Branson IPC 3000 User manual

NANOSYSTEM FABRICATION FACILITY (NFF), HKUST

Version 1.0

Page 1 of 14

Standard Operating Manual

___________________________________________________________

Branson IPC 3000 O2Asher

NANOSYSTEM FABRICATION FACILITY (NFF), HKUST

Version 1.0

Page 2 of 14

Contents

1Picture and Location

2Process Capabilities

2.1 Cleanliness Standard

2.2 Recipes

2.3 Performance of Branson IPC 3000 O2Asher

3Contact List and How to Become a Qualified User

3.1 Emergency Responses and Communications

3.2 Training to Become a Qualified User

4Operating Procedures

4.1 System Description

4.2 Safety Warnings

4.3 Operation Rules

4.4 Initial System Checks

4.5 Status Checks

4.6 Steps to operate the equipment

4.6.1 Load the Wafers or Specimens into the chamber

4.6.2 Select Recipe and Run the Process

4.6.3 Pump Down and Start the Process

4.6.4 Vent and Unload the Samples

NANOSYSTEM FABRICATION FACILITY (NFF), HKUST

Version 1.0

Page 3 of 14

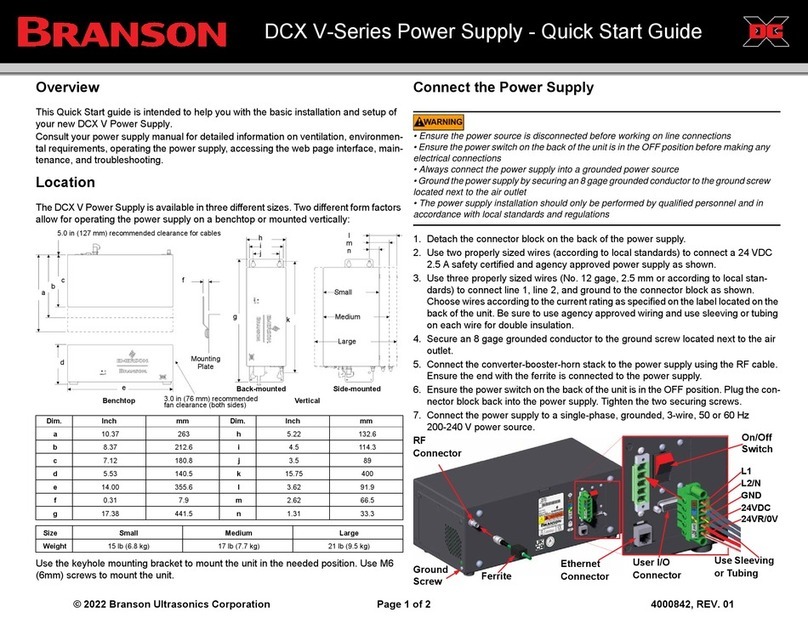

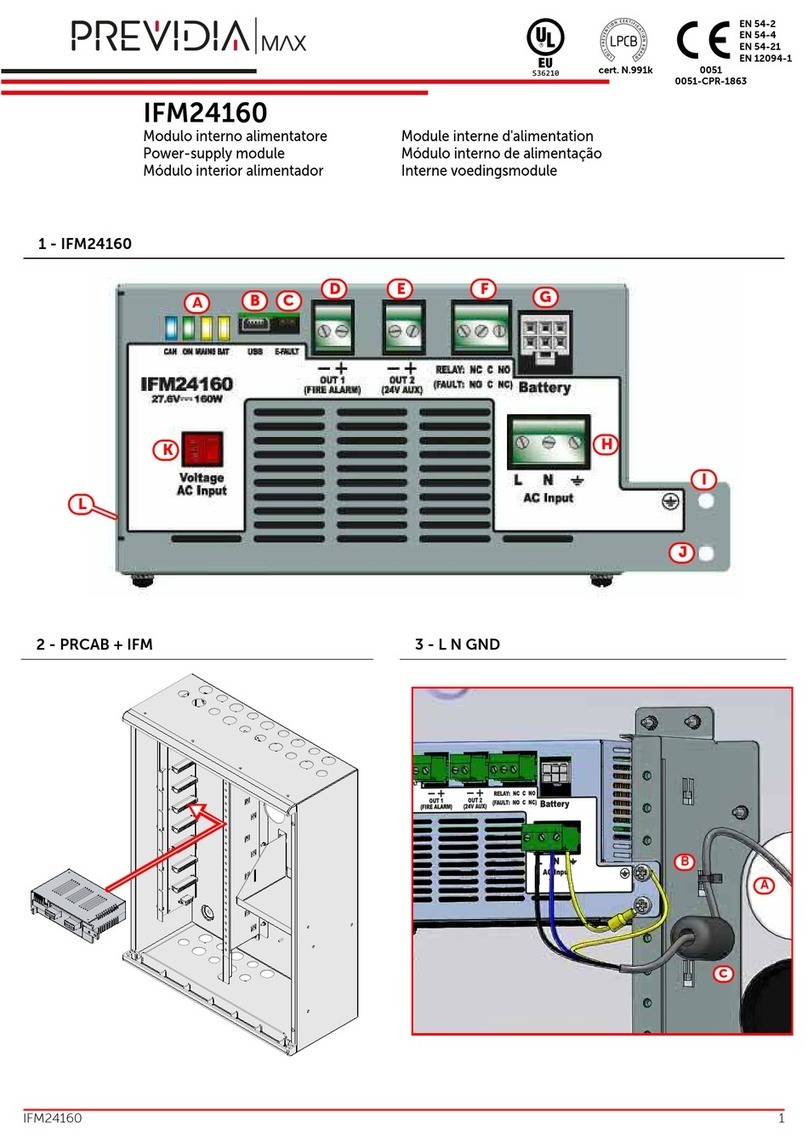

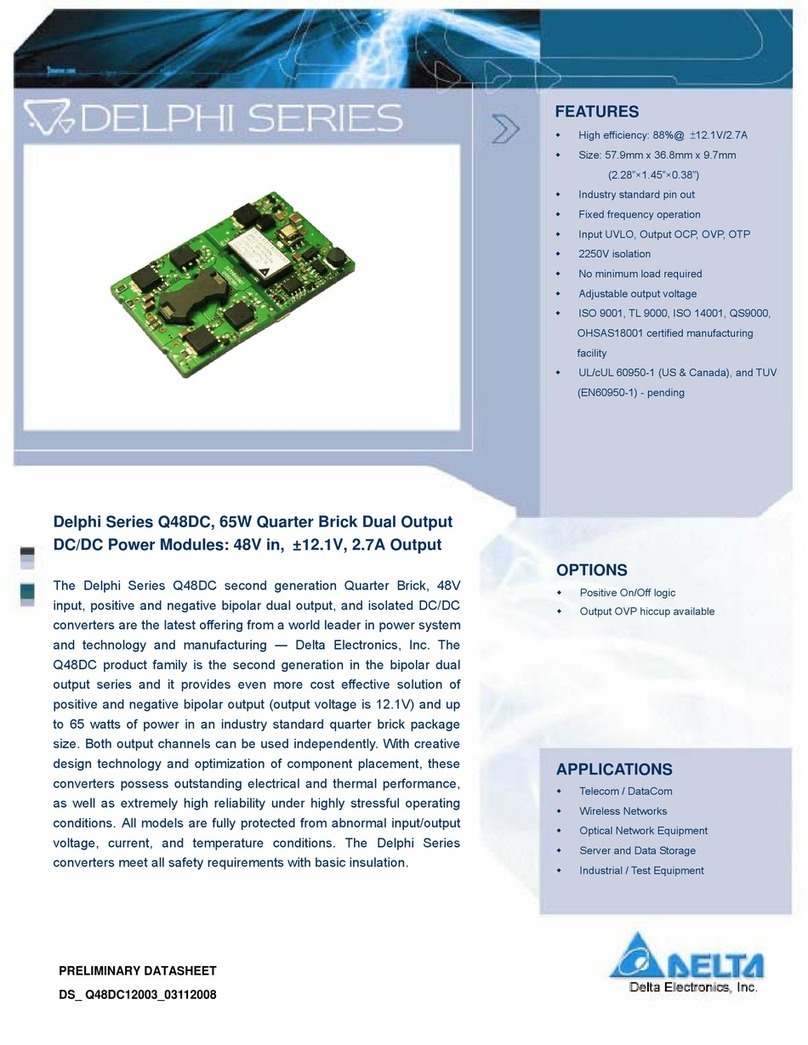

1. Picture and Location

Branson IPC 3000 O2Asher

This tool is located at NFF Enterprise Center Cleanroom Room 4162

Process Capabilities

Fig.1 Branson IPC 3000 O2Asher

2. Process Capabilities

2.1 Cleanliness Standard

Branson IPC 3000 O2 Asher is an “Non-Standard” equipment for Photo Resist

etching.

2.2 Recipes

