Brewer Science Cee 1300CSX User manual

1

Brewer Science®

Cee®1300CSX

Thermal Debonder

Maintenance Manual

Version 01-2014-A

© 2014 Brewer Science, Inc.

2

1.1 Inspection and Service Schedule

Daily

•Check upper and lower platens for contamination

Quarterly

•Replace contaminated vacuum lines

•Replace or repair damaged cables

•Clean any material off of the platens

•Check parallelism of upper and lower platens

Yearly

•Check Nitrogen / CDA Filters

•Clean and lubricate WaferMax Z

•Clean and lubricate Slide Table

•Check temperature read-out of the platens

1.2 Lockout / Tagout Procedure

In the case of maintenance, follow company specific lockout / tagout safety procedures.

For the 1300CSX Thermal Slide Debonder the following are sources of energy; N2 /

CDA, vacuum, and electrical (220 volts 30 amps). To neutralize the system of energy,

an authorized lock out tag out personel must first power down the 1300CSX Thermal

Slide Debonder and then relieve pressure on the N2 / CDA and the Vacuum systems.

1.3 Cleaning of the Platens

Quick visual checks the upper and lower platens for contamination of foreign objects

(such as particles, adhesive, or other materials) should be done after every substrate

processed. Contamination of the platens can lead to substrate breakage. Large

amounts of contamination may be due to centering issues with the Loading Arm. Please

refer to Setup of Loading Arm document for the procedure to correct this issue.

To remove particles or larger foreign objects, access the back of the tool and use a

glass slide to gently scrape the particulates off the platen. Then wipe the platen down by

applying the solvent for the adhesive used to a cleanroom wipe (WaferBOND®Remover

for WaferBOND®). Thoroughly clean the area by wiping in circles. After area has been

wiped, blow off the platen surface with an air gun. CAUTION! CLEANING IS BEST

WITH PLATEN HOT. AVOID DIRECT HAND CONTACT WITH THE PLATEN. CHECK

SOLVENT FLAMIBILITY AND ENSURE ADEQUATE VENTALATION IS INSTALLED

BEFORE CLEANING.

3

1.4 Replacement of Vacuum Lines

The vacuum lines from the platens to the vacuum manifolds should be visually

inspected quarterly for debris in the lines. If there is excessive debris, replace the 1/8

PTFE tubing with new tubing.

