Index

1Safety Instructions.................................................................................................................................................3

1.1 Warnings ..........................................................................................................................................................3

2EC Conformity.........................................................................................................................................................3

3System Contents....................................................................................................................................................4

4Installation................................................................................................................................................................4

4.1 Hydraulic Installation...................................................................................................................................4

4.1.1 Electrolysis Cell........................................................................................................................................4

4.1.2 Temperature probe installation........................................................................................................5

4.2 Electrical Installation....................................................................................................................................5

4.2.1 Installation of Electrolysis Cell...........................................................................................................5

4.2.2 Installation of Temperature Probe ..................................................................................................5

4.2.3 External Controller Installation (Optional)....................................................................................5

4.2.4 Automatic Coverage Detector Installation (optional)..............................................................6

5Operation .................................................................................................................................................................6

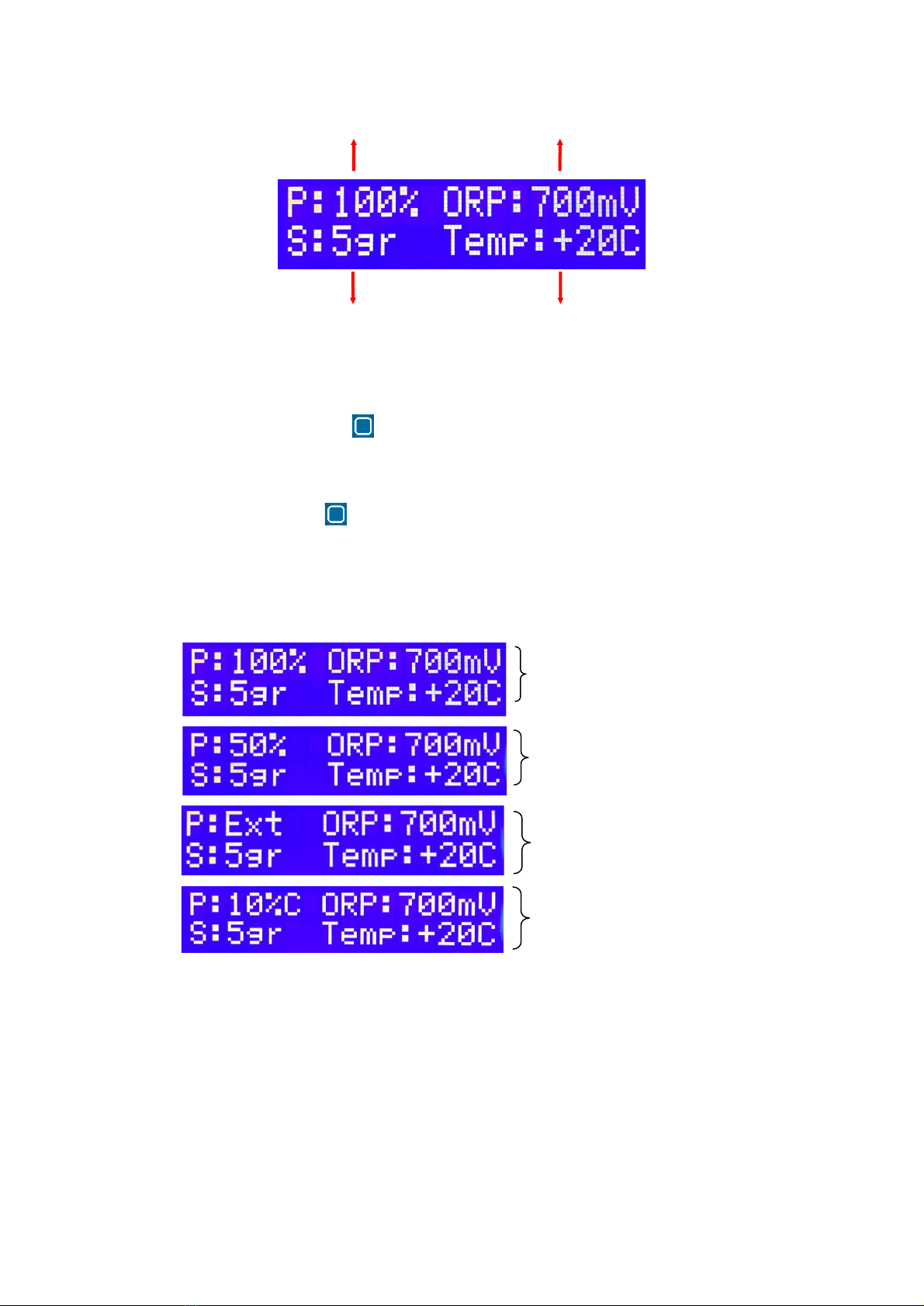

5.1 Control of Chlorine Production...............................................................................................................7

5.2 Operation with Temperature Probe ......................................................................................................7

5.3 Operation with Chlorine Probe (ORP) ..................................................................................................8

5.4 Operation with External Probe ................................................................................................................8

5.5 Operation with Pool Coverage................................................................................................................8

5.6 Low Salt Indication.......................................................................................................................................8

5.7 Disinfection Recommendations..............................................................................................................9

6Configuration and Calibration..........................................................................................................................9

6.1 ORP Calibration .......................................................................................................................................... 10

6.2 Setting ORP Limits..................................................................................................................................... 10

6.3 Polarity Inversion Setting........................................................................................................................ 11

6.4 Swimming pool volume configuration.............................................................................................. 12

6.5 Cell type setup ............................................................................................................................................ 12

7Alarms..................................................................................................................................................................... 12

7.1 Alarm 1 - Low Flow ................................................................................................................................... 12

7.2 Alarm 2A - High Salt................................................................................................................................. 12

7.3 Alarm 4 –Relay........................................................................................................................................... 13

7.4 Alarm 5 –Source........................................................................................................................................ 13

8Electrolysis Hour Totalizer............................................................................................................................... 13

9Terms and Conditions ...................................................................................................................................... 14

9.1 Copyright ...................................................................................................................................................... 14

9.2 Warranty........................................................................................................................................................ 14

9.3 Warranty Exclusions.................................................................................................................................. 14