BrasilSat SCB37-120 User manual

I

MANUAL FOR

MODELS:

SCB37-120

SCB107-120

SCB107E-120

12 METERS CASSEGRAIN EARTH STATION ANTENNAS

I

C o n t e n t

1 General………………………………………………………………………………...2

2 Technical Specifications………………………………………………………………3

2.1 Specifications of the model SCB37-120…………………………………………….3

2.2 Specifications of the model SCB107-120…………………………………………...4

2.3 Specifications of the model SCB107E-120………………………………………….5

3 Structural Character and Operational Principle………………………………………..6

3.1 System Structural Character...................................................................…..................6

3.1.1 Antenna Structural Character..………………………………………….……….7

3.1.2 Antenna Pedestal Structure…..…………………………………………………13

3.1.3 Feed Structure…..………………………………………………………………17

3.2 Antenna Operation Principle..................................................................................... 19

4 Maintenance..............................................................................................................….19

4.1 Operation and Maintenance of Antenna.............…............ .....................…............. 19

4.2 Operation and Maintenance of Servo Equipment......................................…............ 22

2

1 General

The 12m antenna, a synthetic Cassegrain dual-reflector antenna models SCB37-120,

SCB107-120 and SCB107E-120, adopts some new technologies, such as high-

performance corrugated horn and broadband microwave network, etc.

The antenna performance meets the requirements of ITU-R/ITU-T、INTELSAT IESS-207

and Resolution 572 of Anatel standards. It is not only provided with many excellent

electric performances, such as high efficiency, low sidelobe, low cross polarization, low

Voltage standing waves ratio (VSWR), high G/T value, but also with excellent characters

including appropriate structural design, strong wind resistance ability, beautiful

appearance and high tracking accuracy. It is a new generation satellite communication

antenna.

This manual is applicable for the follow models of antenna:

SCB37-120: C-Band Cassegrain 12 meters antenna for Circular or Linear Polarization;

SCB107-120: Ku-Band Cassegrain 12 meters antenna for Linear Polarization;

SCB107E-120: Extend Ku-Band Cassegrain 12 meters antenna for Linear Polarization;

3

2 Technical Specifications

2.1 Specifications of the model SCB37-120:

Electrical Performance

Rx 3625 to 4200 MHz

Frequency Range Tx 5850 to 6425 MHz

Polarization Linear or Circular

Rx 52,2 dBi (@ 4,00 GHz)Gain

(Including Losses) Tx 55,7 dBi (@ 6,00 GHz)

Rx 0,5º (@ 4,00 GHz)

Half-power Beamwidth Tx 0,3º (@ 6,00 GHz)

10º El 42 K (@ 4,00 GHz)

20º El 36 K (@ 4,00 GHz)

Noise Temperature 30º El 33 K (@ 4,00 GHz)

Typical G/T, 20º elevation at clear Sky

with C Band LNA, 30 K 33,8 dB/K (@ 4,00 GHz)

Anatel Resolution 572

FCC regulation 25.209

Radiation Pattern Envelope ITU-RS580

Rx 1.06 (0,5 dB)Axial Ratio

(Circular Configuration) Tx 1.06 (0,5 dB)

Rx 35 dBCross Polarization Discrimination

(Linear Configuration) Tx 35 dB

Rx 1.3 (17.7 dB)

VSWR (Return Loss) Tx 1.3 (17.7 dB)

TX/RX 75 dB

Port to Port Isolation RX/TX 55 dB

Rx CPR 229G

Feed Termination (flange) Tx CPR 137 G

Input Maximum Power 2000 W

Mechanical Characteristics

Diameter 12 meters

Antenna Geometry Cassegrain

Motion Elevation over azimuth

Azimuth ± 90º

Elevation 0 a 90º

Motion Adjustment Polarization ± 50º

Reflector Material Aluminum

Mount Material Steel

Reflector White painting

Finishing Mount Hot dip galvanized

Surface Precision 0.5mm (RMS)

