4

The jack advance circuit contains no safety relief valve. During

lifting, pressure must be controlled and monitored by the user, using

the pump relief valve and system hydraulic pressure gauge.

WARNING: Never operate jack at pressures above

4250 psi [293 bar]. Exceeding this pressure may allow

cylinder plunger to overextend during jack operation.

Cylinder plunger may eject from housing with extreme force.

Serious personal injury, loss of load and/or damage to jack may

result.

IMPORTANT: A working pressure of at least 1650 psi [114 bar]

is required to activate the jack's pilot-operated check valve when

the control valve is moved to the retract position. Jack will not

retract or may retract erratically if working pressure is less.

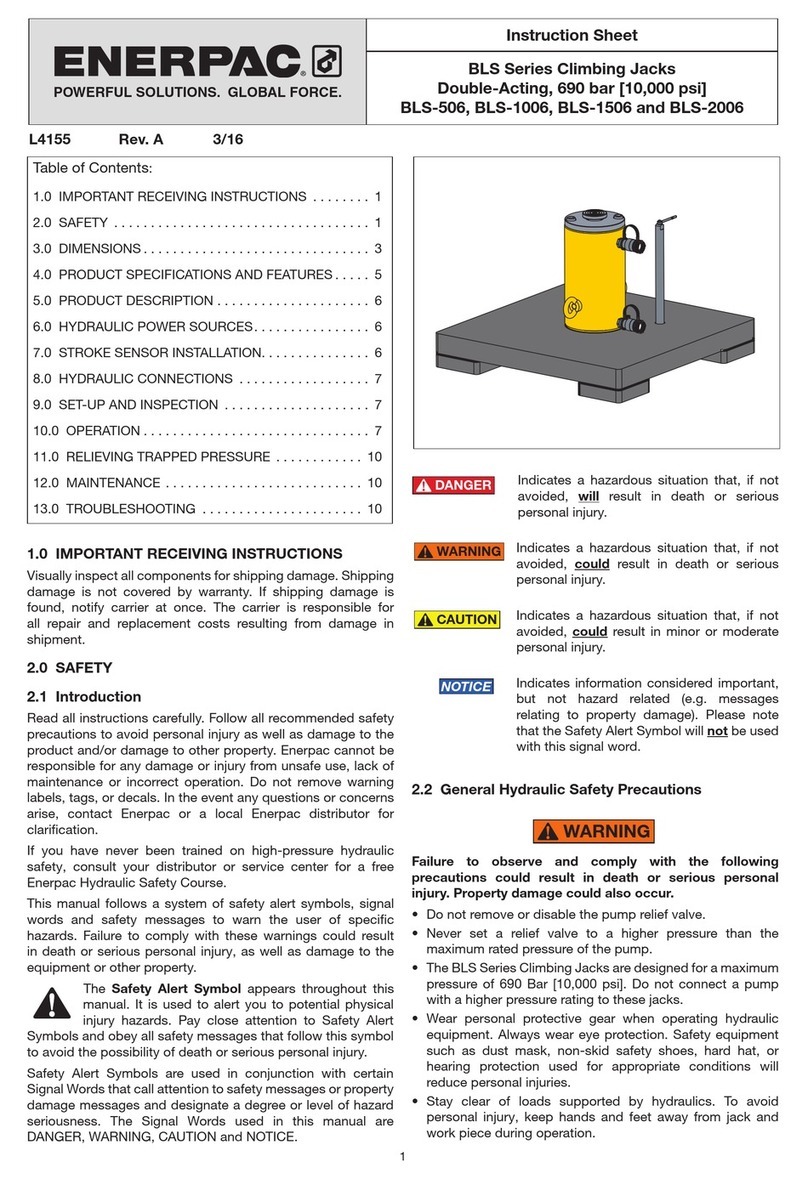

4.5 Using the Handle Assembly to Position the Jack

T

he jack can be lifted and positioned using the two carrying handles

(Figure 2, item 2) located on each side of the cylinder housing.

Adjust the jack position so that the cylinder load cap is centered

under the jacking point of the load.

WARNING: Lift the jack using the carrying handles

only. Do not lift the jack using the cylinder housing.

WARNING: Be sure that the jack is positioned on a

solid and level support surface, with the lifting cylinder

perpendicular to the ground. Jacking at an angle can

allow the jack to slip out of position, resulting in loss of load. As

required, use a swivel load cap to properly engage angled lifting

points. Refer to Section 5.6 for additional information.

5.0 OPERATION

5.1 Control Valve

Hydraulic flow to the jack lifting cylinder must be controlled by

an external 4-way, 3-position valve (user-supplied). See Figure 4.

• Move lever to the

extend position to

raise the load.

• Move lever to the

retract position to

lower the load.

• Move lever to the

neutral/hold position

immediately after

raising or lowering is

completed.

Note: Control valve location and mounting arrangement will vary.

For example, the valve may be installed on a portable hydraulic

pump or might be included as part of a truck-mounted PTO

power unit. Either a rotary or in-line style valve can be used.

5.2 Jacking Safely

You must know the weight of what you intend to lift. The jack

must be rated for at least 20 percent additional capacity.

All persons operating the jack should obtain and be familiar with

the American National Standards Institute rules that apply to

hydraulic rams and jacks (ASME ANSI B30.1) or the equivalent

standards used in your country or region.

