Tesmec CRT160 User manual

INSTRUCTIONS FOR USE

TROLLEY MOD. CRT160/CRT161

- 24050 Grassobbio (Bg) via Zanica, 17/O - 24060 Endine Gaiano (Bg) via Pertegalli

Tel. 0039 / 035 / 4232911 Tel. 0039 / 035 / 825024

Telefax 0039 / 035 / 4522445 Telefax 0039 / 035 / 826375

IMPORTANTE

Per qualsiasi informazione riguardante questa macchina/attrezzatura (utilizzo, manutenzione, ricambi) citare sempre Modello,

Numero di matricola, Commessa, Anno di fabbricazione rilevabile nella targa d'identificazione della macchina.

Questo manuale non descrive le procedure di tesatura, né si è cercato di dare istruzioni all’utilizzatore sui metodi di tesatura.

Il contenuto di questo manuale prevede unicamente un testo di base per l’uso, manutenzione e l’elenco dei pezzi di ricambio

della macchina stessa e come s'intende e si suggerisce di utilizzarla. Saranno graditi suggerimenti da parte degli Utilizzatori per

migliorare questa pubblicazione. Scriveteci all’indirizzo sottoindicato.

IMPORTANT NOTE

State always “Model, Serial Number and Manufacturing Year” of the machine/equipment in case you need information on use,

maintenance and spare parts. The a/m data can be found on the identification plate of the machine itself.

This is not a stringing procedures manual, and no attempt is made or implied herein to instruct the user in stringing methods.

The contents of this manual are intended as base line for operation, maintenance and part list of the unit as it stands alone and

as it is intended and anticipated to be used. Recommendation by the individual user for improving this publication is encouraged

and should be forwarded to the address on this page.

IMPORTANT

Indiquer toujours le modèle, le numéro de série et l’année de fabrication de la machine/équipement même, en demandant à

TESMEC renseignements sur l’utilisation, l’entretien et les pièces de rechange. Ces informations se trouvent sur la plaque

d'identification de la machine.

Ce manuel ne décrit pas les procédures de déroulage, ni on a tache de donner instructions à l'Utilisateur sur les méthodes de

déroulage. Le contenu de ce manuel prévoit seulement un texte pour l’utilisation, l’entretien et la liste de pièces de rechange et

comme TESMEC conseille d’utiliser la machine même.

Pour chaque suggestion pour améliorer cette machine, écrire à l’adresse au-dessous.

IMPORTANTE

Para cualquier información relativa a esta máquina/equipo (utilización, mantenimiento, repuestos) citar siempre Modelo,

Número de serie, Orden de compra, Año de fabricación que se hallan en la tarjeta de identificación de la máquina.

Este manual no describe los procedimientos de tensado y tampoco se ha tratado de dar instrucciones al utilizador acerca de los

métodos de tensado. El contenido de este manual prevé únicamente un texto básico para el uso, mantenimiento y el listado de

repuestos de la misma máquina y cómo se pretende y se sugiere utilizarla. Se apreciarán sugerencias por parte de los

utilizadores para mejorar esta publicación. Nos pueden escribir a la dirección indicada abajo.

IMPORTANTE

Para qualquer informação a respeito desta máquina/equipamento (utilização, manutenção, peças sobresselentes) citar sempre

o Modelo, o Número de Série, a Encomenda, o Ano de fabrico,dados que podem ser encontrados na placa de identificação da

máquina. Este manual não descreve os procedimentos de entesadura, tão pouco foi nossa intenção dar instruções ao utilizador

sobre os métodos de entesadura. O conteúdo deste manual de instruções prevê unicamente um texto básico para o uso, a

manutenção e a lista das peças sobresselentes da mesma máquina e como se entende e se sugere utilizá-la.

Serão muito bem aceitas sugestões por parte dos Utilizadores, no intento de melhorar esta publicação.

Escrevam-nos no endereço abaixo indicado.

WICHTIG

Geben Sie für alle Informationen über diese Maschine/Ausrüstung (Verwendung, Wartung, Ersatzteile) immer Modell,

Matrikelnummer, Bestellung und Baujahr an, was Sie dem Identifizierungsschild der Maschine entnehmen können.

