Branson 900M Series User manual

900M Series

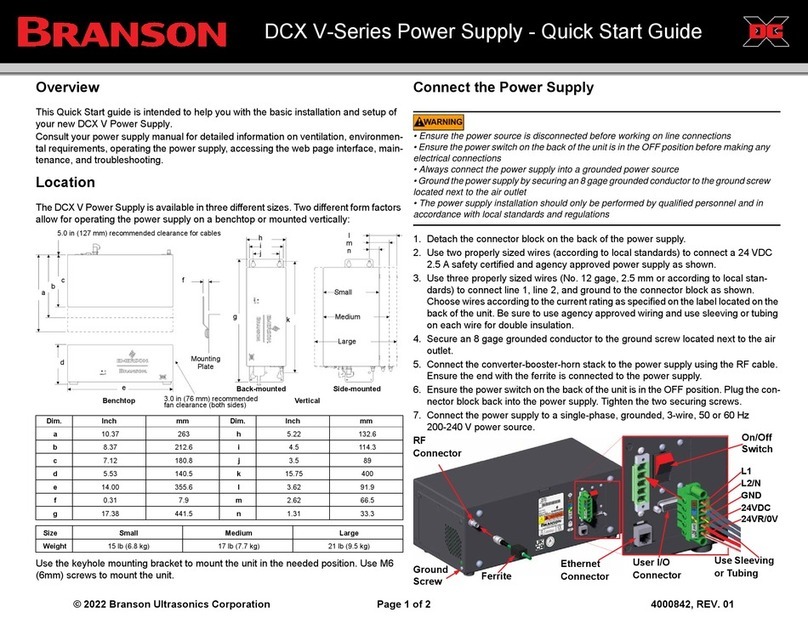

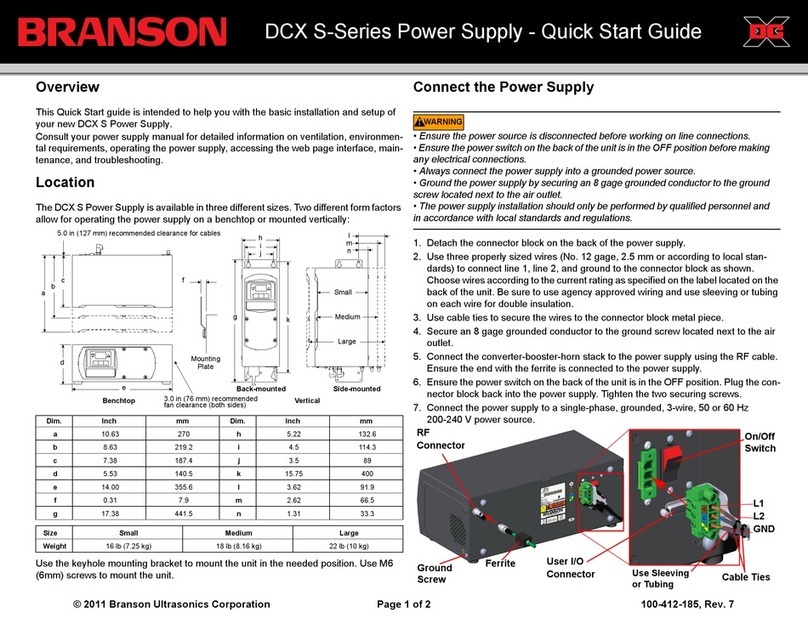

Power Supplies

Controls

Control

Branson 900M

Status

Power

ontents of This Section

2.1 Introduction

2-1

2.2 900M Front Panel

2-1

Power Sub-Panel

2-2

Control Sub-Panel

2-3

Status Sub-Panel

2-4

2.3 900M Back Panel

2-6

2.1 Introduction

This section describes the functions of the 900M front panel keys, it does not explain how

to use the keys. This information is included in Section 4, Operation. The front panel

keys are arranged in three groups of sub-panels - Power, Control and Status. The sections

that follow describe the keys in the same three groupings. This information is followed by

descriptions of the back panel connectors and fuses, etc.

