2

CONTENT

1 DEFINITION........................................................................................................................3

2 DEVICE PURPOSE ............................................................................................................3

3 SECURITY PRICIPLES.......................................................................................................4

3.1 SECURITY PRINCIPLES OVERVIEW .............................................................................4

3.2. SECURITY PRINCIPLES................................................................................................4

3.2.1 Prior to use....................................................................................................................4

3.2.2 When in use ..................................................................................................................4

3.2.3 Risk analysis .................................................................................................................5

3.2.4 Maintenance..................................................................................................................5

4 PACKING, STORAGE AND HANDLING .............................................................................5

4.1 PACKING.........................................................................................................................5

4.2 STORAGE........................................................................................................................5

4.3 HANDLING.......................................................................................................................6

5 MAIN SPECIFICATIONS.....................................................................................................6

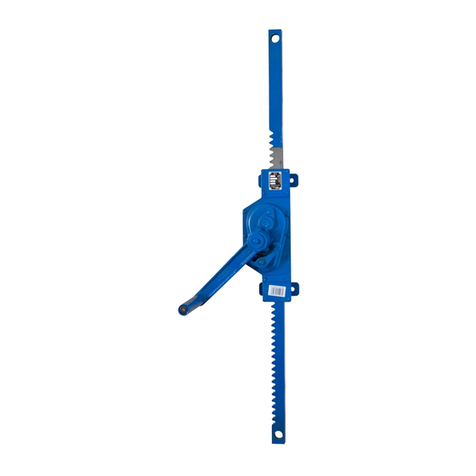

5.1 MECHANICAL DEVICE....................................................................................................6

5.2. MATERIAL AND FINISH .................................................................................................7

5.3 DATA ON THE PRODUCT...............................................................................................7

6 JACK OPERATION .............................................................................................................7

6.1 JACK OPERATION INSTRUCTIONS...............................................................................8

6.2 REST ADJUSTMENT.......................................................................................................8

6.3 RATCHET CRANK OPERATION .....................................................................................8

6.3.1 Raising or lowering........................................................................................................8

6.3.2 Ratchet crank-lever .......................................................................................................9

6.4. BEARING SURFACE CHECK -UP..................................................................................9

6.5 TEST PRIOR TO USE....................................................................................................10

7 OPERATION.....................................................................................................................10

7.1 APPLICATION OF THE JACK........................................................................................10

7.2 SAFETY WORK ENVIRONMENT ..................................................................................10

8 CHECK-UP ON THE JACK...............................................................................................11

8.1 INSPECTION .................................................................................................................11

8.1.1 Inspection types ..........................................................................................................11

8.1.2 Daily inspection ...........................................................................................................11

8.1.3 Regular inspection.......................................................................................................11

8.1.4 Jack occasionally used................................................................................................11

8.1.5 Report on inspection....................................................................................................11

8.2 INSPECTION PROCEDURE..........................................................................................12

9 TROUBLE-SHOOTING .....................................................................................................13

10 GRASING........................................................................................................................13

10.1 GENERALLY................................................................................................................13

10.2 JACK MECHANISM .....................................................................................................13

11 MAINTENANCE ..............................................................................................................13