Dieses Handbuch beschreibt nicht die Verfahren des Spannens, und es wurde auch nicht versucht, dem Verwender Anleitungen

über die Methoden des Spannens zu geben. Der Inhalt dieses Handbuchs enthält allein einen Basistext für den Gebrauch und

die Wartung, die Ersatzteilliste der Maschine und außerdem, welche Verwendung für sie bezweckt und empfohlen wird.

Wir freuen uns über Tipps von Seiten der Verwender, um diese Veröffentlichung zu verbessern.

Schreiben Sie uns an unten angegebene Adresse.

ÓÇÌÁÍÔÉÊÏ

Ãéá ïðïéáäÞðïôå ðëçñïöïñßá ó÷åôéêÜ ìå áõôü ôï ìç÷Üíçìá/åîïðëéóìü (÷ñÞóç, óõíôÞñçóç, áíôáëëáêôéêÜ) áíáöÝñáôå ðÜíôïôå ôï

ÌïíôÝëï, ôïí Áñéèìü ìçôñþïõ, ôçí Ðáñáããåëßá, ôï ¸ôïò êáôáóêåõÞò ðïõ ðñïêýðôïõí óôçí ðéíáêßäá ÷áñáêôçñéóìïý ôïõ ìç÷áíÞìáôïò.

Ôï åã÷åéñßäéï áõôü äåí ðåñéãñÜöåé ôéò äéáäéêáóßåò ôïõ ôåíôþìáôïò, ïýôå êáé èåëÞóáìå íá äþóïõìå ïäçãßåò óôïí ÷ñÞóôç åðß ôùí

ìåèüäùí ôåíôþìáôïò. Ôï ðåñéå÷üìåíï ôïõ åã÷åéñéäßïõ áõôïý ðåñéëáìâÜíåé áðïêëåéóôéêÜ ôï âáóéêü êåßìåíï ÷ñÞóçò, óõíôÞñçóçò êáé ôïí

ðßíáêá áíôáëëáêôéêþí ôïõ ìç÷áíÞìáôïò êáé ðùò åííïåßôáé êáé óõíéóôÜôáé ç ÷ñÞóç áõôïý.

Åõ÷áñßóôùò èá äå÷èïýìå ôéò óõìâïõëÝò åê ìÝñïõò ôùí ×ñçóôþí ãéá íá âåëôéþóïõìå ôçí Ýêäïóç áõôÞ.

ÃñÜøôå ìáò óôç áêüëïõèç äéåýèõíóç.

- 24050 Grassobbio (Bg) via Zanica, 17/O - 24060 Endine Gaiano (Bg) via Pertegalli

Tel. 0039 / 035 / 4232911 Tel. 0039 / 035 / 825024

Telefax 0039 / 035 / 4522445 Telefax 0039 / 035 / 826375

TROLLEY

Model: CRT160/CRT161

1. INSTRUCTIONS MANUAL 1

1.1 MANUFACTURER’S DATA 1

1.2 MACHINE’S DATA 1

1.3 INTRODUCTION 2

1.3.1 CARE OF THE INSTRUCTION MANUAL 2

1.3.2 RESPONSIBILITY 2

1.3.3 PREVENTION MEASURES TO BE CARRIED OUT BY THE USER 3

1.3.4 CONDITION OF USE 3

1.3.5 USE NOT ALLOWED 3

1.3.6 NORMS ABOUT MAINTENANCE 3

1.3.7 LIFTING AND TRANSPORT 4

1.3.8 STORAGE 4

1.3.9 APPLIED NORMS 4

2. MOUNTING THE TROLLEY ON CABLES 5

3. HOW TO OVERCOME THE SPACERS OR THE SUSPENSION CHAINS 5

4. TOWING UNIT USE (MOTORISED VERSION MOD. CRT160) 5

5. MAINTENANCE 6

5.1 HYDRAULIC CIRCUIT MAINTENANCE (MOTORISED VERSION MOD.CRT160) 6

TROLLEY

Model: CRT160/CRT161

1

1. INSTRUCTIONS MANUAL

1.1 MANUFACTURER’S DATA

•MANUFACTURER TESMEC S.p.A.

