Breeze AWC Series User manual

We bring better air to life

2020

USER’S MANUAL

PLATE MOUNTED WALL FAN

Thank you for choosing full metal plate mounted wall fan. Please

read and save this user's manual for future reference. Read carefully

before attempting to assemble, install, operate or maintain the

product described. Protect yourself and others by observing all safety

information. Failure to comply with instructions could result in

personal injury and property damage.

AWS 250-4E/D

AWS 315-4E/D | AWS 355-4E/D

AWS 400-4E/D | AWS 450-4E/D

AWS 500-4E/D | AWS 560-4E/D

AWS 630-4E/D | AWS 630-6E/D

AWC Series

01

www.breeze.com.vn | [email protected]

We bring better air to life

USER’S MANUAL

AWS SERIES

ŸPlease read the user’s manual carefully prior to installing and operating the unit.

ŸThis user’s manual is the primary operating document intended for technical, maintenance and operations staff.

ŸAll user’s manual requirements as well as the provisions of all the applicable local and national construction, electrical and

technical norms and standards must be observed when installing and operating the unit.

ŸThe warnings contained in the user’s manual must be considered most seriously since they contain vital personal safety

information.

ŸFailure to follow the rules and safety precautions noted in this user’s manual may result in an injury or unit damage.

After a careful reading of the manual, keep it for the entire service life of the unit.

ŸWhile transferring the unit control, the user’s manual must be turned over to the receiving operator.

Disconnect the unit from power mains prior to any

installation operations.

While installing the unit, follow the safety

regulations specific to the use of electric tools.

Do not lay the power cable of the unit in close

proximity to heating equipment.

Do not change the power cable length at your

own discretion. Do not bend the power cable.

Avoid damaging the power cable. Do not put any

foreign objects on the power cable.

Do not use damaged equipment or cables when

connecting the unit to power mains.

Do not operate the unit outside the temperature

range stated in the user’s manual. Do not operate

the unit in aggressive or explosive environments.

Do not touch the unit controls with wet hands.

Do not carry out the installation and maintenance

operations with wet hands.

Do not wash the unit with water. Protect the

electric parts of the unit against ingress of water.

Disconnect the unit from power mains prior to any

technical maintenance.

Do not store any explosive or highly flammable

substances in close proximity to the unit.

When the unit generates unusual sounds, odour

or emits smoke, disconnect it from power supply

and contact the Seller.

Do not direct the air flow produced by the unit

towards open flame or ignition sources.

Do not block the air duct when the unit is

switched on.

In case of continuous operation of the unit,

periodically check the security of mounting.

The product must be disposed separately at the end of its service life. Do not dispose the unit

as unsorted municipal waste.

Do not allow children to operate the unit.

The unit must be grounded!

Do not open the unit during operation.

Unpack the unit with care.

Multiple bend

Pipe diameter shrinks

at connecting part

< 0.8m

Adapter

Duct

Outlet closed to crook

UNIT INSTALLATION AND OPERATION SAFETY PRECAUTIONS

ŸBefore installing this product, ensure that the

voltage and frequency consistent with the

product nameplate.

ŸWhen connected to power supply, all-pole

power switch with more than 3mm contact

separation is necessary to be installed on the

power supply circuit. Please do the connection

according to the local electrical equipment

technical regulations.

ŸPlease set up vent and spot inspection.

ŸInstallation height should be more than 2.3m.

ŸShould be firmly installed. Gradient installation

forbidden.

ŸDo not disassemble the junction box by

yourself, if the power cord is damaged, it

should repair by qualified serviceman

ŸInstallation on window or outdoor is forbidden.

ŸPlaces with overmuch lampblack or steam

forbidden.

ŸBelow connection way of air duct is forbidden.

