BrandTech Scientific BOCHEM B11115 User manual

Operating Manual for

SUPPORT JACKS

Support Jack Operating Manual

1. OPERATING/ SAFETY LIMITS

• Operators using support jacks should use caution and follow all appropriate

laboratory safety guidelines during operation, including wearing proper protective

clothing, goggles, and gloves. Additionally, all safety precautions for apparatus,

vessels, and reagents to be placed on support jacks should be followed.

• Never exceed the maximum load capacity of the support jack. Please refer to the

chart in "Ordering Information" for the maximum capacity of your support jack or

call BrandTech®Scientific Customer Service at 888-522-2726.

• Jacks must be placed on a level, stable surface capable of safely supporting the

combined mass of the jack and its load before use.

• Always raise or lower support jack deck to desired height prior to placing a load on

the support jack. Loads that are on the support jack while it is moving can become

unstable and cause severe injury.

• Loads should be placed squarely in the center of the support jack's deck. Improperly

placed loads can become unstable and cause severe injury.

• Operators should never force the lift mechanism or place hands, other body parts, or

anything else inside the lift mechanism of the support jacks.

• Never stand on support jacks.

• Never attempt to operate support jack after disassembling it.

• The area of the base of any apparatus placed on the support jack should be no larger

than the area of the deck.

• Never expose support jacks to operating temperatures greater than 130º C.

• Use care with Maxi-Lift jacks to ensure stability of base and load when elevated.

• Confirm chemical compatibility of the materials of construction of the support jack

with anticipated exposure prior to use.

Support Jack Operating Manual

2. APPLICATION

These adjustable lab supports are designed for leveling scientific apparatus. Stainless

steel support jacks are resistant to sanitizing agents, are autoclavable, and may be

used in corrosive environments, including fume hoods and solution-baths. Jacks with

anodized aluminum or epoxy-coated aluminum deck and base have different chemical

compatibilities, and should be used only in appropriate environments. Please follow

the operating instructions for safe use.

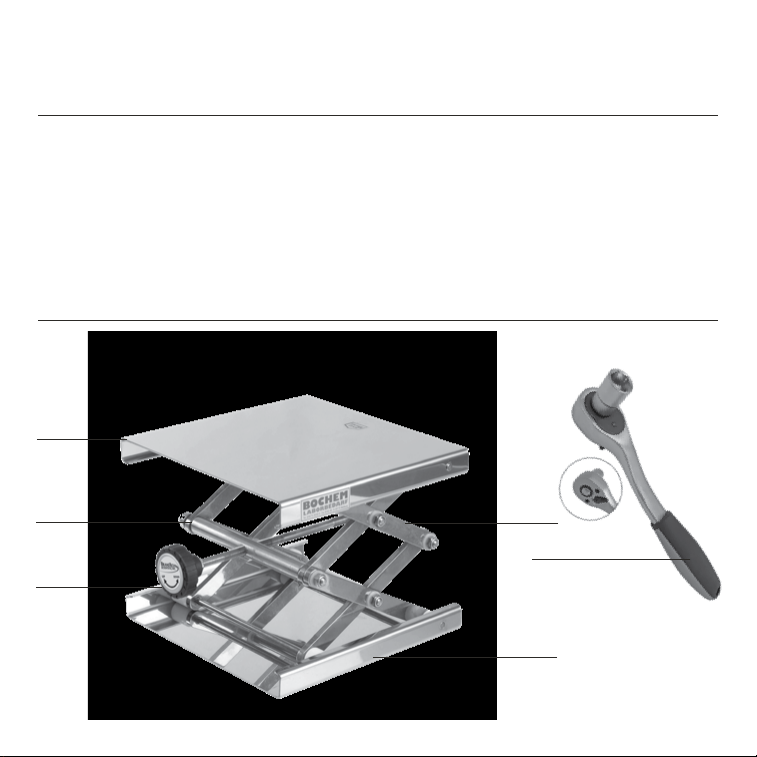

3. COMPONENTS

deck

base

lift mechanism

lift screw

hand

wheel

ratchet wrench

Support Jack Operating Manual

4. OPERATING INSTRUCTIONS

4.1 Raising the Deck

a) Place support jack on a level, sturdy surface.

b) Turn handwheel clockwise until deck is at desired height.

c) Place load on deck while following all applicable safety precautions.

4.2 Lowering the Deck

a) Remove any items that may be on deck or between deck and baseplate

while following all approprate safety precautions.

b) Turn handwheel counter-clockwise until deck is at desired height or

completely lowered.