•ADDRESS via Zanica, 17/O, 24050 Grassobbio (BG) - ITALY

•PHONE NUMBER 035/4232911

•FAX NUMBER 035/4522445

•E-MAIL [email protected]

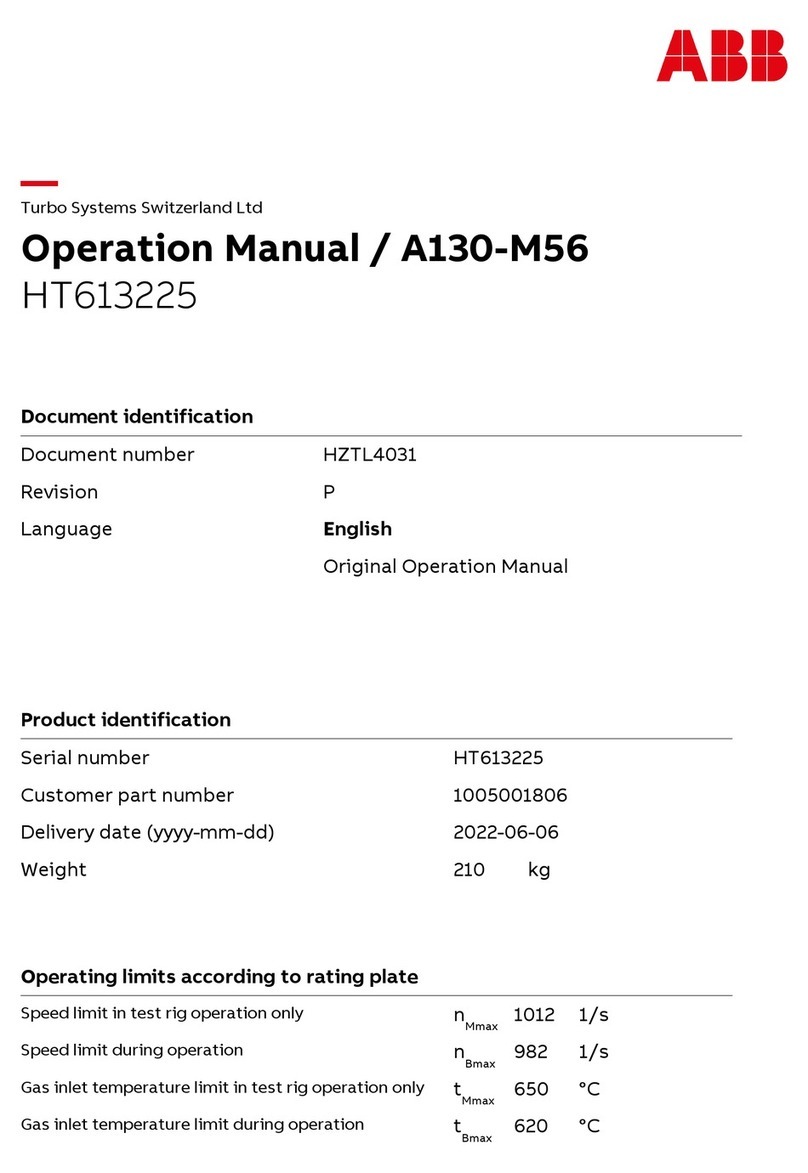

1.2 MACHINE’S DATA

•NAME TROLLEY

•MODEL CRT160/CRT161

•WORKING NUMBER ........................

•MANUFACTURING YEAR ........................

TROLLEY

Model: CRT160/CRT161

2

1.3 INTRODUCTION

This manual contains the necessary information for the use and the maintenance of the

TESMEC equipment.

To get the optimum performance and the correct working of the machine please follow these

instructions.

Due to TESMEC’s program of constant improvement, materials and specifications are

subjected to change without notice or obligation.

THE REPRODUCTION, EVEN PARTIAL, OF THE PICTURES AND/OR THE TEXT IS

FORBIDDEN.

1.3.1 CARE OF THE INSTRUCTION MANUAL

a) Before using the equipment the chief of the job site and the operator must read the

instruction manual.

b) The information contained in the instruction manual applies to all the operators charged

with the use and/or the maintenance of the equipment.

c) The chief of the job site is obliged to inform all the operators about the instructions

contained in the manual.

In particular, it is necessary that before using the equipment the operator know exactly the

operations to be carried out.

Moreover the operator must be able to carry out all the operations described in the manual,

being sure to have understood the safety directives and to apply them correctly during the

use and maintenance operations.

The operator must know the directives for accident prevention.

d) The chief of the job site must verify that the instructions contained in the manual are

applied.

e) The instruction manual must be kept, in order to be consulted, for all the life of the

equipment and also when it is given to another user.

f) The instruction manual must be kept in a sheltered and dry place.

g) The instruction manual is not a training manual.

