SAFETY

31020340-BEnglish Manual

================================================================================================

• Ensure the combined weight of the towing vehicle (tow

vehicle weight + operator weight) is greater than the maxi-

mum towed weight of attachment (empty attachment weight

+ weight of load).

• Do not exceed maximum towing capacity of towing vehicle.

• Do not exceed maximum tongue weight of the vehicle.

• Do not use product without ratchet straps connecting product

and ATV/UTV.

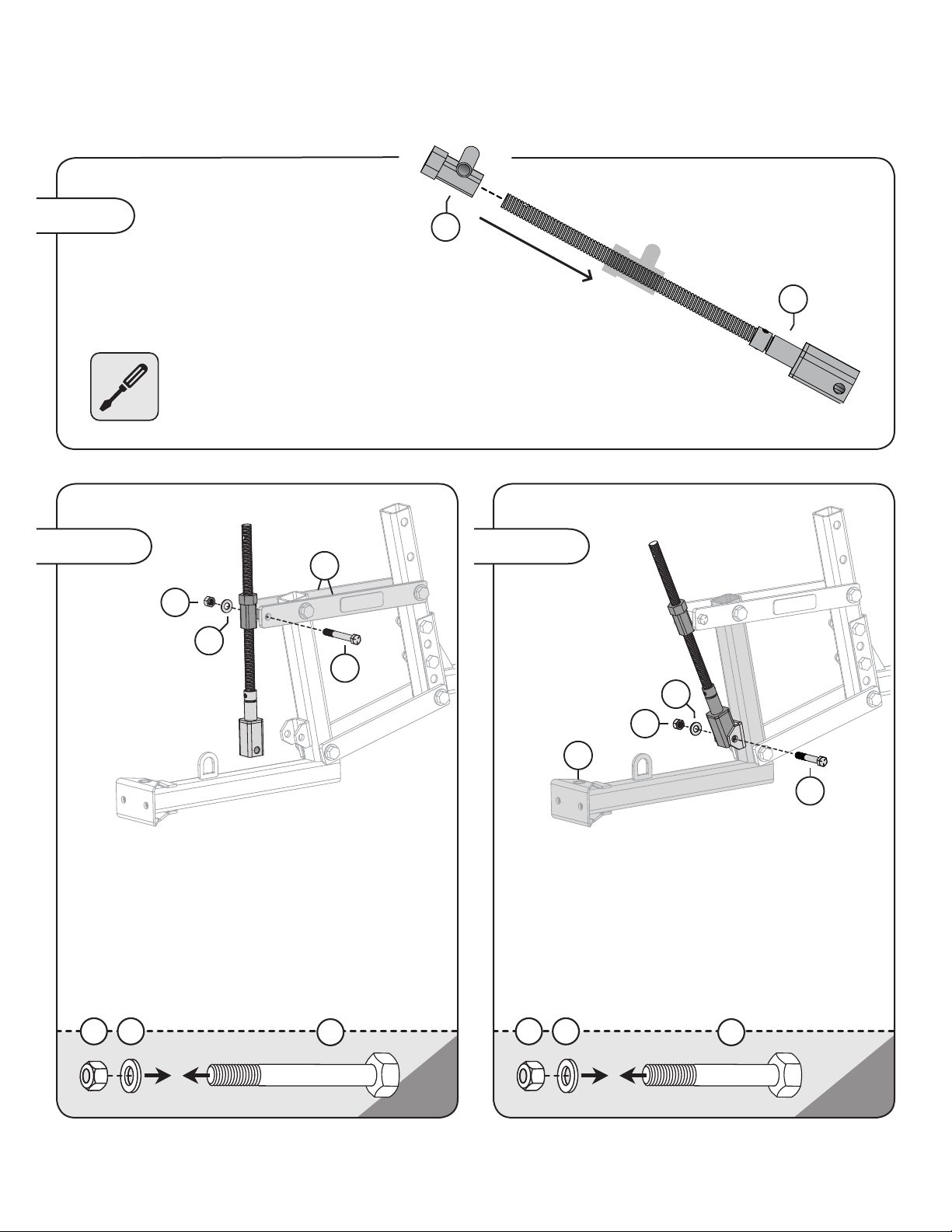

• Before each use the lead screw should be prepared with a

coat of light machine oil.