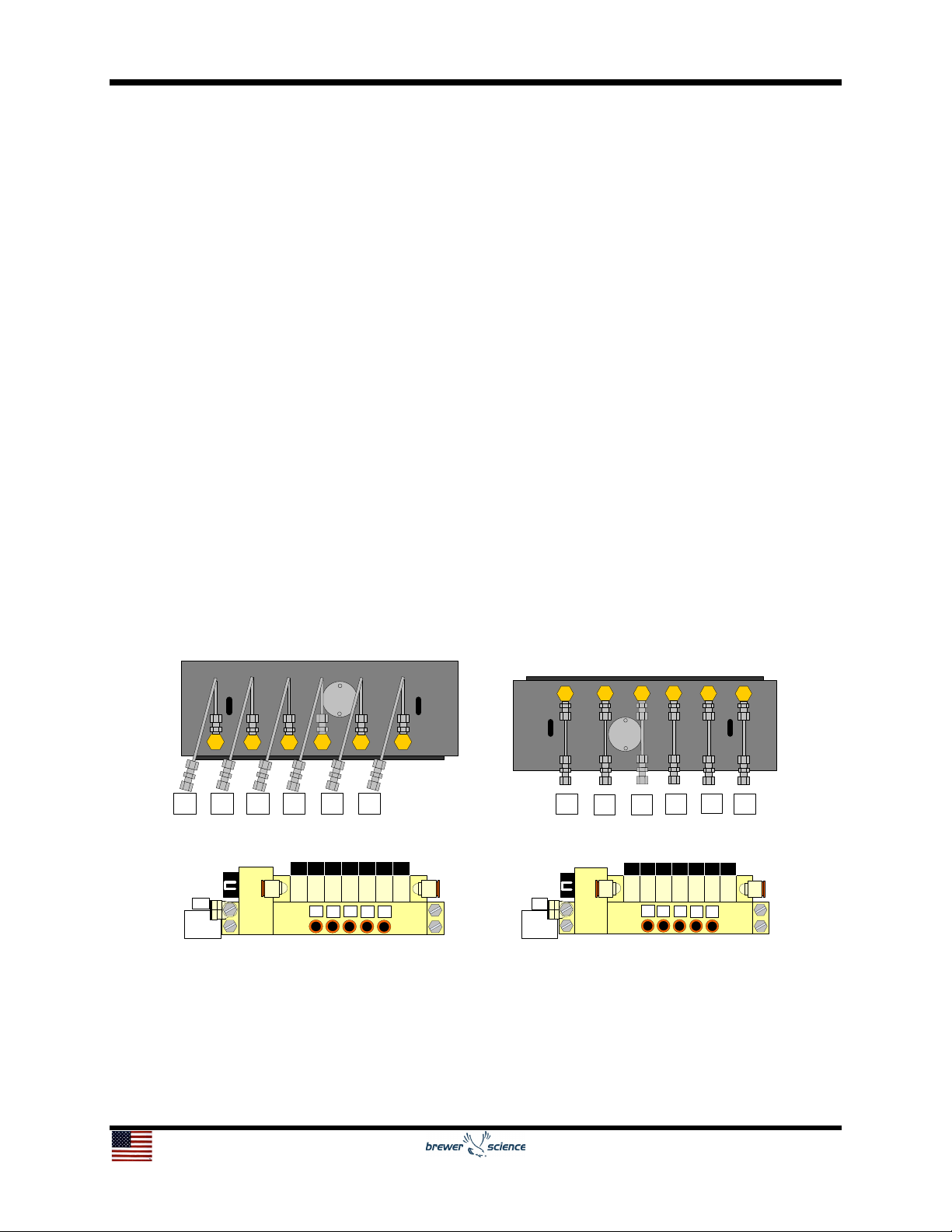

Vacuum Line Replacement Instructions

1. Using a 7/16 wrench, loosen the stainless steel compression nuts on the back of

the platen but do not remove completely.

2. Pull the lines out of the nuts. If the line is difficult to pull out, loosen the

compression nut up a little more.

3. Remove the back panel off of the Electronics Box by removing the two thumb

nuts.

4. Locate the Upper and Lower Vac / Prox Manifolds. Remove the lines by pressing

in the orange ring of the quick connect fitting while pulling out the line. Cut any

necessary wire ties to remove the vacuum lines.

5. Cut the new tubing to the same length as the old tubing.

6. Press the new ends into the Upper and Lower Prox / Vac Manifolds.

7. Run the tubing up to the platens and press into correlating stainless steel

compression nuts. The proper line destinations are numbered in figure below for

the upper and lower patens and vacuum manifolds.

8. Lightly tighten the stainless steel compression nuts with the 7/16 wrench.

9. Restrain the lines with new wire ties.

531246

53 1 246

Upper Platen Prox / Vac Lines Lower Platen Prox / Vac Lines

To

Press

Trans

1

Vac

N2

23456

To

Press

Trans

1

Vac

N2

23456

Upper Prox / Vac Manifold Lower Prox / Vac Manifold

4

1.5 Parallelism of the Lower and Upper Platen

The parallelism of the lower and upper platens should be checked quarterly or when an

issue in tool performance is noticed (vacuum loss, contaminated platen, etc.). For the

tool to be operational the lower platen must be parallel with the linear movement of the

X Axis slide and the upper platen must be parallel to the lower platen. The procedure to

check parallelism of lower and upper platens is as follows:

1. Navigate to Diagnostics – Debonder Diagnostics - Other Controls tab.

2. Wait for lift pins to lower and then move the lower platen to the press position by

pressing the Press Position button.

3. Move the lower platen up using the Z Axis controls until the lower platen is

almost touching the upper platen. The closer the platens, the more precise the

platen setup will be. The gap should be approximately 20-50 µm; enough to see

light through.