Two standard recipes are provided for processing photo resist stripping and plasma

Touch Screen Panel

RF Generator

Mechnical Pump

Chamber Door

Chamber

NANOSYSTEM FABRICATION FACILITY (NFF), HKUST

Version 1.0

Page 4 of 14

descum. Recipes’ parameters are shown below.

Plasma Descum (DESCUM.RCP)

Ramp ambient N2flow rate (slpm)

0.45

Temperature at the end of ramp (oC)

70

Power during ramp (W)

300

N2pressure (Torr)

1.3

Process O2flow rate (slpm)

0.45

Temperature at the end of ash (oC)

75

Power during ash (W)

150

O2pressure (Torr)

1.3

Ash time (minutes)

1

Photoresist Stripping (Striper.RCP)

Ramp ambient N2flow rate (slpm)

0.45

Temperature at the end of ramp (oC)

100

Power during ramp (W)

300

N2pressure (Torr)

1.3

Process O2flow rate (slpm)

0.45

Temperature at the end of ash (oC)

200

Power during ash (W)

300

O2pressure (Torr)

1.3

Ash time (minutes)

20

NOTE: Please consult with NFF staff for the feasibility if you request to run the

process by your own recipe.

NANOSYSTEM FABRICATION FACILITY (NFF), HKUST

Version 1.0

Page 5 of 14

2.3 Performance of Branson IPC 3000 O2Asher

Gases available

N2 & O2

RF Power Source

400W at 13.56 MHz

Substrate size

2”, 4” and 6” wafers or specimen

3. Contact List and How to Become a Qualified User

3.1 Emergency Responses and Communications

Security Control Center: 2358-8999 (24hr) & 2358-6565 (24hr)

