Britex TP6 User manual

Other Britex Outdoor Fountain manuals

Britex

Britex Dado DDR2-HFBF User manual

Britex

Britex DDR1-D User manual

Britex

Britex DIWR User manual

Britex

Britex DVR User manual

Britex

Britex Dado DDS2 User manual

Britex

Britex Dado DDS1-D User manual

Britex

Britex DPDF User manual

Britex

Britex DDR1-S User manual

Britex

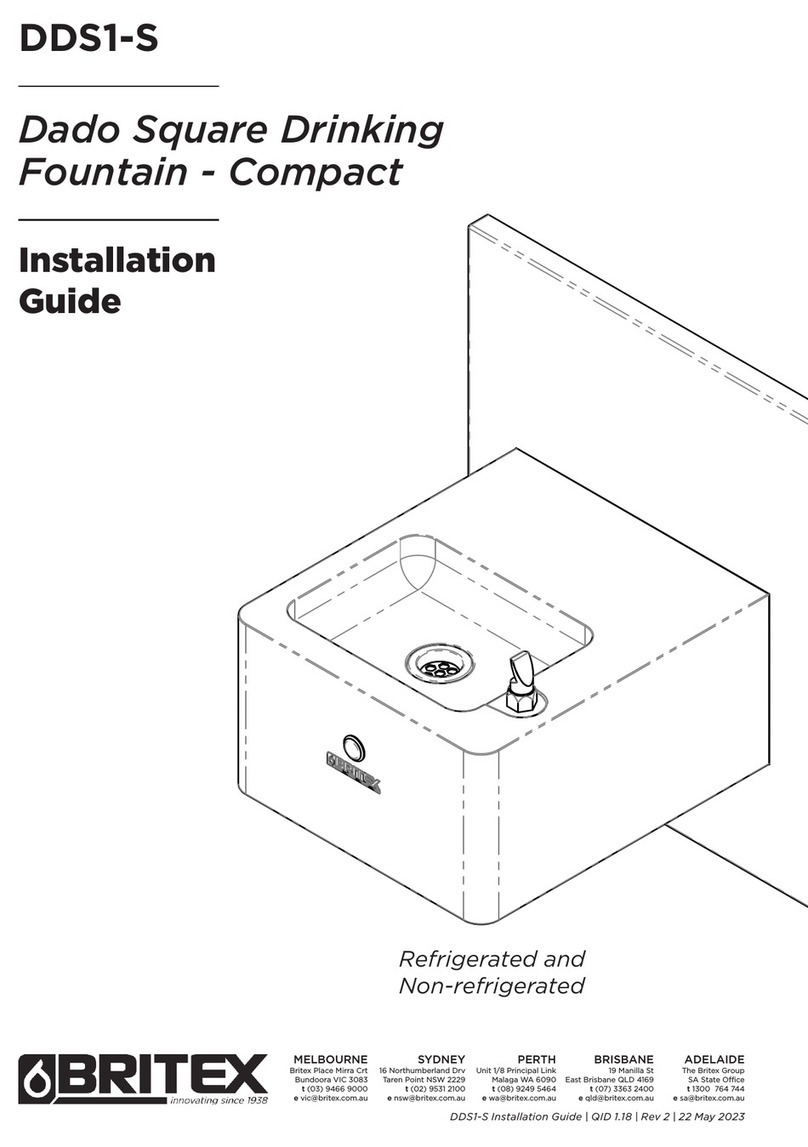