4. If the gap between the platens is not uniform from the ends of the tool, adjust the

two leveling screws on the far right of the upper platen.

a. To adjust, loosen the locking socket bolts with a 3/16-inch Allen wrench

and turn the leveling screw using the tool provided.

b. Turning the leveling screw clockwise will raise the corresponding side of

the upper platen and counter clockwise will lower it. Tighten locking socket

bolts when done.

c. If the gap is large, the lower platen may need to be lower or raised during

this step.

5. Once the gap from the side looks uniform, look at the gap from the front. If the

gap is not uniform, adjust the leveling screw on the left of the upper platen.

a. To adjust, loosen the locking socket bolt on the right with a 3/16-inch Allen

wrench and turn the leveling screw using the tool provided.

b. Turning the leveling screw clockwise will raise the corresponding side of

the upper platen and counter clockwise will lower it. Tighten locking socket

bolts when done.

c. If the gap is large, the lower platen may need to be lower or raised during

this step.

6. Once the gap is uniform from the side and the front, the parallelism of the platens

to the X Axis slide must be checked.

a. To do this, navigate to X Axis controls-Velocity Jog. Enter 200 mm into the

distance field and 5 mm/s into the velocity field.

b. Move the lower platen to the left and monitor the gap.

c. If the gap narrows, stop the platen and adjust the leveling screw on the

right of the lower platen counter clockwise. If the gap grows, the leveling

screw on the right of the lower platen must be turned clockwise. Tighten

locking socket bolts when done.

7. When an adjustment has been made to the lower platen, the upper platen will

need to be adjusted again. Move the lower platen back to the press position.

Repeat steps 5 and 6 until the gap no longer increases or decreases in step 6.

8. Once the platens are parallel, run the Vac Search Start Routine in the Setup tab.

5

1.6 Cleaning and Lubrication of the Slide Table

Cleaning of the Slide Table should be cleaned and lubricated annually or every 10,000

cycles (whichever comes first).

1.6.1 Cleaning

The cleaning process is used in Step 5 of the Lubrication Procedure in Section 1.6.2.

Before using a cleaning solvent on any part of the Slide Table, blow away small

particles and dust with clean, dry, compressed air. Any metal surface of the slide can

be cleaned with either acetone or isopropyl alcohol.

1.6.2 Lubrication

For the slide bearings, use Krytox grease.

Lubrication Procedure

1. Go to Diag – Other Controls – Distance and enter a distance of 150 mm and

move right.

2. Wait for the slide to move into position and then power down the 1300CSX.

3. Remove one of the side panels of the 1300CSX upper enclosure in order to

pull the black Slide Table cover out of the tool.

4. Remove the black slide cover off the slide (6 bolts, 3 mm allen wrench).

5. Remove any dirty or dried lubricant from the bearing rails and lead screw.

Use a clean, lint-free cloth with a side-to-side motion. Use a swab soaked in

Isopropyl Alcohol to remove stubborn debris (See Section 1.6.1)

6. Apply a thin, continuous film of lubricant to the bearing rails and lead screw. A

good quality, natural bristle artist's brush makes an excellent applicator.

7. Manually move the lower platen and repeat steps 5 and 6 for areas covered

by the original slide position.

8. Refasten the cover and side panel.

9. Power on the 1300CSX and Home.

10.Go to Diag- Other Controls and move the slide from the Home Position to the

Press Position and then back to the Home Position 5 times in order to ensure

lubricant is distributed evenly.

6

1.7 Cleaning and Lubrication of the WaferMax Z

The WaferMax Z stage should be cleaned and lubricated annually or every 10,000

cycles (whichever comes first).

1.7.1 Cleaning

The cleaning process is used in Step 5 of the Lubrication Procedure in Section 1.7.2.

Before using a cleaning solvent on any part of the WaferMax Z, blow away small

particles and dust with clean, dry, compressed air. Any metal surface of the stage

can be cleaned with either acetone or isopropyl alcohol.

