Trav-ler Radio TT-595 User manual

r.f:)

ac,-^

HE;

-l l-

et rrl

vva *,",EEEIItrEGE

GENTRAL INFORMATION

The Trav-ler Models TT5925 and TT-595 are two-speed, four-track stereo tape re-

corders.

These reeorders have pushbutton controls for each mode ofoperation. These modes are:

Play, Reeord, Rewind, Fast Forward, and Stop. Model TT-595 is equipped with a Pause lever.

Four track recording is used, giving four full-tength monaural recordings on a reel of

tape. Any size reel up to ? inches can be used.

A neon record Ievel indlcator is used to simplify recording. A new recording ean be

made over a previously recorded tape since the rec,ording is erased before new material is

recorded. Recordings can be made from a radio, television receiver, or phonograph as well

as those made directly from the microphone.

The two tape speeds are: 7 L/ 2 ips and 3 3/ 4 ips. Using four traeks,

playing times are as follows:

ReeI Size Dual

),

4

211

o

C?

a$

dr

HP

oF

=d

trt

co\

lr|ln

dtlb

>i-

r8

,r1

*

F

7

{

I

Ur

It

\D

if

(aiil

9F

}\'

.(/t =

-O

d9

TE

g i/f

g)

o

D

rot

50(

5" (600 ft. )

?" (1200 ft. )

33/4

I hr.

2 hrs.

Track

7 r/2

L/ 2 hr.

I hr.

Quarter

33/4

2 hrs.

4 hrs.

Indianapolis 6, Indiana.

0ATE t0 - $2

the recording and

Traek

7 L/2

I hr.

2 hrs.

Pir

IL

IL

34(

t6t

L

IL

3?5

T.

Connect these recorders to an outlet supplying Il0-I20 volts AC, 60 cycles only.

Man uf actu red By:

Trav-ler Radio Corporation

5 7 W. Jackson Blvd.

Chicago 6, lllinois

HOWARD W. SATtrS &

The listing of any available replacement part herein does

not constitute in any case a recommendation, warranty or

guarantyby Howard W. Sams & Co., Inc., as to the quality

and eultability of euch replacement part. The numbers of

theae parte have been compiled from lnformation furnished

to Howard W. Sams & Co. , Inc. , by the manulacturers of

cQ485

G (o.r I N C. lndlanapolls Ci, lndlana

the particular type of replacement part listed. Repro-

duction or use, without express permission, of editorial or

pictorial content, in any manner, ls prohibited. No patent

liability is assumed with respect to the use of the informa-

tioncontainedherein. @ISGZ HowardW. Sams & Co. , Inc.,

a

]-t

-l

ctit

er

-rl

e

e,

l';l

-t

CJI

Printed in U.S. of Amerlca

TRAV-LER MODELS

TT-595, TT-5925, TTS-593O

MODEL TT-595 M0DtL n-5925

stT 601 totDER 15

TO P V IEW OF MECHAN I SM W ITH TO P COVER REMOVED

FUNCTION OF

Stop

Depressing the stop button stops the recorder

in any mode. This button should be depressed first

when going from one mode to another.

Forward

This control advances the tape onto the take-up

reel at a rapid speed.

Rewind

This control rewinds the tape onto the supply

reel at a rapid speed.

Record

Depressing this button actuates the play-record

switch in the amplifier. Any signal fed into the ampli-

fier will be recorded on the tape.

Play

This button places the recorder in the playback

mode of operation.

PAGE 2

CONTROLS

Pause Lever - Model TT-595

The Pause lever allows the operator to stop the

tape travel for short periods of time.

Channel Selector

The Channel Selector selects the channel or

channel.s the recording is to be made on, or played

back on.

Speed Change Knob

In the down position, the recorder is set for

7 L/2 Lps. In the up position, 3 3/4 ips. The Stop

button must be depressed before operating the Speed

Change knob.

0n -0ff -Vol u m e

Turning the control clockwise turns the power

on to the recorder. Further rotation increases the

volurne level.

Tone

Turning this control clockwise rvill increase the

high frequencies and decrease the low frequencies.

OPERATING

Threading the Tape

l. Place a reel of tape on the supply spindle (left).

2. Plaee an empty reel onthe take-up spindle (right).

3. Unwind two feet of tape from the supply reel,

hold a section taut and insert it in the tape slot.

4. Insert the free end into one of the slots in the

take-up reel and turn the reel a few turns to

secure the tape to the reel and to take up all

slack between reels.

Speed Change

To ptay or record at 7 L/ 2 ips, depress the

Speed Change knob. To play or record at 3 3/4 ips,

raise the Speed Change knob.

CAUTI0N: The Stop button must be depressed

before changing speeds.

Channel Selector

This eontrol selects the channel or channels the

recording is to be played on. The channels for side

one of a reel are l-4; and for side two, they are 3-2.

Recording Monaurally - Quarter Track

1. Thread the tape, see "Threading the Tape".

2. Set the Speed Change to the desired speed.

3. Set the Channel Selector to the l-4 position.

4. Plug the microphone into the microphone input

jack.

5. T\rrn the recorder on by rotating the On-Off-

Volume control knob clockwise.

6. Depress the Record button, talk into the mic-

rophone and adjust the volume control until the

Record Indicator flashes onthe loudest passage.

7. Depress the Record button andat the same time

depress the PIay button to lock the Record but-

ton down.

8. After track one is recorded, depress the Stop

button.

9. Remove the full and empty ree1s, turn them

over, place the full reel on the supply spindle,

and the empty reel on the take-up spindle.

10. Rethread the tape.

Il. Place the Channel Selector in the 3-2 position.

12. Proceed with the recordlng.

13. After track two is recorded, reverse the reels,

retlread the tape, and proceed with the record-

ing.

14. Aftertrack threeit recorded, reversethereels,

place the Channel Seleetor in the l-4 position,

I NSTRUCTI ONS

rethread the tape, and proceed with the record-

ing.

Playing Monaural Recordings - Quarter Track

l. Thread the tape.

2. Set the Speed Change to the speed the tape was

recorded.

Set the Channel Selector in the l-4 position.

Turn the recorder on by rotating the On-Off-

Volume control clockwise.

Depress the Play button.

Adjust the Volume and Tone controls to the de-

sired listening level.

7. When all the tape is wound onto the take-up

reel, depress the Stop button, reversethereels,

set the Channel Selector in the 3-2 position and

depress the Play button.

8. After the second track is played thpough, de-

press the Stop button, reverse the reels, Ieaved

the Channel Selector i.n the 3-2 position and de-'i{

press the Play button. g

9. After the third track is played through, dep"e"s!'

the Stop button, reverse the reels, set thel

Channel Selector inthe l-4 position and depressl

the Play button. g

)9

Stereo Playback - Quarter Track .ut

{

l. Threadthe tape. d

2. Set the Channel Selector to Stereo. tI

€

(')

3. With side one of the reels up, tracks I and BO

will be played back.

4. After the tape is wound onto the take-up reel,

reverse the reels and depress the play button.

Tracks 4 and 2 will be played back with side

two of the reels up.

Stereo Playhack - Dual Track

l. Thread the tape.

2. Set the ehannel selector to Stereo.

3. .Depress the PIay button and adjust the Volume

and Tone controls so they are equal.

Fast Forward or Reverse

When acertain portionof the tapeis to beplayed

over again, it is not necessary to rewind the entire

tape. The tape will advance or rewind at a rapid

speed to the desired place by depressing the Forward

Rewind button.

Tape Timer

If you wish to play back a certain recording,

note the reading on the timer scale when the recording

3.

4.

5.

6.

-l

F

I

F

m

It

3

o

g

ll|

F

ta

o

J-

tr)

trl

n

\JI

PAGE 3

is being made or heard. Rewind or advance the tape

to the number on the scale and then depress the Stop

button. Depress the Play button and the desired re-

cording will be played back.

When starting a new reel of tape, reset the

timer pointer to "O" by rotating the reset knob. By

starting at "O" on all tapes, the number location can

be catalogued for each recording on any reel.

Erasing Recorded Material

Set the channel selector as outlinedinRecording

Monaurally-Quarter Track.

The erase head is energized when the Record

button is depressed, erasing any previous recording

before a new one is made. Tapes may be erased

without putting new material on the tapes by depress-

ing the Record button and turning the Volume control

to its minimum position.

To Edil and Splice Tape

NOTE: Since it is impossible to edit and splice

one track without affecting the others, re-

cordings which are to be edited should be

limited to one track only.

l. Tape may beedited by cutting outunwanted por-

tions or by joining selections into another se-

quence. Announcements may be inserted be-

tween selections, etc. Unused sections can be

spliced together for re-use.

2. For best results, cut the tape at a slight diag-

onal, join ends together with splicing tape on

the glossy side and trim off any excegsive

width.