Britex Dado Square Drinking Fountain Compact User manual

Britex

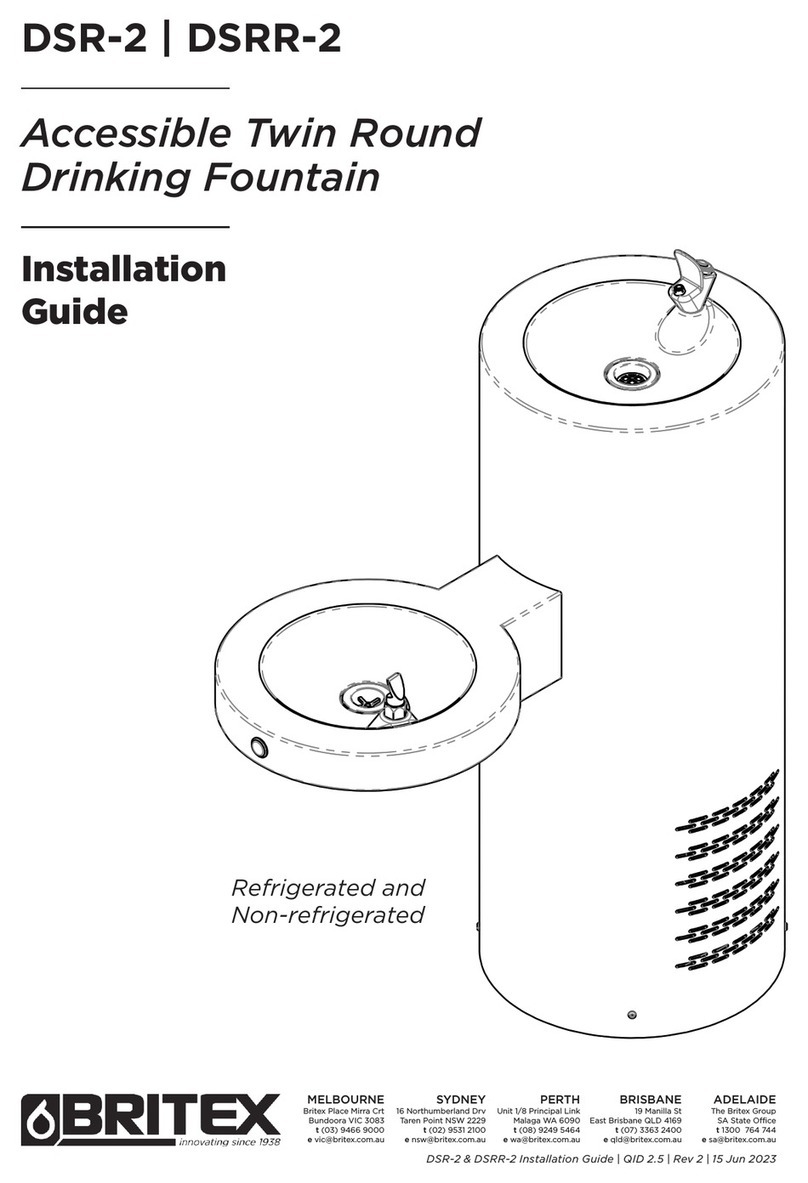

Britex DSR-2 User manual

Popular Outdoor Fountain manuals by other brands

Profi-pumpe

Profi-pumpe FELS-ZAUBER operating instructions

Hasley Taylor

Hasley Taylor 2501A owner's manual

Sunnydaze Decor

Sunnydaze Decor XSS-578 Assembly instructions

Campania International

