2PowerBox-Systems − World Leaders in RC Power Supply Systems

Dear PowerBox customer,

It is now ten years ago to the month that the rst Competition SRS was introduced.

At that time it represented a milestone in the redundant deployment of receivers

using our new type of bus technology. The unrestricted output assignment, ser-

vo matching and linking to early telemetry systems were unique features, and re-

mained so for a long time.

Technology has continued to develop, and modellers’ requirements have become

more exacting. Here at PowerBox Systems we are proud to present our latest de-

velopment: the PowerBox Competition SR2. Incorporating a new external look and

the very latest technology, this single unit integrates more than twenty years of ex-

perience in the design and construction of airborne electronics.

The external changes are immediately evident: the most obvious and eye-catching

feature is the new full-colour TFT screen, which is clearly legible even in full sunshi-

ne. The size of the screen has allowed us to include a self-explanatory menu struc-

ture which is so simple to use that its operation has raised not a single query from

our test-pilots. Another obvious change is the large heat-sink, machined from solid

metal, which signicantly enhances the performance of the power supply. At the

same time we were able to reduce the overall size of the Competition SR2 subs-

tantially. The associated Sensor-Switch and TFT screen are also housed in a ma-

chined aluminium case, matching the quality appearance of the SR2 itself.

However, the most signicant innovations only become evident once the unit is

switched on. The main display contains all the essential data - including battery

voltage, current, consumed capacity and all receiver-relevant information - which

can be viewed at a glance. The screen also displays status messages concerning

the iGyroSAT or GPS III, if connected to the system.

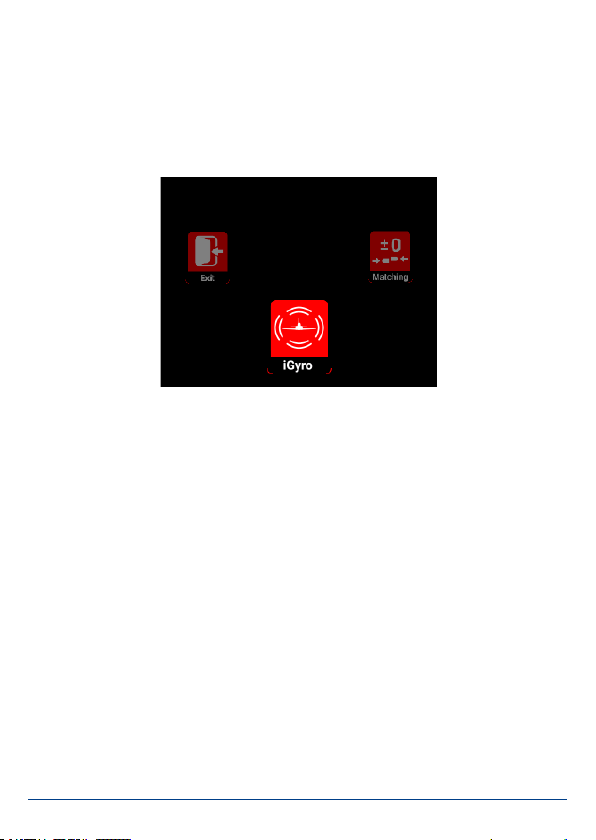

The menu system is clearly and logically laid out, and includes many new functions

as well as the familiar menu points - and all in two languages: German and English!

Important new features implemented in the new Competition SR2 include the most

efcient and sophisticated iGyro technology ever developed by PowerBox Systems.

Used in conjunction with the optional iGyroSAT sensor, the system offers twelve

gyro axes which cater for every existing model variant. The highly rened Setup

Assistant enables the pilot to set up complex models, such as types with dual thrust

vectors, ailerons and tailerons, in just a few minutes. Once the Assistant has been

completed, the transmitter channels are assigned, the directions of gyro effect are

set, and the servos connected to the outputs.