1. GENERAL SAFETY INFORMATION

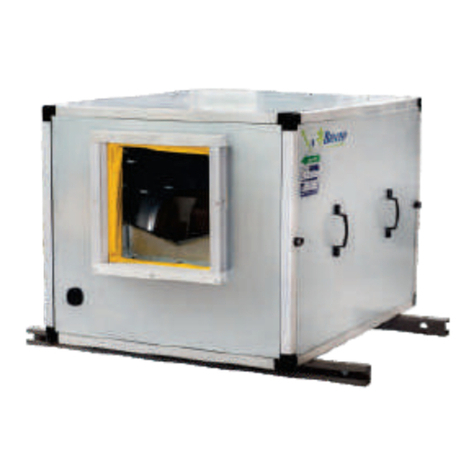

The AWS series are plate mounted wall fan with inlet bellmouth. The AWS series offered reliable performance in commercial and

industrial exhaust air applications suitable for wall installation providing good air flow performance against medium level pressures.

Range sizes are fitted 250mm to 630mm diameter.

AWS series are offered with AC Voltage:

Ÿ E: Single-phase with 220V-240V/50Hz.

Ÿ D: Three-phase with 380V-415V/50Hz.

Material:

Ÿ Casing: Plate steel with power-coated and anti- corrosion protection.

Ÿ Impeller: Steel with power-coated and high efficiency sickle axial impeller driven by external rotor motor

Ÿ Motor: 100% copper coil and fitted with high quality ball bearing, high efficiency, low noise, maintenance free and long service

life. Equipped with thermal overload protection.

Ÿ Standard motor range is protected to IP 54, class F insulation.

Application:

Ÿ Factory and warehouses, restaurants, gymnasiums, meeting rooms, workshops, swimming pools, green houses, public toilet

and stores, etc.

Construction.

The full metal plate mounted wall fan consists of the following main parts:

2. PRODUCTS OVERVIEW

02

Full metal plate mounted wall fan with standard motor are suitable for ventilation of:

• Clean air

• Slightly dusty and greasy air

• Slightly aggressive gases and vapour

• Mediums up to an atmospheric density of 1.2 kg/m3

• Mediums with a temperature of -20°C up to +40°C

• Mediums up to a max. Humidity of 85%

• The ambient temperature of the motor must be between -20°C and +40°C make sure and adhere to the specifications of the

motor manufacturer.

www.breeze.com.vn | [email protected]

We bring better air to life

AWS 250-4E/D

200 400 600 800 1000 1200

0

10

20

30

40

50

60

70

80

Pa

3

m /h

AWS 315-4E/D

600 800 1000 1200 1400 1600 1800 2000

0

10

20

30

40

50

60

70

80

Pa

3

m /h

3. PERFORMANCE CURVE

1. Plate Steel Casing

2. Motor Impeller

3. Protection Guard and Motor Support

4. Terminal Electric Box

5. Wiring Electric

USER’S MANUAL

AWS SERIES

03

www.breeze.com.vn | [email protected]

We bring better air to life

AWS 355-4E/D

500 1000 1500 2000 2500 3000

0

10

20

30

40

50

60

70

80

90

Pa

3

m /h

AWS 400-4E/D

500 1000 1500 2000 2500 3000 3500 4000

0

20

40

60

80

100

120

140

160

180

Pa

3

m /h

AWS 450-4E/D

500 1000 1500 2000 2500 3000

0

20

40

60

80

100

120

140

160

180

Pa

3

m /h

3500 4000 4500 5000

AWS 500-4E/D

1000 2000 3000 4000 5000 6000 7000

0

20

40

60

80

100

120

140

160

180

Pa

3

m /h

AWS 560-6E/D

1000 2000 3000 4000 5000 6000 7000

0

10

20

30

40

50

60

70

80

90

Pa

3

m /h

AWS 560-4E/D

1000 2000 3000 4000 5000 6000

20

40

60

80

100

120

140

160

180

Pa

3

m /h

7000 8000 9000

AWS 630-4E/D

5000 7000 9000

0

50

75

100

125

150

175

200

225

250

Pa

3

m /h

11000 13000

AWS 630-6E/D

3000 4000 5000 6000 7000

0

20

40

60

80

100

120

140

160

180

Pa

3

m /h

8000 9000 10000

USER’S MANUAL

AWS SERIES

04

www.breeze.com.vn | [email protected]