Campania International Bibendum FT-400 Assembly instructions

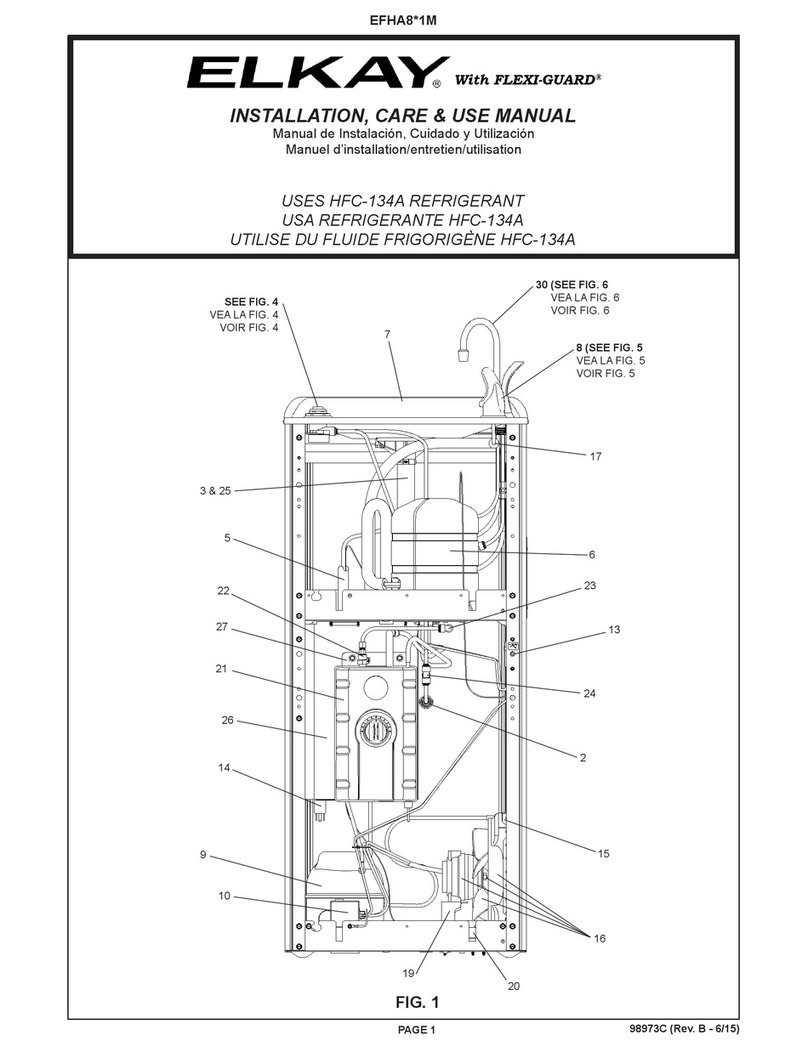

Elkay

Elkay FLEXI-GUARD EFHA8 1M Series Installation, care & use manual

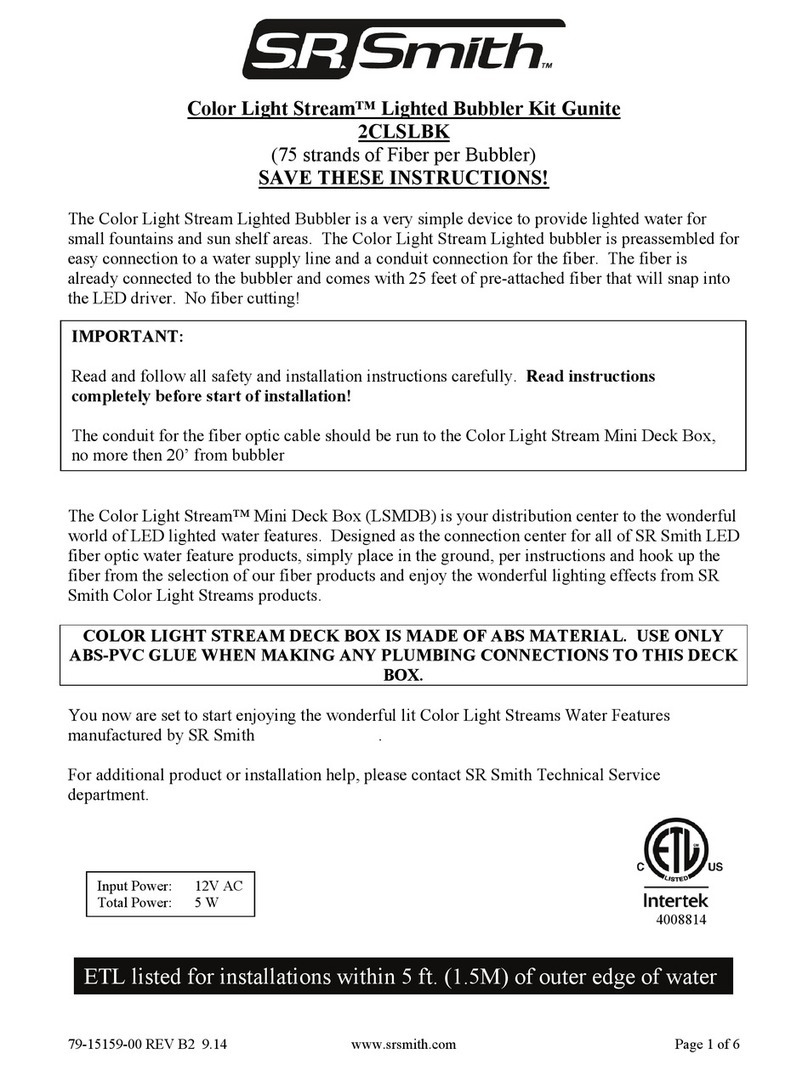

S.R.Smith

S.R.Smith Color Light Stream 2CLSLBK instructions

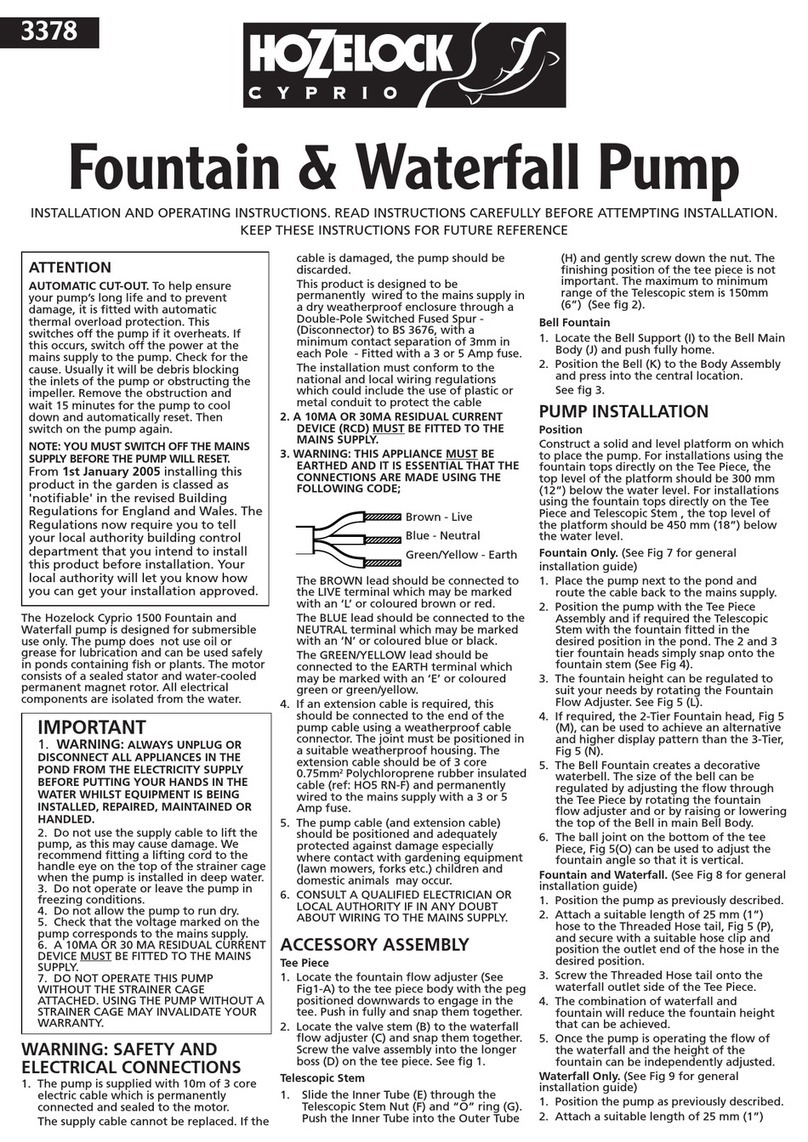

Hozelock Cyprio

Hozelock Cyprio Cascade 1500 Installation and operating instructions