Safety Officer: Mr. Wing Leong CHUNG 2358-7211 & 64406238

Deputy Safety Officer: Mr. Man Wai LEE 2358-7900 & 9621-7708

NFF EC Technician: Mr. Peter Yiu Cheong PUN 2358-7225 & 2358-7218

NFF Phase 2 Technician: Mr. Wilson Pui Keung YIP 2358-7894

3.2 Training to Become a Qualified User

Please follow the procedure below to become a qualified user.

1. Read the operation manual of Branson IPC 3000 O2asher which can be found

at NFF web site.

2. Send an e-mail to NFF requesting Branson IPC 3000 O2asher operation

training. Scheduling can take up to several weeks due to the many requests

coming in for this tool.

NANOSYSTEM FABRICATION FACILITY (NFF), HKUST

Version 1.0

Page 6 of 14

4. Operating Procedures

4.1 System Description

Branson IPC 3000 O2Asher can generate a low pressure, low temperature gaseous

plasma. Ashing, etching and polymer surface modification can be performed quickly

and reproducibly. It consists of a quartz process chamber, main unit, touch screen

panel, RF generator, pressure gauge, thermal couple and power supply. O2and N2are

provided for process and vent.

Fig2. Touch Screen Panel

Fig3. RF Generator

NANOSYSTEM FABRICATION FACILITY (NFF), HKUST

Version 1.0

Page 7 of 14

Fig4. Mechanical Pump

Fig5. Main unit including chamber

NANOSYSTEM FABRICATION FACILITY (NFF), HKUST

Version 1.0

Page 8 of 14

4.2 Safety Warnings

This equipment can cause injury if it is not being used under a cautious manner.