We bring better air to life

Capacity

( F)

2.5

2.5

4

6

8

10

12

8

15

10

-

-

-

-

-

-

-

-

-

-

Power

(W)

50

75

120

190

280

370

550

320

800

550

50

70

120

180

210

380

520

300

760

520

Speed

(rpm/min)

1450

1400

1400

1400

1380

1390

1380

950

1380

930

1450

1400

1400

1400

1380

1390

1380

950

1380

930

Noise

dBA

(at 3m)

55

60

64

68

69

72

74

68

75

70

55

60

64

68

69

72

74

68

75

70

Max.

Air Volume

3

(m /h)

1250

1750

2650

3800

5000

6800

8200

6500

13000

10000

1250

1750

2650

3800

5000

6800

8200

6500

13000

10000

Model

AWS 250-4E

AWS 315-4E

AWS 355-4E

AWS 400-4E

AWS 450-4E

AWS 500-4E

AWS 560-4E

AWS 560-6E

AWS 630-4E

AWS 630-6E

AWS 250-4D

AWS 315-4D

AWS 355-4D

AWS 400-4D

AWS 450-4D

AWS 500-4D

AWS 560-4D

AWS 560-6D

AWS 630-4D

AWS 630-6D

Currency

(A)

0.25

0.35

0.57

0.9

1.25

1.75

2.6

1.5

3.7

1.9

0.23

0.25

0.45

0.6

0.75

0.8

0.95

1.0

1.6

1.35

Voltage

(V/P/Hz)

220/1/50

220/1/50

220/1/50

220/1/50

220/1/50

220/1/50

220/1/50

220/1/50

220/1/50

220/1/50

380/3/50

380/3/50

380/3/50

380/3/50

380/3/50

380/3/50

380/3/50

380/3/50

380/3/50

380/3/50

Max.

Pressure

(Pa)

70

80

160

150

170

180

80

200

150

70

70

80

160

150

170

180

80

200

150

70

4. PERFORMANCE PARAMETERS

5. DIMENSION INFORMATION

D

C

A

B

4OE Model Weight

(Kg)

E

AWS 250-4E/D 4

7

AWS 315-4E/D 69

AWS 355-4E/D 89

AWS 400-4E/D 109

AWS 450-4E/D 1111

AWS 500-4E/D 15

11

AWS 560-4E/D 18

11

AWS 630-6E/D 23

11

AWS 560-6E/D 18

11

AWS 630-4E/D

C

100

118

130

138

148

153

167

185

167

185

D

258

315

359

400

456

509

563

639

563

639

A

370

430

485

540

575

655

725

805

725

805

B

320

380

435

490

535

615

675

750

675

750 23

11

USER’S MANUAL

AWS SERIES

7. INSTALLATION METHOD

Motor

Black

Blue

Brown

Capacity

Yellow

Green

Terminals

Yellow Green

Brown

Blue

N

L

FU

Motor

Brown

Blue

Black

Capacity

Yellow

Green

Terminals

Yellow Green

Brown

Blue

N

L

FU

Reversible in single phase

AC

~ 380-415V

50 Hz

Fan

1

2

3

Black

Blue

Brown

MCB

L1

L2

L3

PE Yellow

Green

U

V

W

AC

~ 220-240V

50 Hz

Fan

L1

2

3

4

N

L

N

MCB

PE

PE

6. ELECTRIC INSTALLATION

Electric Connection

• The fan is designed for 220-240V/50Hz (single-phase) and 380-415V/50Hz (three-phase) alternating current mains.

• The fan shall be connected to power supply by means of insulated, durable and thermal-resistant cords (cables, wires).

