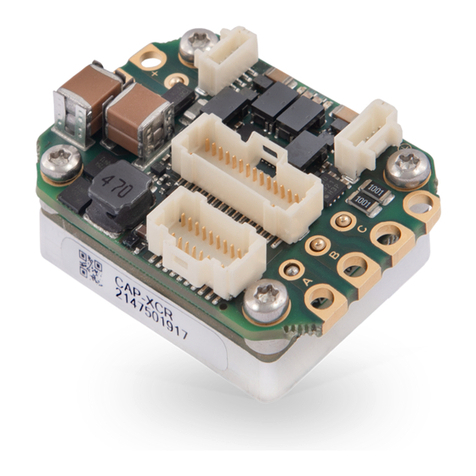

Everest XCR - Product Manual|Product Description

4. Product Description

PRELIMINARY

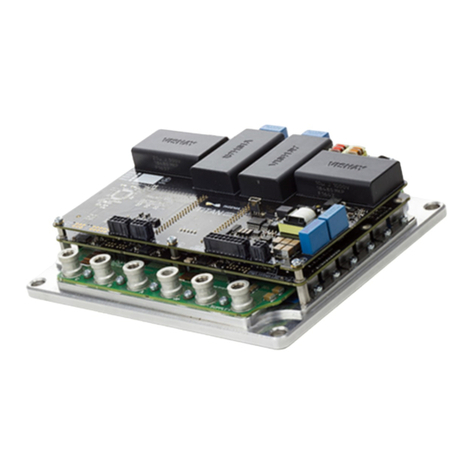

Everest XCR is a compact, smart digital servo drive. Thanks to its small size and rugged design it can be mounted

virtually anywhere: collaborative robot joints, wearable robots, unmanned ground or aerial vehicles as well as