1.7.2 Lubrication

For the cross-roller bearings, use Kluberplex BEM 34-132 grease. The motor is

completely non-contact and requires no lubrication.

Lubrication Procedure

1. Power down the 1300CSX.

2. Be sure the pressure to the pneumatic counterbalance is still supplied to the

stage.

3. Remove the button head screws that attach the outer covers to the stage

base and then remove the covers.

4. Remove any accumulated debris from the inside of the assembly.

5. Remove any dirty or dried lubricant from the crossed roller bearing ways. Use

a clean, lint-free cloth with a side-to-side motion. Use a swab soaked in

Isopropyl Alcohol to remove stubborn debris (See Section 1.7.1).

6. Apply a thin, continuous film of lubricant to the linear bearing ways. A good

quality, natural bristle artist's brush makes an excellent applicator.

7. Manually move the wedge to the opposite end of travel. This will work the

grease into the linear bearings. The stage table should move freely with little

resistance.

8. Repeat steps 3 through 5 for any areas covered by the original table position.

9. Refasten the covers

10.Restore power to the 1300CSX and home the stage.

7

1.8 Replacement of Filters

Replace the elements every 2 years or when the pressure drop across the filter

becomes 0.1 MPa (14.5 psi), whichever comes first, to prevent damage to the element.

Filter Replacement Instructions

1. Power down the 1300CSX, turn off and vent the N2 / CDA supply, and remove

the back panel off of the Electronics Box by removing the two thumb nuts.

ALWAYS POWER DOWN THE TOOL BEFORE TURNING OFF N2 / CDA

SUPPLY.

2. Locate the filters and remove the lines by pressing in the orange ring of the quick

connect fitting while pulling out the line.

3. Unbolt the filters from their brackets; making a note of which filter goes where.

4. Using a remove the 2 quick connect fittings off of each filter. Clean all Teflon tape

from the threads.

5. Wrap the quick connect fittings with new Teflon®tape and install on the new

filters.

6. Remove the plug from the bottom of the old filter and put into the new one.

7. Bolt the filters back onto the brackets and press the lines into the fittings on the

new filters.

8. Replace the back panel, turn on the N2 / CDA, and power the 1300CSX on.

ALWAYS TURN ON N2 / CDA BEFORE POWERING ON THE TOOL.

8

1.9 Measuring and Setting the Temperature Bias

The bias allows the operator to compensate for any difference between the sensor

temperature and the point to be measured. The process display and setpoint will be

offset by the value entered in the “Offset” parameter in the controller software. Ex:

Desired temperature is 150 degrees. Sensor is adjacent to heater and reads 50 degrees

higher than the actual process temperature. Enter bias of –50. Enter setpoint of 150.

Process will display 150 even though sensor will be measuring 200 degrees.

Measuring and Setting the Temperature Bias Instructions

1. Using a temperature calibration device, measure the temperature at the center of

the upper and lower platens.

2. Note the temperature differences of the calibration device to each of the patens.

These are the offset values.

3. From the startup screen, please select the DIAG tab at the bottom of the Display.

4. Next, press the “Exit” key to close the CeeX software and allow access to the PC

Desktop.

5. Now, locate and press the “START” menu in the lower left hand corner of the

Display.

6. Using the “START” menu, navigate and press the following:

Programs/Accessories/Accessibility/On-Screen Keyboard.

7. Next, locate the “CeeX Software” folder on the desktop.

8. Open the “CeeX Software” folder and locate the Solo-Temperature Controller

Software.

9. Upon the software opening, locate and press the Controller image/icon in the

upper right hand corner.

10. This should open an additional window. Locate the “Address Connect 1” box in

the upper right hand corner of the display. Address 1 establishes communication

to the upper platen temperature controller and Address 2 establishes

communication to the lower platen temperature controller.

11. Then, click “connect” and you should establish communication with the Solo

temperature controller.

12. The controller configuration setting should now be reflected on the screen and

locate the “P1-16 tPoF Offset” in the left side menu.