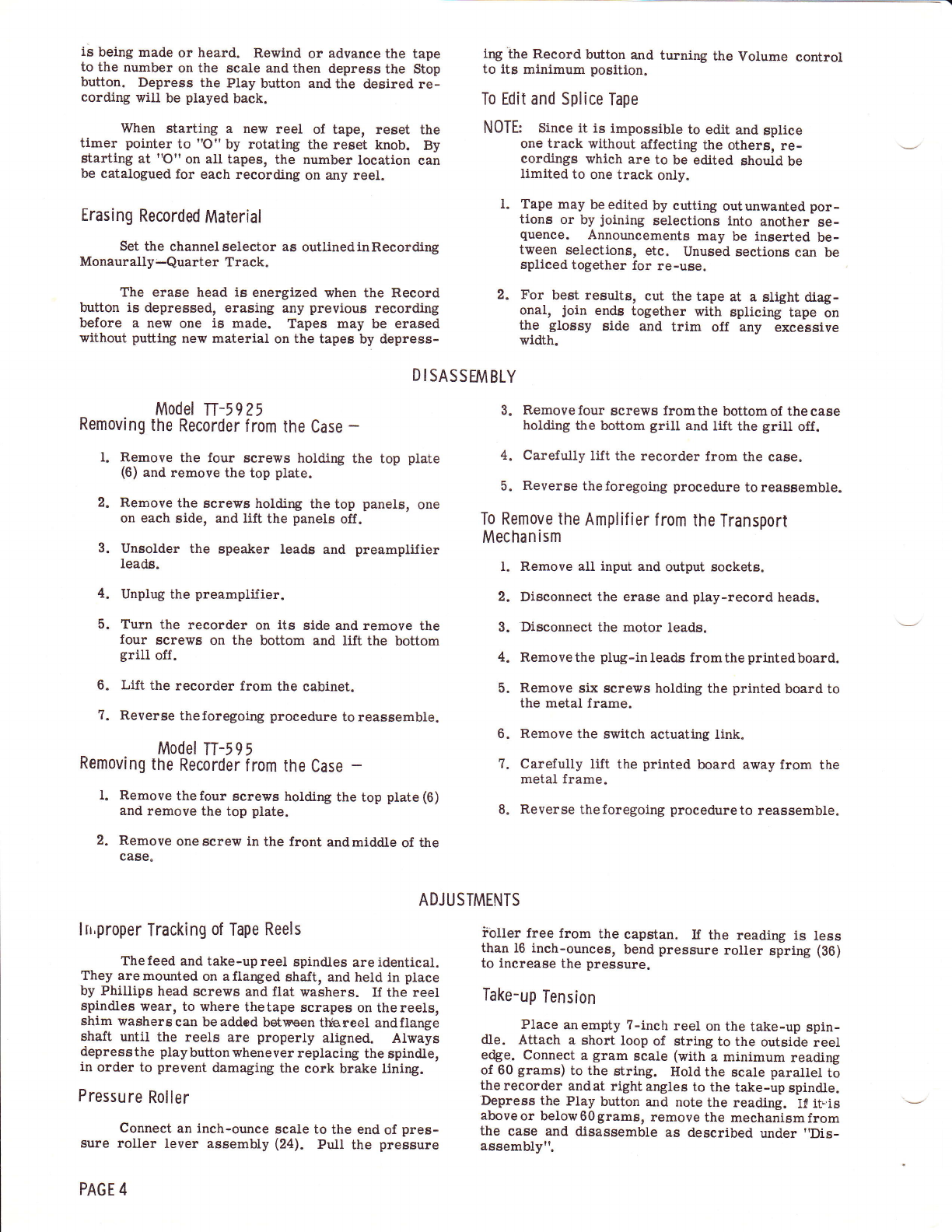

Model TT-5925

Removing the Recorder from the Case -

l. Remove the four screws holding the top plate

(6) and remove the top plate.

2. Remove the screws holding the top panels, one

on each side, and lift the panels off.

3. Unsolder the speaker leads and preamplifier

leads.

4. Unplug the preamplifier.

5. Turn the recorder on its side and remove the

four screws on the bottom and tift the bottom

grill off.

6. Lift the recorder from the cabinet.

7. Reverse theforegoing procedure toreassemble.

Model TT-5 9 5

Removing the Recorder from the Case -

l. Remove the four screws holding the top piate (6)

and remove the top plate.

2. Remove oneacrew in the front andmiddle of the

case.

3. Removefour screws fromthe bottomof thecase

holding the bottom grill and lift the grill off.

4. Carefully lift the recorder from the case.

5. Reverse theforegoing procedure toreasgemble.

To Remove the Amplif ier from the Transport

Mechanism

l. Remove all input and output sockets.

2. Disconnect the erase and play-record heads.

3. Disconnect the motor leads.

4. Removethe plug-inleads fromtheprintedboard.

5. Remove six gcrews holding the printed board to

the metal frame.

6. Remove the switch actuating link.

?. Carefully lift the printed board away from the

metal frame.

8. Reverse theforegoing procedureto reassemble.

DISASSEMBLY

ADJUSTMENTS

ln,proper Tracking of Tape Reels

Thefeed and take-up reel spindles are identieal.

They aremounted on aflanged sha.ft, and held in place

by Phillips head screws and flat washers. If the reel

spindles wear, to where thetape scrapes on thereels,

shim washerscan beadded betwtsen ttle,reel andflange

shaft until the reele are properly aligned. Always

depressthe play button whenever replacing the spindle,

in order to prevent damaging the cork brake lining.

Pressure Roller

Connect an inch-ounce seale to the end of pres-

sure rol,Ier lever asgembly (2a). PuU the pressure

PAGE 4

iblter free from the capstan. If the reading is less

than 16 inch-ounces, bend pressure roller spring (36)

to increage the pressure.

Take-up Tension

Plase an empty ?-inch reel on the take-up spin-

dle. Attach a short Ioop of string to the outside reel

edge. Connect a gram scale (with a minimum reading

of 60 grams) to the string. Hold the scale parallel to

therecorder andat rightangles to the take-upspindle.

Depress the Play button and note the reading. Itr it is

aboveor below60gramg, remove the mechanismfrom

the case and disassemble as described under "Dis-

assemblytt.

{

7

I

F

trt

v

3

o

I

m

F

(a

{

-{

I

gt

€

(rl

-l

d

I

(Jt

€

)o

Ur

{

-l

tr

T

gt

€

GI

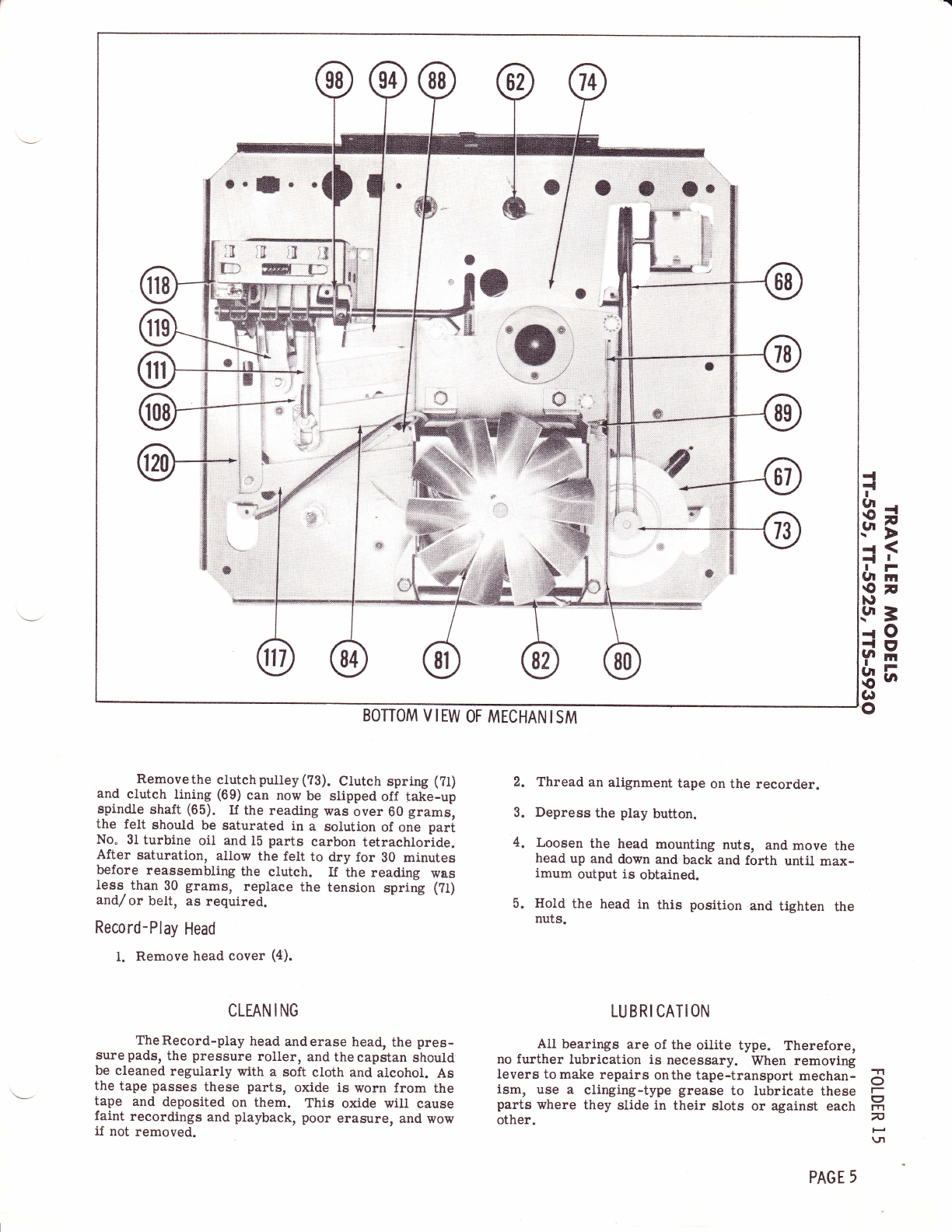

BOTTOM V IIW OF MECHAN ISM

Removethe clutchpulley(TB). Ctuteh spring (?l)

and clutch lining (69) can now be slipped off falie-up

spindle shaft (65). If the reading was over 60 grams,

ihe felt should be saturated in a solution of one pari

No. 3l turbine oil and 15 parts carbon tetrachloride.