1.3.2 RESPONSIBILITY

a) Only employed and qualified operators must use the equipment.

b) The equipment must be used only for the work it was designed for.

c) The manufacturer is not responsible for any use not in compliance with the given

instructions that could cause damages to persons and/or things:

•improper use of the equipment or for the consequences caused by tampering and/or

modifications carried out without the manufacturer’s written acceptance

•use of not original spare parts

•bad maintenance

•total or partial non-performance of the instructions for use.

TROLLEY

Model: CRT160/CRT161

3

1.3.3 PREVENTION MEASURES TO BE CARRIED OUT BY THE USER

1) To observe peremptorily the directives for accident prevention in force in the relevant countries.

2) To follow all the indications of warning and caution.

3) Use always the following necessary individual means of work: GLOVES, BOOTS,

PROTECTION HELMET, etc.

The operator in charge with the installation and maintenance of the equipment must

use suitable clothes to the working site and to the situation where he finds himself; in

particular he must avoid the use of very large clothes, chains, bracelets, rings or whatever

can get entangled with moving parts.

4) The operator must not carry out on his own initiative operations or interventions which are

not up to him.

1.3.4 CONDITION OF USE

The equipment is designed for being used by qualified personnel in the working sites.

The equipment can not be used when not authorised personnel are present on the working site.

1.3.5 USE NOT ALLOWED

The equipment MUST NOT BE USED:

•to transport tools different from those to be used on the line

•with a working load higher than the one indicated on the plate for the data

•with safety devices disengaged.

1.3.6 NORMS ABOUT MAINTENANCE

•Do not modify for any reason parts of the equipment (connections, drillings, finishing, etc.:

the customer is liable for any types of interventions not authorised by Tesmec S.p.A.

because in this case he becomes the manufacturer.

•All maintenance operations, either ordinary or extraordinary, have to be carried out

following the descriptions listed in the present manual or on the basis of technical

specifications written by the manufacturer. The non-respect of this point declines the

manufacturer from any responsibility and the guarantee conditions have no value.

Do not tamper or modify any mechanical or electric component without a clear

written authorisation.

•Eventual modifications must be authorised by the manufacturer.

In case the equipment is used outside its limits of use or changing somehow the prerogative

features of Tesmec S.p.A., Tesmec S.p.A. declines any responsibility for this.

TROLLEY

Model: CRT160/CRT161

4

It is absolutely forbidden to effect maintenance works with running

equipment (except for the ones indicated in the use and maintenance

book).

When the equipment is working, the contact with any part of it is

absolutely forbidden (except for the ones indicated in the use and

maintenance book).

1.3.7 LIFTING AND TRANSPORT

•For lifting the equipment, use ropes suitable to its weight.

Any other system ANNULS THE INSURANCE GUARANTEE for eventual damages

occurred to the equipment.

1.3.8 STORAGE

•In any case of long inactivity of the equipment, the customer shall check the site where it is

positioned and in relation to the type of storage (box, pallets, etc.) verify if the preservation

condition is possible.

•Storage and use of the equipment have to be carried out paying attention in order to don’t

damage the same compromising its functionality.

•Tesmec S.p.A. declines any responsibility in case the user doesn’t specify or require the

above-mentioned information.

THE NON-RESPECT OF THE PRESCRIBED RESTRAINS CAUSES A SITUATION

OF IMPROPER USE FOR TECHNICAL AND PERSONS SAFETY PURPOSES AND

RELIEVES TESMEC S.p.A. FROM ANY RESPONSIBILITY IN CASE OF

ACCIDENTS TO PERSONS OR DAMAGES TO THINGS AND/OR TO THE

MACHINE, CAUSING ALSO THE LOSS OF WARRANTY.

1.3.9 APPLIED NORMS

Trolley is manufactured in conformity with the following norm:

98/37/CE Norm of the European Parliament and Council, dated 22 June 1998 referring to

the laws of the machines member States.

89/336/CE Norm of the European Council, dated 03 May 1989 referring to the laws of the

electromagnetic compatibility member States.

TROLLEY

Model: CRT160/CRT161

5

2. MOUNTING THE TROLLEY ON CABLES

1) Open the wheel holder booms acting on the pins (table 1, pos. 5).

2) Hook the lifting ropes to the special lugs and then put the trolley into the correct position.