WARNING:

Never place any part of your body under the

load at any time while it is being lifted, lowered or

hydraulically supported by the jack.

WARNING: The jack is intended for lifting purposes

only and should not be used to hydraulically support

the load for any period of time after the lift has been

completed. Support the load with suitable load supports

immediately after it has been lifted to the desired height.

WARNING: Never leave the jack unattended during

operation, even for a brief period of time. Closely

monitor jack operation at all times and be prepared to

stop lifting or lowering immediately.

WARNING: Do not use the jack outdoors in windy

conditions. Changes in wind direction or velocity could

cause the load to become unstable or fail.

CAUTION: Never exceed the maximum load rating of

the jack. Refer to Table 1 for load rating information.

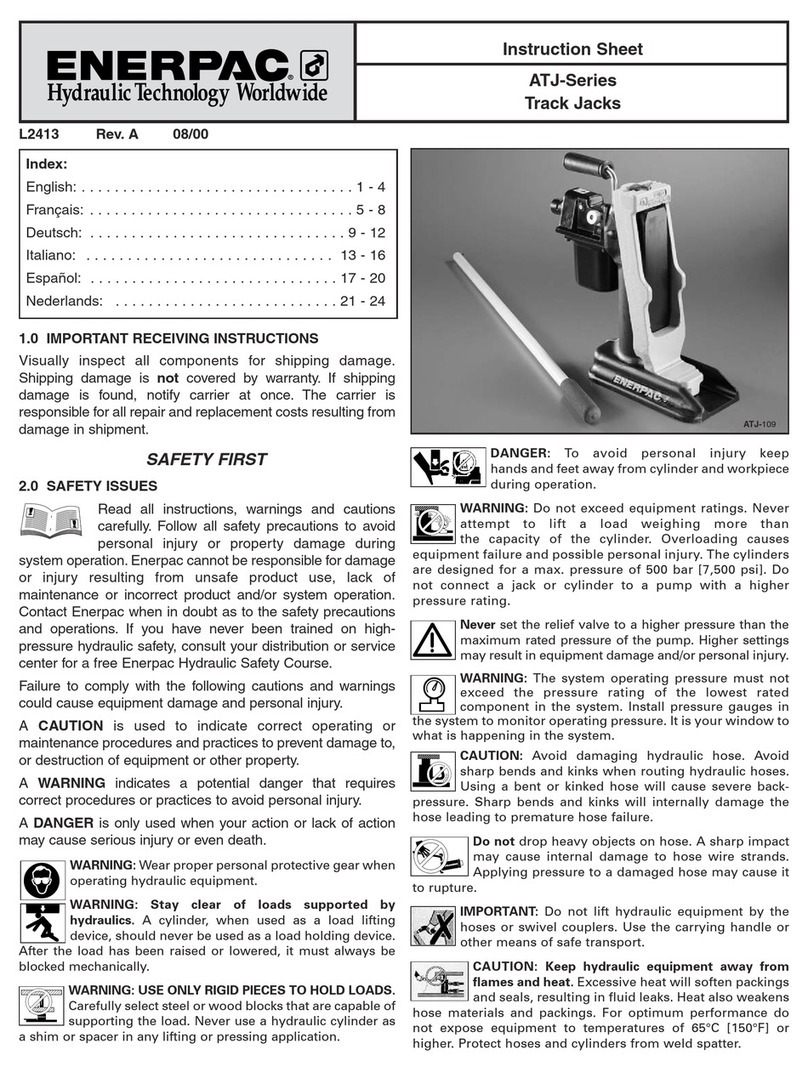

5.3 Use of U-Rings Forbidden

The load holding U-Rings used on

various other Enerpac rail products

are NOT COMPATIBLE with the

model WJ60 wheel truck jack. See

Figure 5.

U-Rings should NEVER be used

with the jack. It is not designed to

function as a load holding device.

After lifting, all loads must be

immediately supported with support

stands (or other suitable load

supports) of appropriate load rating.

WARNING: Use of U-Rings with the model WJ60 wheel

truck jack will result in a potentially unstable lifting

arrangement. The load cap may become disengaged

from the cylinder plunger, allowing U-Rings to shift and load to

drop. Serious personal injury and/or property damage may result.

5.4 Operating Instructions

TO RAISE THE LOAD:

1. Be certain that the jack is positioned on a solid and level

surface, capable of supporting the load and the base of the

jack. Be sure that the lifting cylinder is perpendicular to the

ground.

2. If a high jacking point requires a taller jack, install extensions

and spacers (optional accessories) on the cylinder as

required. Refer to Section 5.5 for installation instructions

and additional information about extensions and spacers.

3. Place a piece of good quality plywood or other compression

material (approximately 1/4 inch [6,3 mm] thick with good

friction characteristics) between the cylinder load cap

and the jacking point. This will provide a small amount of

cushioning and will also help prevent damage to the jacking

point.

4. To raise the load, move the control valve lever to the advance

position.

CAUTION: When lifting with more than one jack, be

especially careful to keep the load level. Leveling is best

accomplished by alternately starting and stopping the

jacks to keep the load level enough so it remains stable.

5. When load has reached the desired height, move the control

valve lever to the neutral/hold position.

6. Be sure that load supports of appropriate load rating are in

place under the load.

4

Figure 5, Never use

U-Rings with jack!

$

37

%

Figure 4, Control Valve

(User Supplied)