After saturation, allow the felt to dry for B0 minutes

before reassembling the clutch. If the reading w&s

Iess_ than 30 grams, replace the tension spring (?I)

and/or belt, as required.

Record-Play Head

1. Remove head cover (4).

CLTAN ING

TheRecord-play head anderase head, the pres-

sure pads, the pressure roller, and the capstan should

be cleaned regularly with a soft cloth and alcohol. As

the tape passes these parts, oxide is worn from the

tape and deposited on them. This oxide will cause

faint recordings and playback, poor erasure, and wow

if not removed.

Thread an alignment tape on the recorder.

Depress the play button.

Loosen the head mounting nuts, and move the

head up and down and back and forth until max-

imum output is obtained.

Hold the head in this position and tighten the

nuts.

LUBRI CATION

All bearings are of the oitite type. Therefore,

no further lubrication is necessary. When removing

levers tomake repairs onthe tape-transport mechan-

ism, use a clinging-type grease to lubricate these

parts where they slide in their slots or against each

other.

t

3.

4.

5.

o

(7

rrl

n

\tl

PAGE 5

=

lJJ

o-

o

o

e,

c)

dr

o

u-j

o-

rr\

o\

rn

I

lJ.l

o

o

=

N

l-

d

r{

lrr

\o

E

TJ

€

\t

ra

s

PAGE 6

6

u

F

o

z

o

o

F

k

o

# g.g.

ftsh

4oo

E9!6'

56gg

c,XAl'

HOOO

.ijddi

EAes

E*fi6

6{+ x

c k k.i3

q o od

olooli

6#&E

fr;

lF

>c

EG

F

k

o

F€

6NF

@oo=

@Nroo

OFFO

FOC'F

trl

z

e

4' oooo

EBEE

htD6b

Es rd o

tn

U

F

o

z

F

o

F-

z

q

=

u

U

J

g

u

&

d

az

g?

T{<

NN

o6

tr

frl O

,72

ir

H

@@

{.{

oo

oo

66

u

c

F

C

=

U

ttt

o

q

LEE

AA

u

!<r$

66

Ei iN

AA

tn

q

F

o

z

F

o

F

z

!

=

q

U

L

u

e

-oZ

.9p

LE r

ori

IL

o.

vd

6<

lc

F

LO

o7

CL

oit

6<

4

o

.=L

OF

<&

&

E:

la:

lL

>ir

Eo

t{

€

€

6

o

o

@

u

U

z

o

u

c

a,

(-

a

a

g

q

6I

@

o

6

rrr

ii N

t'r

a

q

F

o

z

o

o

,

a

i$

frH

;6

Hr

ad

fiA

o

F

o

F

z

q

{

q

U

L

q

E

o

vZ

o

iq 4

oo

EF

Od

Fd

so

o2

oiz

6<

e

o

'i4

OF

=t

c

tr

ts-t, d

'iz

bp

E3

o

tr

@

6

{.

o

o

6

o

z

F

4

@

hg

cix

Hq

'@

@

:s

ia

Er E{

l-

o

o

z

I

c,

;

an

=

o

1rl

z

J

J

trl

(J

L

e,

gJ

Y

Itt

4

UI

F

f

o-

F

f

o

I

o

3

d,

tlt

=

e,

o

lr

ttl

z

E

F

e.

tlt

=

o

g

c

lrl

=

&

o

l!

ra

z

c,

l-

t!I

t!

&,

lr.|

J

o

()

=t

ot

E

ot

0

.E

at,

E

1)

6

6

o,

rnE

4a

9s

FO

vtl

;;b

lll :-

et

E.

l,lg

z€

fi:

-1

-

l-

r

I

/

(,

la

lr|

a

o

z

l-

.-- llf

I

J

ta

h

&

c

I

-

n

o.

ltt

*

l-

w,

lr|

!o

3

F

d

c

o

(

u

o

tu

s

o

o

E!

€

o

o

.t

o..

E'

I

oj

:so

+2

-l

{

I

Ul

8;

\D

rf

t-

ut iil

€F

\t

srt 3

-O

dH

lr

Sr,'

0|

o

d

.9

o

k

o

o

E

o

o

€

a)

o

o 'll

so

Or

sb

EFI

fin

Or tl

,!i

I

o

a

o

L

o

u

"o

k

JA

gd

Poi-

odt

1r>t

SgrE

6E5

.o_

g<z

o

d

o

,,

g

ad

a

d

E

h

o

d

I

o

trv,

UJ

io

ee

'=F

EZ

?o

Ee

o

dt

d

tn

c,

o

E

I

o-

(J

(J

l-

J

o

c

F

(J

llr

J

ul

vl

&

-o

5F-

bo

E<

i4

.E<

d(J

k

fo

.E lrt

€x

=-

.glL

a<

H*

-o

}4o

ri

AV

{Es

!Jk

il ot

o'tt o

& -6t

:;E

gEE

EEo

& E;

$Et

v,

g

F

o

z

d

*c

c2

o-

EF

td

Od

>

.d

gz

CE

oiz

'tf,

o

oL

=.

<d A

o

4z

OL

=i

4

Ei9

.tF

>ts

ti

g

tt,

lo

o

)

Ei -1

F

o

F

z

u

d

U

U

G

p

d

$xeFEx*cxBx*'xsHHEuE

g(?€F€oOido{{@@F@OO:N

NNNNNNOOOO600066s*i

&e&frtr d C d tr trfi trtr C tr C tr !i !i

F

6

F

z

u

{

u

U

c

u

e

t

g

o

N

s}

xgigHHHgxHHrXrEEHgHx

<,@.4F -o g =S gE 99IPgR F S R

E&e&trtr trtrtrtrtrcctrtr!(d tr tr d

th

u

F

o

z

z

o

J

J

ts

tt,

1

E{

3t

+i,

oo€

!$ei

oooS

>At<tr

Bt

+F

1Z

aq

s

f

z

!

E

!

J

5

ud

e7

IL

tt iy

5f

ts

<.;

61

O-

eit

da

te

<z

fiF

trF

Fld

t-

<rz

G<

ti4

o

35e

o o;l

N N=

o oo

F FF

o

z

F

e

q

F

;

FI

nt

tz

p< E*

v!8e

o.coo

o Foo

6(a@N

Ei <El

d

ts

o

F

z

q

:

u

u

I

c

u

x

Rd

o4

E?

6L $E gEgHHAH $ fiEEHgEEEgEgEggH

>:

E!

oz

=! et i:eixgE E ficsHE Efi=E;E;H6

o,

UJ

uF

ilA Eg Hd$Hd6H I frada6E3gEddH6Hd

ie;

=Er

3d; gg g;Ag;Ng B HSEHEHEHggfrHHHE

E

<d

<L

tss

EL

6f *i EAAAEA A AAEA Ei:EH Ni

gt

9E

u<

<A

sE r i F s E

EE :nlnni* g *IIA: Eng El:H$

.t

tl

g

=

U

4N

o

F

ag

c)

o

z

o

z

F

4

s€ F* s

dcef : -:!E.ii*i s*H gs i: H

RB -:t qt s.qq3.E s. e QR 8.Q iE I Qs =q?€ qe

F: sY?eE: es, 9 iEE g99l99RdSR*KFF RR3*

()oo o e o o o o o oe eee e () a U o oO ct qt O ij() ii

gci

oz

dq

A<

6A

F

o

@

'oO

{d

3i

HF

oci

=z

{r

e4

4d

@

N

I

oI

a

F{

i_d

o.

3t N

N

C'

H

:ei

EEi 6I

t{

o

t

D

I

D

i,)

*

4E2

FEE

Ud;<

@

N

I

o

G

rl

n

Ii

9E

u<

<A

o

6

6l

TA

c

Fr

frs

.rF

>c

F{

o

o

o

6

F

lat

Do

)o

:F

(

I

F

J

oto oo

o660(tno6

$ONOOAG|N

4

UtOOOOOOa

o6q{$66=

.l ll.

S-e 5teo*noQo

)o()

d

a

o

6

14

()

o

E

o

o

d

o

a

c

o

z

J

()

o

2

=

J

t/,

a

z,

o

lrt

!

F

E.

I

(J

a

F

()

lfl

J

trl

J

d,

l4l

z,

l4l

I

b*

EE

E&r

O od

E frE

tr!6c

tL

rD ro

oo

E Er:

<<d

frf*?

