IMPORTANT: Only fully qualified personnel should

attempt maintenance or repair.

WARNING! Disconnect jack from air supply before changing

parts, servicing or performing any maintenance.

7.1. When the jack is not in use, the piston must be in the lowest

position to minimise corrosion.

7.2. Keep the jack clean and lubricate all moving parts, and the

air intake connector with air tool oil on a regular basis.

7.3. To check oil level, fully lower jack. Remove the filler plug

(located next to the piston or for YAJ20-40LR it is located on

the side of the jack). The oil level should be level with the

indicator inside the filler hole, for YAJ20-40LR, it should be

level with the bottom of the filler hole.

Top up the oil level if necessary but do not overfill as the jack

will become inoperative. If inadvertently overfilled the excess

oil should be poured off. After topping up or pouring off

excess oil it may become necessary to purge air from the

unit. See section 6.3 / 6.4.

NOTE: Use a good quality Jack oil, such a SEALEY HYDRAULIC

JACK OIL.

7. MAINTENANCE

8. TROUBLESHOOTING

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of this product.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

INFORMATION: For a copy of our latest catalogue and promotions call us on 01284 757525 and leave your full name and address, including postcode.

01284 757500

01284 703534

sales@sealey.co.uk

Sole UK Distributor, Sealey Group,

Kempson Way, Suffolk Business Park,

Bury St. Edmunds, Suffolk,

IP32 7AR

www.sealey.co.uk

Web

email

Original Language Version YAJ15-30, YAJ15-30DC, YAJ20-40,

YAJ20-40DC, YAJ20-40LR Issue 2 - 13/03/12

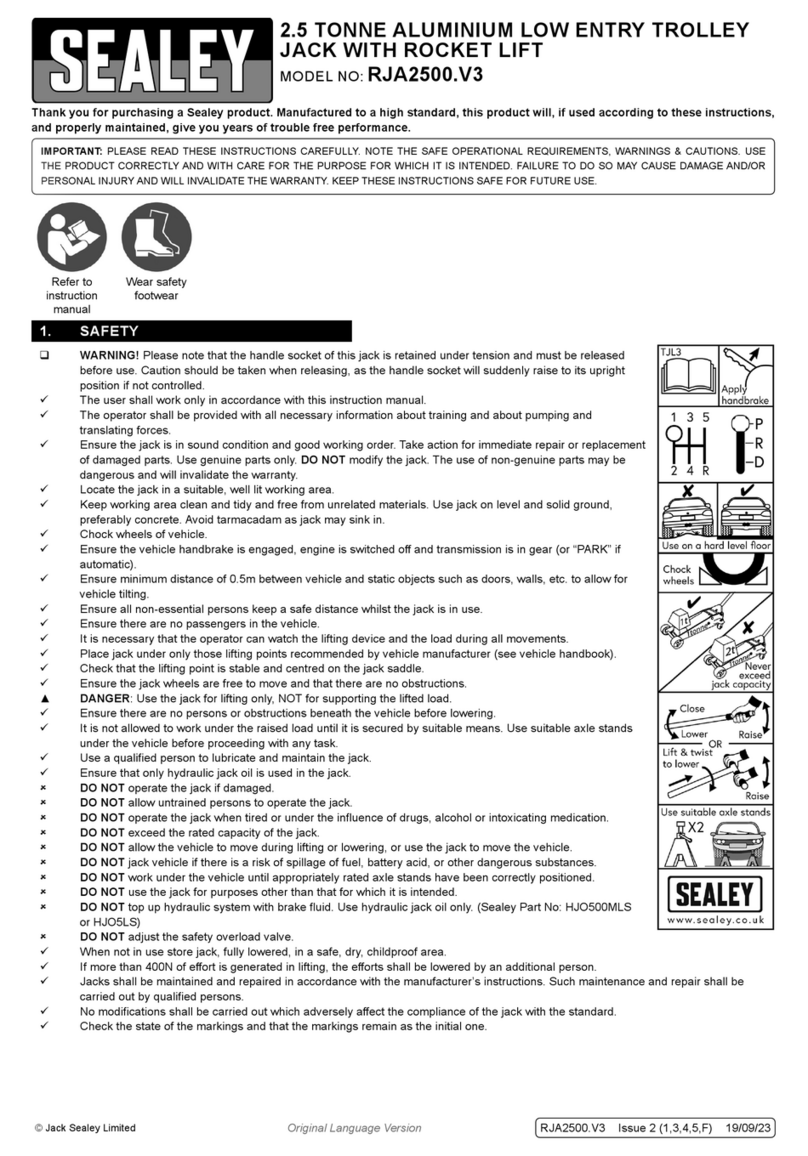

PROBLEM POSSIBLE CAUSE REMEDY

Jack does not lift

but pump is ok.

1. Oil Exhausted.

2. Air in hydraulic

system.

