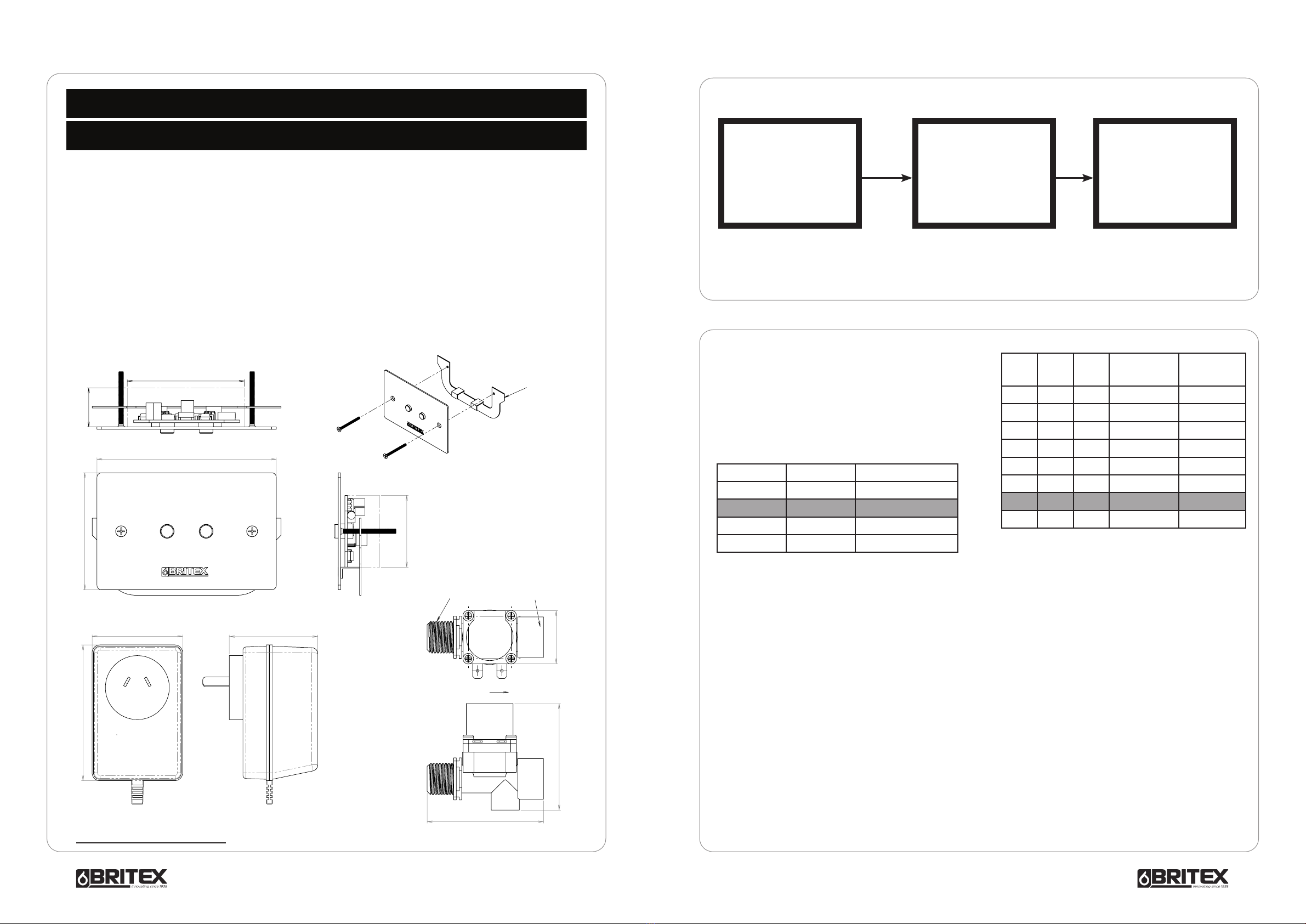

AESW

Wall Mounted Sensor*

(as provided with TW-WMS)

Installation

and Cleaning

Guide

MELBOURNE

Britex Place Mirra Crt

Bundoora VIC 3083

t(03) 9466 9000

evic@britex.com.au

SYDNEY

16 Northumberland Drv

Taren Point NSW 2229

t(02) 9531 2100

ensw@britex.com.au

PERTH

Unit 1/8 Principal Link

Malaga WA 6090

t(08) 9249 5464

ewa@britex.com.au

BRISBANE

19 Manilla St

East Brisbane QLD 4169

t(07) 3363 2400

eqld@britex.com.au

ADELAIDE

The Britex Group

SA State Office

t1300 764 744

esa@britex.com.au

Care and MaintenanceTrouble Shooting Guide

Stainless steel products should be kept clean at all

times. The secret to stainless steel’s ability to maintain

a high quality finish and promises of a long life

expectancy is the invisible chromium-oxide film that

sits on the surface and protects the steel beneath.

