3. SPECIFICATION

Model no: ............................................................YAJ20B.V3

Max. capacity: ........................................................... 20tonne

Min. height: ................................................................ 228mm

Max. height(including extension)/capacity:

Stage 1 (mm/tonne): ................................................... 548/20

Stage 2 (mm/tonne): ......................................................... n/a

Piston stroke: ............................................................. 120mm

Screw extension:........................................................ 110mm

Extensions: ........................................................ 20/60/90mm

Chassis length: .......................................................... 575mm

Length including handle: .......................................... 1270mm

Width without wheels: ................................................ 187mm

Overall width: ............................................................. 322mm

Air consumption: ......................................................... 9.5cfm

Working pressure: ................................................ 102-145psi

Weight:........................................................................... 43kg

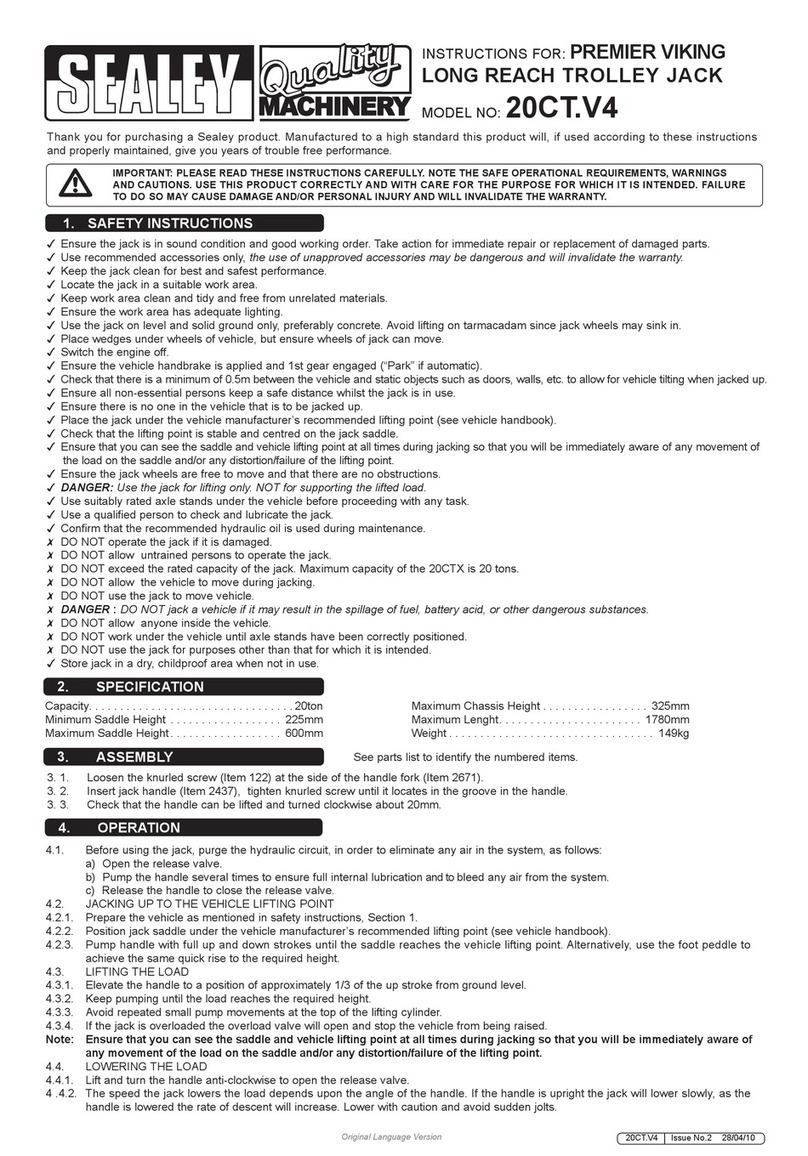

4. AIR SUPPLY

4.1. Ensure the jack pneumatic switch (or trigger) is in the “off” position before connecting to the air supply.

4.2. Youwillrequireanairpressureofatleast102psi(max145psi)andanairowof9.5cfmtogetthebestperformancefromthisjack.Usea

compressor of 3HP or above.

WARNING! Ensure the air supply does not exceed 145psi while operating the jack. Too high an air pressure and unclean air will shorten

the product’s life owing to excessive wear, and may be dangerous causing possible damage and personal injury.