• Electric wiring must be in accordance with technical connection regulations and local ordinances and national electric codes as

per enclosed wiring diagram in the terminal box or on the casing.

• The recommended wire cross section is minimum 0.75 mm2.

• The actual conductor cross-section selection must be based on its type, maximum permissible heating, insulation, length and

installation method (in the air, pipes or inside walls). Connect the cables to the terminal block incorporated inside the terminal

box located on the fan casing in compliance with the fan wiring diagram and the terminal designation. The terminal designations

are shown on the sticker inside the fan casing.

• Check that supply is according to data on nameplate.

• Insert cable according to the instructions in the junction box and seal it (Avoid water enter). The equipment connected ground

for motor protection according to the instructions - Unless the guarantee isn’t accepted. Connect electric supply.

• After connecting the wiring, install the terminal cover with screws.

Wiring Diagram

In the case of reverse direction of rotation:

Ÿ With 1 phase motor to change direction of rotation, transpose the position of leads black and brown.

Ÿ With 3 phases motor to change direction of rotation transpose two of the phases.

•Take care of direction of air flow shown by arrow

stickers.

•Plate mounted wall fans with square inlet cone plate.

•Installation only on a flat surface on the drilled holes in

the inlet cone plates. Installation on an uneven

surface may lead to deformation of the wall ring and

may result in the impeller rubbing the fan casing.

•Make a frame or install direction in the wall.

•The sizes of frame and hole refer to the above

dimension sheet.

•Install the fan with screws to the frame or wall

(refer to the right picture).

Fig 01 Fig 02

Fig 03 Fig 04

05

www.breeze.com.vn | [email protected]

We bring better air to life

USER’S MANUAL

AWS SERIES

Installation overview

with weather cover

Frame for Installation

(by Contractor)

Rain Hood

Wall

Inside Outside

Frame view

8. OPERATION INSTRUCTION

Visual Inspection of Equipment

• The equipment type and arrangement should be verified as ordered at once when it arrives at the jobsite. When a discrepancy

is found, the local Breeze Sales Representative must be notified immediately so that corrective action may be investigated, also

verify electrical conformance to specifications. Unauthorized alterations and unauthorized backcharges will not be recognized by

Breeze Fan.

• After the unit has been assembled, installed and all utilities have been hooked up, the unit is now ready for operation.

Check

Before starting the unit, check the following:

• Confirm that building supply voltage matches the voltage for which the unit is wired.

• Check all piping and wiring penetrations

• Made by contractors for water tightness. All penetrations must be made watertight to prevent water damage to the unit and

building.

• Rotate the fan impeller manually to be sure that it is free to operate. Remove any dirt or debris that may have accumulated

during installation.

• Inspect all fasteners to ensure that none have loosened during shipment.

• Check all electrical connections for proper attachment.

• Check casing and ductwork, if accessible, for obstructions and foreign material that may damage the fan impeller.

Checks prior to initial start-up

Proceed with the fan's initial start-up in the following sequence:

• Check that the mechanical assembly has been carried out properly

• Remove foreign bodies located in the suction and outflow areas and in the fan space

• Check that the electrical installation has been completed in accordance with regulations

• Does the mains voltage match the motor voltage specified on the rating plate?

• Is the motor protection system set correctly with regard to the motor's nominal current? The setting must be carried out in

accordance with the corresponding details contained on the motor output plate.

• Has the motor been connected correctly in accordance with the wiring diagram? The connection schematic supplied by the

motor suppliers applies for the connection of the motor.

Starting up the fan for the first time.

Only put the fan into operation after it has been assembled in accordance with the regulations:

• Put the fan into operation.

• Monitor its correct function (quiet running, vibration, imbalance, power consumption, controllability)

Once the unit has been put into operation, a routine maintenance schedule should be set up to accomplish the following:

• Lubrication of bearings and motor.

• Impeller, casing, bolts and set screws on the entire fan should be checked for tightness.