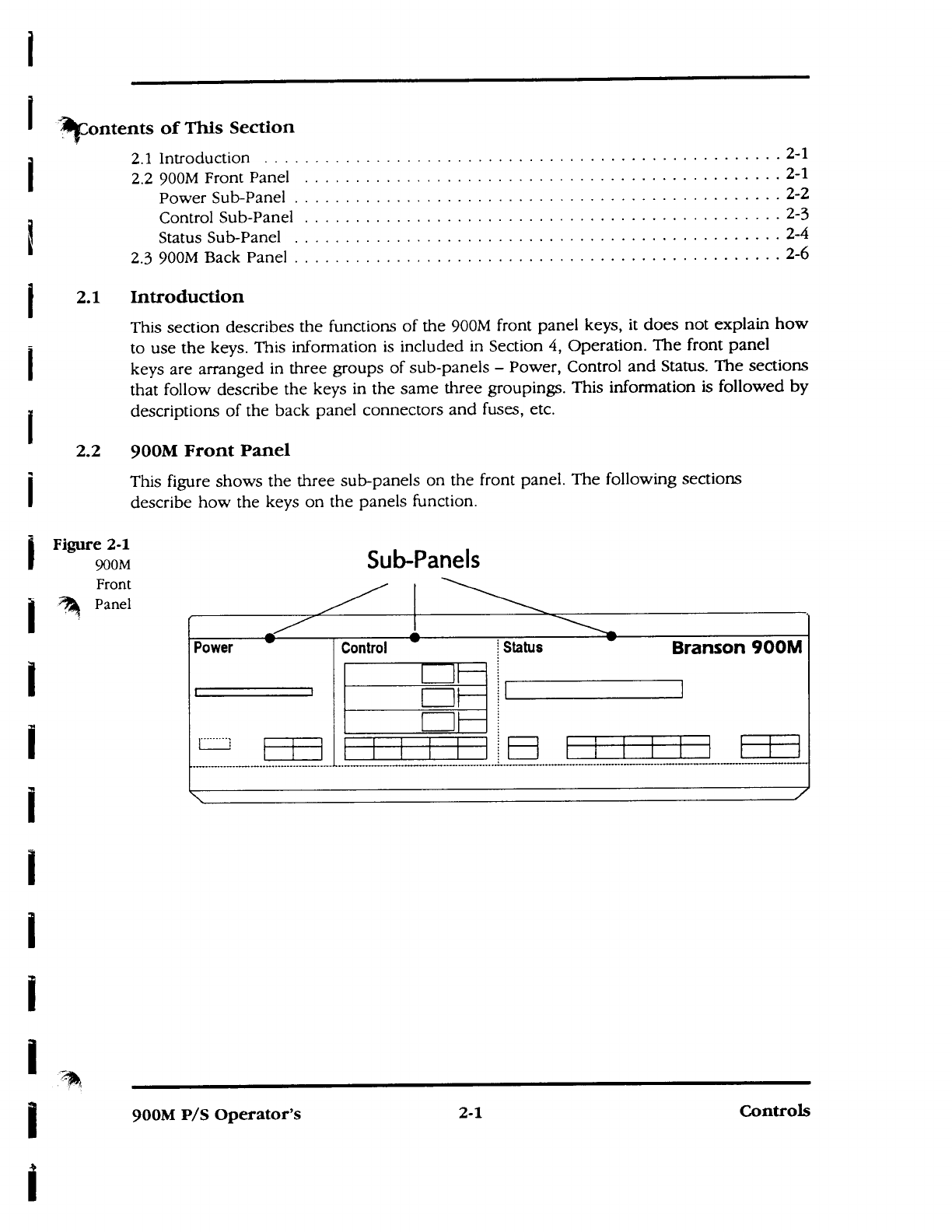

2.2 900M Front Panel

This figure shows the three sub-panels on the front panel. The following sections

describe how the keys on the panels function.

Figure 2-1

900M

Front

Panel

Sub-Panels

900M P/S Operator's

2-1

Controls

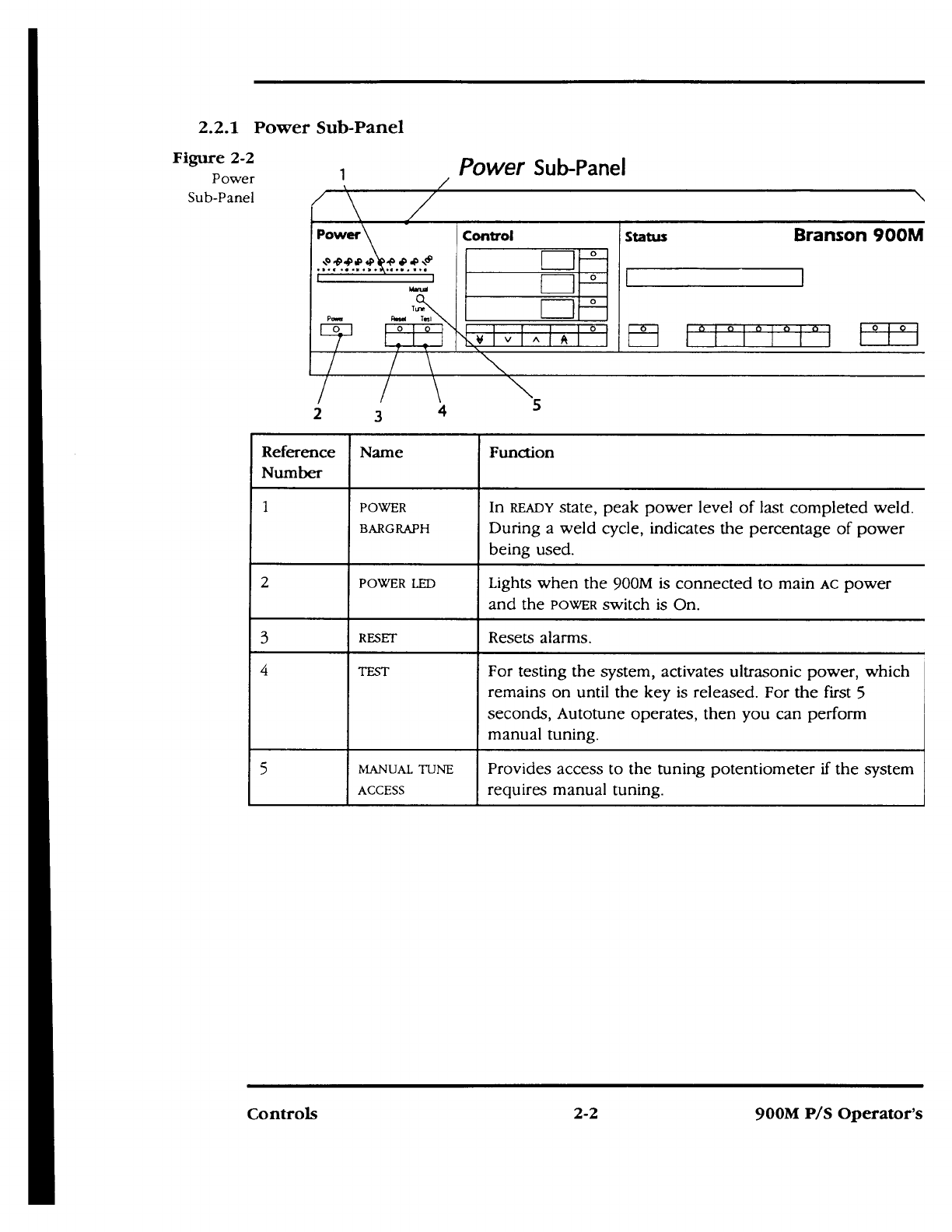

2.2.1 Power Sub-Panel

Figure 2-2

Power

Sub-Panel

1

Power

Sub-Panel

_

Power

Control

Status

Branson 900M

0

i

D

ower

Rased

Iasi

0

0 0

WMI

IMIEMBEF111

MIME

TN

V

V

A

A

3

\

4

N

5

Reference

Number

Name

Function

1

POWER

BARGRAPH

In

READY

state, peak power level of last completed weld.

