Brasiltec SC1-3003 User manual

AC servo system

Brasiltec

Technical Manual

Safety notification

Indicates an error in use, it will leads to hazardous conditions and result in death or serious

injury.

Dangerous

While the motor is running, please do not touch the rotating parts.If not,it will lead to

injury.

When installed on the machine running, please put the motor may at any time in

advance the state of emergency stop. Otherwise it will lead to injuries, mechanical

damage.

Please don't touch the servo unit inside. Otherwise it will cause electric shock.

In an energized state, please make sure it install the power supply terminal block

cover. Doing so may cause an electric shock.

After the power is turned off or withstand voltage test, during running lights, do not

touch the power terminals. Otherwise they will be residual voltage caused by electric

shock.

Please follow the corresponding instructions in the user manual and product

commissioning

Servo motor installed in the machinery of the state,.if there is an error, it will not

only cause the mechanical damage, sometimes it may result in personal injury

accidents.

Except for special purposes, it is not necessary to change multi-turn limit on the

number of turns. If you accidentally changed the data,it will be dangerous.

When more inconsistent rotation laps limit alarm, please be sure to first make sure

the parameters of the servo unit is correct.

If it is under the parameter value error condition for multi-turn limit on laps, it will

set the value of the error to the encoder. Although can remove alarm,due to detect the

location of the deviation is very big, it cause mechanical moved to the location of the

unexpected, and very dangerous.

Please do not remove the main positive before the upper outer garment, cable,

connectors, and choose a class in the condition of electricity. Otherwise it will cause

electric shock.

Please do not damage or pulling on the cable, and don't make the cable to bear too

much force, under the weight or be clamped. Otherwise it will cause electric shock,

product stop running or fire.

Please don't modification to our products. Otherwise it will lead to injuries,

mechanical damage or fire.

In the mechanical side setting, please stop device to ensure safety.

The servo motor with brake holding brake is not the stop device for ensuring safety.

Otherwise it will cause injury.

If the momentary power failure occurs during operation, then power is restored, and

machinery may suddenly Power off and restart, so do not close to the machinery.

Please take measures to ensure re-start without endangering personal safety.

Otherwise it will cause injury.

Please make sure it will connects the grounding and grounding of the servo unit.

Otherwise it will cause electric shock or fire.

Do not set, remove or repair by unauthorized persons. Otherwise it will cause

electric shock or injury.

when you designed the use of security functions(Hardware base block function)in

the system, it must worked by the related safety standards of technical personnel in

understanding the contents of this manual before operation. Otherwise it will lead to

injuries, damage to the machine.

Do not care, set up in the following conditions. Otherwise it will cause fire, electric

shock or do damage to the machine.

The place of direct sunlight

when we use it, the environment temperature must higher than the place of custody

and set the temperature condition.

Relative humidity higher than the place of the custody and set humidity condition.

The place of large temperature difference and condensation.

Corrosive gas and combustible gas.

The place where has more dust, dirt, salt and metal powder

The place where is easy to splash water, oil and medicine, etc

The place where the vibration or shock may spread to the main sites.

vibration or shock may spread to the main sites.

Do not hold the cable, the motor shaft or see the early handling. Otherwise it will

cause injury or malfunction.

Please do not put too much products together,(please according to the instructions.

)Otherwise it will cause injury or malfunction.

Need to deal with the packing of wooden materials (including wood, plywood,

shelves), insecticidal processing, please make sure the method of fumigation outside.

Example: heat treatment (material core temperature in 56 ℃ above, the processing

time in more than 30 minutes) in addition, the processing, please before packaging

for packing materials for processing, rather than after packing to deal with the whole.

Use after fumigation treatment of wood packaging electrical products (monomer or

installed on the mechanical product), the packaging materials produced by the gas

and steam may cause fatal damage of electronic products. Especially halogen

disinfectant (fluorine, chlorine, bromine, iodine, etc.) will cause corrosion to the

capacitor inside.

Installation Note

Do not be splashed with water or place in an environment prone to corrosion and

flammable gases and combustible materials in the vicinity of using this product.

Doing so may cause an electric shock or fire.

Do not sit on the product or put heavy objects on it. Otherwise it will cause injury or

malfunction.

Do not block the air inlet and exhaust ports. Do not make the foreign body into the

inside of the product. Otherwise, it will due to aging of the internal components and

cause a malfunction or fire.

