- 4 -

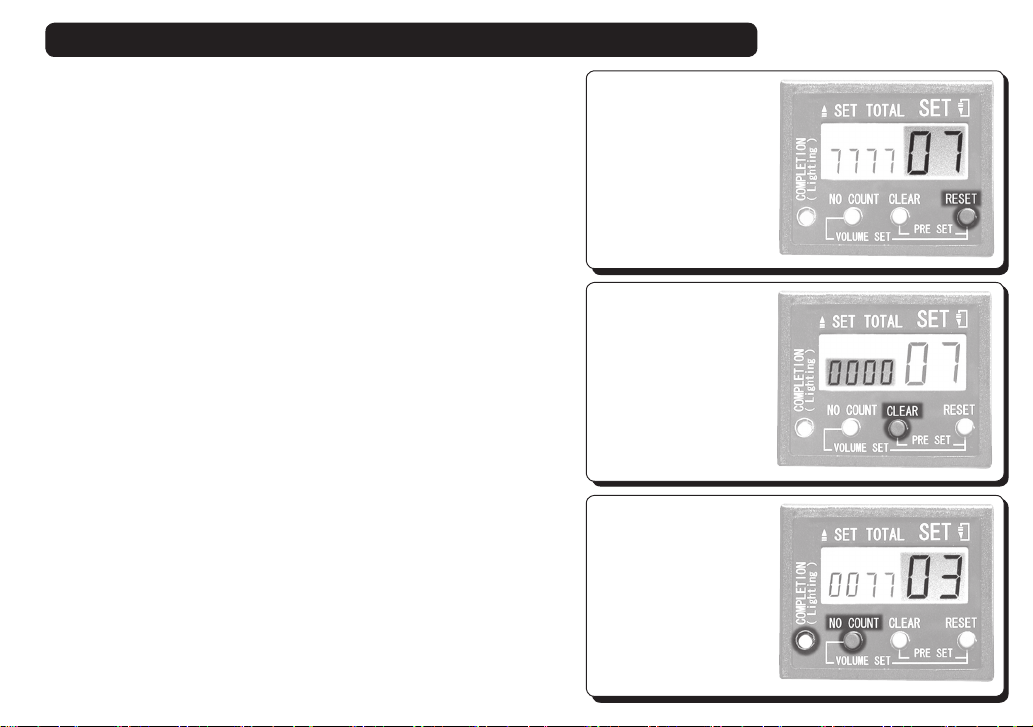

《Setting a set count → PRESET》

-You can set or change a set count when SET TOTAL is “0000”.

Clear the SET TOTAL eld. (See the next page.)

-You can set a single digit number by the RESET button (the right

PRESET button) and a tens digit number by the CLEAR button (the left

PRESET button).

-When you press down and hold on one of the PRESET buttons, the

buzzer beeps in about 2 seconds; another 2 seconds later, it beeps again

and the digit above the button will ashes on the LCD panel.

In this status, you can change (or set) a value on the digit, The value on

the digit changes each time you click the button.

-To set the value, just wait the value stops ashing,

You can use either of the PRESET buttons to set a value on the ashing

digit.

《Changing the sound volume → VOLUME SET》

-You can change the magnitude of beeping of the buzzer. Press both

VOLUME SET buttons (NO COUNT and PRESET buttons) at the same

time for about 4 seconds. The COMPLETION indicator ashes. Now you

can change the volume.

-The beeping volume changes in the order below by pressing the RESET

button while the COMPLETION indicator is ashing.

Minimum→Medium→Maximum→Mute→Minimum→Medium→….

-To set the beeping magnitude, wait untill the indicator stops ashing.

Turn on Automatic Screw Feeder and set or change counts while the screw feeder is at rest.

《PRE SET》

Set a set count.

《VOLUME SET》

Set a beeping

magnitude.

Setting on the panel before starting screw feeding