During a weld cycle, indicates the percentage of power

being used.

2

POWER LED

Lights when the 900M is connected to main

AC

power

and the

POWER

switch is On.

3

RESET

Resets alarms.

4

TEST

For testing the system, activates ultrasonic power, which

remains on until the key is released. For the first 5

seconds, Autotune operates, then you can perform

manual tuning.

5

MANUAL TUNE

ACCESS

Provides access to the tuning potentiometer if the system

requires manual tuning.

Controls

2-2

900M P/S Operator's

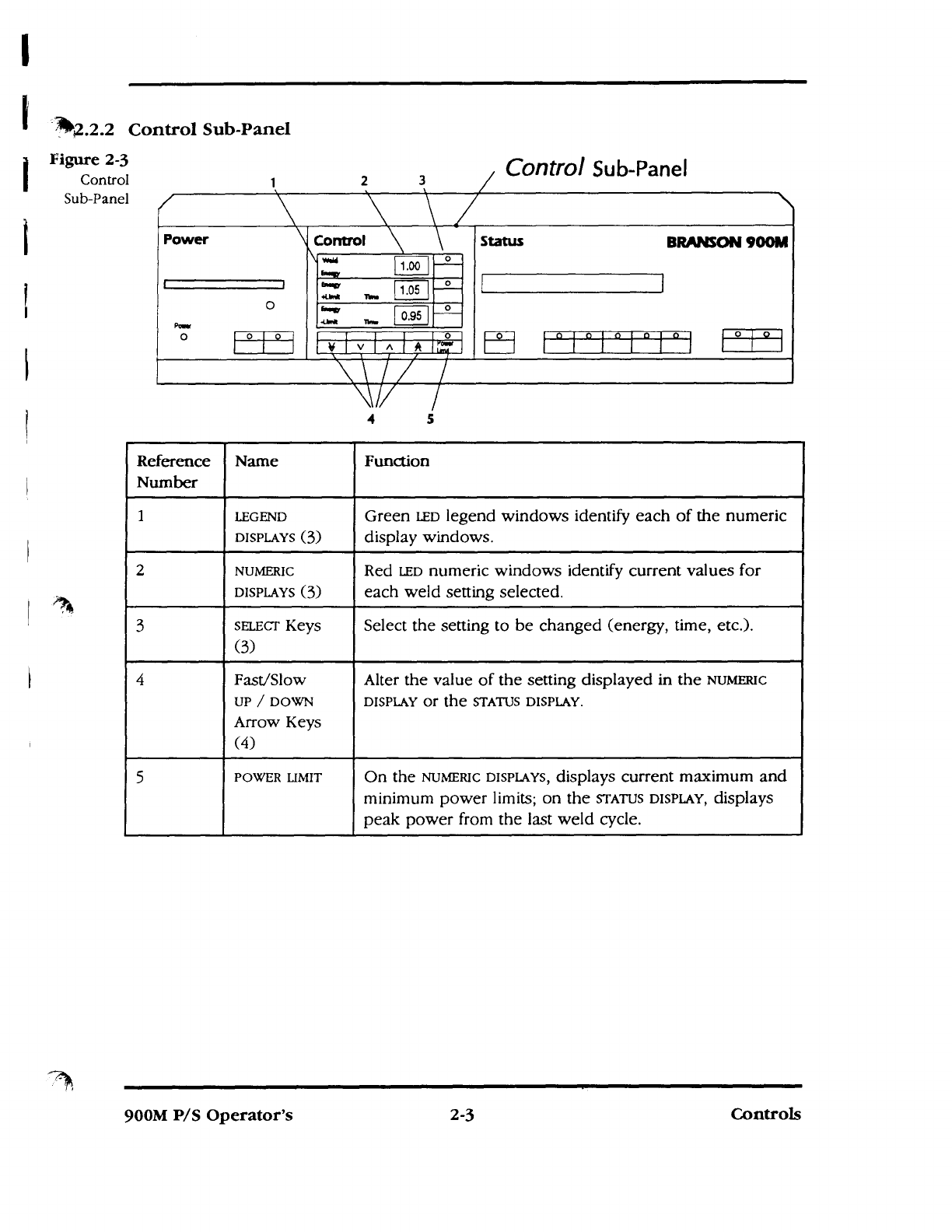

2.2.2 Control Sub-Panel

Figure 2-3

Control

Sub-Panel

2

3

Control

Sub-Panel

/

Power

\Control

\ \

Status

BRANSON 900M

Imp

1.00

°

Imp

Mink

Mrs

1.05

°

1

1

0

Pour

`Mg,

-Linit

Th.

0.95

0

o

0

0 0

0

0

o

o

iN;Mi

0

o

NMI

1

\ \

i /

7

4

5

Reference

Number

Name

Function

1

LEGEND

DISPLAYS

(3)

Green

LED

legend windows identify each of the numeric

display windows.

2

NUMERIC

DISPLAYS (3)

Red

LED

numeric windows identify current values for

each weld setting selected.

3

sm.Ecr Keys

(3)

Select the setting to be changed (energy, time, etc.).

4

Fast/Slow

UP / DOWN

Arrow Keys

(4)

Alter the value of the setting displayed in the

NUMERIC

DISPLAY

or the

STATUS DISPLAY.

5

POWER LIMIT

On the

NUMERIC DISPLAYS,

displays current maximum and

minimum power limits; on the

STATUS DISPLAY,

displays

peak power from the last weld cycle.

I

900M P/S Operator's

2-3

Controls

Status

Sub-Panel

2.2.3 Status Sub-Panel

Figure 2-4

Status

Sub-Panel

Power

O

0

0 ]

Branson 900M

Status

Tyne

s,up

Ensgy

eaki-AB

6

4

Control

READY TIME MODE 1X

0

1

0

0

0

Figure

Reference

Name

What it does

1

STATUS DISPLAY

A 20-character alphanumeric display that indicates the

current operating status and provides prompts,

error/fault messages, help messages and menu choices.