• Any dirt accumulation on the impeller or in the casing should be removed to prevent unbalance and possible damage.

• Inspect fan impeller and casing looking for fatigue, corrosion or wear.

Checks after initial start-up

Check the mechanical connections after initial start-up, especially the joints at the fan.

06

www.breeze.com.vn | [email protected]

We bring better air to life

USER’S MANUAL

AWS SERIES

9. ROUTINE MAINTENANCE

• Regular maintenance is needed each year. The blades require thorough cleaning once in 6 months.impeller

• Before any maintenance work is undertaken:

o Stop fan in accordance to regulations and disconnect all poles from mains supply.

Wait until impeller is stationary.o

Make sure that a restart is not possibleo

• Use only original spare parts tested and approved by the manufacturer.

• The following safety notes must be observed when maintaining the machine.

• Replace the ball bearings of the motor whenever the grease utilization period has elapsed in accordance with the maintenance

instructions of the manufacturer.

• The technical maintenance includes periodic cleaning of the surfaces from accumulated dust and dirt.

• Use a soft dry brush or a vacuum cleaner to remove dust.

• Only use usual commercial cleaning material paying attention to the prescribed safety measures and do not use any abrasive

tools (surface protection will be destroyed).

Prior to all servicing work:

• Bring the fan to a halt in the prescribed manner and completely isolate the fan from the mains supply.

• Wait until the rotor has come to a halt.

• Ensure that the machine cannot be switched on again.

•Clean the fan

General Check:

• Too much bearing play?

• Lubricant leaking from the bearings?

• Surface protective coating damaged?

• Attention: Conveyed medium too aggressive?

• Unusual noises during operation?

• Fan output still sufficient for possibly extended or shortened ducting system?

Clean fan:

• Unscrews external terminal box for electric installation.

• Unscrews and remove protection guard and motor impeller.

• Clean plate casing with inlet cone.

• Clean motor impeller.

o Do not flood motor.

o Do not bend impeller, blades.

• Assembly fan.

•Control whether installation is correct:

Motor impeller must rotate freeo

The gap between impeller and casing must be regular.o

o Checking direction of rotation is correct.

•Install the fan into the wall or frame.

•Push into operation after clean.

•Connect electric supply of motor.

Fig 1

Fig 2

Fig 3 Fig 4

Fig 6

Fig 5

10. REPAIR

Change of the motor impeller:

Ÿ Disconnect electric supply.

Ÿ Remove protection guard.

Ÿ Unscrew motor suspension and pull out of wall plate

complete with motor impeller.

Ÿ Remove motor suspension from motor impeller.

Ÿ Change new motor impeller on protection guard, insert in

wall plate (casing) and secure with screws.

07

www.breeze.com.vn | [email protected]

We bring better air to life

USER’S MANUAL

AWS SERIES

Before any repairs are undertaken please:

• Stop fan in accordance to regulations and disconnect all poles

from mains supply.

• Wait until impeller is stationary.

• Make sure that a restart is not possible.

• Only use original spare parts manufactured and supplied by

Breeze Fan.

Ÿ Control whether direction of rotation is correct.

Motor and impeller must rotate free. o

Annular gap between impeller and wall plate must be o

regular.

Control whether direction of rotation is correct. o

o Install maintenance cover if have.

Ÿ Push into operation after repaired.

Ÿ Connect electric supply of motor.

08

11. TROUBLESHOOTING TABLE

www.breeze.com.vn | [email protected]

We bring better air to life

PROBLEM POSSIBLE REASONS TROUBLESHOOTING

ŸWhen switching on the

unit the fan does not

start.

ŸCircuit breaker

tripping during the fan

start.

ŸLow air flow.

ŸThe automatic circuit breaker is

triggered by an abnormally high current

consumption due to a short circuit.

ŸClogging of air ducts or other ventilation

system elements. Impeller clogging.

Damaged air ducts. Air damper closure.

ŸDisconnect the fan from power mains and

contact the Breeze Seller.

ŸDo not turn on the fan again.

ŸClean the air ducts and other ventilation system

elements as well as the impeller.

ŸCheck the air ducts for damage.

ŸMake sure the air dampers and louver shutters

are open.

ŸPoor foundation ŸExcessive noise

ŸExcessive vibration

ŸReinforce the foundation

ŸFault installation ŸExcessive noise

Excessive vibration

ŸRe-adjust the installation

ŸLow voltage ŸInsufficient air flow ŸCheck power source

ŸSucked in objects /

Adhere dust

ŸMotor too hot

ŸExcessive noise

ŸExcessive vibration

ŸInspect and clean

ŸIncorrect wiring ŸRun abnormally ŸChange wiring

ŸNo power supply.

ŸMotor jamming.

ŸCheck the electrical connections and the power

switch status.

ŸTurn off the fan.

ŸTroubleshoot the impeller jamming.

ŸRestart the fan.

USER’S MANUAL

AWS SERIES

Transport

• Our products are packed at the factory to suit the respectively agreed mode of transportation. Transport the fan in its original

packaging.

• Fans are protected against damage during shipment. If the unit cannot be installed and operated immediately, precautions need

to be taken to prevent deterioration of the unit during storage. The user assumes responsibility of the fan and accessories while

in storage. The manufacturer will not be responsible for damage during storage. These suggestions are provided solely as a

convenience to the user.

• Only use suitable means of transport, such as pallet trucks or fork-lift trucks or hoist machine.

• If the fan is to be transported by hand, ensure that supporting and carrying loads are kept within reasonable limits for the

personnel involved.

• The fans must not be dropped or thrown. Avoid scratches or rough handling during loading and unloading.

• Parts which have been stacked too high can collapse.

• Avoid a distortion of casing or blades or other damage.

• Danger ! Do not step under hanging loads.

12. TRANSPORT AND STORAGE

Storage

• Store the unit in the manufacturer’s original packaging box in a dry closed ventilated premise with temperature range from +5˚С

up to +40˚С and relative humidity up to 85%.

•Store the fan in a dry, weather-protected location in its original packaging or protect it from the effects of dirt and the weather

until final assembly. Storage environment must not contain aggressive vapours and chemical mixtures provoking corrosion,

insulation and sealing deformation.

•Rotate fan impeller monthly and purge bearings once every three months.

•If storage of fan is in a humid, dusty or corrosive atmosphere, rotate the fan and purge the bearings once a month. Improper

storage which results in damage to the fan will void the warranty.

•Avoid lengthy storage periods (a maximum of one year is recommended) and check that the motor bearing assembly is in good

functional order prior to fitting. With storage times of more than 1 year, please check the bearings on soft running before

installation (turn by hand).

Thank you for your cooperations!

Applied standard:

BREEZE INDUSTRIAL VENTILATION JOINT STOCK COMPANY

Vietnam

Head Office:

215D8 Nguyen Van Huong Street, Thao Dien Ward,

District 2, Ho Chi Minh City, Vietnam.

Tel: +84 28 6651 8585 | Hotline: +84 931 920 368

Factory:

12 Road No. 570, Xom Moi Hamlet, Trung Lap Ha

Commune, Cu Chi District, Ho Chi Minh City, Vietnam.

Tel: +84 28 6659 9589

Ha Noi Office:

55, Alley No. 14, Vu Huu Street, Thanh Xuan Bac Ward,

Thanh Xuan District, Ha Noi City, Vietnam.

Tel: +84 24 6683 8797 | Hotline: +84 906 568 557.

Website: www.breeze.com.vn

Email: [email protected]

Singapore

Office:

No 15, Yishun Industrial Street

1, #03-29, WIN5 Singapore

S768091.

Tel: +65-6254-2648

Myanmar

Office:

No.13/B, Kan Yeik Thar

Street, Thingangyun

Township, Yangon, Myanmar.