Must follow the requirements of the installation directions. Otherwise it will lead to

failure.

When installing ,without the servo unit and control cabinet surface or the other with

a predetermined gap between machinery. It will cause fire or malfunction.

Please do not apply too. Otherwise it will cause failure.

wiring precautions

Please correct and reliable wiring. Otherwise it will cause the motor control,

personal injury, or malfunction.

Please don't connect the servo unit in the servo motor and terminals U, V, W with the

commercial power supply source.

Otherwise it will cause injury or fire.

Please firmly connected the power supply terminal with the motor terminals.

Otherwise it will cause a fire.

Do not make the main circuit cables and input and output signal cables / encoder

cables use the same tube, do not put their banding together. When wiring the main

circuit cable input and output signal cables should leave 30 cm or more.

Please use the signal cable to input and output ,and the encoder cables use

twisted-pair wire or suspicious double strand angle and the overall shield.

Input and output signal wiring cable length: maximum of 3 m.Encoder cable:

maximum of 20 m.

Even if power is turned off, servo unit internal may still remain high

voltage.Therefore, during the period of operation instructions (RUN) lights, do not

touch the power supply terminals

Please confirm operation instructions (RUN) in the lamp out, such as further

connection and check the homework

For main circuit wiring terminal row, please observe the following precautions.

When main circuit terminals is the switch, please remove servo unit from the subject

,then wiring

Please within the terminal row of a wire connector socket insert 1 wire. When

inserted into the wire, please do not make the core of burr and the adjacent wire short

circuit.

Please use the specified power supply voltage. Otherwise it will cause fire or failure.

In the case of a bad power supply, when using it, please ensure that the specified

input voltage change within the scope of supply power. Otherwise it will cause

damage to the machine

Please set the circuit breaker and other safety devices to prevent external wiring

short circuit. Otherwise it will cause a fire.

When used in the following places, please take the appropriate measures.

When electrostatic cause the interference

The place where produce a strong electric field or magnetic field.

There may be have the place where have the radiation.

The place where has power cord nearby.

Otherwise it will cause damage to the machine.

When you connect the battery, please pay attention to the polarity. Otherwise cause

the battery, servo unit and servo motor damage and explosion.

Please wiring or check the homework by professional and technical personnel

5

Chapter 1 Product Inspection and Model

Description

1.1 Inspection

In order to prevent missing parts during packaging and transportation, please check

the carefully:

Is it the model you purchased: it can be found on the side of the drive body.

Check if the appearance of the product is normal: if there is a strong impact or

damage of the appearance.

Whether the motor is working normal: the shaft can be smoothly rotated by hand

means it’s normal. However, motors with electromagnetic brakes cannot be rotated

by hand.

Is the screw loose or lost, If it is, please tighten it.

A fully operational servo components shall include:

Servo driver

Servo motor

UVW power line

Encoder line

Input and output signal lines (optional)