2

PRINT

Selects print settings when an External Communications

Interface (E0-1) has been installed; used with RECALL to

send data to the printer port; used with SETUP to enter

the Setup Menu; press to move from one sub-menu to

the next.

3

ENERGY

Selects ENERGY weld mode. When pressed with TIME,

selects TEc weld mode.

4

TIME

Selects TIME weld mode. When pressed with ENERGY,

selects

TEc

weld mode.

5

HOLD-AB

Selects HOLD'AB settings and displays current hold time,

afterburst delay, and afterburst time settings.

Controls

2-4

900M P/S Operator's

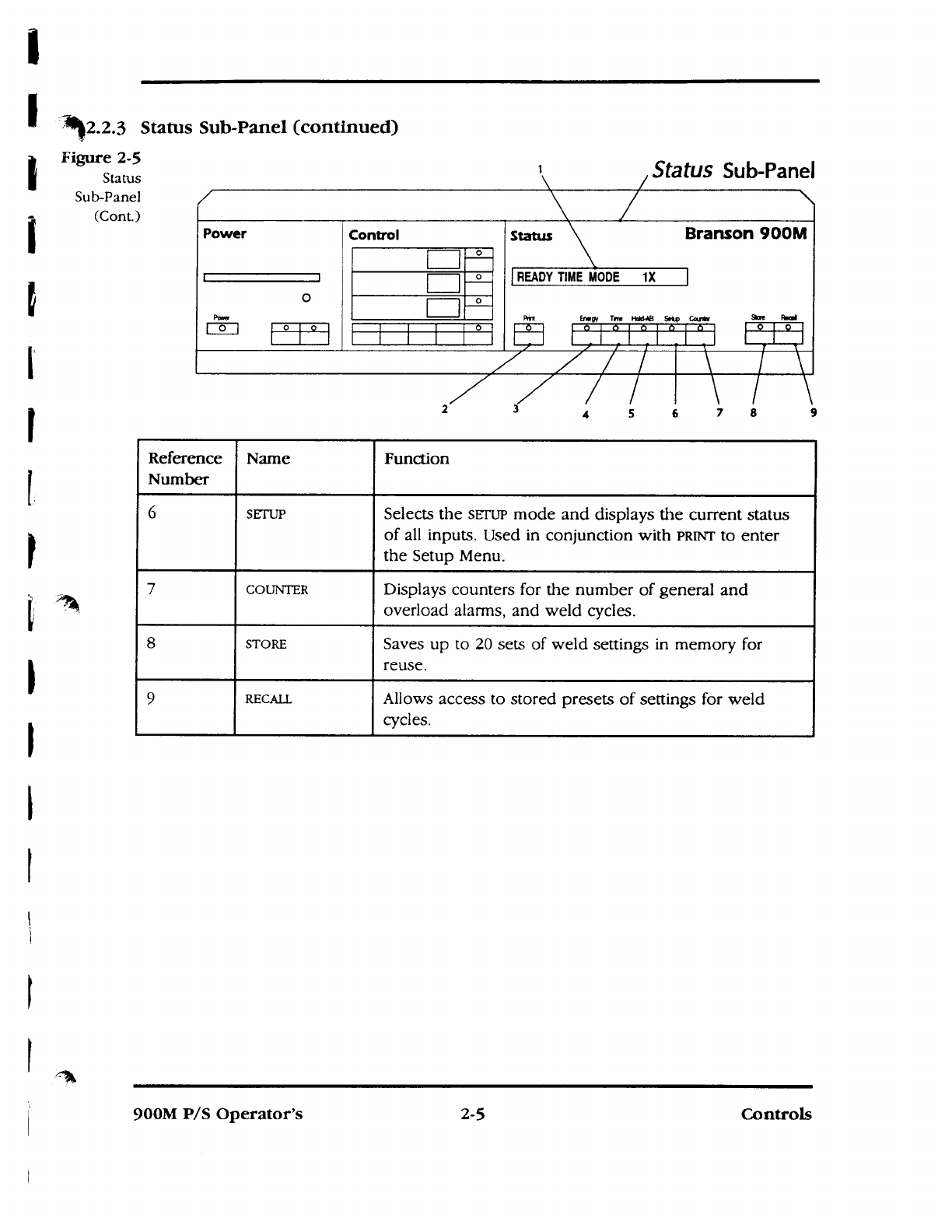

2.2.3 Status Sub-Panel (continued)

Figure 2-5

Status

Sub-Panel

(Cont.)

Power

O

Control

0

0

0

Status

Branson 900M

READY TIME MODE 1X

Status

Sub-Panel

Stae Fluel

I

Rnt

Enegy Trne Held-AB Selp Gamier

2

3

1

77

4 5 6 7 8 9

Reference

Number

Name

Function

6

SETUP

Selects the

SETUP

mode and displays the current status

of all inputs. Used in conjunction with

PRINT to

enter

the Setup Menu.

7

COUNTER

Displays counters for the number of general and

overload alarms, and weld cycles.

8

STORE

Saves up to 20 sets of weld settings in memory for

reuse.

9

RECALL

Allows access to stored presets of settings for weld

cycles.

0 I

O

900M P/S Operator's

2-5

Controls

5

10

a

i7

.18

is

.7

7S

C MINX

START 1 WIN L

TN LINK CLAM

DD

U

U

BRANSON

8

-

-0

0=

BRANSON

INYININO

2.3 Back Panel

Figure 2-6

Back

Panel

Reference

Number

Name

Function

1

Power Switch

Turns 900M On and Off.

2

Fuses (F1) and (F2)

Protects the 900M from damage if the AC main

power source fails. Fuse (F2) protects the 920M,

930M, and 905/910M 100-200/250V models only.

3

RF Connector (J1)

3-pin MS, for RF cable, provides ultrasonic energy

to the converter.

4

Line Cord

Connects 900M to AC power source.

5

External Power Signal

Connector Knockout (J8)

2-pin, provides an optional 0-5V interface for

power monitoring devices (refer to Appendix A).

6

Control Cable (J7)

15-pin D-shell, connects the 900M to an actuator or

stand.

7

START Cable (J6)

9-pin D-shell, connects 900M to external START/STOP

controls.

