Jack connectors (8x)

-Switches (2x)

-LED (1x, be careful to put the longer lead into the plus (+) hole)

Be careful to push the potentiometers right down to the PCB. Mount the spacers back again on the PCB.

Take the front front panel and lower it down on the board. Hold it together and mount it with the screw,

jack washers and nuts (you do not have to tighten them too much as you may damage the panel).

5

Then turn the unit facing with PCB

upwards. Make sure that everything

is properly aligned. Push the

switches and LED to be sure that

they come through the panel. Now

you are finally ready to solder all

these inserted parts.

FINAL ASSEMBLY

Congratulations! You have made it through. Now just connect the PCBs together, secure the spacers

with screws from the bottom and put the wooden knobs on.

Before you connect anything, make sure that your system is disconnected from power. Also double

check the polarity of the ribbon cable, the red cable should match the -12V rail both on the module and

on the bus board!

CALIBRATION

At last you have to do the calibration of Tromsø. You need a tool for measuring frequency and a little

screwdriver for turning the trimmers. You can use one of free tuner apps for mobile phones (e.g. Tuner

T1 for iPhone or Pano Tuner on Android worked pretty well in our testing).

So basically there is just one thing to calibrate: the volt per octave characteristics of the VCO

section when the attenuator is fully open.

6

Use Triangle output and amplify it yo so can hear it. Flip all the switches up. Set VCO RATE and

ThRESHOLD at twelve o'clock (as precisely as possible) and turn the ATTENUATOR at full. Now turn

on your tuner and adjust the trimmer until you will measure 240 Hz and that’s it! This process is

approximate but really close to the results of precise calibration that we do on our testing station. For

more precise calibration you have to connect your volt per octave source and play octaves (1 volt

differences) and listen if you hear an octave interval or measure if you get double frequency.

TROUBLESHOOTING

Check the F.A.Q. on our website first. If you are still in trouble the best thing is to take a nap! Especially

3

late at night! Then you can can send the detailed description of the problem with enclosed

that you are unable to make the module work on your own.

BILL OF MATERIALS

TROMSØ v1.0 BILL OF MATERIALS

SOLDERING_TOP_TROMSØ

qty

value

part

2

1k

R-EU_0204/5

1

33k

R-EU_0204/5

1

39k

R-EU_0204/5

3

100k

R-EU_0204/5

1

470nF

ceramic capacitor

1

2N3904

NPN, BULK

2

B100k

linear potentiometer

1

B200k

linear potentiometer

2

switch

8

jack connector

PJ-301BMB

1

difuse green 3mm

LED

1

18 pin

male

SOLDERING_BOTTOM_TROMSØ

qty

value

part

1

470R

R-EU_0204/5

4

1k

R-EU_0204/5

3

10k

R-EU_0204/5

1

15k

R-EU_0204/5

1

30k

R-EU_0204/5

1

33k

R-EU_0204/5

8

100k

R-EU_0204/5

1

150k

R-EU_0204/5

3 http://www.bastl-instruments.com/diy-kits-f-a-q/

7

1

220k

R-EU_0204/5

2

100pF

ceramic capacitor

1

560pF

ceramic capacitor

1

47nF/63V

WIMA polyester capacitor

11

100nF

ceramic capacitor

2

10uF

electrolytic capacitor

2

1N4148

DIODE-D-5

2

1N4007

DIODE-D-7.5

1

8 pin DIL

DIL socket - in foam

2

14 pin DIL

DIL socket - in foam

1

16 pin DIL

DIL socket - in foam

2

TL074

IC in foam

1

V2164D

IC in foam

1

LF398

IC in foam

1

10k

trimr

2

100mA

fuse

1

male 2x5

1

18 pin

female

ASSEMBLY_TROMSØ

qty

value

part

1

PCB Top

1

PCB Bottom

2

8mm

panel screw

2

6mm

screw

1

nut-screw

hex spacer

1

nut-nut

hex spacer

8

jack washers

8

jack nuts

1

allen key

3

pot knob

1

front panel

1

power cable 10-16pin

8

Table of contents

Other Bastl Recording Equipment manuals