13.Using the stylus, click into this prompt box and then use the On-Screen

Keyboard to set the appropriate temperature offset.

14. After inputting the correct bias temperature, press enter on the On-Screen

keypad to save this parameter.

15. Next, close both the Solo Temperature Controller software and the On-Screen

Keypad.

16. Restart the system software, by double clicking the CeeX software Icon.

17. Upon the software initialization, navigate to the DIAG Menu and compare the

current physical temperature to the external surface probe.

18. Repeat steps 4-16, if additional bias offsetting is required.

Table of contents

Popular Industrial Equipment manuals by other brands

Maggi

Maggi 21 Prestige Use and maintenance manual

Best

Best GENIUS Compact Operator and maintenance manual

Tesmec

Tesmec CRT160 Instructions for use

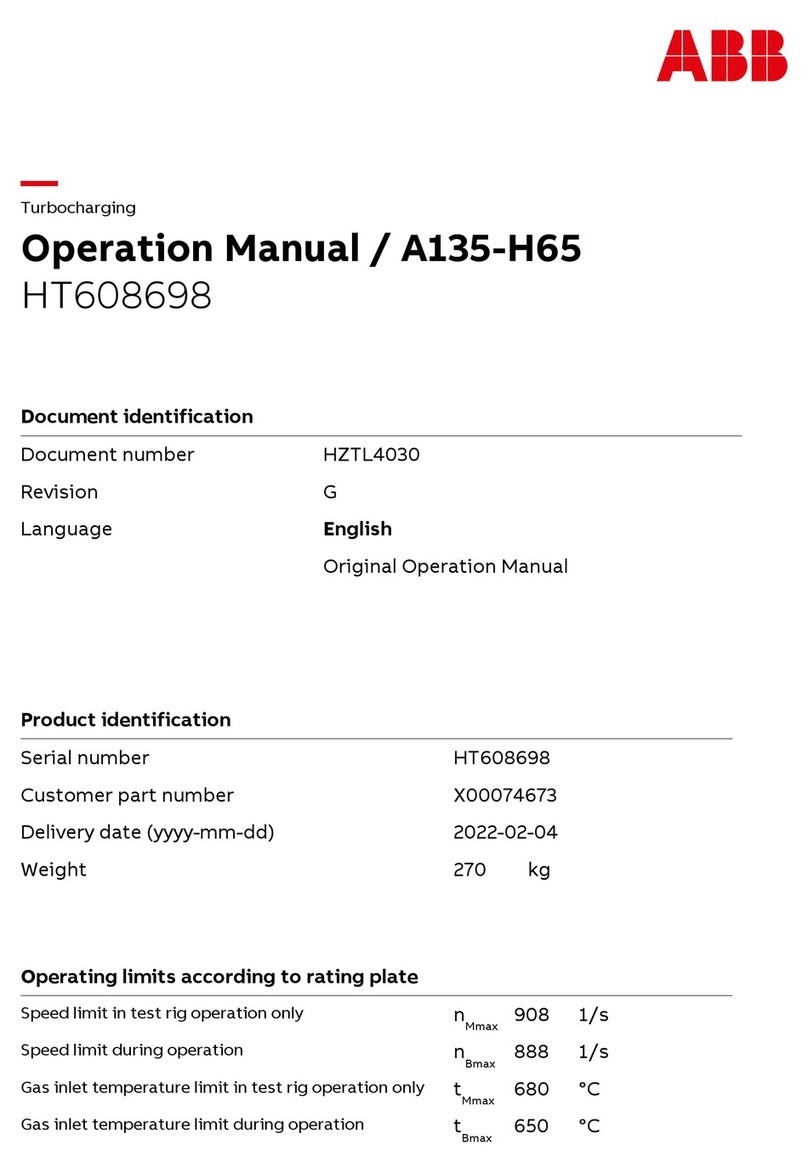

ABB

ABB HT608698 Operation manual

Quantronix

Quantronix Cubiscan 110-XT Operation and technical manual

Heidolph

Heidolph Hei-VAP Industrial operating instructions