8

DATA LINK connectors (J4

and J5)

Provides connectivity for optional external

900AES/AOS or ECI-1.

9

ALARM connector (J3)

25-pin D-shell, provides input/output signals for an

external alarm interface.

10

EXTERNAL AMP. CONTROL

(J2)

7-pin, provides connectivity for optional EXTERNAL

OUTPUT CONTROL (Appendix A).

Controls

2-6

900M P/S Operator's

I

I

I

I

I

I

I

I

900M Series

Power Supplies

Installation

ontents of this Section

3.1 Introduction

3-1

3.2 Unpacking and Handing

3-1

3.3 Location

3-2

3.4 Power Requirements

3-2

AC

Power Connection

3-2

Setting Taps

3-3

3.5 Electrical Connections

3-6

RF

Connections

3-9

EXTERNAL START

Cable Connections

3-9

Input/Output Connections

3-11

Opto-Isolation Outputs

3-15

Suspect Weld Detection

3-15

Control Cable Signals

3-16

3.6 Branson Maintained Start Operating System

3-16

3.7 Automation Systems

3-17

Using Maintained Start MBOS

3-17

Choosing 24V Status Alarms or Contact Closures

3-18

Using

EMERGENCY STOP

as an Interlock

3-18

3.8 Assembling Converter, Booster and Horn

3-19

Assembling the Converter, Booster and Horn Stack

3-19

Connecting Tip to Horn

3-21

Disassembling Converter, Booster or Horn

3-22

Removing Tip from Horn

3-22

3.9 Converter Cooling

3-22

3.10DIP Switch 51

3-24

Setting

DIP Switch

Si

3-24

3.1 Introduction

This section describes how to install and set up a 900M together with a welding system. It

describes power connections, setting taps and how to connect the 900M to different

actuator configurations. These connections include non-automated, automated and

computer controlled connections. In addition, the section describes how to connect the

actuator stack (converter, booster and horn) and setting the

DIP

switch Sl.

3.2 Unpacking and Handling

1.

Unpack the 900M as soon as it arrives.

2.

Inspect the controls, indicators and surface for signs of damage.

3.

Open the cover of the 900M to check whether components became loose during

shipping. While the 900M's cover is removed, set the line transformer taps, described

in Section 3.4,

b. Setting Taps.

900M P/S Operator's

3-1

Installation

Note: If damage has occurred, notify the shipping company immediately. Retain

packing materials for inspection.

3.3

Location

1.

Install the 900M within 25 ft./7.5 m (15 ft./5.5 m for 40 kHz) of the converter and in

an area away from radiators or heating vents.

2.

Allow sufficient clearance to the back of the 900M to provide access to the connectors

(approx. 6 in/150 mm minimum).

3.

Observe the following:

•

Do not block exhaust and intake air circulation, which is needed to maintain a

safe operating temperature.

•

Operate the power supply only in an ambient temperature range of 41°F to 122°F

(5°C to 50°C).

If the power supply temperature reaches 185°F/85°C, a thermal switch will stop

ultrasonics and the power supply will display an Overload alarm. Ultrasonics remain

off until the unit cools to a safe operating temperature and you press RESET.

4. Check to see that dust or dirt does not restrict the flow of air exhaust, and clean the

air ports as necessary.

3.4 Power Requirements

A

Warning:

Be sure the power switch is in the Off position before making any electrical

connections.

To prevent the possibility of an electrical shock, always plug the 900M into a

grounded power source.

3.4.1 AC Power Connection

Plug the 900M into a single-phase, grounded, 3-wire, 50-60 Hz, 200-250 VAC power

source.

Figure 3-1

Plug and

Receptacle

Requirements

Model

Equipped with:

Needs:

905/910/943/947M 117V

NEMA 5-15P plug

NEMA 5-15R receptacle

920M

NEMA L6-20P plug

NEMA L6-20R receptacle

930M

NEMA L6-30P plug

NEMA L6-30R receptacle

k* Caution:

When connecting the line cord plug, make sure the shield is connected to

ground.

Installation

3-2

900M P/S Operator's

3.4.2

Setting Taps

If you have a 200-250V 900M, you may have to set the line transformer taps. These

models may also require other plugs, conforming to local codes.

The line transformers on units other than 117V models contain voltage selection taps

allowing you to match the 900M to your main

AC

voltage. Use the following procedure:

1.

Using a voltmeter, measure the main

AC

voltage at the receptacle and record the

value.

Warning:

Be sure the 900M is unplugged before removing the cover.

2.

Turn the 900M on its side and loosen the four captive retaining screws located on the

bottom of the 900M (Figure 3-2).