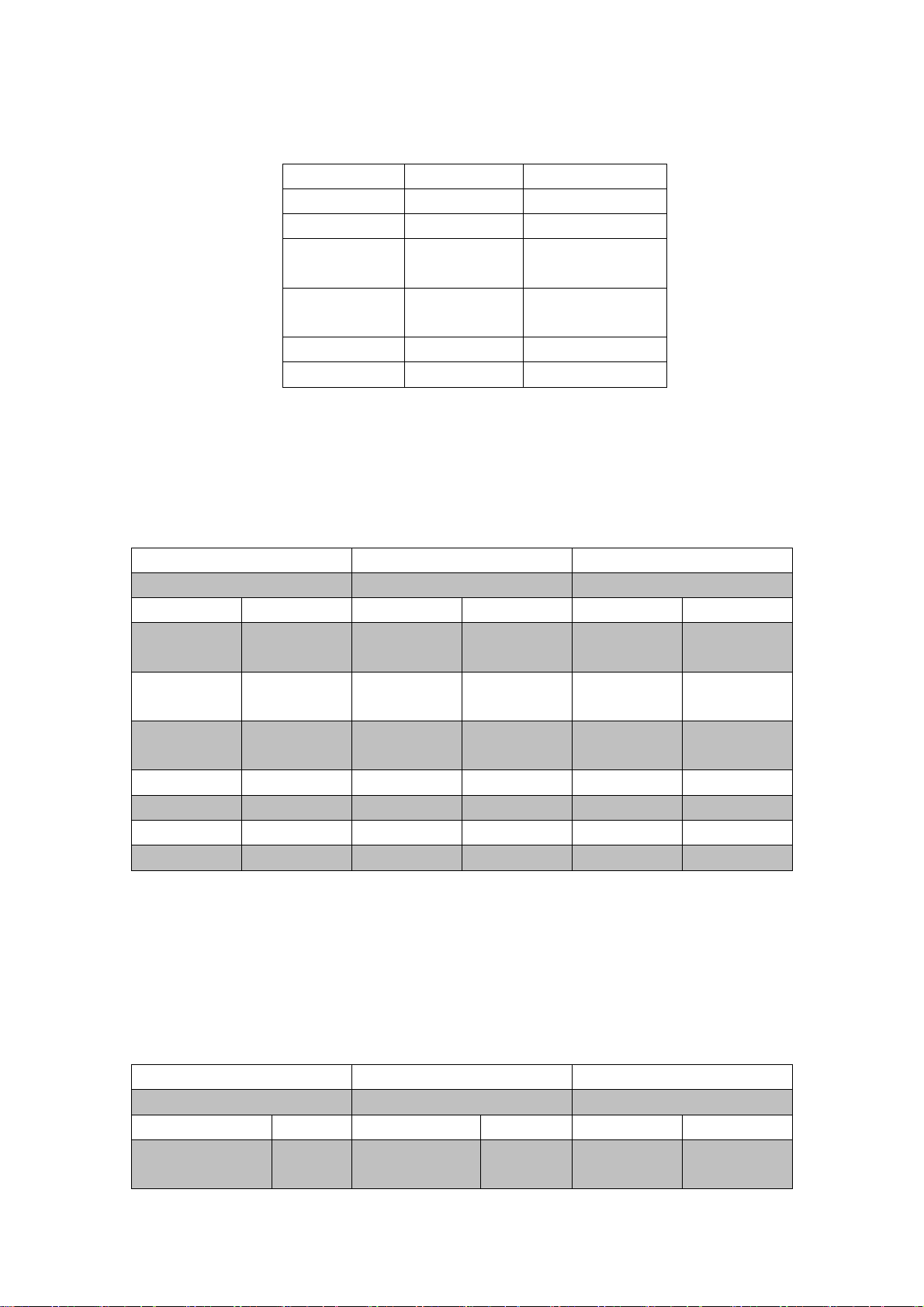

1.2 Driver and motor model reference

Server driver

model

Driver

specification

(output

voltage /

current)

Matched motor specification

Motor

flange(mm)

Maximum

rated power

(kW)

Maximum

rated torque

(Nm)

Maximum

rated speed

(rev/min)

SC1-3003

220V/2.8A

60

0.4

1.27

3000

SC1-3010

220V/3A

80

0.75

2.39

3000

SC1-3011

220V/4.4A

80

1.0

4

2500

6

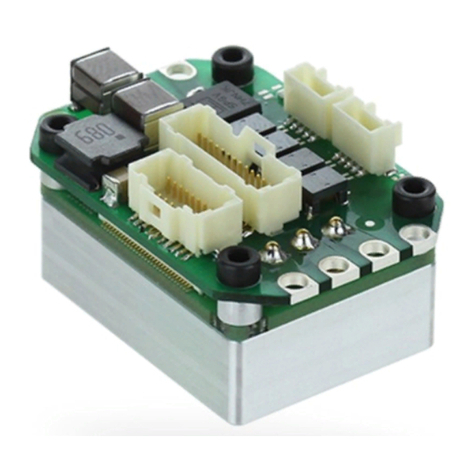

1.3 Driver appearance

Chapter 2 Installation

2.1 Notice

Please pay special attention to the following:

1) The connection between the driver and the motor cannot be tightened;

2) When fixing the driver, it must be locked at each fixed position;

3) The motor shaft must be in good alignment with the shaft of the equipment;

4) If the drive and motor are connected more than 20 meters, please thicken the UVW cable and

the encoder cable;

5) The four screws of the motor must be locked.

2.2 Storage condition

This product must be placed in its packaging before installation. If not use now,please pay

attention to the following instruction of storage:

1) Must be placed in a dust-free and dry place.

2) The temperature of storage must be in the range of -20 degree to +65 degree.