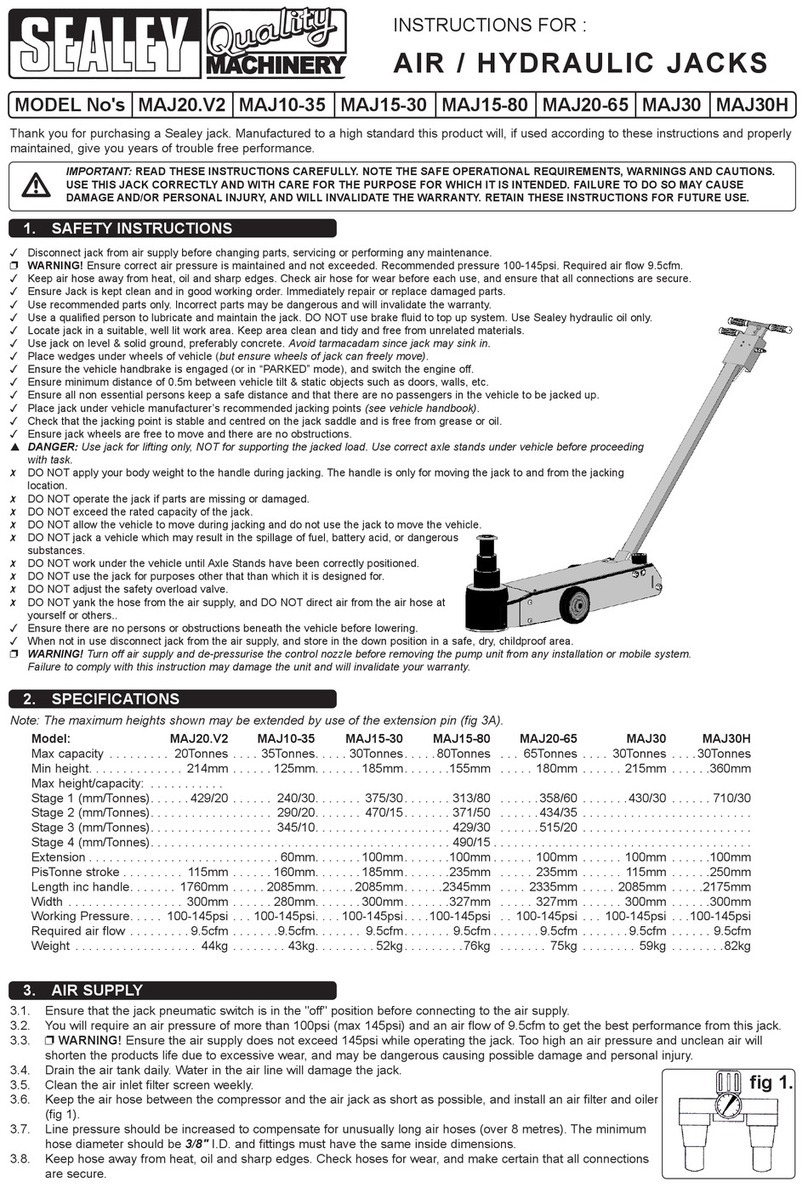

4.3. Keep the air hose between the compressor and the air jack as short as possible, and install an air filter and oiler, see fig.1.

4.4. Drain the air tank daily. Water in the air line will damage the jack.

4.5. Clean the air inlet filter screen weekly.

4.6. Line pressure should be increased to compensate for unusually long air hoses (over 8 metres). The minimum hose diameter should be

3/8” I.D. and fittings must have the same inside dimensions.

4.7. Keep hose away from heat, oil and sharp edges. Check hoses for wear, and make certain that all connections are secure.

