-4-

16. Before tra sporti g o public roads, locate the machi e i to its tra sport positio as i structed i this

operators ma ual.

17. Never leave the tractor seat while the machi e is operati g.

18. Drive speed must be adapted to grou d co ditio s as well as roads a d paths.

Always avoid abrupt cha ges of directio .

19. Precisio steeri g, tractor adhere ce, road holdi g a d efficie t braki g are i flue ced by the type of

impleme t, weight, ballast of fro t axle, grou d or road co ditio s. It is therefore of utmost importa ce to be

cautious i every give situatio .

20. Be particularly cautious whe tur i g cor ers, payi g atte tio to machi e overha g, le gth, height a d

weight.

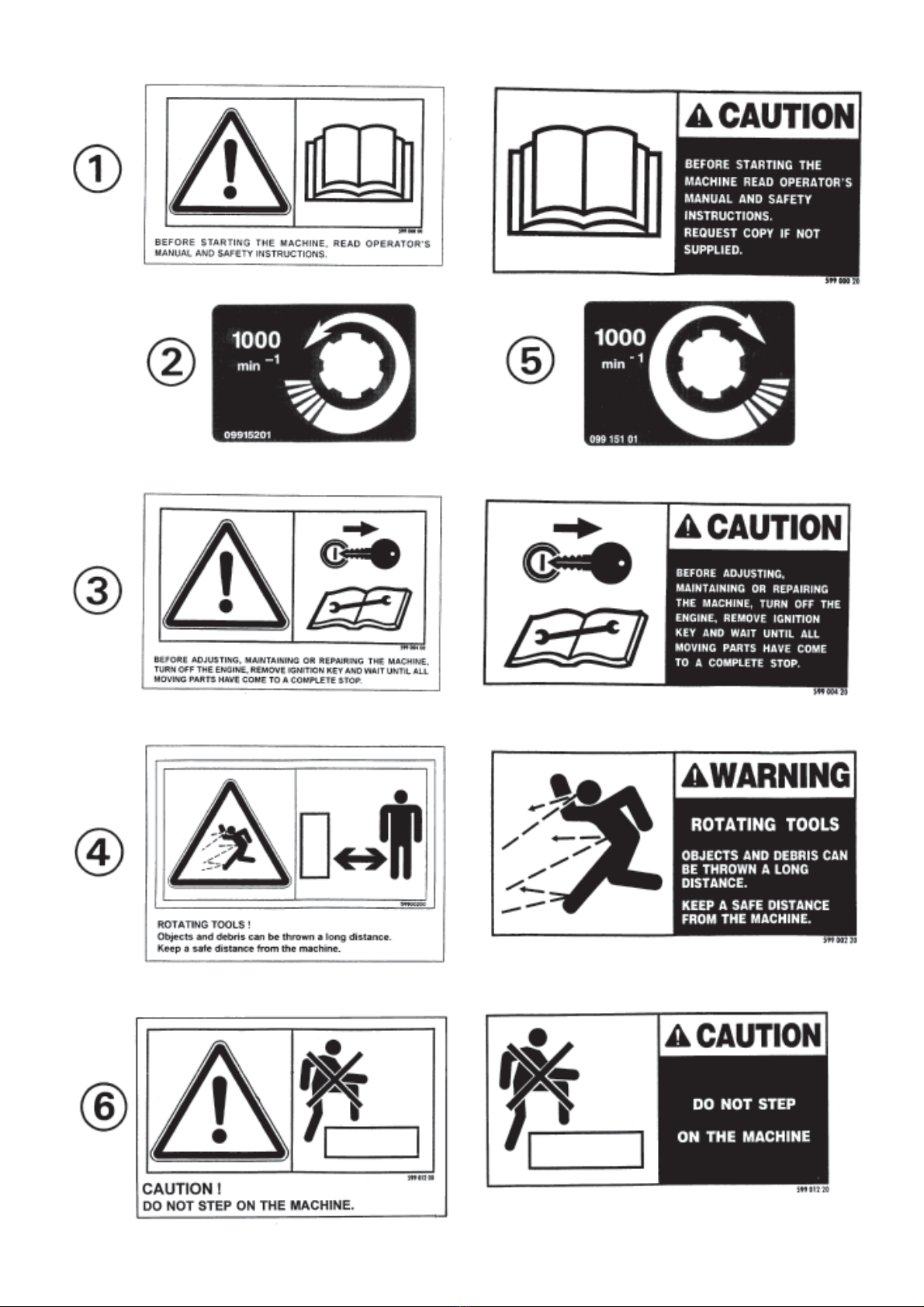

21. Before operati g the machi e, e sure that all safety guards are firmly i place a d i good co ditio . If wor

or damaged, replace immediately.

22. Before operati g the machi e, check tight ess of uts a d bolts, particularly o fixi g eleme ts (blades,

ti es, k ives, spades ...)

23. Keep clear of the machi e operati g area.

24. WARNING ! Da ger of crushi g a d sheari g ca exist whe compo e ts are operated by hydraulic or

p eumatic co trols.

25. Before leavi g the tractor or before adjusti g, mai tai i g or repairi g the machi e, tur off the e gi e,

remove ig itio key a d wait u til all movi g parts have come to a complete stop.

26. Do ot sta d betwee the tractor a d the machi e u less the ha d brake is tight a d/or stops have bee

placed u der the wheels.

27. Before a y adjustme ts, mai te a ce or repairs are carried out, e sure that the machi e ca ot be started

up accide tally.

ATTACHMENT

1. Whe attachi g or removi g the machi e from the tractor, positio hydraulic lift co trol lever i such a way that

it ca ot be set off accide tally.

2. Whe attachi g the machi e to tractor hydraulic li kage, e sure that diameter of li k pi s correspo ds to

diameter of ball joi ts.

3. WARNING ! Da ger of crushi g a d sheari g ca exist i the lifti g zo e of the tractor hydraulic li kage !

4. Do ot sta d betwee the tractor a d the machi e whe operati g the outer co trol lever of the lift mecha ism.

5. I tra sport, the machi e lift mecha ism should be stabilized by tractor tie rods to avoid floatatio a d side

shifti g.

6. Whe tra sporti g machi e e sure that it ca ot be lowered accide tally.