<<o

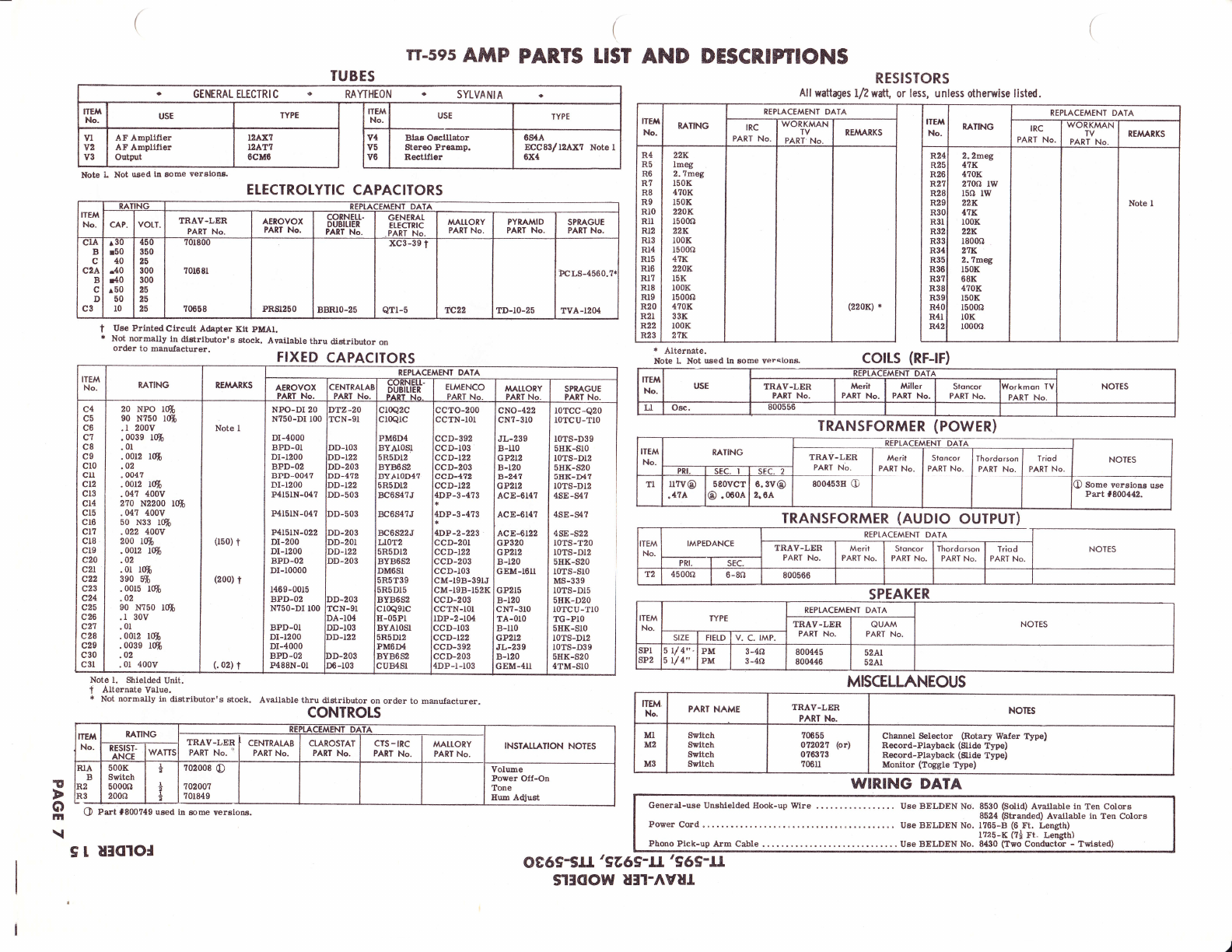

PAGE 7

ECC83 6X4

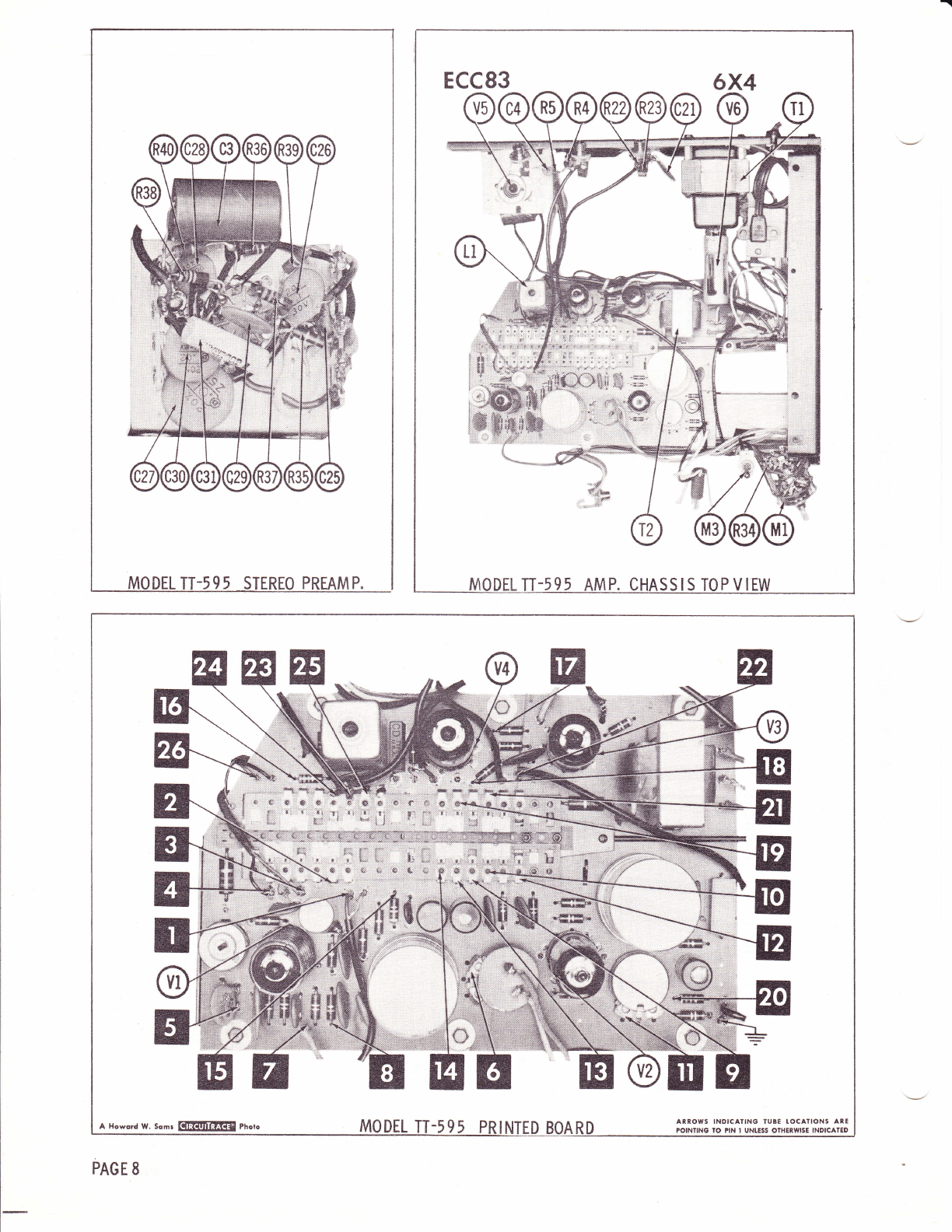

MODELTT-595 AMP. CHASSIS TOPVI

A Howord w. somr Qf,lSf,fllS rtoro MODEL TT.595 NTED BOARD ARROIYS INDICATING TUBE IOCATIONS ARE

POINTING IO PIN I UNI.ESS OIHERWISE INDICATED

MO DEL TT.5 9 5

PAGE 8

A Howord w. ssmr

tn

u

F

o

z

tr

J

o

E,-:.

*-9

iDo

2z

i!

t{

A

o

F

o

F

z

q

{

q

U

J

I

o

o

'-F

G

x

\tl

N

0

o

oci

IL

o.

TE

6<

€&

F

o

!r

o

@

N

.ct

gz

oiy

.;<

L

o

t|l

o

N

I

o

,=A

OF

<d

d

a

{.

@

o

N

I

o

€

H;

F{;

IL

<t

d<

E{d

@

I

o

k

u.

EE?

ufo

)UQ

2e= F

t^

U

e

U

oc

11:

<.

-t

u-

di

r:i

J@

U> o

f;-e

l-Z sl

ll

tn

q

F

o

z

!

c

F

z

g

€

!

J

L

!

v

tsd

c7

o-

Ets

ve

bt

l

8z

oiy

,tf,

o

6z

=t

A

<t

OL

=t

4

Hi

IE

ds

F<

@

6

6I

o

o

6

u,l

th q)

o

o

u

ql

trl

f;-e

l- Z. ,l

ut

tz

o

I

u

&

tlt

F

J

l!

t!l

IL

E

rn

J

6

(J

E

o

e

.2

(D

6

'=

L

qt

!o

a

6

o)

-.: (/!E

S c,=

.i 9 s

rr F o)

60

oo vl .

o€-=

29 llJ E'

38 EE

166

EE \.

oo a

*-< F

66 -

pp t;

&&-

HH

@@

Fc fq

oo

dd

aa

dd

oo

88

Fl Fl

tl

tst{

99

v,

-l

o

&

F

z

o

I

UI

2

o

I

l-

r

e

(,

UI

EI

a

o

z

l-

ta

I

J

ta

F

4

I

4

-

Ir:l

o{

o

tr1

I

l-

Fv,

ur

co

=

F

o

d

l{

o

*

k

o

h

t

o

cd

rd

H

o

I

rt,

d

t{

o

o

k

E

t{

o

€

c

t{

o

d

d

,la

C'

o

o

3

k

.o

6E

E!

eE

&c

an 'i

A>

EE

git

lL--

>o

6lg

-t{ e

FO

,z

r* *

k

o

k

3

o

,g

t

a!.