This manual suits for next models

9

Table of contents

Other Breeze Fan manuals

Popular Fan manuals by other brands

Siku

Siku QUIET user manual

RS PRO

RS PRO WS-18BM operating instructions

Rittal

Rittal SK 3138000 Assembly and installation instructions

Vassilias

Vassilias R-853 Instructions for use

Westinghouse

Westinghouse Damen owner's manual

Monte Carlo Fan Company

Monte Carlo Fan Company 5SLR52 Series Owner's guide and installation manual

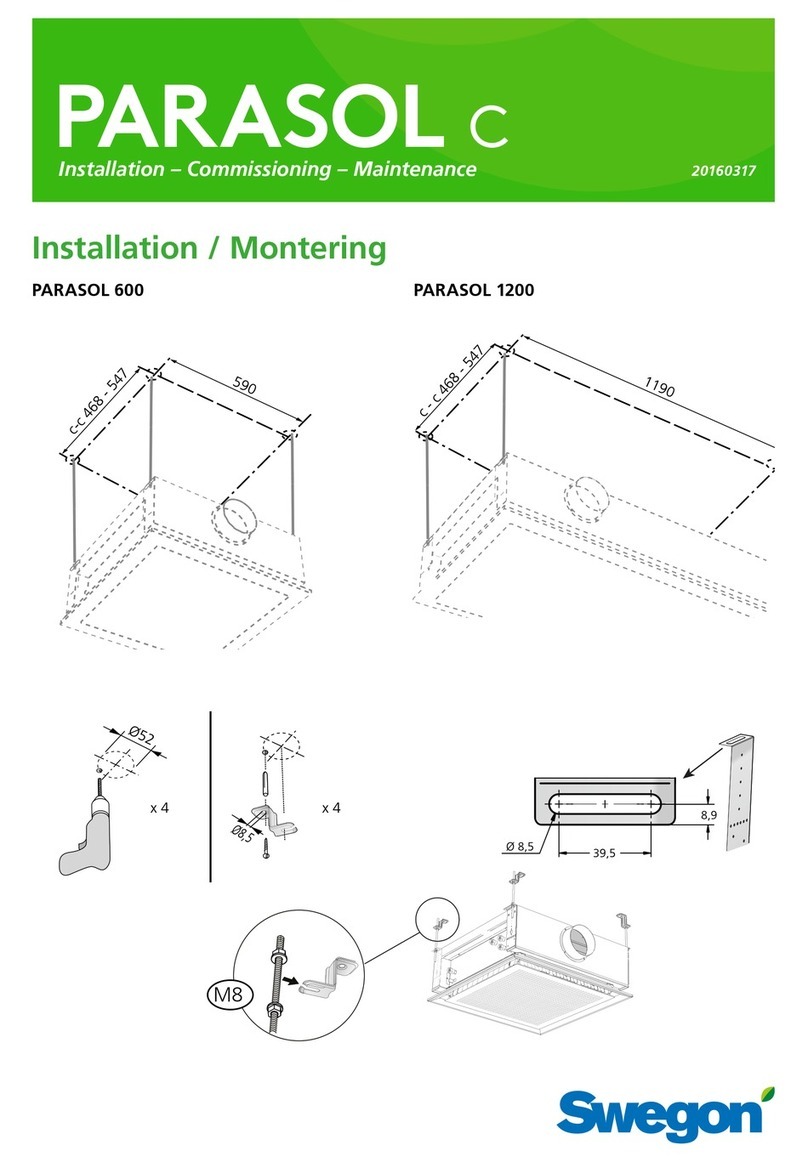

Swegon

Swegon PARASOL c Series Installation, commissioning maintenance

Hunter

Hunter Sturridge II installation manual

Clas Ohlson

Clas Ohlson SF-910B4 quick start guide

Faro Barcelona

Faro Barcelona ventyly SULA Assembly manual

Thermador

Thermador HMCN 36 FS installation manual

CorVent

CorVent RESPOND 19 user manual