Power Indicator

Servo ON indicator

Cooling base, High temperature

during work,don’t touch

220V/50/60Hz

L1 L2 when single phase

L1 L2 L3 when three phase

Motor UVW

Regenerative resistor

Protective grounding

5-digit LED display

Key input

Communication port

Signal terminal of input

and output

Encoder terminal

7

3) The relative humidity of the storage location must be in the range of 0% to 90% without

condensation.

4) Avoid storage in environments containing corrosive gases and liquids.

5) It is best to store it properly on a shelf or countertop.

2.3 Installation environmental conditions

The using temperature range of our driver is 0 degree to 55 degree.If the temperature exceeds 45

degree, please place it in a well-ventilated place. Long-term operation is recommended at an the

temperature below 45 degree to ensure product reliability. If it’s installed in a power distribution

box,please assure that all internal electronic devices are not at risk of overheating. Also, please pay

attation to the vibration of machine. In addition to this, the conditions used include:

1) no high heat device around;

2) free of water droplets, vapors, dust and oily dust;

3) non-corrosive, flammable gases and liquids;

4) non-floating dust and metal particles;

5) Strong and vibration-free places;

6) without electromagnetic noise interference.

2.4 Installation direction and space

Please install the driver correctly according to the following picture, so as not to cause

unnecessary loss!

Right installation

Wrong installation

8

Please install in strict accordance with the specified installation spacing to ensure good ventilation

and heat dissipation.

Chapter 3 Wiring

3.1 Servo system schematic

>100mm

>100mm

Input and output terminals are

connected to PLC and analog

and pulse input

再生

电阻

地

Voltage

>50mm

>50mm

>50mm

9

3.2 Driver terminal and connection instructions

Terminal symbol

Name

Fuction

L1 L2 L3

R S T

Power terminal

Three/single phase 220V to 240V 50/60Hz. (If

single phase connect L1 & L2)

U V W

Motor power line

terminal

Connect with motor

P+ D C

Regenerative

braking resistor

Terminals

Connected to the regenerative resistor, the external

resistor is connected between P+ and C

Ground terminal

Connect to the power ground wire, ground

protection

CN1

Input and output

terminal

Input and output signal DI/DO wiring

CN2

Encoder terminal

Encoder terminal connected to motor encoder

COM1

Communication

port

Communicate with the host computer to support

485, RS232 communication

3.3 Braking resistor

Function : Discharge, to ensure the stability of the DC bus voltage. In servo motor control, the

back EMF generated by the motor is feed back to the bus capacitor, causing the bus voltage to rise.

When the voltage reaches the alarm limit (P0-14), the servo output alarm EN-03

Therefore, to ensure that the bus voltage does not exceed the voltage limit of device, the system

will conduct the discharge terminal when the voltage rises to the limit, and quickly balance the bus

voltage through the brake resistor.

Model selection:

Wiring terminals:

Servo series

Terminal

A/B/C series

P+ and C

E series

P+ and PB

Braking resistor model selection

Model

Output

current

Resistance

range

Power range

Recommended resistance value

CZ-A

13A

50~100Ω

》=100W

50Ω

CZ-B

30A

50~100Ω

》=200W

50Ω

CZ-C

40A

40~50Ω

》=500W

40Ω

CZ-E

50A

25~35Ω

》=1000W

35Ω

CZ-E

75A

20~35Ω

》=2000W

35Ω

Notice: For 220V servo, discharge voltage is 370V;and 380V discharge voltage is 700V; The

discharge current can not exceed 80% of maximum output current when resistance value is

selected; more power can be selected when starting and stopping frequently

10

3.4 Brake wiring

In a vertical mechanism, when power off or the servo is enable OFF, the workpiece will fall due to

gravity.So we need to use the servo motor with brake to avoid it’s slide down

Parameter setting:P5-24 set 0084;P5-26 set 0000;then power off the driver and restart.If the

workpiece is slightly down when enable OFF, increase P5-06 around 100ms or decrease the value

of P5-08, and fine tune according to the situation; when the speed is lower than the setting value

of P5-07, the brake is on.