E

.; vt

3Ee

J: O

rdo F

rlt

:Q (J

s.E

e'd o-

dE

3: L'

6k

gf o

8.9 ut

:6 x

J.l

€s u.

.g<

>'!l

E8

@6

tto

tr!

$t

Hf

-o

*.9

dtt

E.g

a-

od

EE

ok

>o

o-

EO

oz,

an'

o"

r,r)

g,

o

=

t\,

o.

(J

(J

t-

J

o

&

F

(J

ttl

J

ul

F

o

F

z

u

{

U

U

J

c

U

4

aJ',

!z

e

{

u

e

I

+

M

N

N

o

z

i*e

4

o

uz

UF

-e c

o

z

F

es x F ixEs$rH H gHEE*H sE $re csx

Ei O ddo<{ 6OF OOO dNo{l6cOr€O O iN6g

c? a a a c? o o o c! m $ $ {r <| $ <r :n ir itr r{r 6 n @ @ 6

tr tr tr tr tr tr c c d c tr c e&&&&frfr &Gdoid(!

F

o

F

z

u

{

u

U

4

u

&

v,

Y

4

I

q

d

E-;

;L

uz

d,t

-d,d

o

z

F

e

s-y

X gf HH HH g HxHH H xEH rHcHxxEx f

Ei Aqq.q "r 9 =E : J E 9 = 9ER FS RS F RF R R

trtr trtr tr trtrtrfi trd c cddtr tr E&frdctrcc

E

€

q,

E

€,

E

o

g

L

5

Io

F

o

F

z

q

{

q

U

J

0.

q

&

Ei

i5

at

{lo

@(o

NN

td il.

trl ts]

PF II

od

dt

Its

6e

bf

F

<C;

OL

o-

e'a

64.

€

<d

<z

EF

z<

qd

(J

c

rno

'JZ

!

!3

F{

@(l,

o d oo

N N ilttl

I n €€

9e6d

FU

I/)(J

toz.

H<

BF

NN

BxBvee

oooooo

oooooo

6660dN

ul

o

3

*-^

:e:5SS

I H 9sl or'ci

E6 Es H H

?E?HE fl

tr: tr: tr ll

oooot,

t<>F>EEl

Ei <!o{E

J"N O<

& & Erd

F

o

F

z

U

:

u

U

5

A.

q

4

u-

f*

oz

'E

A<

U)A 9Eeggagega ea$gAggEgaggAecHHgEEH

i-d

oz

=! a**lgiixgq qfieH8;eiEifriEEaf;ni EH

8+

uF

fs ssm$EEEBI IHsEBEfrEHsEEaiis$E3gd

ls;

xeE

Fr

gg$EERHHHfiH$gHAH$f;HHHHHHHHHfrHHH

6

<d

<L

Fr

=e

6f s:+++ q$$F FqSF$H+H$ F$$HEFFH H

HHBAA AAAA AABAAA*AA AAdAAAEA d

!*

9n

u<

<a

*!- E 3 3SR

EEIHEEHHIF FFHAEA*HEEEHE**EEE AH

.a

Y

&

=

lrl

e

60

66

FF

c)o

FF

(,

z

F

d.

eB -S.S

,r, EE sA:$AF; E ts ss sE oE

2EH EB lr*Ez*;E s H EB EsYV Ft

-QQerQQg o$N ooa-'*oc5adi5o@NNroAN

ee <oeo oooooFoooo oo io66o66-oocj666 6

No,. ..6N..N...;.

F: -OrNo$6@F6oOiNo$@€F6O()dNO$n@Fi!f,!- laiY, I - - d d d - d d d N N NN NN N NN N oe o O gO a o

o()()()(J()()()C)Qo(Juo()()()uoa()o()C)()()()()()o()oo

F

o

F

z

q

{

u

u

U

d

Hd

oa

*!

i

r

ci9

!9 0H

{ 9f

t E*

u trF

A

6d

=z

{r-

e4

tf sB

!t

o6

NN

tlll

=>

Et

iF o

o

ts

tsa

F{ F{

ieJ

44L

uF

6E* @N

lt

tr tr

:E

isz

g:3 pB

tt

o6

@d

}B

ill

zz

Xc

Yz

9t

U<

<A

@

RS

At.

Ct{

AA

c

q.i

A,

tL

Fp

E3

o

86nE

6@tt'

F F HH

o

F

J

ooo oo

6060068.^o

{roNo€NN=6

A

Uoooooooo6

?t*1166mN

Fi SEgX*-*-*

o o otl

z.

=

ar1

I

z.

o

u

+

F

e,

I

d.

F

(J

l4.l

J

l4l

J

u,

l4l

a

q,

I

d.d

E€E

o_ 5

kFr :'

tr{<O

. NNN

"9d66

:Jtrtrtr

iitrr:c

oal6ldl

o.c,c.c

co9c)

d4

ll Hr

slgg

A<oi

idr6

d66!

tr tr cv

FFFs

!El .g;r

oootrl

PAGE 14

6CA4

6CM6

12AT7

3

vEl I

c

o

F

I

I

ra

UI

I

4

tJ

4

=

It:l

(\

o\

?

F

F

?

o

o

(J

od

o

.c

U

t^tt

F?

NV

s:

l- '0

urE

zni

6e

(J: {,

06f

vl8

i! 06

zP-

I

co .:

<f

(Je ut

c

o

!

o

o

:

att

f

o

lrl

z

J

J

trt

\J

L

4

trj

v

ttt

A.

ttt

^

+

tr

o

L'

Y

tn

z

o

-

F

g

e,

(,

8a

o;

o9

Z3

{ft

hF

EY

J;

ra=

hD

EF

L

A

E

654

ECC83 {

F

I

F

tn

F

-

o

I

FI

F

I,l

{

{

I

gl

€

(rr

{

{

I

(,l

I

h,

gl

1

r

(lt

I

6t

o

l-

o

o

z

I

4

=

al

o

F

E,

tn

7

I

(rr

u.l

ol

YO u'l

I

F

F

z

o

F

c

d

(J

rn

r

o

s fr m.t

.dC)

Uw vc

!!.. a F,

n:$ n:3

g.: rd -9.: !

6€!6EE

tioo,:oo

o

z

F

d

4F

rrxON.^ON

no@o@=-_rar

YY?lYYErd

VXMXgMQQ

U

{

z

gHEHEE

.1.1 H.?.? F

o o,c o oE

>>a>>o c)

.o.o.o.a -o.o o €

oooooooc

trdtrcctrdd

VldMldXVC)E

6

4

F

o

z

9y

e.q

ci ()

du)

'! c

9.9 ur

o o.=

o c€

8Eg

!:o

A'

rts

>ts

td

F{

I

Notl'

!tt

BBF

ra u) (h

qi

z

F

c,

GEE.4

ooo

BFF

aD lD u,

6t rNO

>E>

tn

U

F

o

z

q)

o

Q

h

C)

'l{

(d

o

o.

IA

r{

k

o

X

H

cg

o

o

@

!

.t)

I

l.

€

o

o

t

F

F

z

U

{

u

U

U

d

o

Az

{*

-oZ. KFSs

FFHH

<<<=

9$ee

H

fi

ie

tr<

Fra

t+

eeA9I

eoXX

tttl

xvv14

AAAO.

.A (h @ lt)

U

L

F

L

=

U

t6€AO

!att

@@@@

o

g

L>>E:

AAAA

q

N

6@€

j($::

- - oo

UJ

F1 iNO$

AAAO.

v7aba/j

F

f

o-

D

o

o

rn

u

F

o

z

F

o

F

z

u

:

U

U

G

W

d

o

rZ

.9F

Ld

d

X

o

I

u

c.