For larger decks using the ratchet wrench, see special instructions in section

5 of this manual.

Support Jack Operating Manual

5. OPERATION OF SUPPORT JACK RATCHET WRENCH

Note: The support jack ratchet wrench may only be used with support jacks measuring

30 x 30 cm (BrandTech®Cat. Nos. B11180, B11081 and B11080) or

40 x 40 cm (BrandTech®Cat. Nos. B11190, B11091 and B11090).

5.1 Raising the Deck

a) Following all pertinent safety precautions, place entire support jack on level,

sturdy surface.

b) Flip the lever on the ratchet wrench to the right.

c) Slide the ratchet wrench over the metal lift screw protruding from the

support jack hand wheel, and turn hand wheel clockwise until the deck

is at desired height.

d) Place load on deck while following all applicable safety precautions.

5.2 Lowering the Deck

a) Remove any items that may be on deck or between deck and baseplate while

following all appropriate safety precautions.

b) Flip the lever on the ratchet wrench to the left.

c) Slide the ratchet wrench over the metal lift screw protruding from the

support jack hand wheel, and turn hand wheel counterclockwise until the

deck is at desired height or is completely lowered.

Support Jack Operating Manual

* For more information on Mucasol®lab detergent, contact BrandTech®Scientific at 888-522-2726.

6. MAINTENANCE

Stainless steel support jacks are constructed from Type 304 stainless steel and POM for

long life, even in corrosive environments. Handwheels are made from PF31 phenolic.

Anodized aluminum support jacks (blue models) feature the same 304 stainless

steel/POM lift mechanism as the stainless steel jacks, but feature decks and bases

constructed of anodized aluminum for economy or different chemical compatibility.

Epoxy-coated aluminum support jacks (green models) feature the same 304 stainless

steel/POM lift mechanism as the stainless steel jacks, but feature decks and bases

constructed of epoxy powder-coated aluminum for economy or different chemical

compatibility.

To ensure optimal performance from your support jack, please adhere to the following

guidelines.

• Clean support jacks as necessary with a mixture of warm water and any standard

household or laboratory stainless steel cleanser, such as Mucasol®lab detergent*.

Support jacks should be cleaned prior to autoclaving. After cleaning or autoclaving,

always apply a light coat of any standard household lubricant to the lift-screw.

• Always wipe off any chemicals spilled on support jacks as quickly as possible.

• Never clean your support jack with an iron brush, steel wool, or pad. This can

damage the surface, and increase risk of corrosion.

• Avoid exposure of your support jack to chemicals incompatible with the materials

of construction. Clean promptly after any exposure to incompatible chemicals to

minimize damage.

• Because the rollers are manufactured from POM, immediately clean up any spills of

reagents that may react adversely with POM.

Support Jack Operating Manual

[continued on back]

7. ORDERING INFORMATION

These products may be ordered from leading laboratory suppliers by requesting the

BrandTech®catalog number.

STAINLESS STEEL

Size Plate,

L x W, cm

Min. Ht

cm

Max. Ht

cm

Max. Static Load

kg Cat. No.

10 x 10 5.5 12 10 B11115

16 x 13 6.0 27.5 30 B11120

20 x 20 6.0 27.5 30 B11130

24 x 24 6.0 27.5 30 B11140

30 x 30 9.0 47 60 B11180

40 x 40 9.0 47 60 B11190

MAXI-LIFT STAINLESS STEEL

16 x 13 7.5 40 30 B11122

20 x 20 7.5 40 30 B11132

11 Bokum Road

Essex, CT 06426-1506

Toll Free: (888) 522-2726

www.brandtech.com

4/19 - PP - 1500

ANODIZED ALUMINUM

Size Plate,

L x W, cm

Min. Ht

cm

Max. Ht

cm

Max. Static Load

kg Cat. No.

10 x 10 5.5 12 10 B11016

16 x 13 6.0 27.5 30 B11021

20 x 20 6.0 27.5 30 B11031

24 x 24 6.0 27.5 30 B11041

30 x 30 9.0 47 60 B11081

40 x 40 9.0 47 60 B11091

EPOXY POWDER COATED ALUMINUM

10 x 10 5.5 12 10 B11015

16 x 13 6.0 27.5 30 B11020

20 x 20 6.0 27.5 30 B11030

24 x 24 6.0 27.5 30 B11040

30 x 30 9.0 47 60 B11080

40 x 40 9.0 47 60 B11090

Replacement ratchet wrench for 30 cm x 30 cm and 40 cm x 40 cm support jacks B11088

This manual suits for next models

7

Table of contents