3.5 CN1 input and output signal line and terminal description

3.3.1 CN1 connector terminal arrangement is as follows (face to solder tab):

Pin

Name

Signal

Pin

Name

Signal

Pin

Name

Signal

P

in

Name

Signal

1

SO1

Output1

2

6

SI-COM

Input Public

side 24V

2

SO1-CO

M

Output

10V

3

SO2

Output2

27

SI-COM

Input

Public

side 24V

2

8

SI1

Input

1

4

SO2-CO

M

Output

20V

5

SO3

Output3

29

SI2

Input 2

3

0

SI3

Input

3

6

SO3-CO

M

Output

30V

7

SO4

Output4

31

SI4

Input 4

3

2

SI5

Input

5

8

SO4-CO

Output

9

SO4

Output4

33

SI6

Input 6

3

SI7

Input

24

25

2

49

1

27

50

26

11

3.3.2 Input and output signal wiring

The input and output signals of the servo unit and its connection to the host device:

(1) Analog input circuit

Application mode: Speed control (analog voltage) P0-01: parameter setting 4

Torque Control (Analog Voltage) P0-01: Parameter setting 2

Circuit parameters: Input impedance RI = 13KΩ

Input voltage Vmax<=10V

(2) Pulse input circuit

M

40V

4

7

10

SO4-CO

M

Output

40V

11

35

AGND

Input

negative

of analog

3

6

AGND

Input negative

of analog

12

13

37

V-REF

Speed

analog

3

8

T-REF

Torque

analog

14

15

PULS-

Pulse

Input

39

-10V

Output

4

0

+10V

Output

16

17

PULS +5V

Pulse 5V

41

485 A

Bus

communic

ation

4

2

485 B

Bus line

Communicatio

n

18

19

PULS

+24V

Pulse24

V

43

4

4

20

21

DIR-

Direction

45

B+

Encoder

feedback

4

6

B-

Encoder

feedback

22

ZOC-

Z pulse

Negative

electrode

23

DIR +5V

Direction

5V

47

A+

Encoder

feedback

4

8

A-

Encoder

feedback

24

ZOC+

Z pulse

negative

electrode

25

DIR +24V

Direction

24V

49

Z+

Encoder

feedback

5

0

Z-

Encoder

feedback

Host device

Analog input circuit

Servo driver

+10V

-10V

T-REF Torque analog input

V-REF Speed analog input

AGND

12

Application mode: Position control (external pulse) P0-01 Parameter setting 6

Speed Control (External Pulse) P0-01 Parameter setting 7

(3) Input and output signal circuit

Optocoupler output circuit

Host device

Servo driver

Host device side

Pulse command input wiring

Servo driver

PULS

PULS+24V

DIR+24V

DIR

3.3K

3.3K

+24V

0V

Y0

COM0

Y1

COM1

Collector open drain input

SI-COM

SI

3.3K

+24V

0V

Y0

COM

Host device side

Servo driver

13

3.6 CN2 encoder wiring and terminal description

CN2 connector terminal arrangement is as follows (face to solder tab):

3.7 Communication port

COM connector terminal arrangement is as follows(face to solder tab):

Driver

interface

Name

Driver

interface

Name

Driver

interface

Name

Driver

interface

Name

1

A+

2

A-

11

U+

12

U-

3

B+

4

B-

13

V+

14

V-

5

Z+

6

Z-

15

W+

16

W-

7

5V

8

5V

17

GND

18

GND

9

5V

10

5V

19

GND

20

GND

9

10

20

1

12

11

2

19

Relay input

+24V

0V

Y0

3.3K

COM

SI

SI-COM

Host device side

Servo driver

14

3.8 MODBUS Protocol

1. Servo single register value setting:

Sending

Servo correct feedback

Servo error feedback

Hexadecimal

Hexadecimal

Hexadecimal

Station No.

01

Station No.

01

Station No.

01

Function

code

06

Function

code

06

Function

code|0x80

86

Starting

address H

00

Starting

address H

00

Error code

**

Starting

address L

01

Starting

address L

01

CRCH

**

Set value H

00

Set value H

00

CRCL

**

Set value L

05

Set value L

05

CRCH

**

CRCH

**

CRCL

**

CRCL

**

Eg:Set P0-01 data Use the default parameters of the servo the station number is 1

sending data:01 06 00 01 00 05 CRCH CRCL

Reading correct feedback data:01 06 00 01 00 05 CRCH CRCL

Reading error feedback data:01 86 ** CRCH CRCL //** error code

2. Continuously setting servo multiple register values:

Sending

Servo correct feedback

Servo error feedback

Hexadecimal

Hexadecimal

Hexadecimal

Station No.