3. Defective suction or

delivery valves.

4. Defective packing or

O-ring.

5. Poor quality oil.

1. Supply oil.

2. Drain air by.

opening cap plug

of suction and

delivery valves.

3. Clean clogged

valve.

4. Replace.

5. Replace oil.

Air pump does

not operate.

1. Insufcient

compressor power.

2. Pump oil used up.

1. Use a larger

compressor.

2. Find leak and

rectify, rell with

oil. Rebuild and

lubricate air valve.

Jack stops before

end of travel.

1. Hydraulic oil is

insufcient.

1. Supply oil.

Jack Lowers or

does not hold

in the raised

position.

1. Defective suction

delivery, release or

safety valve.

2. Defective piston

packing.

1. Clean and adjust

valve.

2. Replace packing.

Lifting is slow. 1. Air leakage due to

worn servo-valve.

1. Replace servo-

valve.

Pump continues

to operate when

the air valves

are closed

1. Air valve will not close. 1. Replace Valve.

WARNING! DO NOT use brake fluid, or any fluid other

than hydraulic jack fluid as this may cause serious damage to

the Jack and will invalidate the warranty!

7.4. Ensure the air filter located in the air valve is clean.

7.5. Should the piston not rise and the oil level is correct, this may

indicate a problem with air seeping into the hydraulic valve

passage. Purge any air from the system. See 6.3 / 6.4.

7.6. Confirm that the piston can rise to the highest position.

7.7. Before each use check for broken, cracked, bent, or loose

parts. Or any visible damage to welds, piston, pump, saddle,

air connector, levers, frame and all parts including nuts, bolts,

pins and other fasteners. If any suspect item is found, remove

jack from service and take necessary action to fix the problem.

DO NOT use the jack if believed to have been subjected to

abnormal load or shock. Inspect and take appropriate action.

7.8. Every three months remove the locking rings on the caster

wheels and lubricate the ball bearings with grease.

7.9. After a year of extensive use, the oil should be replaced in

order to extend the life of the jack. To drain the oil, remove

the filler plug and valve. Make sure that no dirt is allowed to

enter the hydraulic system See 7.3. for refilling instructions.

7.10. Periodically check the pump piston and piston rod for signs of

corrosion. Clean exposed areas with a clean oiled cloth.

IMPORTANT: NO RESPONSIBILITY IS ACCEPTED FOR INCORRECT USE OF

THE MACHINE.

Air / Hydraulic products are only repaired by local service agents. We have

service/repair agents in all parts of the UK. DO NOT RETURN JACKS TO US.

Please telephone us on 01284 757500 to obtain the address and phone number

of your local agent. If jack is under guarantee please contact your dealer.

De-commissioning the Jack

Should the jack become completely unserviceable and require disposal, draw off

the oil into an approved container and dispose of the jack and the oil according to

local regulations.