Environmental Characteristics

Operational Wind 130 km/h

Survival Wind 198 km/h

Shock and Vibration Typical in sea, air and terrestrial shipments

Atmosphere Found in seashore and industrial areas

4

2.2 Specifications of the model SCB107-120:

Electrical Performance

Rx 10700 to 12750 MHz

Frequency Range Tx 13750 to 14800 MHz

Polarization Linear

Rx 61,7 dBi (@ 12,00 GHz)Gain

(Including Losses) Tx 63,0 dBi (@ 14,00 GHz)

Rx 0,13º (@ 12,00 GHz)

Half-power Beamwidth Tx 0,11º (@ 14,00 GHz)

10º El 60 K (@ 12,00 GHz)

20º El 50 K (@ 12,00 GHz)

Noise Temperature 30º El 46 K (@ 12,00 GHz)

Typical G/T, 20º elevat

ion at clear Sky

with C Band LNA, 60 K 40,9 dB/K (@ 12,00 GHz)

Anatel Resolution 572

FCC regulation 25.209

Radiation Pattern Envelope ITU-RS580

Rx 35 dB

Cross Polarization Discrimination Tx 35 dB

Rx 1.3 (17.7 dB)

VSWR (Return Loss) Tx 1.3 (17.7 dB)

TX/RX 75 dB

Port to Port Isolation RX/TX 55 dB

Rx WR 75

Feed Termination (flange) Tx WR 75

Input Maximum Power 1000 W

Mechanical Characteristics

Diameter 12 meters

Antenna Geometry Cassegrain

Motion Elevation over azimuth

Azimuth ± 90º

Elevation 0 a 90º

Motion Adjustment Polarization ± 50º

Reflector Material Aluminum

Mount Material Steel

Reflector White painting

Finishing Mount Hot dip galvanized

Surface Precision 0.5mm (RMS)

Environmental Characteristics

Operational Wind 130 km/h

Survival Wind 198 km/h

Shock and Vibration Typical in sea, air and terrestrial shipments

Atmosphere Found in seashore and industrial areas

5

2.3 Specifications of the model SCB107E-120:

Electrical Performance

Rx 10700 to 12200 MHz

Frequency Range Tx 12750 to 14500 MHz

Polarization Linear

Rx 61,3 dBi (@ 11,45 GHz)Gain

(Including Losses) Tx 62,7 dBi (@ 13,50 GHz)

Rx 0,16º (@ 11,45 GHz)

Half-power Beamwidth Tx 0,13º (@ 13,50 GHz)

10º El 60 K (@ 11,45 GHz)

20º El 50 K (@ 11,45 GHz)

Noise Temperature 30º El 46 K (@ 11,45 GHz)

Typical G/T, 20º elevation at clear Sky

with C Band LNA, 60 K 40,4 dB/K (@ 11,45 GHz)

Anatel Resolution 572

FCC regulation 25.209

Radiation Pattern Envelope ITU-RS580

Rx 35 dB

Cross Polarization Discrimination Tx 35 dB

Rx 1.3 (17.7 dB)

VSWR (Return Loss) Tx 1.3 (17.7 dB)

TX/RX 75 dB

Port to Port Isolation RX/TX 55 dB

Rx WR 75

Feed Termination (flange) Tx WR 75

Input Maximum Power 1000 W

Mechanical Characteristics

Diameter 12 meters

Antenna Geometry Cassegrain

Motion Elevation over azimuth

Azimuth ± 90º

Elevation 0 a 90º

Motion Adjustment Polarization ± 50º

Reflector Material Aluminum

Mount Material Steel

Reflector White painting

Finishing Mount Hot dip galvanized

Surface Precision 0.5mm (RMS)

Environmental Characteristics

Operational Wind 130 km/h

Survival Wind 198 km/h

Shock and Vibration Typical in sea, air and terrestrial shipments

Atmosphere Found in seashore and industrial areas

6

3 Structural Character and Operational Principle

3.1 System Structural Character

The 12m limit-motion antenna system is composed of antenna feed subsystem and

structure subsystem. The antenna feed subsystem contains feed and main reflector and

subreflector curves. The structure subsystem contains main reflector and subreflector,

polarization rotation device, pedestal and antenna feeder. The composition principles of