9o

i:z

o.

yd

6<

tr

F

o

:f

S

c,

lll

=

d

o

t!

ttt

z

4

F

uO

gz

od

.;<

C

o

'=L

qtF

2Z

c

c^'

tr] J

.tF

>d

dq

F

@.a

3F

or

€<

U

U

z

o

u

c

=

cd

€6

tl

(o ro

d

Lce

oo

oo

@@

<. rO

F: NO

ti F{

v)

q

F

o

z

F

o

F

z

U

{

U

U

U

d

ci

o

::E

d

oo

o

TF

Ld

9<

o-

CF

Od

,;<

o

o

'=L

OF

<d c

lrl o

Fl Z

3

>E

Ef

F{

€

n

0

c

Fr

()

z

F

e

@

B<

!@

(Oo

d

(,

q

ts<

tia

3(a

9s

F€I

=. @

OJ

d-:

F: I{

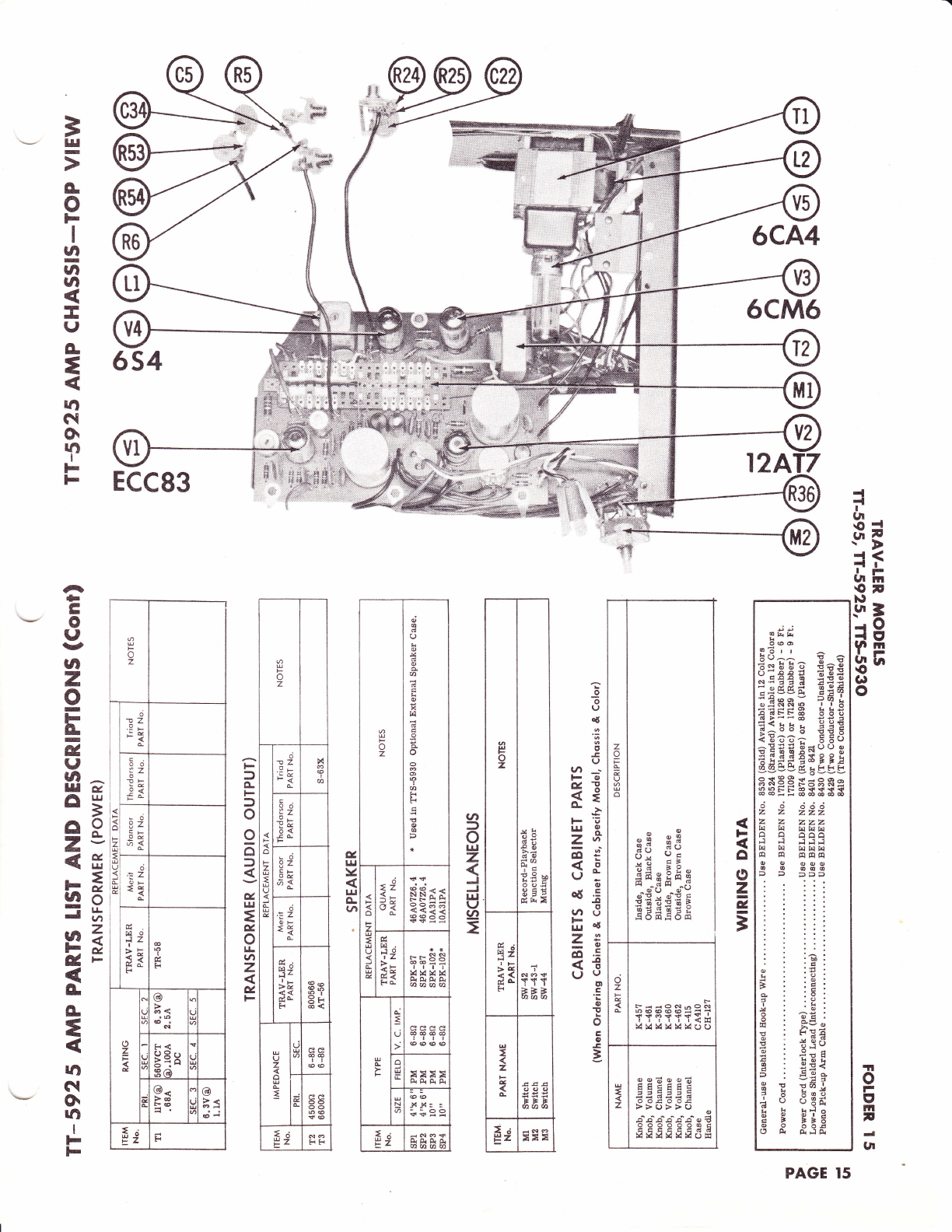

PAGE 15

l :,,

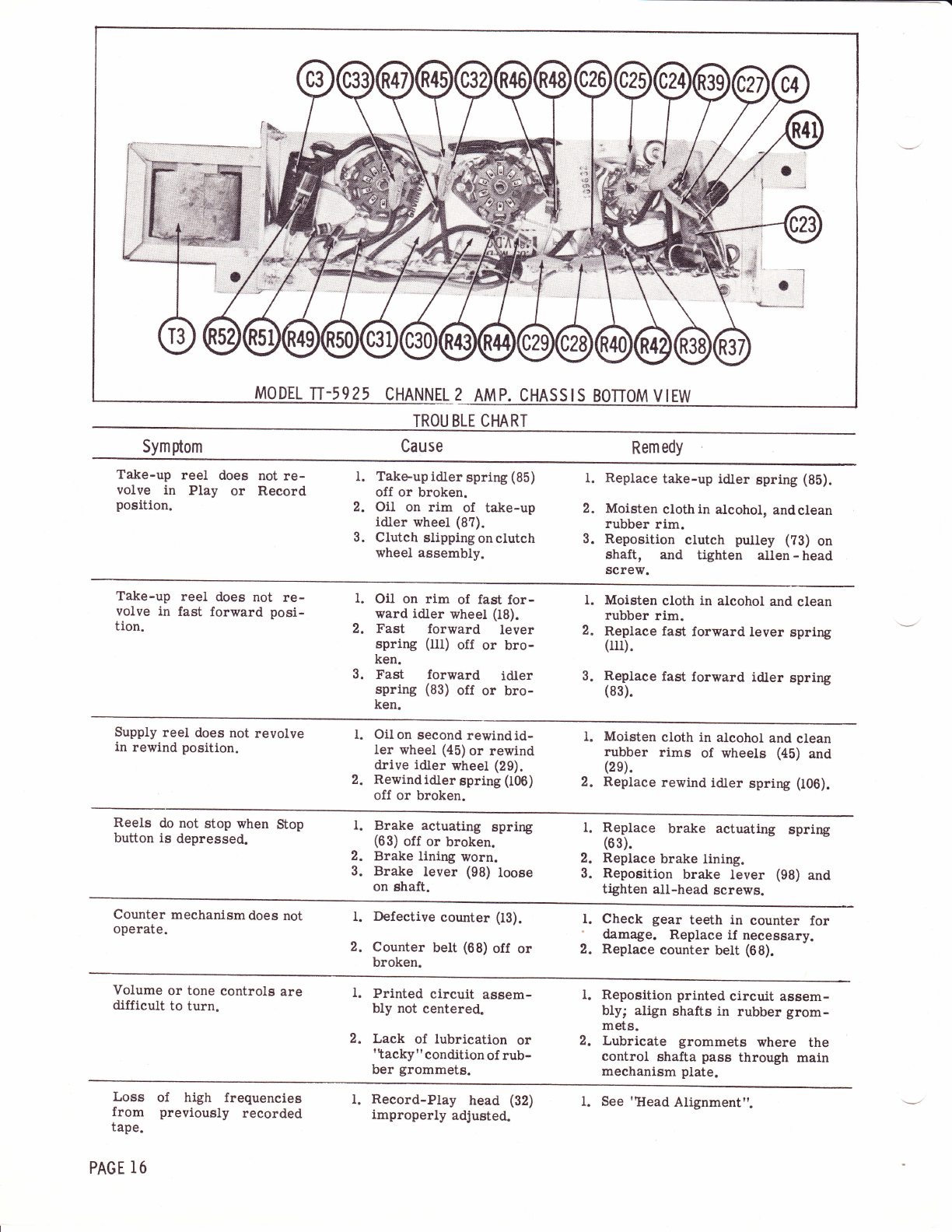

MODEL TT.5925 CHANNEL2 AMP. CHASSIS BOTTOMVTEW

TROU BLE CHART

Sym ptom Cause Remedy

Take-up reel does

volve in PIay or

position.

Takeup idler spring (85)

off or broken.

Oil on rim of take-up

idler wheel (87).

Clutch slipping on clutch

wheel assembly.

Replace take-up idler spring (8b).

Moisten clothin aleohol, andclean

rubber rim.

Reposition clutch pulley (73) on

shaft, and tighten allen-head

gcrew.

not re-

Record l.

2.

3.

l.

2.

3.

Take-up reel does not re-

volve in fast forward posi-

tion.

Oil on rim of fast for-

ward idler wheel (18).

Fast forward lever

spring (Ill) off or bro-

ken.

Fast forward idler

spring (83) off or bro-

ken.

Moisten cloth in alcohol and clean

rubber rim.

Replace fast forward lever spring

(lu).

Replace fast forward idler spring

(83).

1.

2.

3.

t.

2.

3.

Supply reel does not revolve

in rewind position. Oil on second rewindid-

ler wheel (45) or rewind

drive idler wheel (29).

Rewind idler spring (106)

off or broken.

Moisten cloth in alcohol and clean

rubber rims of wheels (4b) and

(2e).

Replace rewind idler spring 006).

2.

l.

2.

Reels do not stop when Stop

button is depressed. Brake actuating spring

(63) off or broken.

Brake lining worn.

Brake lever (98) loose

on shaft.

l. Replace brake actuating spring

(63).

Replace brake tining.

Reposition brake lever (98) and

tighten all-head screws.

t.

2.

3. 2.

3.

Counter mechanism does not

operate. Defective counter (13).

Counter belt (68) off or

broken.

l. Check gear teeth in eounter for

' damage. Replace if necessary.

2. Replace counler bett (G8).

l.

2.

Volume or tone controlg are

difficult to turn. Printed circuit assem-

bly not centered.

