BrewTek Energy Saver ES Series User manual

Operating Instructions Energy Saver Automatic Series 1/15/12

Operating Instructions

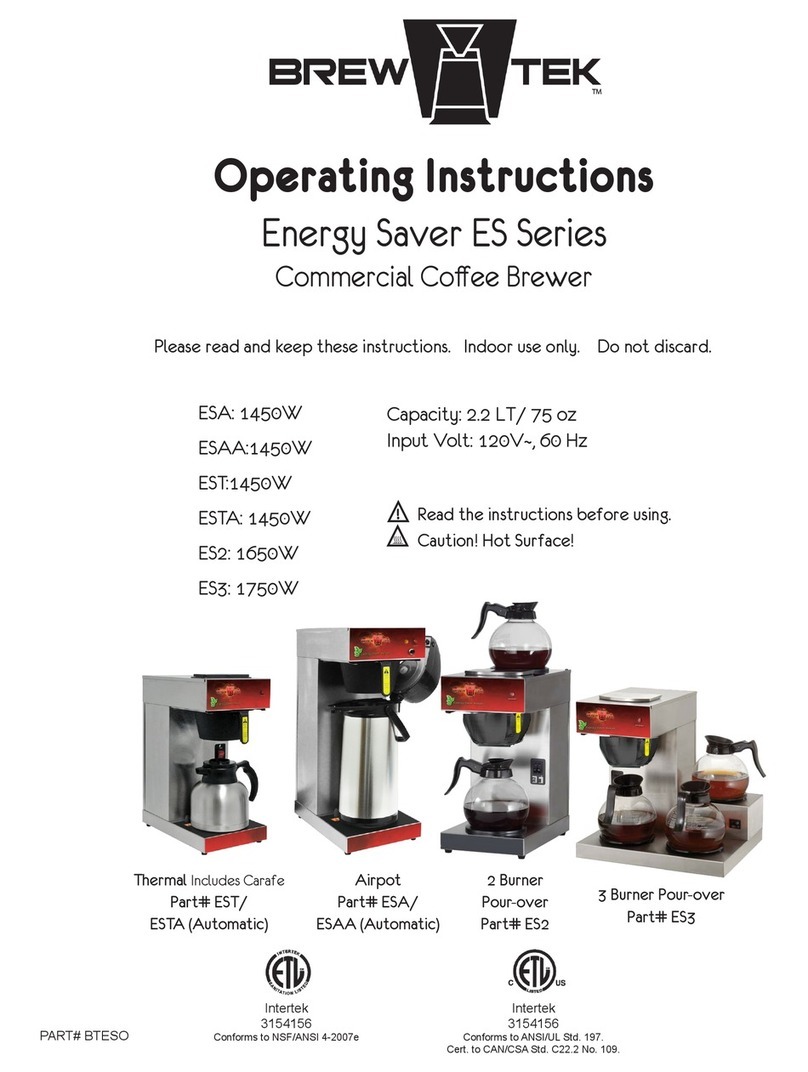

Energy Saver ES Series

Automatic Commercial Coffee Brewer

ESAA: 1450W

ESTA:1450W

Please read and keep these instructions. Indoor use only. Do not discard.

Read the instructions before using.

Caution! Hot Surfaces!

!

Part# ESTA

Includes Thermal Carafe TC19X

Airpot

Part# ESAA

Capacity: 2.2 LT/ 75 oz

Capacity: 1.9 LT/64 oz

Input Volt: 120V~, 60 Hz

Intertek

3154156

Conforms to NSF/ANSI 4-2007e

Intertek

3154156

Conforms to ANSI/UL Std. 197.

Cert. to CAN/CSA Std. C22.2 No. 109.

PART# BTESOA

1/15/12 Page 1 of 4

Airpot

Operating Instructions Energy Saver Automatic Series 1/15/12

WARNING!

• This coffee brewer is a professional type appliance, it must be operated by trained personnel.

• Remain in the vicinity of the machine while brewing.

• Never immerse the brewer in water. If brewer becomes wet, it must be dried and checked by a service technician before use.

• Never pour hot water, coffee, or other liquids into the water reservoir.