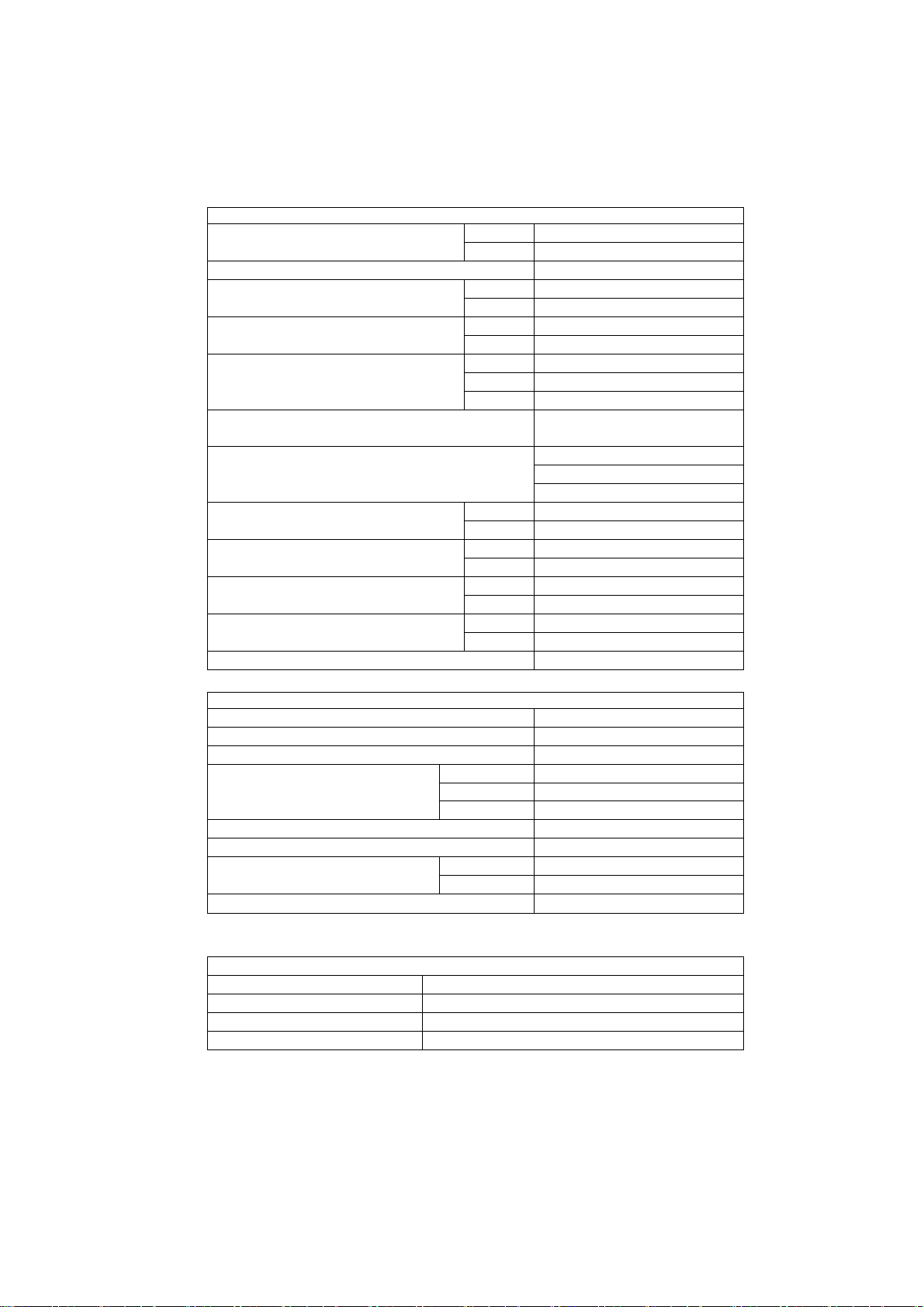

antenna system are shown in Fig.3.1-1. The picture is shown in Fig.3.1-2.