3) Close the wheel holder booms positioning the pins (table 1, pos. 5) and lock the shoe

brakes acting on the lever (table 1, pos. 2).

The shoes of the brakes can be regulated by means of the knob.

3. HOW TO OVERCOME THE SPACERS OR THE SUSPENSION

CHAINS

1) Take the trolley as near as possible to the obstacle to be overcome.

2) Open the boom no. 1 (table 2) acting on the pins (table 1, pos. 5).

3) Move the trolley forward and close the boom inserting the pin (table 1, pos. 5).

4) Proceed as above mentioned for the other 3 wheel holder booms.

5) Eventually remove the motorised wheels from the conductor acting on the stretcher

(table 1, pos. 9).

NOTE: for the boom no. 2 and 3 it is necessary to disassemble the brake acting on the

pins (table 1, pos. 4).

4. TOWING UNIT USE (motorised version mod. CRT160)

a) Set the motorised wheels (table 1, pos. 8) in contact with the conductor acting on the

stretcher (table 1, pos. 9).

b) Adjust the motorised wheels pressure on the conductor, acting on the stretcher

(table 1, pos. 9), as per the line slope, the conductor diameter and the ambient conditions

(i.e. wet conductor). A high pressure between motorised wheels and conductor may

produce over tensions in the conductor itself, as well as a high resistance during feed may

compromise the trolley performances. On the contrary a low pressure between motorised

wheels and conductor may produce the wheels slipping on the conductor.

c) Speed up the engine acting on the suitable rope (table 1, pos. 10).

d) Adjust the engine rpm and therefore the trolley speed acting on the lever (table 1, pos. 11).

TROLLEY

Model: CRT160/CRT161

6

5. MAINTENANCE

Periodically check the consistency of the brake pad.

The equipment does not need any lubrication, as the wheels are equipped with waterproof

bearings.

5.1 HYDRAULIC CIRCUIT MAINTENANCE (motorised version mod. CRT160)

a) Change the hydraulic oil after 500 working hours and, thereafter, every 1500 hours (or in

any case every year).

b) To discharge the exhaust hydraulic oil, use the suitable tap in the tank.

DANGER: let the hydraulic oil be completely cooled before removing it and always use

the suitable safety wears (gloves, etc.).

ATTENTION: the discharge of the exhaust oils has to be effectuated in conformity with

the laws in force in the relevant country.

c) Fill the oil in the tank by means of the suitable filler (table 1, pos. 12).

ATTENTION: make maximum care when filling to make sure no foreign matter, which

could cause irreparable damages to the circuit’s components, enters along with the oil; if

possible filter the oil with a 10 µm filter.

d) Replace the filter cartridge (table 1, pos. 14) after 500 working hours and, thereafter, every

1500 hours (or every year at least)

For further maintenance operations of installed hydraulic components (pumps and motors)

refer to the enclosed documentation.

TROLLEY MOD. CRT160/CRT161

TABLES

- 24050 Grassobbio (Bg) via Zanica, 17/O - 24060 Endine Gaiano (Bg) via Pertegalli

