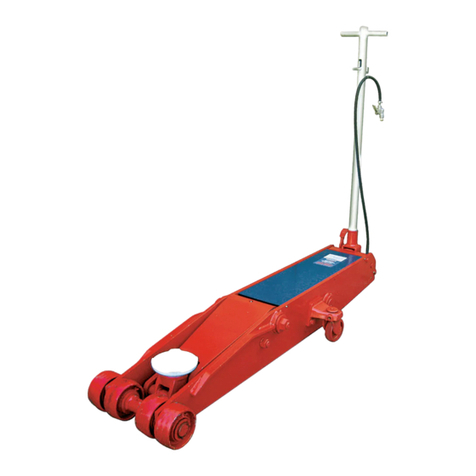

MODEL 72036D FORKLIFT JACK

SETUP • OPERATING • MAINTENANCE INSTRUCTIONS

PROFESSIONAL LIFTING EQUIPMENT

®

BEFORE USING THIS DEVICE, READ THIS MANUAL

COMPLETELY AND THOROUGHLY, UNDERSTAND ITS

OPERATING PROCEDURES, SAFETY WARNINGS AND

MAINTENANCE REQUIREMENTS. FAILURE TO DO SO COULD

CAUSE ACCIDENTS RESULTING IN SERIOUS OR FATAL

PERSONAL INJURY AND/OR PROPERTY DAMAGE.

The use of portable automotive lifting devices is subject to certain

hazards that cannot be prevented by mechanical means, but

only by the exercise of intelligence, care, and common sense. It

is therefore essential to have owners and personnel involved in

the use and operation of equipment who are careful, competent,

trained, and qualied in the safe operation of the equipment and

its proper use. Examples of hazards are dropping, tipping, or

slipping of motor vehicles or their components caused primarily by

improperly securing loads, overloading, off-centered loads, use on

other than hard level surfaces, and using equipment for a purpose

for which it was not designed.

It is the responsibility of the owner to make sure all personnel read

this manual prior to using this device. It is also the responsibility of

the device owner to keep this manual intact and in a convenient

location for all to see and read. If the manual is lost or not legible,

contact Norco Industries, Inc. for a free replacement. If the operator

is not uent in English, the product and safety instructions shall be

read to and discussed with the operator in the operator’s native

language by the purchaser/ owner or his designee, making sure

that the operator comprehends its contents.

WARRANTY

This product is covered by a Limited Lifetime Warranty. For details

see the back cover of Norco’s product catalog.

IMPORTANT: READ THESE INSTRUCTIONS BEFORE OPERATING

WARNING

• Inspect the jack before using. Do not use the jack if any jack

component is cracked, broken or bent, shows signs of damage

or excessive use, leaks hydraulic uid, has loose or missing

hardware or components, or is modied or altered in any way.

Take corrective action before using the jack again.

• Do not use the jack beyond its rated capacity.

• Use the jack for lifting purposes only. Support the load with the

appropriate means immediately after lifting and before working

on the vehicle.

• Consult the vehicle manufacturer for the proper locations of the

support stands.

• Use only on a hard level surface capable of sustaining the

maximum capacity of the jack and allowing the jack wheels to

roll unobstructed during raising and lowering operations.

• Make sure the setup is stable and secure before lifting.

• Do not tilt the vehicle more than 15 degrees or whatever is safe

when using the gripping saddle on a at lifting surface.

• Lift only on areas of the vehicle specied by the vehicle

manufacturer.

• Keep a handle length away from the jack and load during

raising and lowering operations.

• Keep entire personal body clear of pinch points when jack is

operating.

• While vehicle is on the jack, avoid excessive vehicle rocking or

movement.

• Always lower the loaded jack slowly and carefully.

• Do not drive a vehicle off the jack and do not move or dolly the

vehicle while on the jack.

• Do not use saddle adapters unless approved by Norco.

SETUP

1. Assemble the two handle halves together and secure them

with the hex head bolt provided.

2. Remove the handle receiver bolt and lockwasher from the

handle receiver. Install the handle in the handle receiver so the

hexagonal portion of the release valve enters the hexagonal

shaped insert at the bottom of the handle. Once the handle is

inserted in the handle base all the way, secure the handle to the

handle base with the bolt and lockwasher provided. The bolt will

enter the groove at the bottom of the handle thus allowing the

handle to rotate but not be removed.

3. Sometimes air gets trapped in the hydraulic system during

shipment. An air bound hydraulic system feels spongey when

pumped and sometimes the jack will not pump full incremental

strokes.

PURGING AIR FROM THE HYDRAULIC SYSTEM

a. Open the release valve by turning the knob in a

counterclockwise direction two full turns. Pump the handle

up and down about fteen times.

b. Close the release valve by turning the knob in a clockwise

direction until it stops.

c. Pump the handle until the lift arm is extended to maximum

height.

d. If the condition remains, repeat steps “a” through “c” until all

the air is purged from the system.