Campania International

Campania International Juliet Fountain quick start guide

Alpine

Alpine WIN732 quick start guide

Campania International

Campania International FT-320 Assembly instructions

Kelkay

Kelkay Easy Fountain Rustic Windmill instructions

Alpine

Alpine WIN258 manual

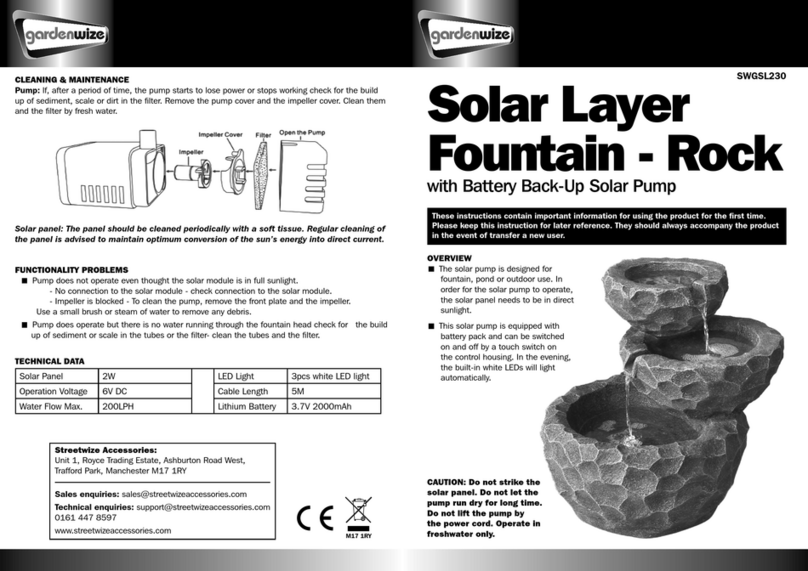

GardenWize

GardenWize SWGSL230 quick start guide

EasyPro