• Never pour more than 2.2 liters (75 oz.) of water into the Water Reservoir

• Do not disconnect brewer with wet hands and do not pull the power cord.

• When the brewer is in use, some parts of the machine will become VERY HOT. Ensure the power cord does not touch the hot parts.

The user should also be careful not to touch hot parts.

INSTALLATION

DO NOT PRE-FILL AUTOMATIC BREWERS

1. Place the machine on a solid surface with plenty of room above to allow easy and safe filling of the water tank if necessary.

2. Connect ESTA and ESAA to a potable water connection with a 3/4” BSP connector. A quality water filter is recommended. Water

line must have water pressure of between 20 and 90 PSI.

3. Plug machine into power.

4. Place an empty decanter at correct position under the filterbasket.

5. Turn the power switch ON. Press the brew button and the “Filling” indicator will light up.

6. When filling is complete the “Filling” light turns offand then the “Heating” indicator will light up.

7. HOT WATER should start to flow into decanter in approximately 90 seconds. (First brew will be short)

8. 3-4 minutes later, the “Heating” indicator light will turn offindicating the brewing process has ended. Do not remove vessel until

water stops flowing.

9. Adjust timer to set water level to either 1.9 or 2.2 liters.

10. You should repeat the above process twice to clean the internal parts of the machine before brewing coffee for first time.

11. During above operation, it is normal to hear some brewing and pumping sounds and to see some water vapor coming out of the

machine.

In case of water over flow, TURN-OFF the power switch immediately to STOP the brewing process.

• Allow water/coffee to continue to flow into decanter

• Empty decanter

• Replace under brewbasket

• Turn on power switch

• Brewer should continue thru its brewing cycle

OPERATION

• Remove filterbasket, and place a paper filter into the filterbasket. Put appropriate amount of coffee in the paper filter.

• Slide the filterbasket into position.

• Place the empty airpot or thermal carafe at the correct position under filterbasket.

• Turn the power switch ON. Press the brew button and the “Filling” indicator will light up.

• When filling is complete the “Filling” light turns offand then the “Heating” indicator will light up.

• Brewed coffee will start to flow into the decanter in approximately 90 seconds.

• When the “Heating” indicator light turns off, the brewing cycle has completed. Do not remove vessel until coffee stops flowing.

• Dispose of used coffee grounds and filter paper, rinse filterbasket in clean water.

Some water will always remain in the hoses and boiler of the machine. If the brewer should be moved or removed for service,

always pour out the remaining water.

!

!

Page 2 of 4

!

Operating Instructions Energy Saver Automatic Series 1/15/12

MAINTENANCE

Cleaning

It is important that the Brewer and its accessories be kept clean.

Clean with a soft damp cloth, and if necessary, with a non-corrosive and/or non-abrasive detergent or cleaner.

De-Liming

Hard water will cause calcium and limestone to accumulate in the boiler. To keep the Brewer in the best operating condition, it is

recommended that when brewer becomes slow to heat that a de-liming operation be carried out in the following manner:

1. Mix 64 oz. of de-liming solution per manufacturer’s directions.

2. Place filterbasket in proper position.

3. Place an empty decanter at the correct position under the filterbasket.

4. Pour de-liming solution into water reservoir. ( See parts list item 2)

5. Turn the power switch ON. DO NOT PUSH BREW BUTTON

6. Allow some solution to enter the decanter then turn the power switch OFF.

7. Wait 5-6 minutes, then turn the power switch ON. Allow 5-6 minutes for the unit to complete the brew cycle.

8. When the solution is no longer dripping out discard solution.

9. Some de-liming solution will remain in the brewer. Run at least 3 brewing cycles and discard all water generated.

1. Power Switch

2. Pour Thru Lid To Water Reservoir

3. Heating Indicator

4. Brew Chamber

5. Thermal Decanter or Airpot. (Separate purchase)

6. Filling Indicator

5

1

4

3

2

2

3

4

1

5

Page 3 of 4

6

6

Operating Instructions Energy Saver Automatic Series 1/15/12

SHIPPING DAMAGE CLAIMS PROCEDURE

NOTE: For your protection, the equipment in this shipment was carefully inspected and packaged by skilled personnel before leaving the factory.