1. The quartz chamber, wafer boats (see Fig.7) are very brittle. Please handle

them carefully.

2. Load the wafers or specimens into the chamber carefully to avoid damage of

thermal couple which is isolated in a quartz tube (see Fig 6).

3. The system will be damaged if wrong recipe parameters are applied. Make

sure NFF staff knows in case of any change of recipe parameters.

4. Machine case is hot during process. Don’t touch any surface to prevent

burns.

5. Do not operate this machine if you are pregnant since small amount of

unpreventable RF power would escape from the machine.

6. Mechanical pump oil is hazardous to human body. Report to NFF staff when

spillage of oil occurs.

Fig.6 Thermal Couple inside quartz chamber Fig.7 Quartz boats

Thermal

Couple

NANOSYSTEM FABRICATION FACILITY (NFF), HKUST

Version 1.0

Page 9 of 14

4.3 Operation Rules

1. If the equipment alarms during operation, do not try to fix the problem by

yourself and should report to NFF staff immediately.

2. Do not operate the equipment unless you are properly trained and approved by

NFF staff.

3. Do not leave an on-going experiment unattended.

4. Do not run the process for more than 30 mins.

5. Enough time of cooling is needed before unloading the wafers or specimens

from the chamber after process completed.

6. Do not start the process while the door is still open.

7. Except for “main menu”, “Process for Engineering menu” and “Diagnostics

menu”, do not click into other menus such as “Maintenance menu”.

8. Do not stop the process by an improper way during normal operation. For

example, turn off the RF generator to stop the process during normal

operation.

9. Do not change the machine settings without permission of NFF staff.

10. This equipment is only for purposes of PR stripping and Descum. For any

other request, please consult with NFF staff.

4.4 Initial System Checks

1. The RF generator is turned on by confirming that “AC ON” red light is on and

“REMOTE ENABLE” green light is on.

2. The mechanical pump is turned on

3. The computer is turned on so the touch screen is functioning.

4. The chamber should be under atmosphere pressure.

NANOSYSTEM FABRICATION FACILITY (NFF), HKUST

Version 1.0

Page 10 of 14

5. The quartz boats, thermal couple and chamber are under good conditions and

without cracks.

6. The sealing surface and the sealing rubber of the door are under good

conditions without damage.

4.5 Status Checks

No reservation is needed for this equipment. The equipment is under “first come

first serve” basis.

4.6 Steps to Operate The Equipment

4.6.1 Load the wafers or specimens into the chamber

1. Put the wafers or specimens into suitable quartz boats. The quartz boats are

located on top of the main unit.

2. Make sure the chamber is vented.

3. If the door is locked, pull the knob and turn it in clockwise direction. Unlock

and open the chamber door.

4. Use the metal fork to load the boats into the chamber.

5. Put the boats in the center position of the chamber. Don’t damage the thermal

couple which is located at the left of the chamber.

6. Close the door, turn the knob in anti-clockwise direction and push the knob to

lock the chamber door.

4.6.2 Select recipe and run the process

1. In AllWin21 operation interface, go to “Process for Engineering menu”.

NANOSYSTEM FABRICATION FACILITY (NFF), HKUST

Version 1.0

Page 11 of 14

2. Four columns can be found in this menu. Go to the last column “Recipe File”,

select the correct recipe and click “Recipe Edit”. All recipes should be in

*.RCP format.

3. Check the recipe parameters to make sure the parameters are correct. The

tables below show the recipe parameters of “DESCUM.RCP” and

“Striper.RCP”.

Step

No.

Step

Function

Time

(sec)

Temperature

(oC)

Steady

Intn

Factor

Gas1

O2

SLPM

Gas2

N2

SLPM

RF

Power

(W)

Vac.

Pressure

(Torr)

END

Point

Detect

RF

1

Delay

70

25

1

0

0.45

0

1.3

0

OFF

2

Wait

120

100

1

0

0.45

300

1.3

0

ON

3

Delay

30

100

1

0.45

0

0

1.3

0

OFF

4

Delay

*300

200

1

0.45

0

300

1.3

0

ON

5

Finish

0

0

1

0

0

0

0

0

OFF

Table1. Recipe parameters of “Striper.RCP”

Step

No.