01

Station No.

01

Station No.

01

Function code

10

Function code

06

Function

code|0x80

86

Pin

Name

Instruction

1

A

RS485-A

3

B

RS485-B

4

RXD

RS232 receiving

terminal

5

TXD

RS232 sending

terminal

8

GND

RS232 ground

2

GND

Downloader

15

Starting address

H

00

Starting

address H

00

Error code

**

Starting address

L

01

Starting

address L

01

CRCH

**

Number of

registers H

00

Number of

registers H

00

CRCL

**

Number of

registers L

05

Number of

registers L

05

Number of bytes

02

CRCH

**

Register value H

**

CRCL

**

Register value L

Register value H

Register value L

CRCH

CRCL

Eg:Continuous setting 2 data values Set P0-01 to 5 Set P0-02 to 6 Station number is 1

sending data:01 10 00 01 00 02 00 05 00 06 CRCH CRCL

Reading correct feedback data:01 10 00 01 00 02 CRCH CRCL //** **data

Reading error feedback data:01 90** CRCH CRCL //** error code

3.Read Servo Register Value:

Sending

Servo correct feedback

Servo error feedback

Hexadecimal

Hexadecimal

Hexadecimal

Station No.

01

Station No.

01

Station No.

01

Function

code

03

Function

code

03

Function

code|0x80

83

Starting

address H

00

Data length

02

Error code

**

Starting

address L

01

Data 1H

**

CRCH

**

Reading

quantity H

00

Data 1L

**

CRCL

**

Reading

quantity L

01

Data 2H

CRCH

**

Data 2L

CRCL

**

…

…

…

CRCH

**

16

CRCL

**

Eg:Reading P0-01 data Use the default parameters of the servo the station number is 1

sending data:01 03 00 01 00 01 CRCH CRCL

Reading correct feedback data:01 03 02 ** ** CRCH CRCL //** **data

Reading error feedback data:01 83 ** CRCH CRCL //** error code

Chapter 4 Panel Display and Operation

4.1 Panel introduction

Name

Function

STA/ESC

State switching, return

INC

Increase display data value,continous increase for

long press

DEC

Reduce display data value,continous reduce for long

press

ENT

Confirmation key, enter to setting parameters, view

parameters

SHIFT

shift

COM

Custom key

Power indicator

POWER

It’s ligh up when power on

Running indication light

RUN

Light up while the servo is running(S-ON Signal is

valid)

运行

RUN

E

D

电源

POWER

C

A

B

STA

ESC

COM

ENTER

SHIFT

INC

DEC

17

4.2 basic state switching

After pressing the STA/ESC key, the states can be switched as the upper figure showed

Parameter setting P0-00

Monitoring status Un-00

Alarm status En-XX

Accessibility Help

a.System Information View F0

b.Torque / speed command offset adjustment F1

Select F1-00 into the analog offset automatic adjustment feature , this time status display : F--, and - blink ,

about 5 seconds or so current detection offset automatic adjustment is completed, then display :F-F, inform the user

automatically adjusting complete.

Select F1-01 to enter the torque control analog offset automatic adjustment function (same operation)

c.F2 alarm View

d.Serial External Communications F3

Select F3-00 into the external serial communication mode , prompting COE, which is in an external monitor

status , serial port 1 (COM1) effective monitoring panel failure , this time, through the host computer (PC) of the

servo unit for tuning. Press the STA / ESC to return , and exit the COE, restore panel monitor .

e.Restore factory defaults F4

A

speed control:Synchronous speed detection

Position control: end of positioning

B

Speed control: torque limit

Position control: approaching

C

Speed control: rotation detection

Position control: rotation detection

D

Speed control: zero clamp

E

Speed control: speed limit

Running display

status

Parameter setting

status

Monitor display

status

Auxiliary Function

18

In bb condition,select F4-00 to enter the factory default settings , suggesting rEt--, stay in a wait state ,

press Ent settings, wait for showing rEt-E, then power off and power on,now finish restore the factory defaults.

f. J-OG mode

In bb condition,choose F5-00,press shift to 0 blink,press Ent into show J-OG,press INC to show P motor

running,press DEC to show N motor reverse running,short press motor jog,long press motor continuous

running,jog speed setting:P3-04.

g. Panel give enable signal S-ON,F6-00

In bb condition,short press STA,show F0-00,press INC,show F6-00,press shift to 0 blink,press Ent to show

E-,press shift again, E-n driver enable,get in and press DEC to cancel enable;can used for correct current,set P0-00

to 2,P0-01,give enable signal about 10 seconds,compelet the current examine;different from F1-00 analog current

check,here correct the UVW control current calibration

h. Program download

Long press ESC before power on,then power on and shows P000,now can use the series to download

program(COM port 2pin short-circuited with 8pin)

4.3 Parameter setting

Here’s the example of change the parameter of P2-09 from 2000 to 1000.