Fig.3.1-1 Composition Principle Block Diagram of Antenna System

7

Fig.3.1-2 Picture of 12m antenna

3.1.1

Antenna Structural Character

3.1.1.1

Antenna Reflector Assembly

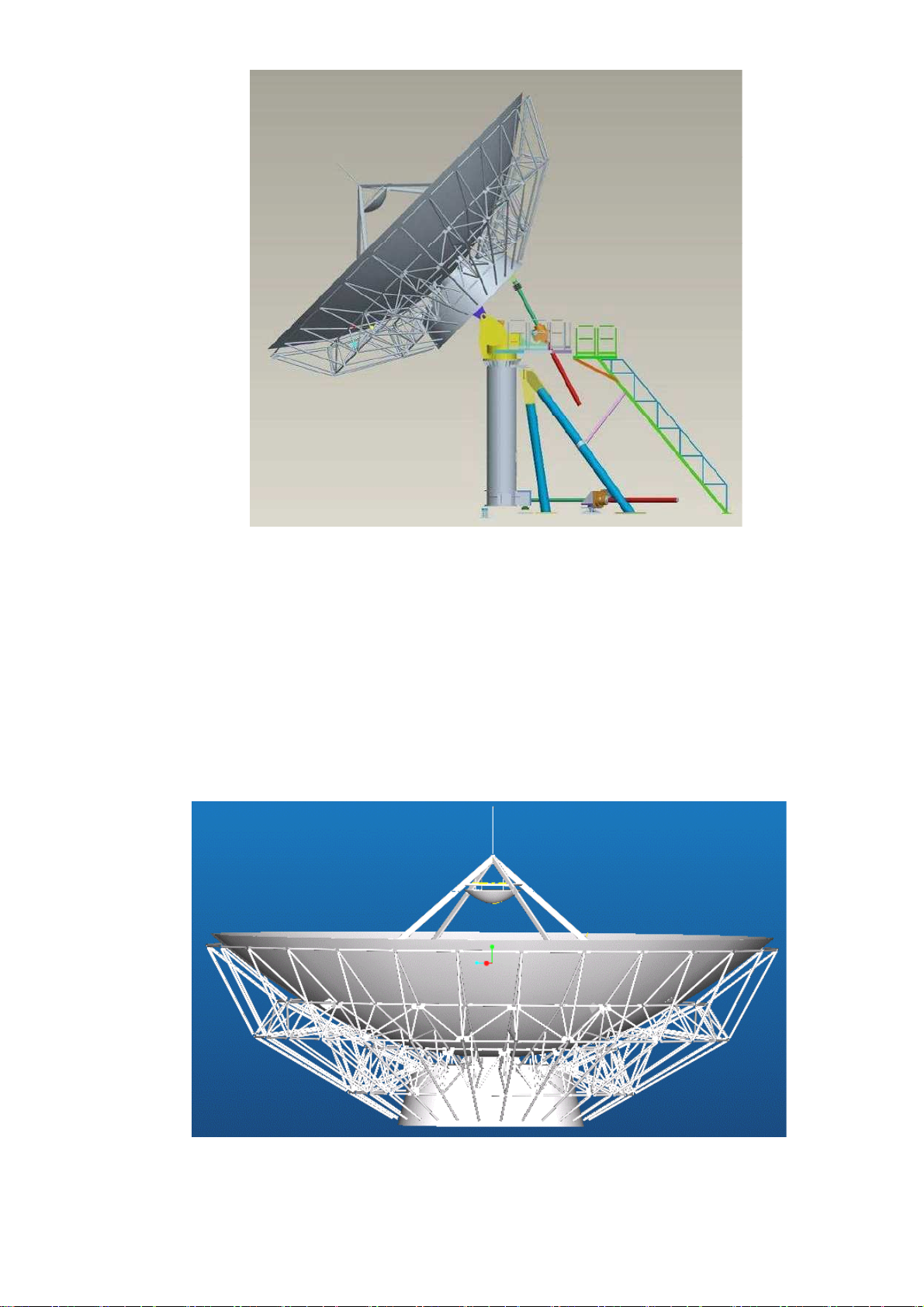

The antenna reflector is mainly composed of main reflector, subreflector,

backups, subreflector supporting device, feed sleeve, etc. The three-dimensional

forming diagram is shown in Fig.3.1-3.