fig.5

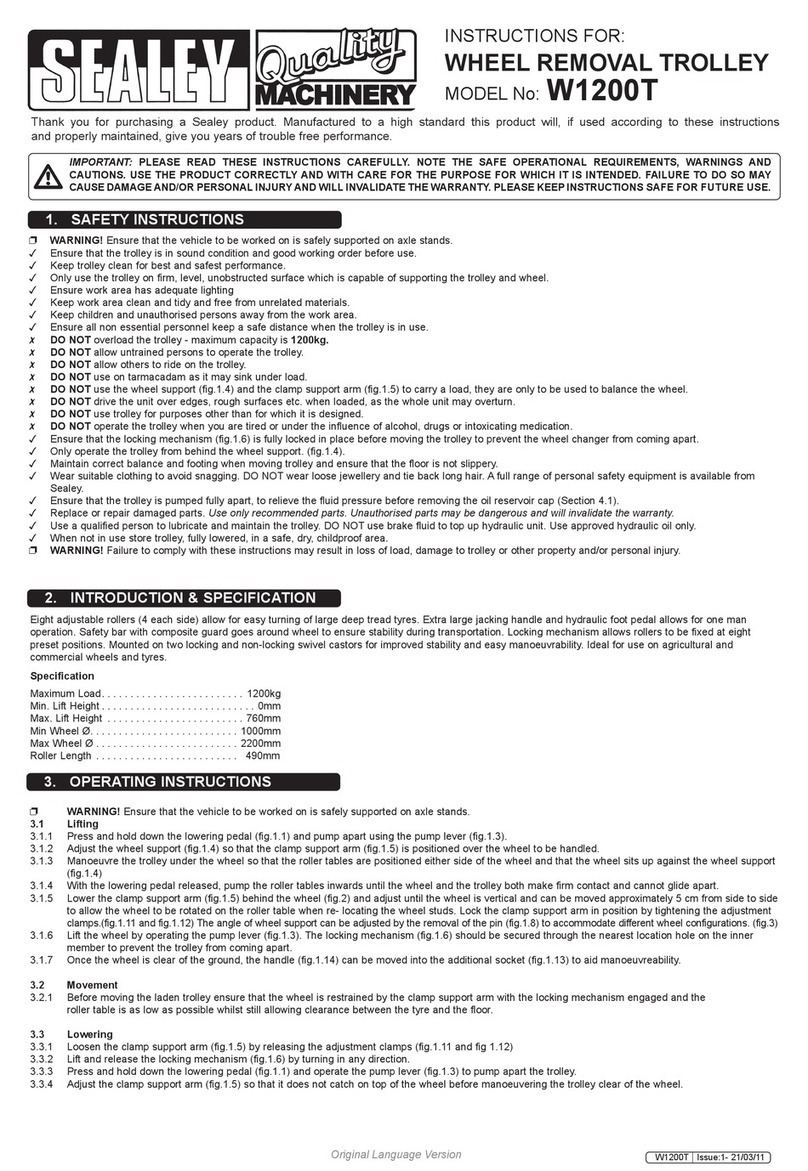

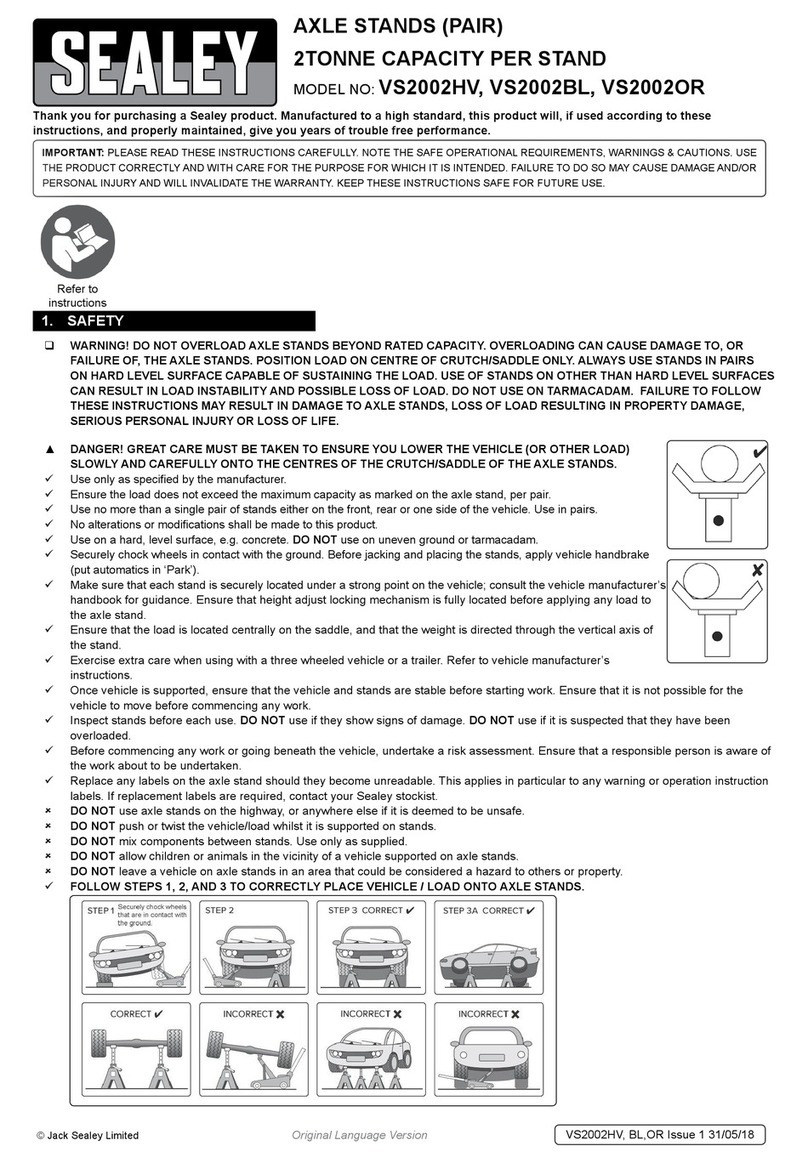

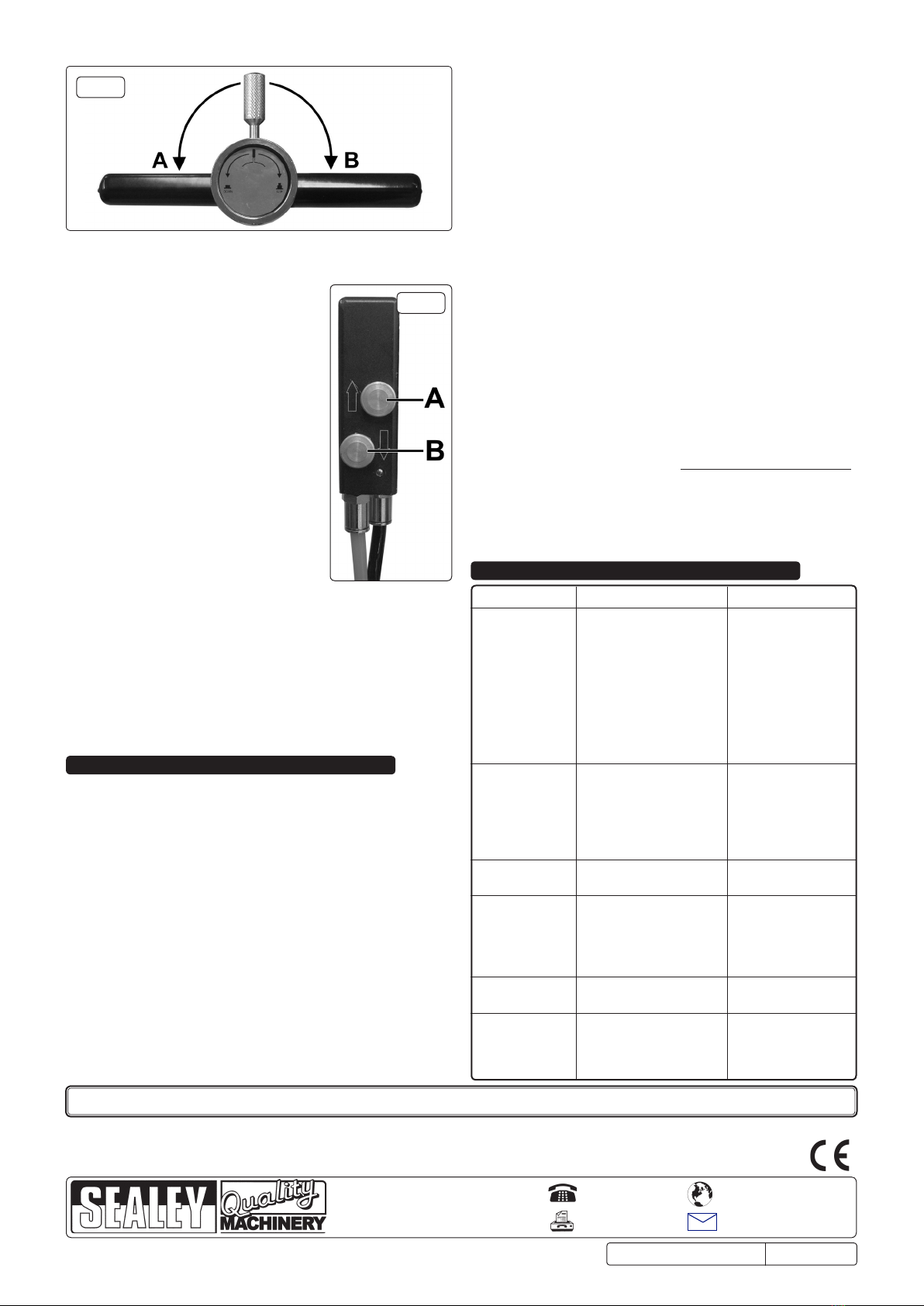

6.6. Using the Jack - YAJ15-30DC, YAJ20-40DC

WARNING! ensure you have read and understood the safety

instructions in chapter 1 before commencing work.

6.6.1. Position the Jack under the vehicle

manufacturer’s recommended

jacking point (see vehicle hand book).

Note: Use the extension pins (fig.3D/fig.4C)

to get the jack closer to the jacking

point before engaging the jack. See

specification for capacity when using

the extension pins.

6.6.2. Whilst holding the main jack handle

lifting is achieved by pushing the 'up'

button (fig.6A).

6.6.3. When the vehicle has reached the

desired height release the 'up' button,

stopping any further air flow holding

the jack at the height to which it has

been raised.

6.6.4. Place axle stands correctly in position

and ensure chapter 1 safety

instructions are strictly applied before

performing any task.

6.7. Lowering the Jack

6.7.1. Ensure there are no persons or obstruction beneath the

vehicle before lowering, and remove any axle stands.

6.7.2. Whilst holding the main jack handle lowering is achieved by

pushing the control lever/button to down (fig.5A/fig.6B), and

the jack will lower in a controlled manner.

6.7.3. Once completely lowered releasing the control lever will

return it to the middle hold position. Remove the jack from

under the vehicle. If you have finished using the jack, turn the

air pressure supply off and disconnect the jack from the air

line and store the jack and air line accordingly.

fig.6

Parts support is available for this product. To obtain a parts listing and/or diagram, please log on to www.sealey.co.uk,

email sales@sealey.co.uk or phone 01284 757500.