EasyPro Tranquil Décor HBB39 installation instructions

Campania International

Campania International Girona FT-102A Assembly instructions

Campania International

Campania International FT-271 quick start guide

Campania International

Campania International Bilbao GFRCFT-1111 Assembly instructions

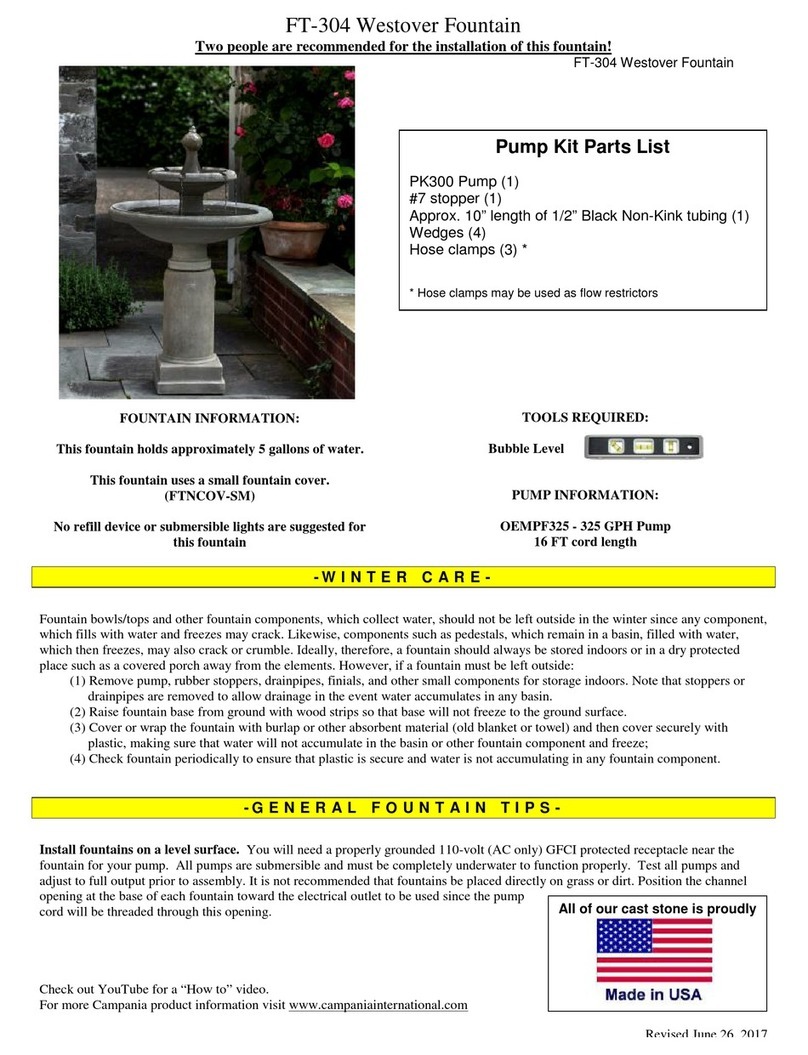

Campania International

Campania International Westover manual