11.1 SECURITY PRINCIPLES .............................................................................................13

11.2 REPLACEMENT OF BRAKE INSERTS AND BRAKE ADJUSTING ............................14

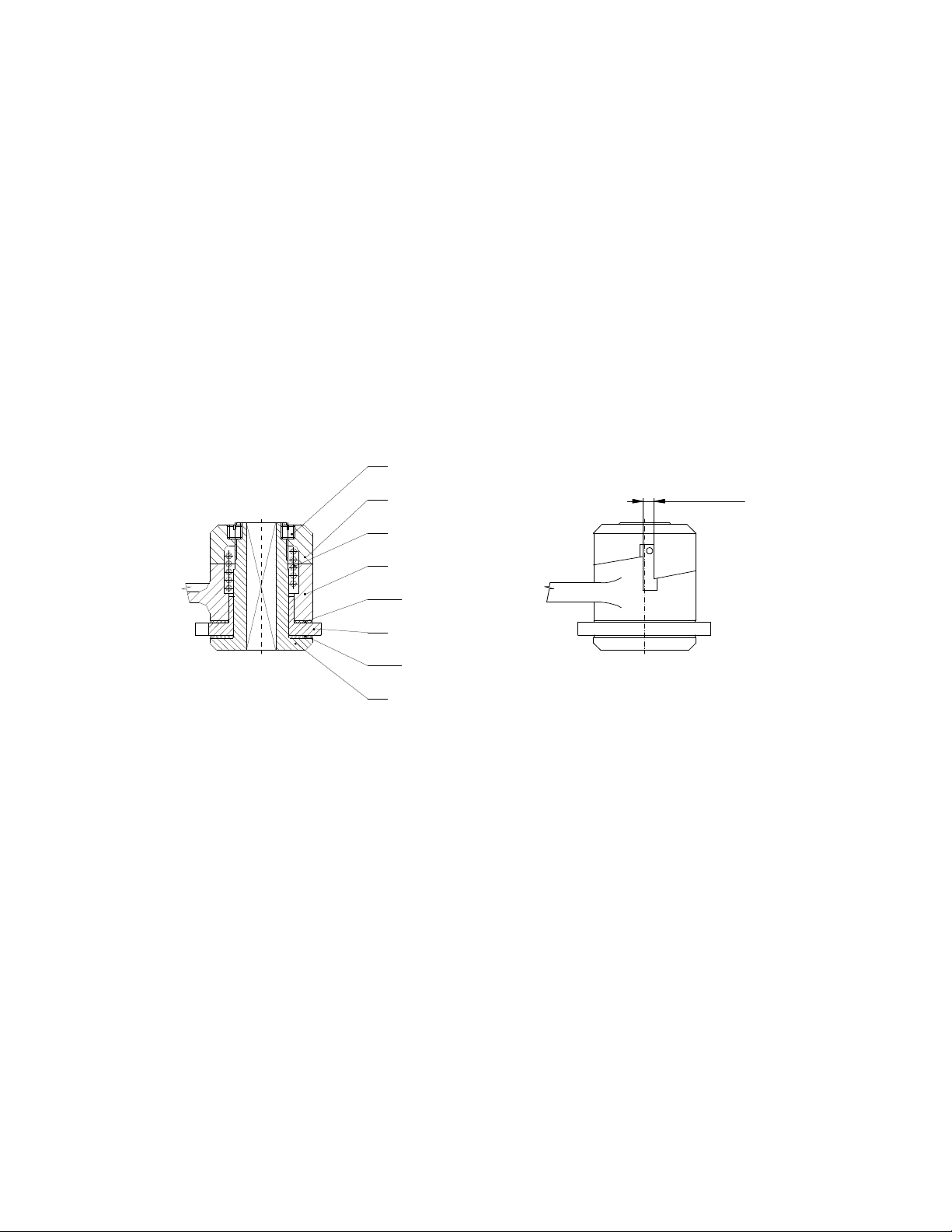

11.2.1 Brake disassembly (fig. 6) ........................................................................................14

11.2.2 Brake assembly and adjusting (fig. 6 and 7) .............................................................14

11.3 GENERAL INSTRUCTION...........................................................................................14

11.4 CHECK UP...................................................................................................................15

11.5 REPAIR........................................................................................................................15

11.6 TEST............................................................................................................................15

12 PUTTING OUT OF OPERASTION – LIQUIDATION .......................................................15

13 RELATED DOCUMENTATION .......................................................................................15

14 FINAL REQUIREMENTS OF THE PRODUCER TO THE CUSTOMER ..........................15

EC DECLARATION OF CONFORMITY ...............................................................................16