Fig.3.1-3 Structural Schematic Diagram of 12m Antenna

8

3.1.1.2

Main Reflector Design

The main reflector is one of the core components of the antenna system. Its theoretical

curved surface is formed by synthetic curve rotating around the axis of the antenna.

The antenna reflector is divided into multiple plates because of cumulative materials,

manufacturing engineering, final assembly adjustment, etc. The reflector is divided into

three rings. Inner ring reflector is divided into 16 same sector unit plates; the middle

ring is divided into 32 sector unit plates and the outer ring is divided into 32 sector unit

plates. So the main reflector of antenna is composed of 80 reflector units, as shown in

Fig.2.1-4 and 2.1-5.

Fig.2.1-4 Structure Diagram of Antenna Main Reflector

Fig.2.1-5 Individual Sector Plate Structure Schematic Diagram of Outer Ring

9

The stretched and shaped 2A12-O aluminum board with thickness of δ=2mm is used as

individual sector plate after quenching, stretching and shaping. Z type aluminum casting

material is used as back rib after quenching, stretching and shaping in order to perform

positioning with rivet the die table for riveting rib and reflector. Each sector plate is

supported at backups via 6 stretching bolts. In order to ensure the process precision, such

process technology as first bonding and second riveting is adopted to improve the

strength of individual plate and reduce the number of rivets and thus decrease the local

deformation of plate caused by riveting points. The high precision mould and tool set up

process are used for all procedures, such as stretching, stretch bending, riveting. The

accuracy of the individual plate is ≤0.15mm (R.M.S). The reassembly precision of

whole main reflector is ≤0.45mm (R.M.S).

3.1.1.3

Subreflector and Its Supporting Mechanism Design

The subreflector is made of aluminum casting material and adopts the integral structure. It

is manufactured with the numerically controlled machine tool to ensure its precision,

which is not more than 0.15mm (R.M.S). The subreflector supporting mechanism is

composed of four support rods and one adjustment mechanism. In order to reduce its

shadow to the main reflector and ensure the supporting rigidity, the subreflector support

rod adopts the flat oval steel tube, of which one end is supported at the main backups and

the other is connected with the subreflector through adjusting mechanism. The four

adjusting bolts of adjusting mechanism are used to implement the adjustment of

subreflector axial movement, lateral movement and drift angle. The three-dimensional

forming diagram of subreflector and its supporting mechanism is shown in Fig.3.1-6.

10

Fig.3.1-6 Three-dimensional Forming Diagram of Subreflector and Its

Supporting Mechanism

3.1.1.4

Reflector Backups Design

The backups are the main stressed component and structural support of the whole

antenna reflector. It adopts space reticular truss structure, of which various structural

parts have such advantages as goodish consistency, smooth stress transmission, uniform

stress, favorable manufacture and installation, etc. and are widely applied because of the

higher rigidity-weight ratio.

The backups consist of the HUB, radiating beams and hoop stress bars and diagonal bars.

It is divided 32 pieces of main radiating beams along circumferential direction, a space

pull bar is laid between two radiating beams. The diagonal bars are laid between the outer

surface radiating beams. The previous bars parts constitute the space reticular truss

structure, as shown in Fig.3.1-7.

11

Fig.3.1-7 Reflector Backups Schematic Diagram

The HUB is the basic stressed component in the antenna structure and also the

connection component between the antenna reflector and antenna pedestal. All loads of

antenna reflector are down-transferred concentratively through the HUB. So the

HUB must have higher rigidity.