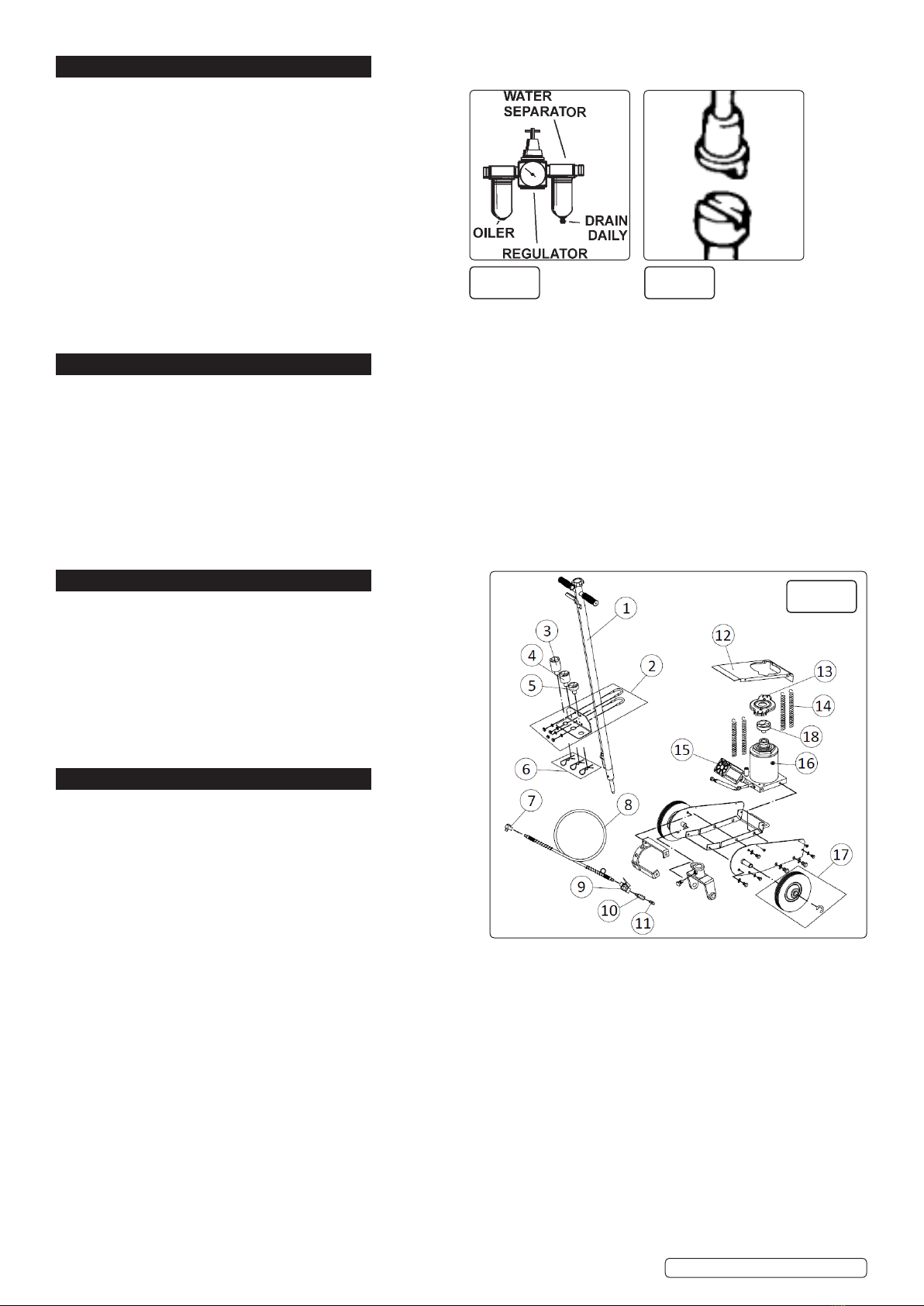

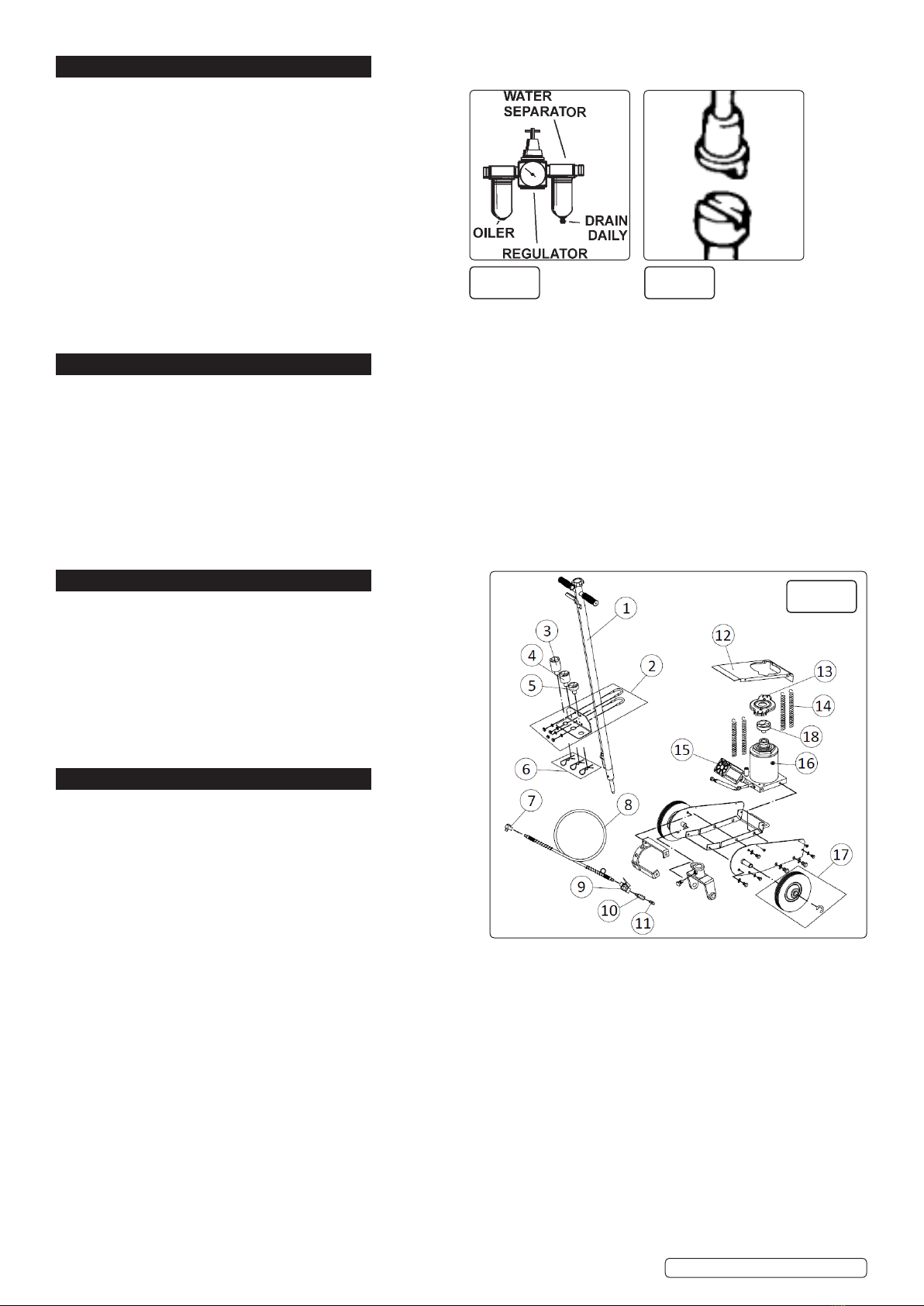

5. ASSEMBLY

WARNING! Ensure the jack is not connected to the air supply

before performing the following:

Refer to fig.3

5.1. Loosen the bolt on handle yoke and insert the handle assembly (1).

5.2. Rotate the release valve knob to locate the connecting rod into the

releasevalverodasshowning.2.

5.3. Secure the handle assembly by tightening the bolt on the handle

yoke.

5.4. Hook the spring on the air hose onto the bracket on the side of

the handle.

6. OPERATION

Refer to fig.3

6.1. Preparation before use.

6.1.1. You will require an air pressure of at least 100psi, (max 145psi)

andanairowof9.5cfmtooperatejack.

6.1.2. Connect the air supply hose .

6.2. Eliminate any air in the system.

6.2.1. Before using the jack, purge the hydraulic circuit in order to

eliminate any possible air that may have entered the system

during transit.

6.2.2. Remove the four screws and lift off the upper cover (12).

6.2.3. Loosen the oil filler screw (16) half a turn.

6.2.4. Close the release valve by turning the knob clockwise.

6.2.5. Operate the air valve (9) and repeatedly tighten and loosen the oil filler screw (16) until the piston starts to rise.

6.2.6. Fully tighten the oil filler screw (16) and ensure that the piston can rise to its highest position.

6.2.7. When complete, open the release valve by turning the knob anti-clockwise and lower the piston to its lowest position.