To maintain this film it is essential that the surface

remains clean and in constant contact with oxygen.

If this film is penetrated (either by abrasion or

chemically) and dirt, liquid, grime contaminants embed

themselves in these micro chasms for an extended

period of time, the chromiumoxide film will not be

able to regenerate and the steel below will eventually

become damaged and discoloured.

What we recommend for general cleaning and

maintenance:

Cleaning Materials:

• A soft cloth

• A soft-bristled brush

• A natural or artificial sponge

Cleaning Solutions:

• Hand washing soap / soft water solution

• Mild soap / soft water solution

• White vinegar / soft water solution

It is recommended that general cleaning of stainless

steel surfaces be carried out weekly, or as soon as

a build up of surface media has been observed. To

clean, simply wash stainless steel surfaces with, warm,

diluted, mild soapy water using a cloth or soft bristled

brush. Once all dirt, oil and grime is removed, rinse

thoroughly with clean water and wipe dry

Do NOT – use a metal brush or steel wool to clean

stainless steel. Ever. These tools will scratch the surface

as well as potentially leave behind steel fragments that

can go rusty and cause the stainless to discolour.

Using these materials will void the warranty.

Do NOT – use scourers of any kind that have previously

been used on ordinary steel. Microscopic steel fibers

transferred onto stainless steel can cause considerable

damage to the surface and will void the warranty.

Do NOT – use abrasive cleaning brushes, pads or agents

on highly polished finishes

Do NOT use harsh cleaners that contain powerful acidic

or alkaline chemicals such as hydrochloric acid and

sodium hydroxide that will damage the surface.

Any water coming into contact with stainless steel,

particularly cleaning solutions, should have zero

chloride content as even minute amounts can cause

damage. Using these cleaners will void any product

warranty.

Do NOT – use chlorinated sanitizers, cleansers or

bleach of any kind. Using these substances will void

the warranty. Despite some cleaners displaying the

text, ‘Suitable for Toilets and Urinals’ this is more likely

in reference to ceramic /vitreous China products and

use of these cleaners can damage stainless steel and

will void the warranty.

Do NOT – use brick cleaning liquids that contain

hydrochloric acid anywhere near stainless. If cement

needs to be removed from stainless (before it sets),

a mixture of hot water and 25% vinegar or 10%

phosphoric acid can be effective. Once cleaned,

the surface should then be neutralised with dilute

ammonia or sodium bicarbonate then rinsed and dried.

Australia’s Finest Stainless | britex.com.au

4

*Please note this item is

pre-programmed to trip and

run setting as per these notes.

Wave on/ Wave off models are

special order.

PLEASE NOTE: A SERVICE CHARGE WILL

BE MADE IF A SERVICE CALL IS REQUIRED

TO ATTEND TO A FAULTY OR CARELESS

INSTALLATION .

FOLLOW THIS PROCEDURE CAREFULLY.

Once it is established that the unit has not been

damaged at installation, first, turn the power to the

unit off & then back on.

In the event that on site trouble shooting does not clear

or rectify any problems that you are experiencing, then

it may be necessary to return the unit for appraisal and

corrective action. Feedback from the field is important

to enable us to improve and refine the product.

Once you have an understanding of what the problem is,

contact your distributor or Trade Store to enable a quick

resolve of these issues.

All parts are proudly manufactured and assembled in

Australia and distributed by the Britex Group.

A. If there is no flow when a hand is

waved past close to the sensor lens;

I. Check the power point is good and that the power

is on.

II. Check the water supply cock/s is on.

III. Place the palm of your hand directly in front &

parallel to the front face of the sensor, about 10 cm

away. Move your hand slowly towards the sensor,

keeping the palm of the hand flat, directly in front

& parallel to the front face of the sensor. If the unit

fails to oeprate even when brought up onto the sensor

replace the sensor unit.

IV. Replace the Power Pack (Power pack failures are

rare).

A. Occasionally;

I. The sensor may have become insensitive and be

difficult to operate. If it will operate when a flat surface

eg. white paper is passed very close to it, directly in

front and parallel with the lenses, but not a moving

hand, then replace the sensor unit.

A. If the unit appears stuck on and

water runs continuously where it has

not been activated by passing the hand

to wave it on and will not turn off by

waving your hand past the lens;

I. Turn the power off.

If water continues to flow then the solenoid valve is

at fault. It may be installed around the wrong way or

have debris under the seat. Check that the valve is

installed correctly for supply. If OK, consider taking

the valve apart & check for debris under the plunger

& diaphragm etc. Contact your distributor for advice.

Or If flow stops, check the sensor unit.

Q. Does the water flow at all?