Disconnecting Cables

1. Turn power “OFF” on all devices.

Note: If the fixture power is not turned “OFF” before

connecting or disconnecting the DMX cable to the

fixture, damage to the ballast may result.

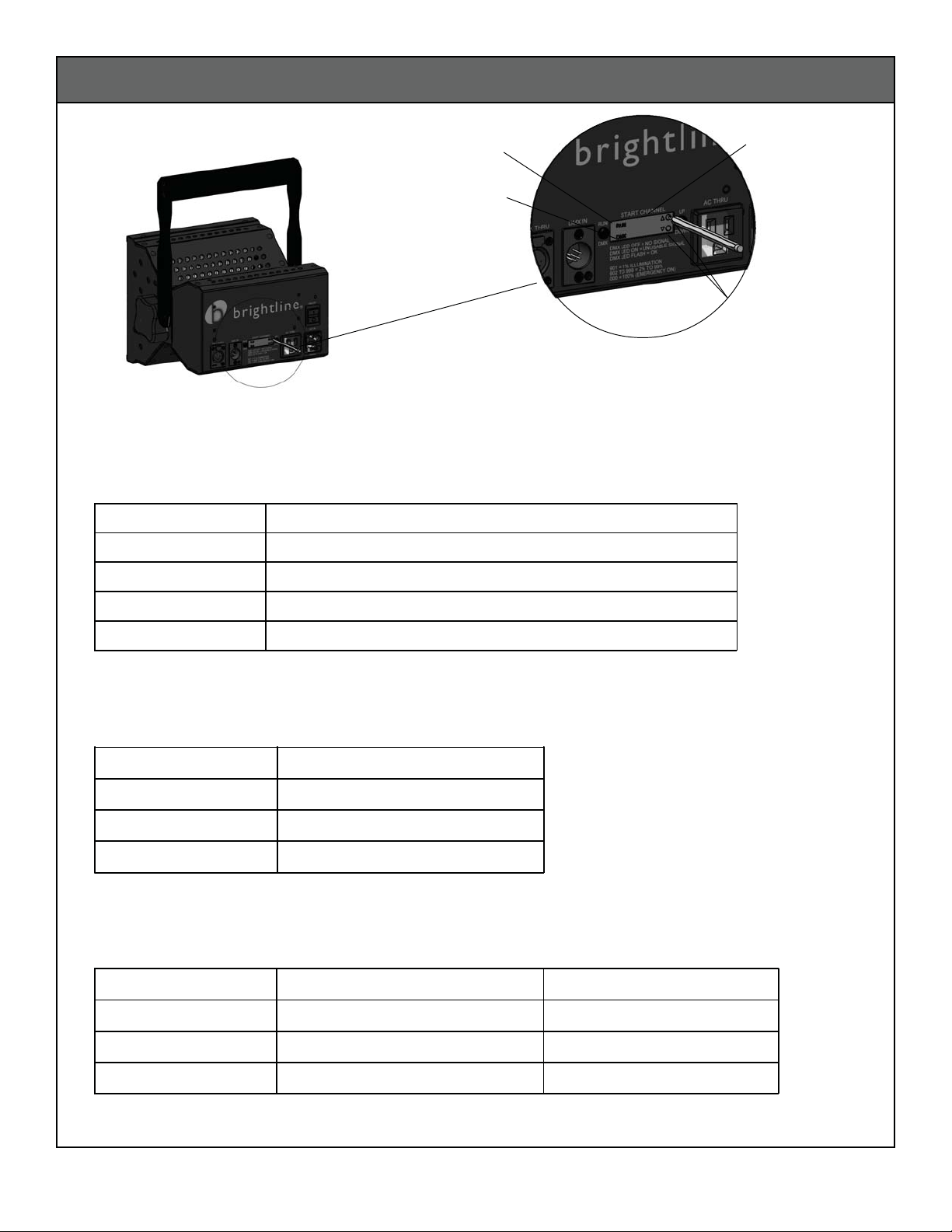

2. Insert the male plug end (Figure 1) into the appropriate

female receptacle on the lighting control console.

3. Line up the locking key on the female plug end (Figure 2)

with the male receptacle on the first fixture labeled

“DMX IN.” Insert the plug into the receptacle until it

locks into place.

4. To add additional fixtures, line up the locking key on the

male plug end of the jumper cable (Figure 1) with the

female receptacle labeled “DMX THRU” on the first

fixture. Insert the plug into the receptacle until it locks

into place.

5. Route the jumper cable to the next fixture.

6. Line up the locking key on the female plug end of the

jumper cable (Figure 2) with the male receptacle

labeled “DMX IN” on the next fixture. Insert the plug

into the receptacle until it locks into place.

7. Repeat Steps 4-6 for remaining fixtures.

8. Turn power “ON” on all devices.

Installing DMX Control Cables

Figure 5 Figure 6

3. To disconnect the male end of cable, press in the

release button on the female receptacle (Figure 5) and

pull the plug out of the receptacle (Figure 6). Pressure

should be applied to the plug, not the cables.

Figure 1 Figure 2

Locking Key

1. Turn power “OFF” on all devices.

2. To disconnect the female end of cable, press down the

release button on the plug (Figure 3) and pull the plug

out of the receptacle (Figure 4). Pressure should be

applied to the plug, not the cables.

Figure 3 Figure 4

8