Lack of lubrication or

'tacky" condition of rub-

ber grommets.

Reposition printed circuit assem-

bly; align shafts in rubber grom-

mets.

Lubricate grommets where the

control shafta pass through main

mechanism plate.

l.

2.

l.

2.

Loss of high frequencies

from previously recorded

tape.

PAGE I6

l. Record-Play head (32)

improperly adjusted. I. See 'Ilead Alignment"

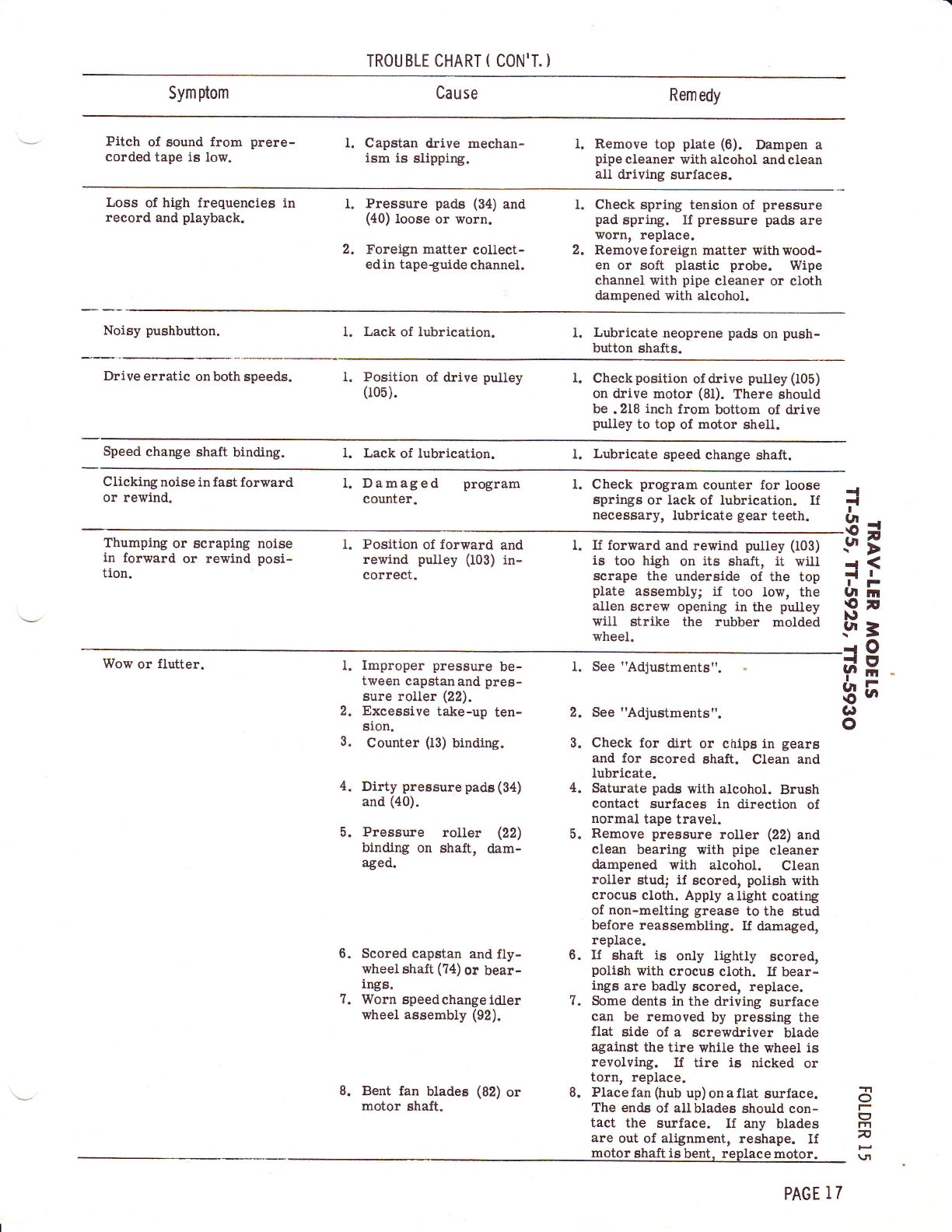

TROUBLE CHART ( CON.T. )

Symptom Cause Remedy

Pitch of sound from prere-

corded tape is low. l. Capstan drive mechan-

ism is slipping. 1. Remove top plate (6). Dampen a

pipe cleaner with alcohol and clean

all driving surfaces.

Loss of high frequencies in

record and playback. Pressure pads (34) and

(40) loose or worn.

Foreign matter collect-

edin tapeguide channel.

Check spring tension of pressure

pad epring. If pressure pads are

worn, replace.

Remove foreign matter with wood-

en or soft plastic probe. Wipe

channel with pipe cleaner or cloth

dampened with alcohol.

2.

2.

Noisy pushbutton. 1. Lack of lubrication. 1. Lubricate.neoprene pads on push-

button shafts.

Drive erratie on both speeds. l. Position of drive pulley

(105). l. Checkposition of drive pulley(105)

on drive motor (81). There should

be .218 inch from bottom of drive

pulley to top of motor shell.

Speed change shaft binding. l. Lack of lubrication. I. Lubricate speed change shaft.

Clicking noise in fast forward

or rewind. l. Damaged program

counter. I. Check program counter for loose

springs or lack of lubrication. If

necessary, lubricate gear teeth.

Thumping or scraping noise

in forward or rewind posi-

tion.

I. Position of forward and

rewind pulley (103) in-

correct.

1. If forward and rewind pulley (103)

is too high on its shaft, it wUl

scrape the underside of the top

plate assembly; iI too low, the

allen screw opening in the pulley

will strike the rubber molded

wheel.

{

F

I

F

til

v

=

o

I

Et

F

UI

-l

{

I

9t

.€

(ll

I

I

l/t

I

}9

(,l

,{

{

UI

f

gt

€

G)

o

Wow or ftutter.

4.

5.

l.

2.

3.

4.

5.

Improper pressure be-

tween capstanand pres-

sure roller (22).

Exeessive take-up ten-

sion.

Counter (13) binding.

Dirty pressure pads (34)

and (40).

Pressure roller (22)

binding on shaft, dam-

aged.

Scored capstan and fly-

wheelshaft (?4) or bear-

inge.

Worn epeedchangeidler

wheel assembly (92).

8. Bent fan bladee (82) or

motor shaft.

l. See "Adjustments".

See "Adjustments".

Check for dirt or chips in gears

and for scored shaft. Clean and

lubricate.

Saturate pads with alcohol. Brush

eontact surfaces in direction of

normal tape travel.

Remove pressure roller (22) and

clean bearing with pipe cleaner

dampened with alcohol. Clean

roller studl if scored, polish with

crocus cloth. Apply alight coating

of non-melting grease to the stud

before reassembling. If damaged,

replace.

If shaft is only lightfy scored,

polish with crocua cloth. If bear-

ings are badly scored, replace.

Some dents in the driving surface

can be removed by pressing the

flat side of a screwdriver blade

against the tire while the wheel is

revolving. If tire is nicked or

torn, replace.

Placefan (hub up)onaflat surface.

The ends of allblades should con-

tact the surface. If any blades

are out of alignment, reshape. If

2.

3.

6.

7.

6.

1.

-T.l

o

(J

]?t

v

\rr

8.

motor shaft is bent

PAGE I7

?

I

@

@

/3

*E

O \_JV 4

A PHOTOFACT "EXPLODED" VIEW

@Howrrd V. Srns & Co,, lnc. 1962

Ei-:%-J-@-ilai iniifrHo noFwnno t]bf -----T-

srrREo_- I /-t-., *ryL <D

'-;;>d _ !# H*,.,t^,)

l-+-cnnNttrstLEcroR lE"r..

Y___),/ r.

i ---l

A\ ourpuT r{pur

i:^.@ @,@ @

.---'-.- AMPLIFIER 5PEAKER RADIO PHONO MICRoPHON€

PARTS ABOVE PLATE ASSEMBLY

PAGE 18

{

n

I

F

m

n

3

o

(t

EI

F

UI

{

-l

I

gt

€

lrt

\

{

{

I

Ut

€

h)

gr

\-l

{

(a

I

(Jr

s

(,

o

.Tf

o

IJ

m

7

\rr

A PHOTOFACT "EXPLODED" VIE\(/

@Howtd V. Samr t Co., lnc, 1962

SB

?

