Safety Information

Read carefully this chapter to raise your awareness of potential risks and hazards when working with the

Neptune Servo Drive.

To ensure maximum safety in operating the Neptune Servo Drive, it is essential to follow the procedures

included in this guide. This information is provided to protect users and their working area when using the

Neptune Servo Drive, as well as other hardware that may be connected to it. Please read this chapter

carefully before starting the installation process.

Warnings

The following statements should be considered to avoid serious injury to those individuals performing the

procedures and/or damage to the equipment:

To prevent the formation of electric arcs, as well as dangers to personnel and electrical contacts,

never connect/disconnect the Neptune Servo Drive while the power supply is on.

Disconnect the Neptune Servo Drive from all power sources before proceeding with any possible

wiring change.

After turning off the power and disconnecting the equipment power source, wait at least 10

seconds before touching any parts of the controller that are electrically charged or hot.

Precautions

The following statements should be considered to avoid serious injury to those individuals performing the

procedures and/or damage to the equipment:

The Neptune Servo Drive components temperature may exceed 100 ºC during operation.

Some components become electrically charged during and after operation.

The power supply connected to this controller should comply with the parameters specified in this

document.

When connecting the Neptune Servo Drive to an approved power source, do so through a line that

is separate from any possible dangerous voltages, using the necessary insulation in accordance with

safety standards.

High-performance motion control equipment can move rapidly with very high forces. Unexpected

motion may occur especially during product commissioning. Keep clear of any operational

machinery and never touch them while they are working.

Do not make any connections to any internal circuitry. Only connections to designated connectors

are allowed.

All service and maintenance must be performed by qualified personnel.

Before turning on the Neptune Servo Drive, check that all safety precautions have been followed, as

well as the installation procedures.

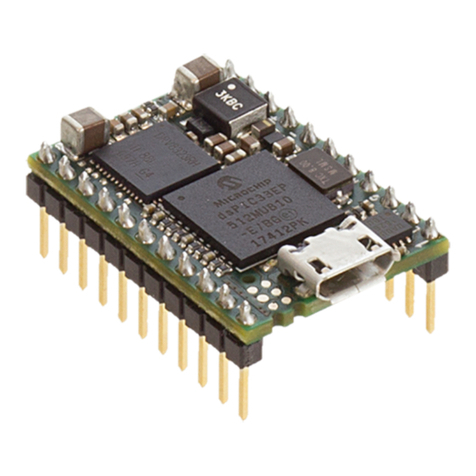

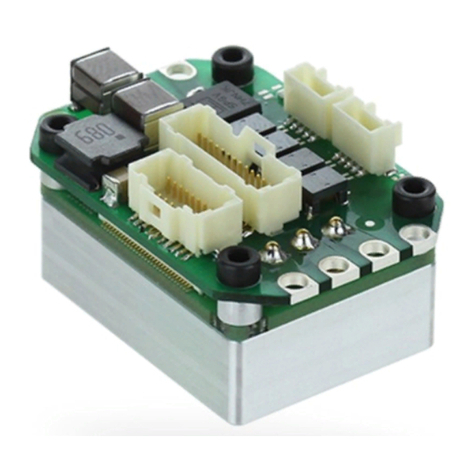

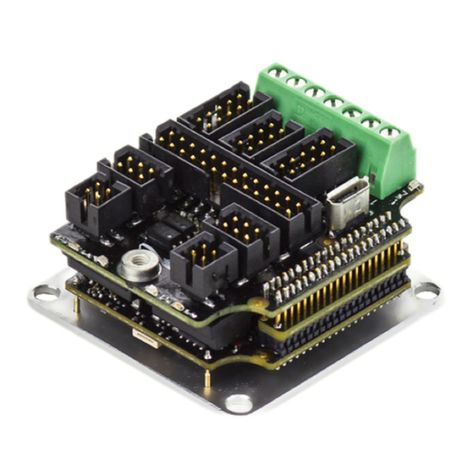

Product Description