Figure 3-2

COVER RETAINIM SCREWS

Cover

Retaining

Screws

900M P/S Operator's

3-3

Installation

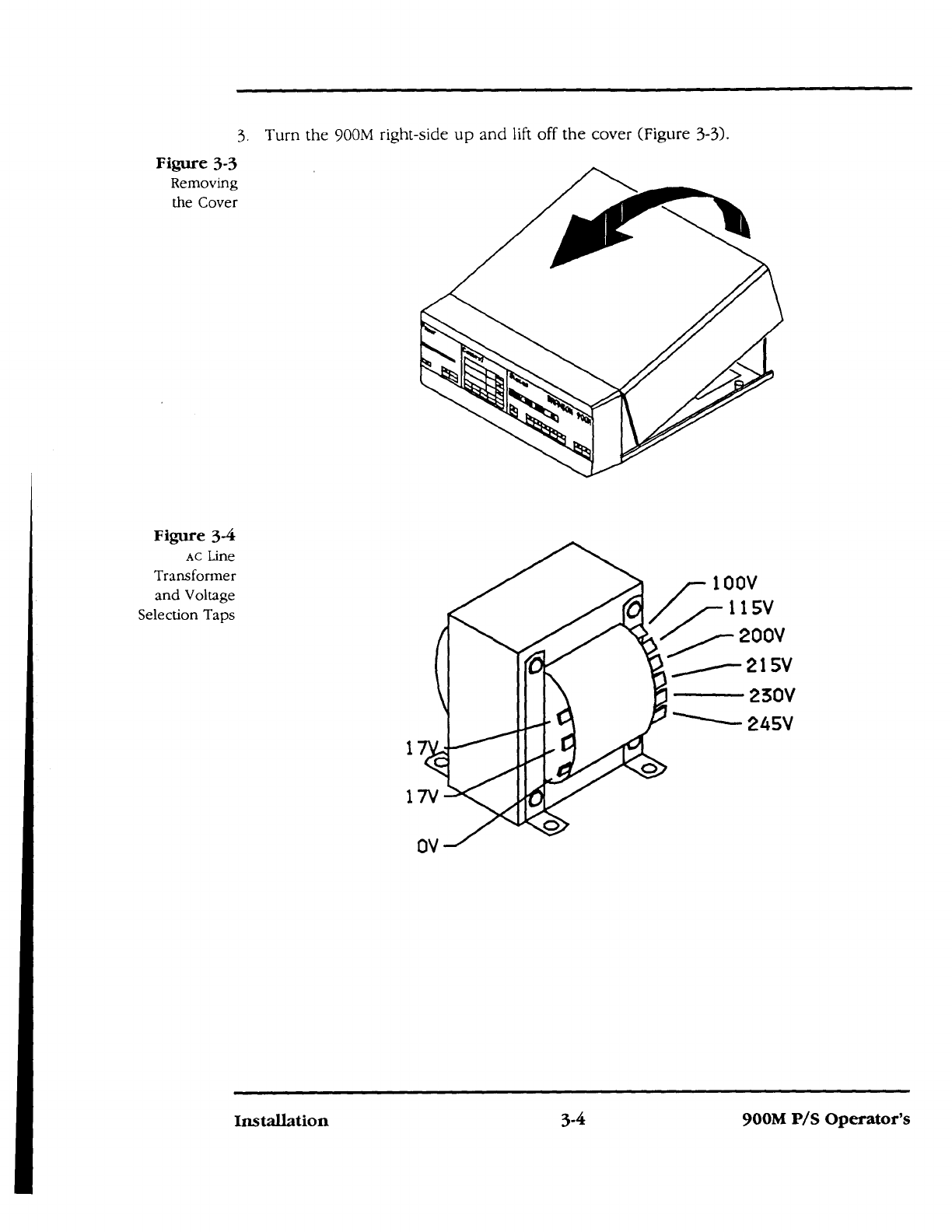

3. Turn the 900M right-side up and lift

off the cover (Figure 3-3).