The appearance design of HUB is tapering barrel type, the bottom diameter is φ4300mm,

the height is 1300mm, the coning angle is 76°. The tapering barrel is made of steel plate

(t=8), the top and bottom (t=10) are seal-welded with flange. 28 heterotypic ribs are in the

corresponding positions of the HUB and radiating beams. One ring and two rings

of concentric circular rib plates with the height of 200mm are respectively at the top and

the bottom, so the cellular structure is formed in the whole HUB to make it have

maximum rigidity. The polyphenyl heat insulating material with thickness of 50mm is

stuck in the tapering barrel of HUB to constitute the high frequency room after built-in of

fireproofing decorative plates for installation of general equipment and high

frequency receiving components, of which minimum available volume is φ2800×1200

and which has larger and comfortable environment space. In order to meet the

requirement of transportation, the HUB is designed as bilateral symmetry connection

type, the thickness of connection steel plate is 16mm, the material type is Q235A, the

fastener is M20 high intensity bolt, as shown in Fig.3.1-8.

The radiating beams is one of the main stressed components in the antenna reflector

space reticular truss structure. It is the planar truss constituted by top boom, low boom,

normal web member and diagonal web member through spherojoint welding. Its main

12

role is to form the supporting back bracket of the main reflector of antenna with

hoop stress pull bar and diagonal draw bar. The top boom and low boom are made of

20# steel material and they are seamless steel tubes with size of φ 57 × 3. The

normal web member and diagonal web member are made of 20# steel material and they

are seamless steel tubes with size of φ50×3. Their characteristics are simple type,

uniform stress, high rigidity and convenient surface treatment, as shown in Fig.3.1-9.

Fig.3.1-8 Schematic Diagram of HUB

Fig.3.1-9 Schematic Diagram of Radiating

Beams

The hoop stress pull bar is the steel pole fitting of φ50×3. The 3 hoop stress pull bars

and diagonal draw bars are connected from beginning to end to the outer end of the

radiating beams to play the role of hoop stress stabilization for the reflector framework.

The material is 20# steel.

13

3.1.1.5

Feed Sleeve

The feed sleeve is the supporting component of feed network, which is divided into two

segment such as upper segment and lower segment. Both are formed through rolling and

welding of Q235A steel plate with thickness of 4mm. The lower segment uses circular

sleeve structure and moving sleeve design, microwave network is installed in the

moving sleeve, which performs moving connection with fix sleeve through two thin

wall bearing, the fix sleeve is fixed in the HUB. The upper segment uses tapering sleeve

structure, of which the upper end surface performs positioning connection with

corrugated horn and the lower end surface performs positioning with the rabbet of

moving sleeve and the flanges are connected with bolts. So, the linear polarization

direction of feed network can be adjusted only by rotating moving sleeve for

implementing linear polarization surface adjustment which uses electric mode.

3.1.2

Antenna Pedestal Structure

The antenna pedestal is mainly used to provide the support for the antenna, and make

the antenna perform the azimuth and elevation rotation and align the satellite accurately

under the control of servo equipment. The antenna pedestal adopts the columnar beams

type pedestal structure, namely A, E two axes type pedestal, it consists of pedestal,

azimuth-elevation driving, synchronization and limit devices, platform ladder,

etc. The structural three-dimensional modeling view is shown in Fig.3.1-10.

14

Fig.3.1-10 12mAntenna Pedestal 3D Modeling View

Its azimuth driving mechanism is below columnar beams and the elevation driving

mechanism is postposition type. The whole antenna pedestal is seated on five reinforced

concrete bases.

3.1.2.1

Azimuth Part

The azimuth part consists of the azimuth-elevation supporting combination, tripod,

azimuth lower bearing pedestal combination, azimuth upper bearing pedestal combination,

etc.

The azimuth-elevation supporting combination is a T-type combination constituted by the

kingpost and the tripod. The kingpost with Ф900mm and length of 3.45m is decumbent on

the previous one. The tripod is constituted with three inclined struts that their upper

ends are converged at one point. The lower ends of the three inclined struts are fixed at

the base with bolts, and the upper ends are connected to the azimuth upper bearing

pedestal combination and fixed at the intersection point of their center connecting lines to

form the upper axle head for azimuth rotation. The lower bearing pedestal combination is

15

fixed at the base with bolts, the centers of the upper and lower bearing are at the same

plumb line and form the azimuth axis.

The annular contact thrust spherical-roller bearing 9069332 is installed in azimuth lower

bearing pedestal, the knuckle sliding bearing is installed in azimuth upper bearing pedestal.