Upon acceptance of this shipment, the transportation company assumes full responsibility for its safe delivery.

IF SHIPMENT ARRIVES DAMAGED:

1. VISIBLE LOSS OR DAMAGE: Be certain that any visible loss or damage is noted on the freight bill or express receipt, and that the note of loss or

damage is signed by the delivery person.

2. FILE CLAIM FOR DAMAGE IMMEDIATELY: Regardless of the extent of the damage.

3. CONCEALED LOSS OR DAMAGE: if damage is unnoticed until the merchandise is unpacked, notify the transportation company or carrier

immediately, and file “CONCEALED DAMAGE” claim with them. This must be done within fifteen (15) days from the date the delivery was made to

you. Be sure to retain the container for inspection.

Brew-Tek cannot assume liability for damage or loss incurred in transit. We will, however, at your request, supply you with the necessary documents

to support your claim.

WARRANTY DESCRIPTION

All electrical equipment manufactured by Brew-Tek is warranted against defects in materials and workmanship for a period of one year from the

date of original installation or eighteen (18) months from the date of shipment from our warehouse, whichever comes first, and is for the benefit of

the original purchaser.

WARRANTY EXCLUSIONS AND SERVICE POLICY

1. Resetting of safety thermostats, circuit breakers, overload protectors, or fuse replacements.

2. All problems due to operation at voltages other than specified on equipment nameplates; conversion to correct voltage must be the customer’s

responsibility.

3. All problems due to electrical connections not made in accordance with electrical code requirements and wiring diagrams supplied with the

equipment.

4. Replacement of items subject to normal wear, to include such items as knobs and light bulbs. Normal maintenance functions including adjustment

of thermostats, microswitches, and replacement of fuses and indicating lights are not covered under warranty.

5. All problems due to inadequate water supply, such as fluctuating, or high or low water pressure.

6. All problems due to mineral/calcium deposits, or contamination from chlorides/chlorines. De-liming is considered a preventative maintenance

function and is not covered by warranty.

7. Full use, care and maintenance instructions are supplied with each machine. Those miscellaneous adjustments noted are customer responsibility.

Proper attention will prolong the life of the machine.

8. Travel mileage is limited to sixty (60) miles from an authorized Service Agency or one of its sub-agencies.

9. All labor shall be performed during normal working hours. Overtime premium shall be charged to the customer.

10. All genuine Brew-Tek replacement parts are warranted for ninety (90) days from date of purchase. Any use of non-genuine Brew-Tek parts

completely voids any warranty.

11. Installation, labor and job check-out are not considered warranty.

12. Charges incurred by delays, waiting time or operating restrictions that hinder the service technicians ability to perform services are not covered

by warranty. This includes institutional and correctional facilities

THE FOREGOING OBLIGATION IS EXPRESSLY GIVEN IN LIEU OF ANY OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, WHICH ARE HEREBY EXCLUDED. Brew-Tek SHALL NOT BE

LIABLE FOR INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES FROM ANY CAUSE WHATSOEVER.

This warranty is void if it is determined that upon inspection by an Authorized Service Agency that the equipment has been modified, misused,

misapplied, improperly installed, or damaged in transit or by fire, flood or act of God. It also does not apply if the serial nameplate has been removed

or unauthorized service personnel perform service. The prices charged by Brew-Tek for its products are based upon the limitations in this warranty.

Seller’s obligation under this warranty is limited to the repair of defects without charge by a Brew-Tek Authorized Service Agency or one of its sub-

agencies. This service will be provided on customer’s premises for non-portable models. Portable models (a device with a cord and plug) must be taken

or shipped to the closest Authorized Service Agency, transportation charges prepaid, for services. In addition to restrictions contained in this warranty,

specific limitations are shown below (Additional Warranty Exclusions). This warranty is valid in the United States and void elsewhere.

www.BrewTekBrewers.com

Page 4 of 4

This manual suits for next models

2

Table of contents

Other BrewTek Coffee Maker manuals