Tel. 0039 / 035 / 4232911 Tel. 0039 / 035 / 825024

Fax 0039 / 035 / 4522445 Fax 0039 / 035 / 826375

TROLLEY

Model: CRT160/CRT161

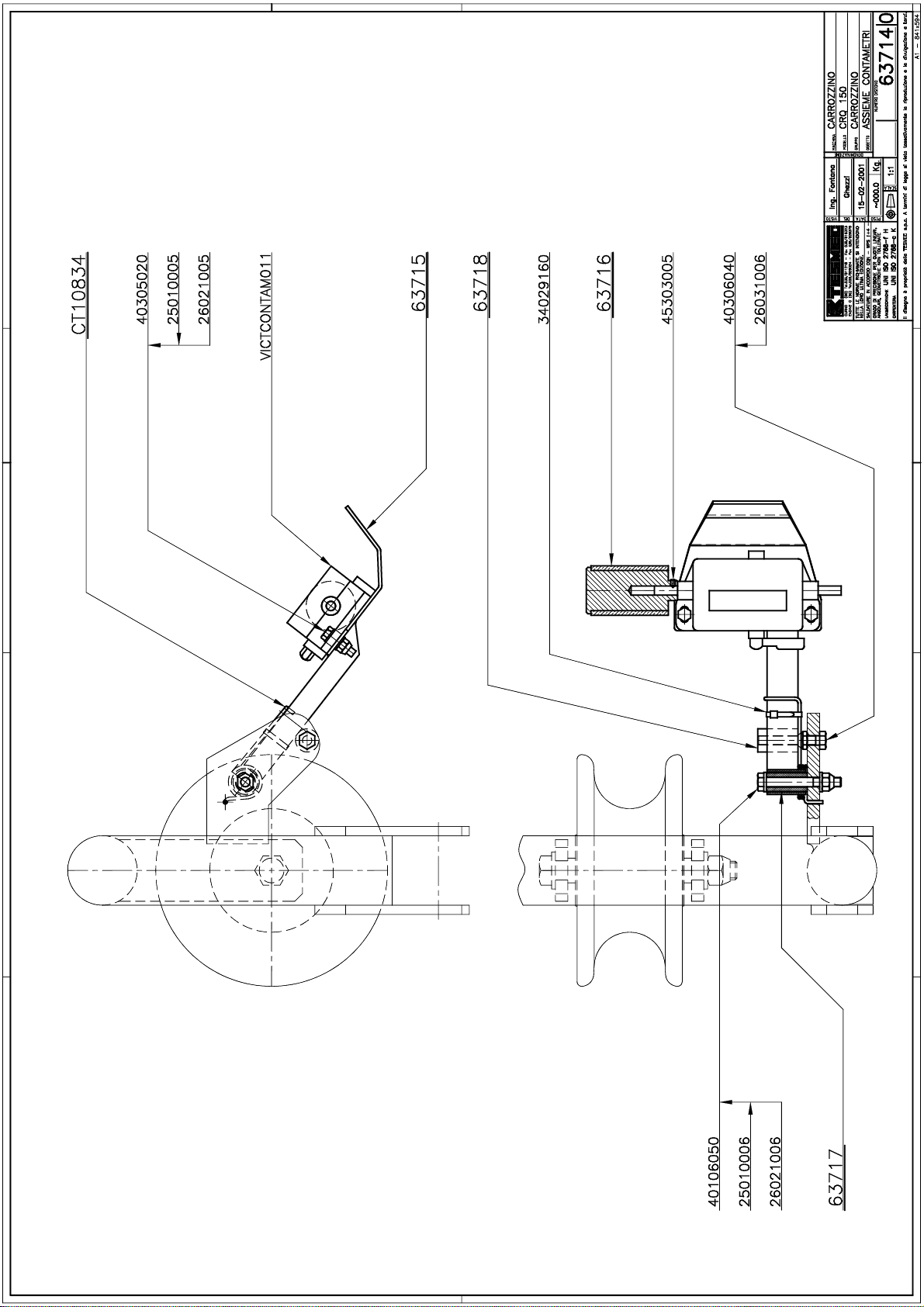

TABLE 1.1

1) Meter counter.

2) Brake control lever.

3) Safety stop for pin.

4) Pin for brake fixing.

5) Fixing pin.

6) Brake adjusting lever.

7) Adjusting lever for holes alignment.

8) Motorised wheels (motorised version mod. CRT160).

9) Stretcher for motorised wheels adjusting (motorised version mod. CRT160).

10) Rope for engine start-up (motorised version mod. CRT160).

11) Accelerator (motorised version mod. CRT160).

12) Hydraulic oil filling cap (AGIP OSO 46) (motorised version mod. CRT160).

13) Hydraulic oil level indicator (motorised version mod. CRT160).

14) Filter (motorised version mod. CRT160).

15) Hydraulic oil draining plug (motorised version mod. CRT160).

TROLLEY

Model: CRT160/CRT161

TABLE 2.1

1) Wheels holder boom no. 1.

2) Wheels holder boom no. 2.

3) Wheels holder boom no. 3.

4) Wheels holder boom no. 4.

TROLLEY MOD. CRT160/CRT161

ENCLOSED DOCUMENTS

- 24050 Grassobbio (Bg) via Zanica, 17/O - 24060 Endine Gaiano (Bg) via Pertegalli

Tel. 0039 / 035 / 4232911 Tel. 0039 / 035 / 825024

Fax 0039 / 035 / 4522445 Fax 0039 / 035 / 826375

This manual suits for next models

1

Table of contents

Other Tesmec Industrial Equipment manuals