The upper and lower axle heads are respectively installed into the upper and lower

rotation axle pedestal holes. In this way, the azimuth-elevation bearing combination can

perform azimuth movement under the role of the azimuth driving device, the azimuth

travel range is within ±90º.

3.1.2.2

Elevation Part

The elevation part mainly consists of the azimuth-elevation bearing combination,

driving pedestal E, elevation bearing pedestal combination, etc.

On the support arms at the two sides of decumbent cylinder at the top of azimuth-

elevation bearing combination, there is a pair of axle holes orthogonal with the azimuth

axis, in which are the bearings. The two axle holes connect the elevation bearing pedestal

combination with the decumbent cylinder via the clevis pin with head to form the

elevation axis E. In this way, the antenna can perform the elevation movement under the

role of elevation driving device. The elevation rotation range is within 0º~90º.

3.1.2.3

Driving Device

The driving device consists of the elevation driving device and azimuth driving device.

The driving device composition block diagram is shown in Fig.3.1-11. The azimuth and

elevation driving devices are lead screw type. The decelerator of driving device

adopts SG-71 type plane secondary envelope worm pair. The decelerator adopts cycloid

pin wheel decelerator and planetarygear decelerator.

Fig.3.1-11 Driving Device Composition Block Diagram

16

AC motor: select and use double-speed AC motor, the type number is YD160L-16/4H

(horizontal type), it is the sealed type three-proof motor, normal power is 2KW/8KW;

rotating speed is 361r/min/1460r/min,the azimuth and elevation motor are same.

Elevation decelerator: planetary gear decelerator, the type number is NGW11-9

(horizontal type), deceleration ratio: i=7.1.

Azimuth decelerator: cycloid pin wheel decelerator, the type number is XW5.5-5-1/9,

deceleration ratio: i=9.

Worm gear-worm pair: SG-71-type plane secondary enveloping surface torus worm pair,

the worm is single-head type, deceleration ratio: i =40, the azimuth and elevation

worm gear- worm pairs are same.

Leadscrew-nutpair:thescrewthreadparameterisTr150X14,theazimuthandelevationleadscrew-nutpairs

aresame.

The final stage of driving chain is lead screw-nut pair, which has self-locking capability.

The antenna can apply the brake safely at any position and at the same time the nut pair

use double nuts for backlash elimination.

3.1.2.4

SynchronizationDevice

The azimuth and elevation synchronization devices are respectively installed on the

azimuth and elevation axle heads, the corners of axis is transformed into the electrical

signals and output to obtain the position information of antenna.

3.1.2.5

Limit Device

In order to make the antenna rotate within the safe range, install safe limit protection

device on the azimuth and elevation axle heads of antenna to make the antenna operate

safely.

The limit device consists of the limit switch and mass. The limit swicths are respectivily

installed on the two extreme positions of travel range of azimuth and elevation axes, when

the antenna travels the extrem position and the mass touches switch, the power supply is

switched off.

3.1.2.6

Platform and Ladder

For the convenience of maintenance and ensuring safeguard, the guardrail, ladder

and platform are installed on the antenna pedestal.

17

3.1.3

Feed Structure

The feed is the core of the whole antenna and its performances directly affect the RF

performance of the antenna. So the optimized scheme and design should be performed

more carefully. The feed is composed of corrugated horn and microwave network.

3.1.3.1

Corrugated Horn

Rx and Tx singles of the antenna share the same corrugated horn. It’s required to

realize ideal radiation at the Rx and Tx bands, with rotary symmetry and low cross

polarization radiation pattern and low VSWA characteristic.

The corrugated horn consists of input taper section, mode converter section,

transition section and output flare section. The transition section may include

frequency transition section and angle transition section. If the frequency band is

narrow, there is no frequency section. The principle block diagram is shown in Fig.3.1-

12. The purpose of the mode converter section is to well convert the main mode TE

11

in

the circular waveguide into the main HE

11

in the corrugated waveguide, at the same time,

maintain good match and reject the generation of the harmful high order mode EH

12

. The

transition section is to accomplish the transition of frequency and the angle between the

mode converter section and the output flare section, at the same time, reject the

generation of the harmful high order mode EH

12

. The output flare section is to generate

the required subreflector brim illumination level. The mode converter section is the key

design. The ring-loaded slots in the mode converter section are adopted to expand the

frequency band. The structural figure of the whole horn in C-band and Ku-band is shown

in Fig. 3.1-13 and Fig. 3.1-14, respectively.