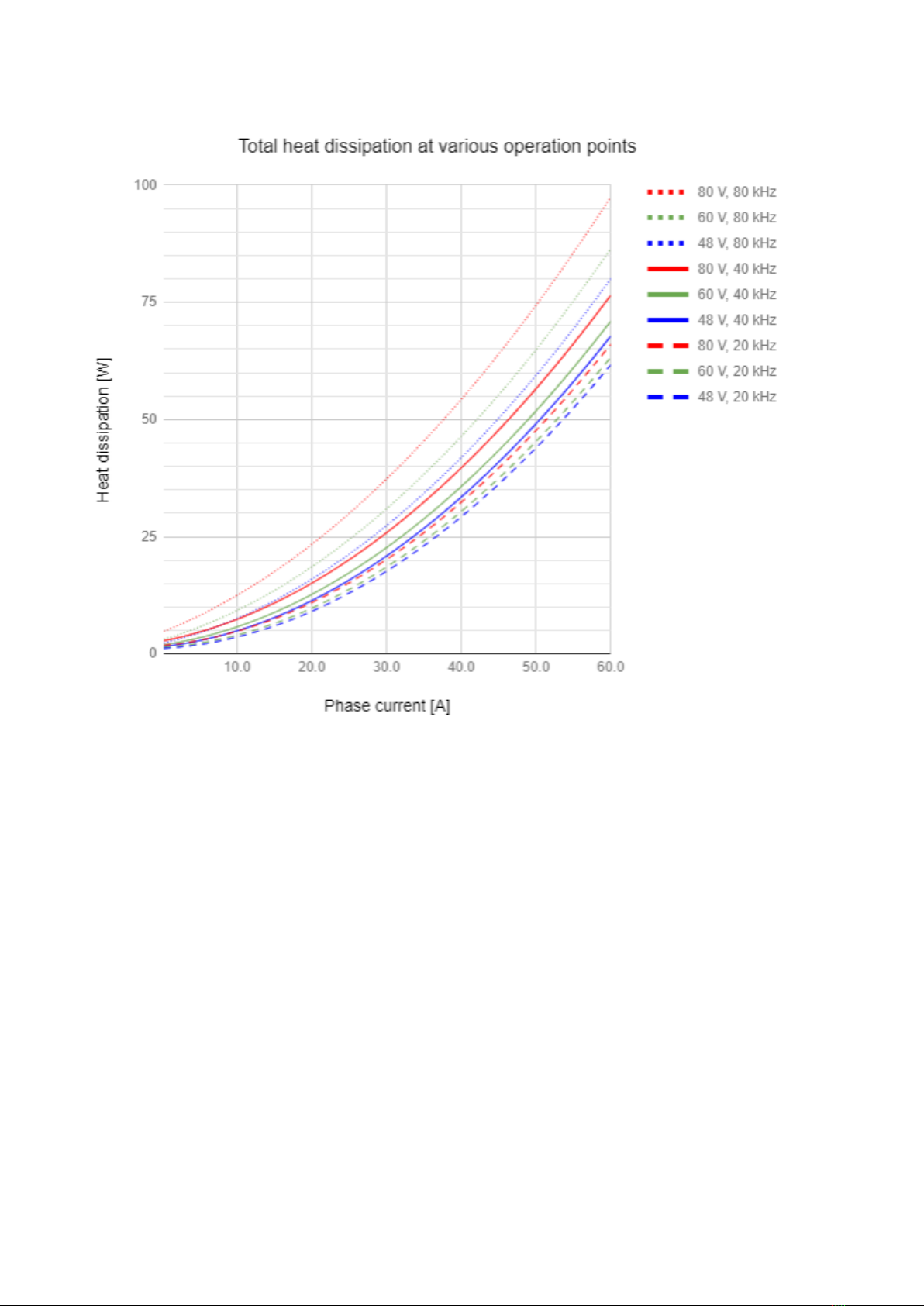

inside motors. The drive features best in class energy efficiency thanks to the latest GAN technology. At 30 ARMS (42

A amplitude) 80 VDC it generates just 20 W of total heat dissipation exceeding by far any comparable servo drive.

The standby power losses of Everest XCR are minimal, even using EtherCAT, the consumption is less than 2.5 W.

Everest will save energy on your project and provide longer battery times.

The control loops have sampling times that exceed the electrical and mechanical time constants of almost any

motor.Up to 14 µs(75 kHz)current loop and 40 µs(25 kHz) position and velocity loops.The bandwidth of the

control system will only be limited by the physical limits of the system and the feedback. Configurable digital filters

offer extra flexibility. In addition, control algorithms can be programmed and executed real time on the drive.

Power stage PWM frequency can be adapted to each application, with a minimum 10 kHz for low electrical noise

and power losses and a maximum of 100 kHz for low inductance motors. Current gain can also be configured on 4

different ranges allowing the same drive and part number to used for various motor sizes and thus simplifying

stocking and complexity in your application.

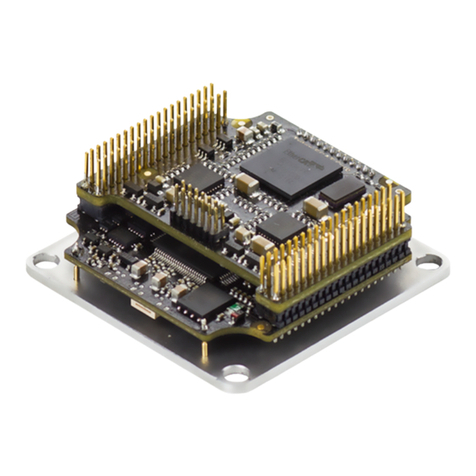

The Everest XCR can close loops with a Digital Incremental Encoder, Dual BiSS-Cencoder and Digital

Halls.Everything can be easily configured with the new INGENIA MotionLab 3.

Everest XCR include compliant EtherCAT & CANopen communication. The drive can be accessed from a standard

EtherNET port for configuration.

The Everest XCR can be operated with a single power supply on its full operating range and includes an additional

logic supply up to 50 V. It includes 4 digital inputs and 4 digital outputs, a dedicated brake output, motor

temperature sensing input and a 16 bit ±10 V analog input to interface with load cells and torque meters.

The driver has built-in safety torque off (STO) and includes several safety protections to protect against most issues

like short-circuits, temperature and voltage based current foldback, overtemperature, overvoltage, and has

industry grade EMC and ESD inmunity.

PRELIMINARY

4.1. Everest XCR part numbering

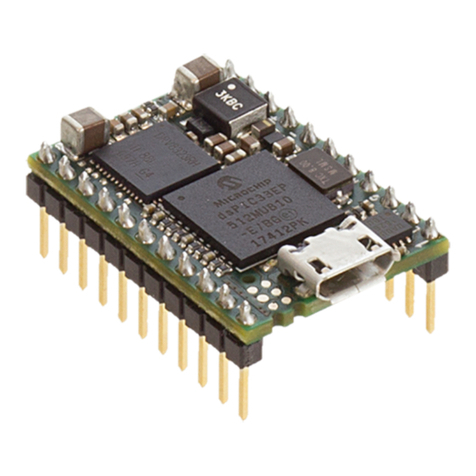

Everest XCR is available on a single part number. Rated at 30 ARMS continuous current and an operation voltage

between 8 VDC to 85 VDC. Variable gain current sense amplifier and 16 bit ADC allow controlling low current motors.