Figure

3

-

3

Removing

the Cover

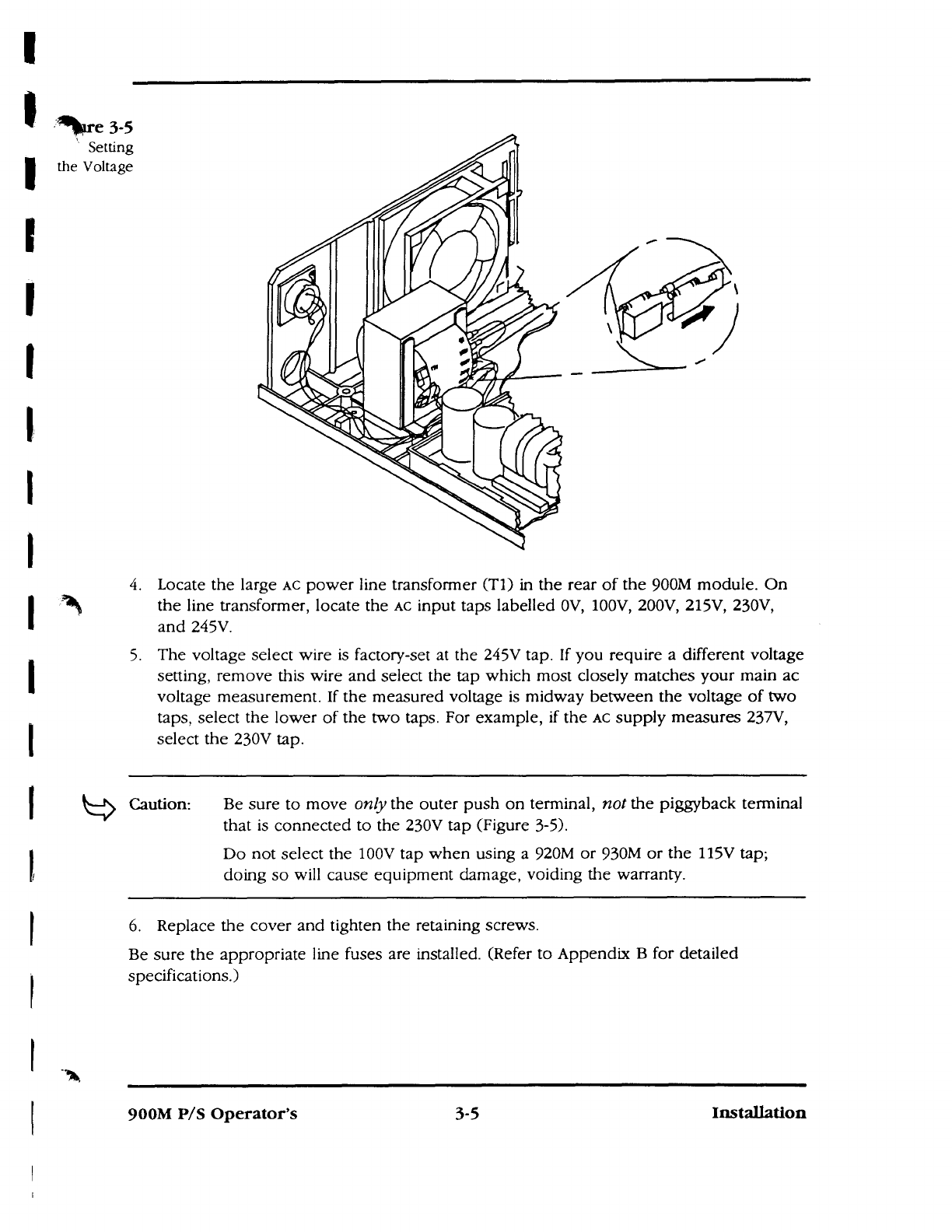

Figure 3-4

Ac Line

Transformer

and Voltage

Selection Taps

111

.000

1

115V

200V

100V

il°0

215V

0

245V

111PP

I

PEr

1

1

1

0

OV

1 7V

Installation

3-4

900M P/S Operator's

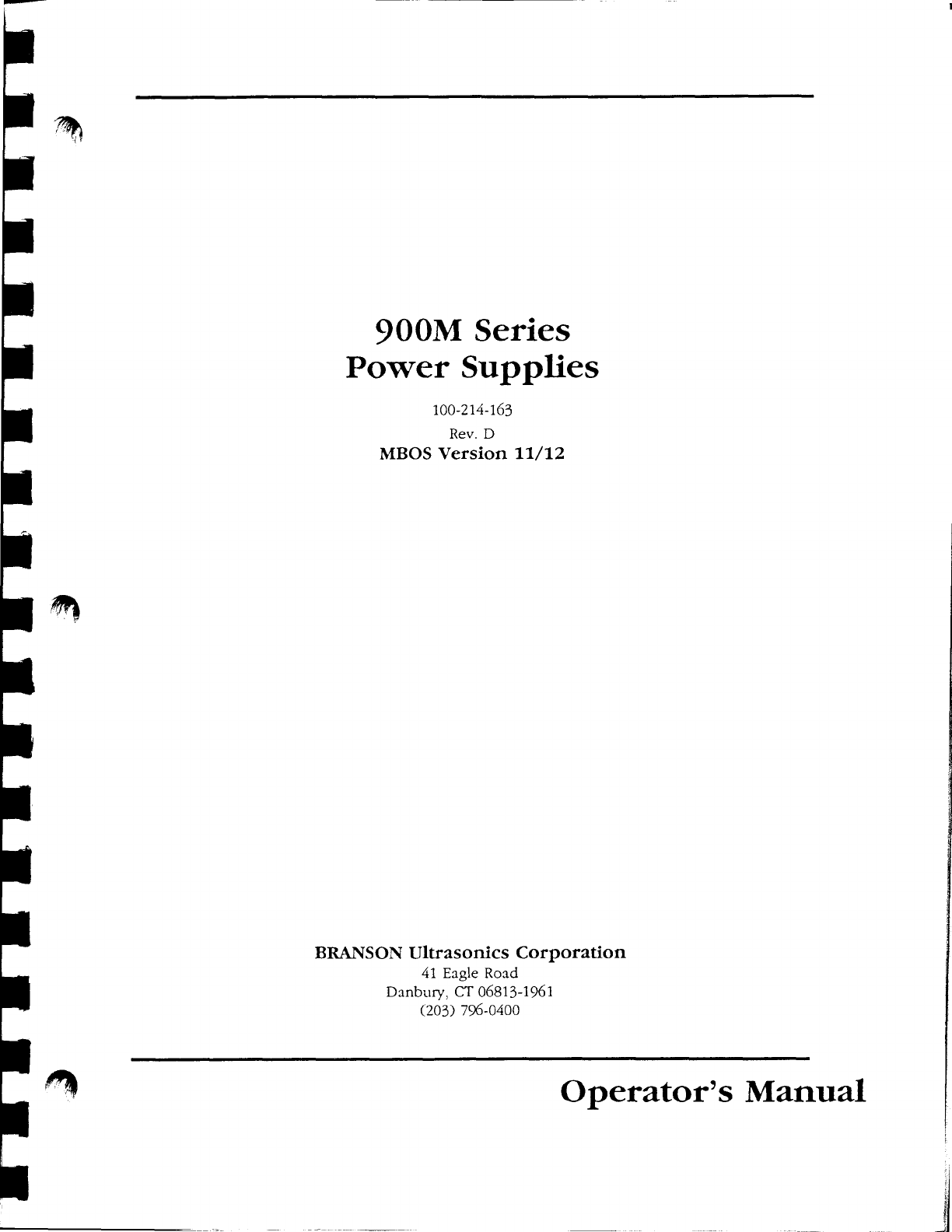

-4111

*.re 3-5

Setting

the Voltage

4.

Locate the large

AC

power line transformer (T1) in the rear of the 900M module. On

the line transformer, locate the

AC

input taps labelled OV, 100V, 200V, 215V, 230V,

and 245V.

5.

The voltage select wire is factory-set at the 245V tap. If you require a different voltage

setting, remove this wire and select the tap which most closely matches your main ac

voltage measurement. If the measured voltage is midway between the voltage of two

taps, select the lower of the two taps. For example, if the

AC

supply measures 237V,

select the 230V tap.

Caution:

Be sure to move

only

the outer push on terminal,

not

the piggyback terminal

that is connected to the 230V tap (Figure 3-5).

Do not select the 100V tap when using a 920M or 930M or the 115V tap;

doing so will cause equipment damage, voiding the warranty.

6.

Replace the cover and tighten the retaining screws.

Be sure the appropriate line fuses are installed. (Refer to Appendix B for detailed

specifications.)

900M

P/S

Operator's

3-5

Installation

Regulator/

gauges

Solenoid

valve 1

Line cord

900M P/S

Figure 3-6

900M-

900AE/AO

Actuator

Connections

RF

Data link

Accessory

interface

(board)

Data link

Alarm

Control

Start/stop

Power signal

Line cord

900AE/A0

Actuator

24V I/O

Module

'Customer controls

L - _

] J931

ECI

(optional)

3951

J971

J921

.7911

3.5

Electrical Connections

The following figures show electrical connections for non-automated, automated and

computer-controlled connections with 900AE/AO, 900AES/AOS and 94A0 Actuators.

Base

Note: 900A0/AOS Actuators use external pneumatic components. The solenoid valve

wires directly to the actuator.

Installation

3-6

900M P/S Operator's

900M Series

Power Supplies

100-214-163

Rev. D

MBOS Version 11/12

BRANSON Ultrasonics Corporation

41 Eagle Road

Danbury, CT 06813-1961

(203) 796-0400

Operator's Manual

Please read before servicing the 900M:

1.