6.2.8. Refit the upper cover (12) and secure using the four screws.

6.3. Using the jack.

WARNING! Ensure you have read and understood the safety instructions in chapter 1 before commencing work.

6.3.1. Lift the lock lever, position the handle as required and release the lock lever.

6.3.2. Position the Jack under the vehicle manufacturer’s recommended jacking point (see vehicle hand book).

6.3.3. To raise the jack up, remove the air valve (9) from the handle and press the air valve lever (9).

6.3.4. Whenthevehiclehasreachedthedesiredheightreleasethelever(10-8)whichwillstopfurtherairowandholdthejackattheheight

to which it has been raised.

6.3.5. Place axle stands correctly in position and ensure chapter 1 safety instructions are strictly applied before performing any task.

6.4. Lowering the jack.

6.4.1. Ensure there are no persons or obstruction beneath the vehicle before lowering, and remove any axle stands.

6.4.2. To lower the jack, slowly turn the release valve knob anti-clockwise and the jack will lower in a controlled manner.

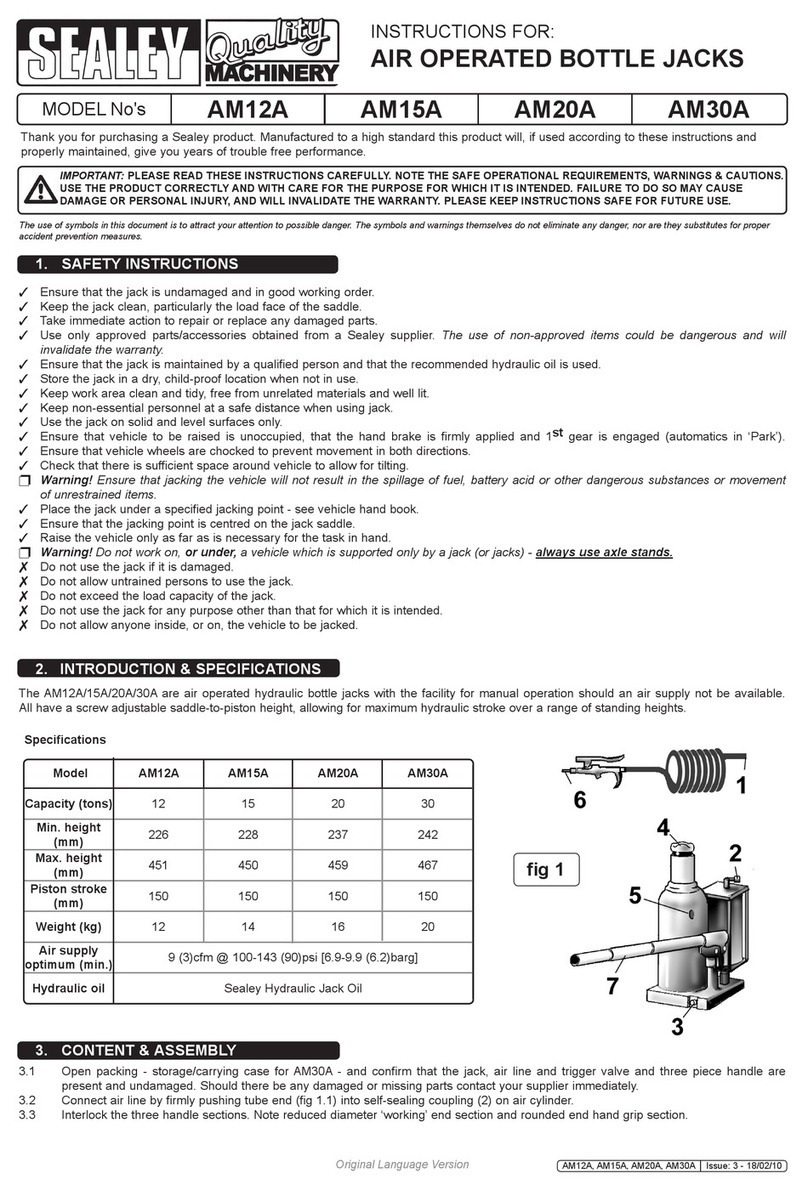

Fig.1 Fig.2

Fig.3

YAJ20B.V3 Issue 3(S) - 21/06/17

Original Language Version

© Jack Sealey Limited