Step

Function

Time

(sec)

Temperature

(oC)

Steady

Intn

Factor

Gas1

O2

SLPM

Gas2

N2

SLPM

RF

Power

(W)

Vac.

Pressure

(Torr)

END

Point

Detect

RF

1

Delay

70

25

1

0

0.45

0

1.3

0

OFF

2

Wait

140

70

1

0

0.45

300

1.3

0

ON

3

Delay

30

70

1

0.45

0

0

1.3

0

OFF

4

Delay

*60

70

1

0.45

0

150

1.3

0

ON

5

Finish

0

0

1

0

0

0

0

0

OFF

Table2. Recipe parameters of “DESCUM.RCP”

* Remark: This is the process time for ashing.

4. If no recipe parameters are being changed, Click “Exit” and then click

“START PROCESS” to start the process.

5. If recipe parameters have to be changed, choose the boxes, change the

NANOSYSTEM FABRICATION FACILITY (NFF), HKUST

Version 1.0

Page 12 of 14

numbers and click “Enter”. To save the new settings, click “RECIPE

VALIDATE” first. Click “Yes” on Popup massage “Congratulation!

Validation Success!” and then click “Save”. After that, click “Exit” to exit this

page and click “START PROCESS” to start the process.

4.6.3 Pump down and start the process

1. Once click “START PROCESS”, the chamber pump down automatically to

reach its vacuum set point which is 0.01Torr. A popup message shows

“Waiting for Vacuum Pump down…” (see Fig.8).

2. After pressure reached 0.01Torr, process starts with real time process

information showing on another page (see Fig.9). Those process feedback

values are presented in formats of graphs and bars.

Fig8. Popup message to show “Waiting for vacuum. Pump down….”

NANOSYSTEM FABRICATION FACILITY (NFF), HKUST

Version 1.0

Page 13 of 14

Fig9. Process running with real time feedback data

Fig 9. X-axis: Time (Sec), Y-axis: Green line: O2flow rate; Blue line: N2 flow

rate; Pink line: RF power; purple line: Pressure; Thin blue line: Temperature

Bars: N2 flow rate, O2 flow rate, RF power, pressure

3. During the process, check the process feedback values to make sure the values

are close to the set values in recipe. Otherwise, report to NFF staff to check for

the equipment. Don’t go away while machine is running and keep

monitoring the process until completed.

4. If the process needs to be aborted during running, Click “STOP NOT PURGE”

and ask NFF staff to vent the chamber to take out the wafers or specimens.

5. Otherwise, “Process Completed” is shown on the screen when process is done.

At the same time, chamber will be vented automatically.

NANOSYSTEM FABRICATION FACILITY (NFF), HKUST

Version 1.0

Page 14 of 14

4.6.4 Vent and unload the samples

1. After venting to atmosphere, pull the knob and turn it in clockwise direction.

Open the chamber door and take out the quartz boats by metal fork. Don’t

touch the quartz boats or chamber by hands because they might be still

hot.

2. Exit and go to the main page. Click “Diagnostics” (see fig.10) to stop venting

and exit again to go back to the main page.

3. Make sure the chamber and the working environment are clean after use.

Fig.10 Diagnostic menu

Table of contents

Other Branson Power Supply manuals

Popular Power Supply manuals by other brands

Delta Electronics

Delta Electronics Delphi Q48DC datasheet

Delta Electronics

Delta Electronics L36SA datasheet

SonicWALL

SonicWALL NSsp 12000 installation guide

Unipower

Unipower Aspiro 1U Enclosure instruction manual

Anker

Anker SOLIX C1000 user guide

TrickleStar

TrickleStar PowerStation1500 quick start guide

Texas Instruments

Texas Instruments UCD3138PSFBEVM-027 user guide

Rockwell Automation

Rockwell Automation 1606-xlp15 instruction manual

BASETech

BASETech BT-153 operating instructions

Altinex

Altinex PS5581SM user guide

Matsusada Precision

Matsusada Precision AMP Series instruction manual

Thermal Dynamics

Thermal Dynamics CE Pak Master 100XL Plus Service manual