1. Press the STATUS/ESC key to enter the parameter setting state,then press the ENTER

key.

2.At this time, the second LED from left flashes, press INC or DEC key to modify the group

number , change it to 3, then short press ENTER to confirm .

3.At this time, the right number two digital tube flashes, press INC, DEC or ENTER key to

select the number 9 , long press the ENTER key for confirm.

4.Now, display the data in P2-09 , the lowest position "0 " flashes , then short press the ENTER key

allows the blinking one move one bit to the left. Press INC , DEC or ENTER key , the data is

changed to 1000 , long press ENTER to confirm the modification.

Thus, the user parameter P3-09 changes 2000 to 1000. Need to further change the value , repeat

the above operations of 2 to 4 .

5.Press the STATUS / ESC key to return to the other group or state you want to do modify

19

4.4 Brief description of code display

code

Display content

In standby mode

Servo OFF status (The motor is powered off)

Running

Servo enable(The motor is powered on)

Prohibition of forward rotation

P-OT OFF status. Please refer to "Overtravel Setting".

Prohibition of reverse rotation

N-OT OFF status. Please refer to "Overtravel setting"

4.5 Restore factory setting

Restore all user parameters to factory settings, including P0-11 motor code

Please confirm the parameters before reseting, or it will not be able to recover.

When need to restore the factory settings?

Alarm EN-02, parameter damage

An abnormal operation caused by setting parameters during debugging

There is a command send to motor,but it does not run, no alarm, check if P3-09

value is 0, if it is, then restore the factory setting.

Steps:

1. Turn off the enable signal first.(External enable: Please disconnect the external signal;

Internal power-on enable: set P0-01 to n.0101 and then power off and restart)

2. Enter F4-00

(Refer to e in section 4.2)

3. Check the motor parameters (take the drive SC1-3010/AMS80-02430Z as an

example)

a) Check motor code power code F0-00 :display 750 means 750W

b) Check motor model code F0-24: shows 02430 indicates 2.4N·M, 3000 rpm

c) Check input voltage level and flange F0-25:display 2080 indicates 220V, 80

flange

If the alarm is EN-02, also need current check, please refer to section 4.6

20

4.6 Current check

Function: Eliminate motor control instability or abnormal noise caused by inaccurate current

sampling,whcih caused by hardware drift

Method:

Turn off the enable signal first.

(External enable: Please disconnect the external signal; Internal power-on enable: set

P0-01 to n.0101 and then power off and restart)

Setting parameters

(Setting P0-00 to 2; P0-01 to 0)

Enter F6-00 to set the enable signal

(In the bb state, press the STA button shortly, when F0-00 appears, press INC, then

F6-00 appears, press shift to 0 to flash, press Ent to display E-, then press shift again

to display E-n drive enable; Wait 10 seconds to complete the verification, press DEC

to cancel the enable)

Chapter 5 Trial and tunning steps

5.1 No-load detection

To avoid damage the servo driver or mechanism, first remove the load connected to the servo

motor (including the coupler and other accessories).Then doing testing according to normal

operating procedures.After testing is OK,can connect with load.

Test items:

Pre-boot detection

(cut off the power supply)

Ensure that the servo driver and motor have no mechanical

damage

Ensure that the terminal wiring is secure and there is no danger

of electric shock

Ensure that the wiring is complete and correct

Ensure that the external input signal meets the standard

Guarantee no other errors or dangers

Running time detection

(power on)

Ensure that the wires are not pulled or abrasion during operation

Does the motor have strong shake or abnormal sound?

Does the indicator light normal?

Is there any alarm display? If there is an alarm, please first find

the alarm code in the alarm parameter table, and then clear the

alarm after eliminating the alarm factor.

When modifying parameters, please confirm the parameter

modification and effective time.

Check if the device execute according to preset modes and

parameters

This manual suits for next models

2

Table of contents