E-@

ffi

6.---@

TE ASSEMBLY

VI

EX

PAGE 19

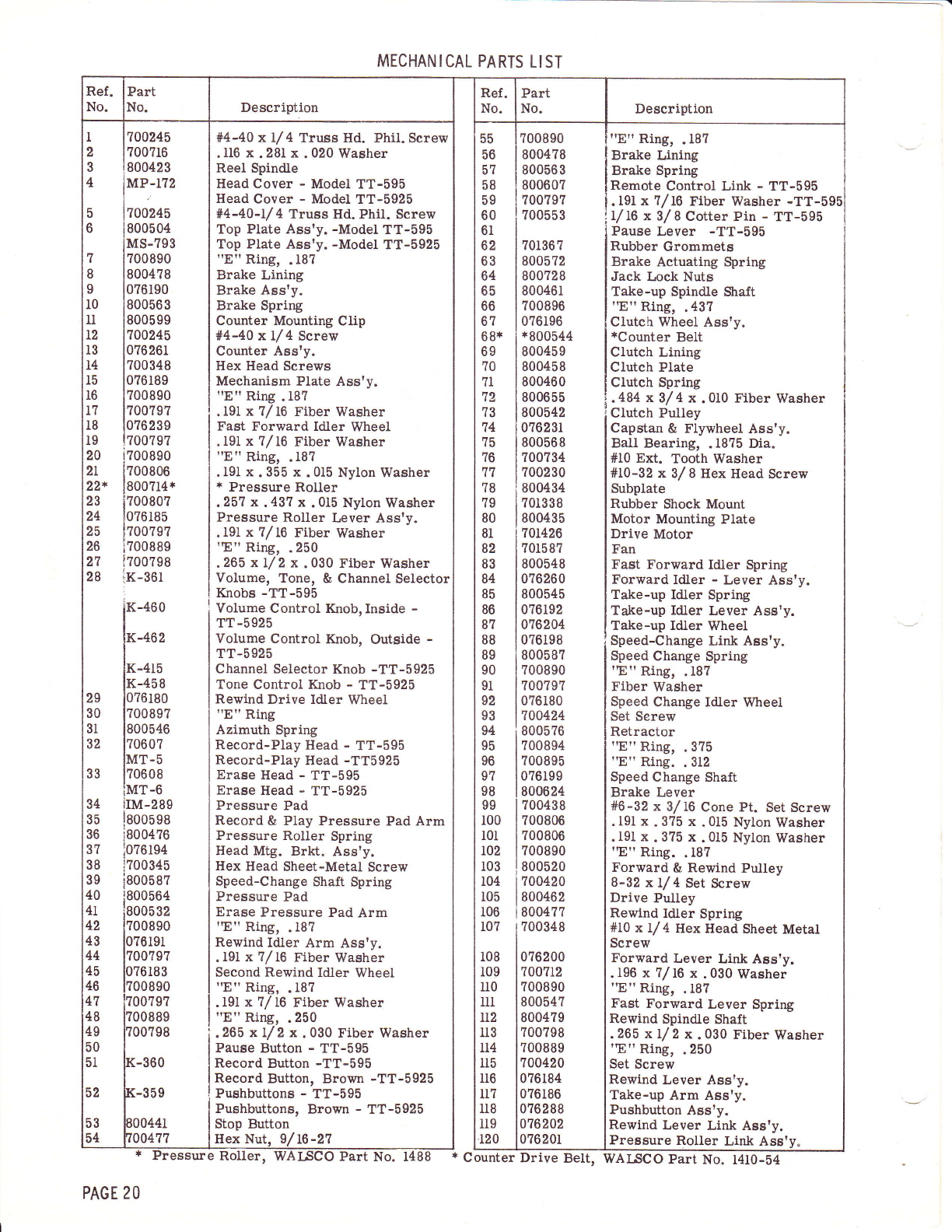

MECHANICAL PARTS LIST

I

2

3

4

5

6

700245

700716

800423

MP-r72

700245

800504

s-793

t2 l|700245

13 107626t

14 l?00348

15 10?6189

16 t?00890

K-460

K-462

K-415

K-458

076180

700897

800546

?0607

MT-5

70608

MT-6

rIM-289

leoorse

ieoo+zo

lozors+

1700345

iaoosez

4

r9l

183

797

-359

77

#4-4Q x l/4 Truss Hd. Phil. Screw

.116 x .28I x .020 Washer

Reel Spindle

Head Cover - Model TT-595

Head Cover - Model TT-5925

#4-40-L/ 4 Truss Hd. Phil. Screw

Top Plate Ass'y. -Model TT-595

Top Plate Ass'y. -Model TT-5925

"E" Ring, .187

Brake Lining

Brake Ass'y.

Brake Spring

Counter Mounting Clip

#4-40 x I/4 Screw

Counter Assty.

Hex Head Screws

Mechanism Plate Assry.

"8" Ring .18?

. I9l x ?/ 16 Fiber Washer

Fast Forward Idler Wheel

.191 x ?/16 Fiber Washer

"E" Ring, .187

.191 x . 355 x .015 Nylon Washer

* Pressure Roller

.251 x.43? x . 015 Nylon Washer

Pregsure Roller Lever Assry.

. f9f x ?/ 16 Fiber Washer

'E" Ring, .250

. 265 x L/ 2 x .030 Fiber Washer

Volume, Tone, & Channel Selector

Knobs -TT-595

Volume Control Knob, Inside -

TT-5925

Volume Control Knob, Outside -

TT-5925

Channel Selector Knob -TT-5925

Tone Control Knob - TT-5925

Rewind Drive Idler Wheel

"E" Ring

Azimuth Spring

Record-Play Head - TT-595

Reeord-Play Head -TT5925

Erase Head - TT-595

Erase Head - TT-5925

Pressure Pad

Record & Play Pressure Pad Arm

Pressure Roller Spring

Head Mtg. Brkt. Ass'y.

Hex Head Sheet-Metal Screw

Speed-Change Shaft Spring

Pressure Pad

Erase Pressure Pad Arm

'E" Ring, .18?

Rewind Idler Arm Ass'y.

.L9Lx7/L6 Fiber Washer

Seeond Rewind Idler Wheel

"E" Ring, .I87

.I91 x 7/16 Fiber Washer

"E" Ring, .250

.265 x I/ 2 x .030 Fiber Washer

Pause Button - TT-595

Record Button -TT-595

Record Button, Brown -TT-5925

Pushbuttons - TT-595

Pushbuttons, Brown - TT-592b

Stop Button

Hex Nut, 9/ L6-27

? 1700890

a leoo+zs

I 10?6190

lo lsoosos

ll laoosss

L7

l8

l9

20 izooaso

2L IZOOAO0

zz+ laoozr+*

23 i70080?

24 [0?6185

2i fzoozsz

26 iZOOeAg

27 lrOOZge

28 ir-sor

29

30

3l

32

33

34

35

36

3?

38

39

40

4t

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

6r

62

63

64

65

66

67

68*

69

70

7l

72

?3

74

75

76

'17

78

79

80

8I

82

83

84

85

86

87

88

89

90

9r

92

93

94

95

96

9?

98

99

100

l0l

102

r03

104

r05

106

10?

i08

10.9

ll0

ilI

LIz

ll3

114

il5

ll6

ll7

ll8

II9

120

?00890

8004?8

80056 3

800607

700?97

700553

"E" Ring, .187

Brake Lining

Brake Spring

Remote Control Link - TT-595

.191 x ?/16 Fiber Washer -TT

il/16 x 3/8 Cotter Pin - TT-595

Pause Lever -TT-595

Rubber Grommets

Brake Actuating Spring

Jack Lock Nuts

Take-up Spindle Shaft

"E" Ring, .437

Clutch Wheel Ass'y.

*Counter Belt

Clutch Lining

Clutch Plate

Clutch Spring

.484 x 3/ 4 x .0I0 Fiber Washer

Clutch Pulley

Capstan & Flywheel Ass'y.

Ball Bearing, . 1875 Dia.

#10 Ext. Tooth Washer

#i0-32 x 3/ 8 Hex Head Screw

Subplate

Rubber Shock Mount

Motor Mounting Plate

Drive Motor

Fan

Fagt Forward ldler Spring

Forward Idler - Lever Assry.

Take-up ldler Spring

Take-up Idler Lever Ass'y.

Take-up Idler Wheel

Speed-Change Link Ass'y.

Speed Change Spring

'E" Ring, .187

Fiber Washer

Speed Change Idler Wheel

Set Serew

Retractor

"E" Ring, . 3?5

"E" Ring. .312

Speed Change Shaft

Brake Lever

#6-32 x 3/16 Cone Pt. Set Screw

.l9l x . 375 x .015 Nylon Washer

.l9l x . 375 x . 015 Nylon Washer

'E" Ring. .187

Forward & Rewind Pulley

8-32 x l/4 Set Screw

Drive PuIIey

Rewind Idler Spring

#LA x I/ 4 Hex Head Sheet Metal

Screw

Forward Lever Link Assry.

.196 x ?/16 x.030 Washer

"E" Ring, .187

Fast Forward Lever Spring

Rewind Spindle Shaft

.265 x l/2 x .030 Fiber Washer

'E"Ring,.250

Set Screw

Rewind Lever Ass'y.

Take-up Arm Ass'y.

Pushbutton Ass'y.

Rewind Lever Link Ass'y.

Presgure Roller Link Assr

70r36 ?

800572

800?28

800461

?00896

076196

*800544

800459

800458

800460

800655

800542

0?623r

800568

700734

?00230

800434

701338

800435

701426

701587

800548

076260

800545

0?6r92

076204

0?6198

80058?

?00890

?00?97

076180

700424

800576

700894

?00895

076199

800624

700438

700806

?00806

700890

800520

700420

800462

8004??

700348

076200

700712

700890

80054?

8004?9

?00?98

?00889

100420

0?6184

076r86

076288

076202

0?6201

PAGE 2O

ressure Roller, WAISCO Part * Counter Drive BeIt, WAI,SCO Part No. I4l0-b4

This manual suits for next models

2

Table of contents