Be sure the power switch is in the Off position before making any electrical

connections.

2.

To prevent the possibility of an electrical shock, always plug the 900M into

a grounded power source.

3.

Be sure the 900M is unplugged before removing the cover.

4.

A 900M powerdown or failure could adversely impact the automation

control box or the programmable controller.

5.

All automation systems working with 900M power supplies MUST use the

READY

state signal

6.

Be sure power is disconnected from the 900M before setting the

DIP

switch.

7.

High voltage is present in the 900M. Do not operate with the cover removed.

8.

Keep hands from under the horn. Down force (pressure) and ultrasonic

vibrations can cause injury.

9.

Large plastic parts may vibrate within the audible frequency range when

welded. If this occurs,

use

hearing protectors to prevent possible injury.

(See Appendix E, "Manufacturers of Hearing Protectors."

10.

Do not press the

TEST

key on the 900M or cycle the welding system if either

the RF cable or converter is disconnected.

11.

Do not contact the horn when you press

TEST.

12.

When using larger horns, avoid situations where fingers could be pinched

between the horn and the fixture.

900M P/S Operator's

iii

Warnings

Limited Warranty

Each standard 900 Series ultrasonic product manufactured by Branson used in

rigid

plastic joining

applications is guaranteed in the United States and Canada to be free

from defects in workmanship and material for thirty six (36) months from the date of

invoice. The guarantee of 900 Series products used in other applications (for example

textiles) is limited to twelve (12) months from date of invoice.

The warranty does not apply to any product which has been subjected to misuse,

misapplication, neglect (including without limitation, inadequate maintenance, proper

ventilation or cooling), accident, or improper installation, modification, adjustment or

repair, or use with an improperly tuned horn.

Products supplied by Seller, but manufactured by others are warranted only to the extent

of the manufacturer's warranty. The guarantee period for certain product lines will be

extended at the discretion of Branson. If rented equipment is converted to purchase,

guarantee period commences at date of original rental shipment and not from date of

conversion.

Disclaimer of Warranty

The foregoing warranty constitutes Seller's only warranty in connection with any sale, and

is in lieu of all other warranties expressed or implied, written or oral: THERE ARE NO

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS OF ANY PRODUCT FOR A

PARTICULAR PURPOSE.

Exclusive Remedy

SELLER'S LIABILITY SHALL BE LIMITED TO REPAIRING OR REPLACING THE PRODUCT

FOUND BY SELLER TO BE DEFECTIVE OR NON-CONFORMING, OR, AT SELLER'S

OPTION, TO REFUNDING THE PURCHASE PRICE OF SUCH PRODUCT. At Seller's

request, Buyer shall send, at Buyer's expense, any allegedly defective product to the

factory where it was manufactured. The remedy set forth above is exclusive.

The repair or replacement of the product, or refund of the purchase price, constitutes

fulfillment of all liabilities of Seller to Buyer under the warranties above-mentioned,

whether based on contract, negligence of any kind, strict liability or tort, or otherwise

with respect to or arising out of product furnished under the sales contract.

Branson Ultrasonics Corp.

Warranty

Limitation of Liability

Buyer expressly agrees that, notwithstanding any other provision of this contract, under

no circumstances shall Seller's total aggregate liability resulting from:

1.

The performance, failure to perform or breach of Seller's obligations; and

2.

Any activity undertaken by Seller with regard to equipment and services covered by

the sales contract; and

3.

All actions based on negligence of any kind, strict liability or tort on the part of Seller

or its suppliers; and

4.

Otherwise, exceed the price paid by the Buyer for the product. BUYER EXPRESSLY

AGREES THAT SELLER WILL NOT BE LIABLE UNDER ANY THEORY OF LIABILITY

FOR ANY DIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES,

INCLUDING, WITHOUT LIMITATION, THE LOSS OF USE, INCOME, PROFITS OR

PRODUCTION; OR INCREASED COST OF OPERATION; OR DAMAGE TO MATERIAL,

ARISING IN CONNECTION WITH THE SALE, INSTALLATION, USE OF, INABILITY TO

USE, OR REPAIR OR REPLACEMENT OF SELLER'S PRODUCTS.

Buyer shall indemnify and hold Seller harmless for any liability to Buyer's employees,

workers, contractors or any other persons beyond the limitation provided in this

section.

Limitation on Claims and Actions

Any claim by Buyer for breach of the foregoing warranty shall be deemed waived by

Buyer unless submitted to Seller in writing within thirty (30) days from the date Buyer

discovered or by reasonable inspection should have discovered the alleged breach. Any

cause of action for breach of the foregoing warranty shall be brought within one year

after the cause of action has accrued.

vi

Branson Ultrasonics Corp.

Warranty

900M Series

Power Supplies

Table of Contents

Section

Page

New Features

xiii

1.

Introduction

1.1 Introduction

1-1

1.2 900M Overview

1-1

1.3 900M Features

1-2

1.4 Inputs

1-3

1.5 Welding Systems

1-3

1.6 Further References

14

2.

Controls

2.1 Introduction

2-1

2.2 900M Front Panel

2-1

2.3 900M Back Panel

2-6

3.

Installation

3.1 Introduction

3-1

3.2 Unpacking and Handing

3-1

3.3 Location

3-2

3.4 Power Requirements

3-2

3.5 Electrical Connections

3-6

3.6 Branson Maintained Start Operating System

3-16

3.7 Automation Systems

3-17

3.8 Assembling Converter, Booster and Horn

3-19

3.9 Converter Cooling

3-22

3.10

DIP

Switch 51

3-24

4.

Operation

4.1 Introduction

4-2

4.2 Weld Modes

4-4

4.3 Weld Mode Settings

4-6

4.4 Weld System Settings

4-27

4.5 Making a Weld Cycle

4-51

4.6 Other Functions

4-62

900M P/S Operator's

vii

Table of Contents

This manual suits for next models

6

Table of contents

Other Branson Power Supply manuals