Fig. 3.1-12 Corrugated Horn Block Diagram

18

Fig. 3.1-13 Structural figure of corrugated horn in C-band

Fig. 3.1-14 Structural figure of corrugated horn in Ku-band

19

3.2 Antenna Operation principle

The C-band or Ku-band 12m Cassegrain antenna can be supplied with two ports (RX/TX) or

four ports (2TX/2RX). The operation principles are described as follows.

Antenna receiving principles:the antenna aligns satellite, the satellite signals are transmitted

via main reflector and subreflector to the feed, then output from the corresponding port of

feed and finally sent to the tracking receiver after LNAamplification.

Antenna transmitting principles: the transmitting signals are sent from HPA to the feed via

waveguide and radiated by the feed, then reflected to the free space via main reflector and

subreflector of antenna and propagated to satellite.

The antenna can simultaneously transmit and receive electromagnetic wave signals. The

step tracking mode (optional) is used to make the antenna be able to align the satellite.

4 Maintenance

As outdoor equipment, the antenna is exposed to natural environment such as wind, rain and

sun. The life of the equipment is greatly affected by correct operation and maintenance.

High-quality maintenance in time is very important to guarantee the service life of the

equipment.

To ensure the service life of the outdoor equipment, follow the requirements described below

for operation and maintenance.

4.1 Operation and Maintenance of Antenna

a) Pay attention to the local weather forecast. When strong wind higher than 32m/s is

coming, make preparations in advance so as to lock the antenna toward the sky with pin

at any time.

b) Once the subreflector has been installed and adjusted well and put into use, nobody is

allowed to go up onto the subreflector support. If it is necessary to go onto it for

maintenance, it is prohibited to step on the subreflector to prevent the installation

accuracy of the subreflector from being changed.

This manual suits for next models

2

Table of contents

Other BrasilSat Antenna manuals

Popular Antenna manuals by other brands

Andrew

Andrew APC300 Installation and user guide

Dielectric

Dielectric TFU instruction manual

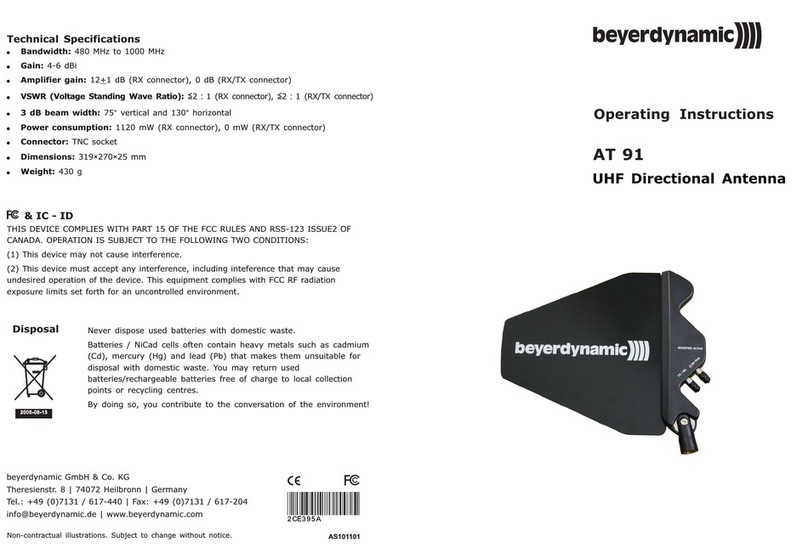

Beyerdynamic

Beyerdynamic AT91 operating instructions

Sony

Sony WD-850 operating instructions

Antares

Antares ANTARION G6+ CONNECT installation manual

CommScope

CommScope ValuLine VHLP3 Series installation instructions