• Minimum recommended towing capacity of the ATV/UTV

to use the lift with is 1500 lbs.

• Do not exceed the maximum drawbar pull rating of the towing

vehicle. Drawbar pull is the horizontal force required to pull the

attachment (including weight of load).

• When an attached product is engaged with the ground, do not

exceed 5 mph. Do not exceed the speed called out by either

attached vehicle or product’s manual.

• Towing speed should always be slow enough to maintain con-

trol. Travel slowly and use caution when traveling over rough

terrain. Avoid holes, rocks and roots.

• Slow down before you turn and do not turn sharply.

• Use wide turning angles to ensure the attachment follows the

path of the towing vehicle.

• Do not use attachment on steep slopes. A heavy load could

cause loss of control or overturn attachment and towing vehi-

cle. Additional weights may need to be added to your vehicle;

check with towing vehicle manufacturer for recommendations.

• Reduce towed weight when operating on slopes.

• Keep all movement on slopes slow and gradual. Do not

make sudden changes in speed, directions, or turning.

• If you start and stop suddenly on hills, you may lose steering

control or the towing vehicle may tip.

• Do not start or stop suddenly when going uphill or downhill.

Avoid uphill starts.

• Slow down and use extra care on hillsides. Turf conditions

can aect vehicle stability. Use extreme caution while operat-

ing near drop-os.

• Do not drive close to creeks, ditches and public highways.

• Watch out for trac when crossing near roadways.

• Use care when loading or unloading the vehicle into a trailer

or truck.

• The attachment can obstruct the view to the rear. Use extra

care when operating in reverse.

• When reversing, carefully back-up straight to avoid jackknif-

ing. Do not allow towing vehicle wheels to contact attached

product. Damage could result.

• Stop on level ground, disengage drives, set the parking

brake, and shut o engine before leaving the operator’s posi-

tion for any reason including emptying the attachment.

• Use this attachment for intended purpose only.

• This attachment is intended for use in lawn care and home

applications. Do not tow behind a vehicle on a highway or in

any high speed applications.

• Do not tow at speeds higher than the maximum recommend-

ed towing speed of the vehicle or any attached product.

• Do not tow this product behind a motor vehicle such as a car

or truck.

• Always wear substantial footwear. Do not wear loose tting

clothing that can get caught in moving parts.

• Keep your eyes and mind on your towing vehicle, attachment

and area being covered. Do not let other interests distract you.

• Stay alert for holes and other hidden hazards in the terrain.

• Keep ratchet straps connecting the lift and attached vehicle

tight when in transport mode. Straps can be slightly loosened

once the attached product is engaged with the ground.

• Do not pick up unit from the inside four corners as it may

cause injury.

• Keep the towing vehicle and attachment in good operating

condition and keep safety devices in place.

• The towing vehicle and attachment should be stopped and

inspected for damage after striking a foreign object. Any dam-

age should be repaired before restarting and operating the

equipment.

• Keep all parts in good condition and properly installed. Fix

damaged parts immediately. Replace worn or broken parts.

Replace all worn or damaged safety and instruction decals.

Keep all nuts, bolts and screws tight.

• Do not modify the attachment or safety devices. Unauthorized

modications to the towing vehicle or attachment may impair

its function, safety and void the warranty.

• Always follow the instructions of the attached product and

vehicle’s manual.

GENERAL NOTES (Operation)

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Caution should be taken when towing and/or using any attachment. This

attachment combined with the weight distribution, turning radius, and speed of

towing vehicle can result in severe injury or death to operator, damage to towing

vehicle, and/or attachment if not used properly. Follow all towing safety precautions

noted in the towing vehicle owner’s manual, including the following precautions: