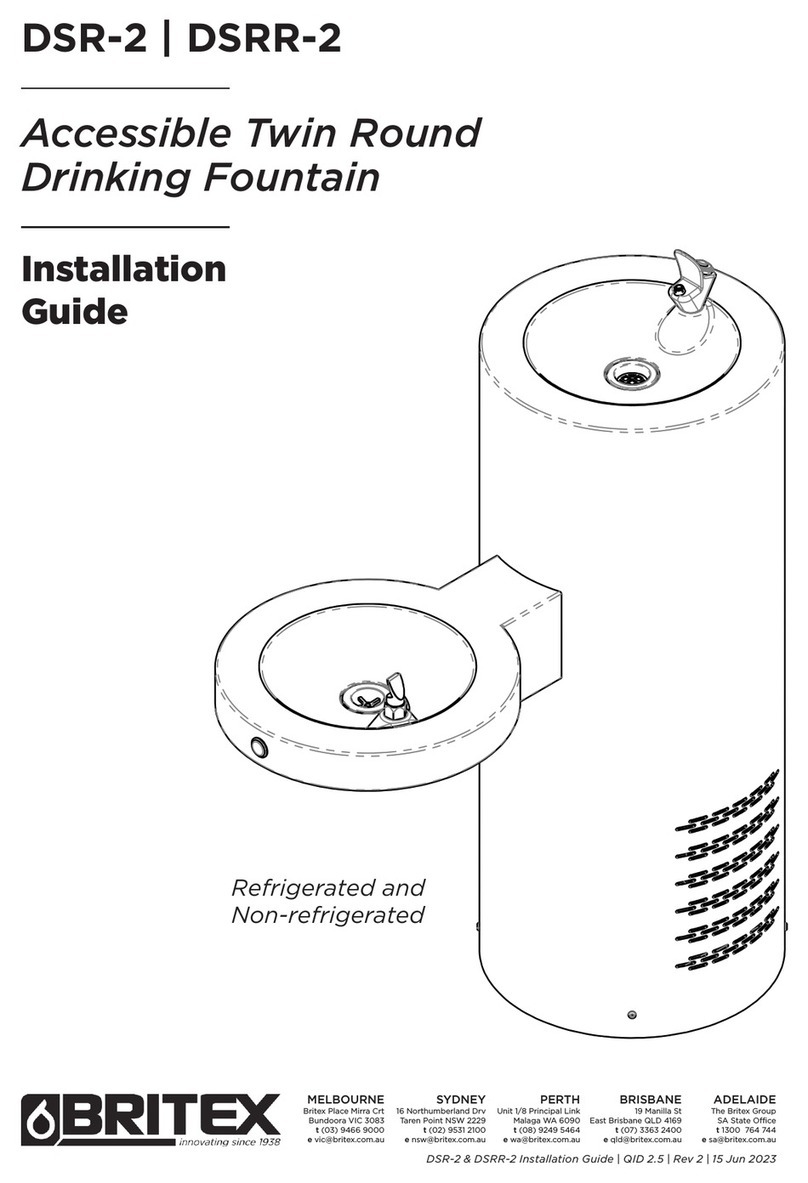

Australia’s Finest Stainless | britex.com.au

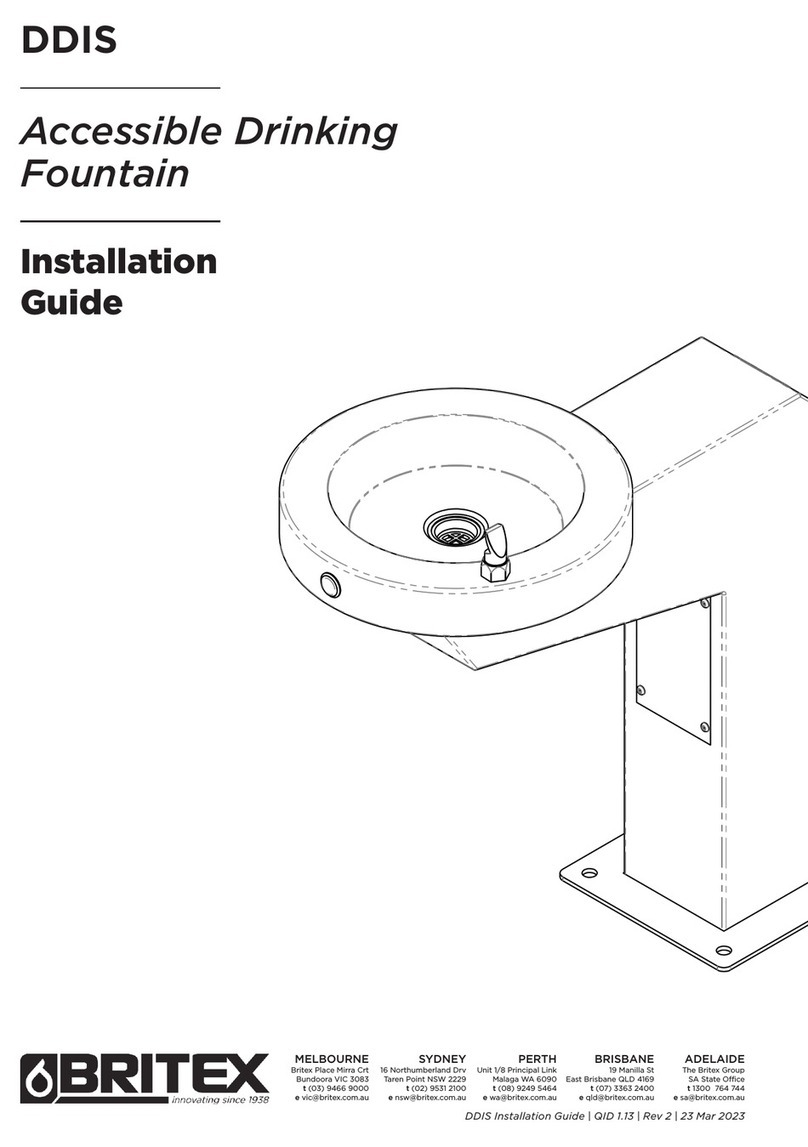

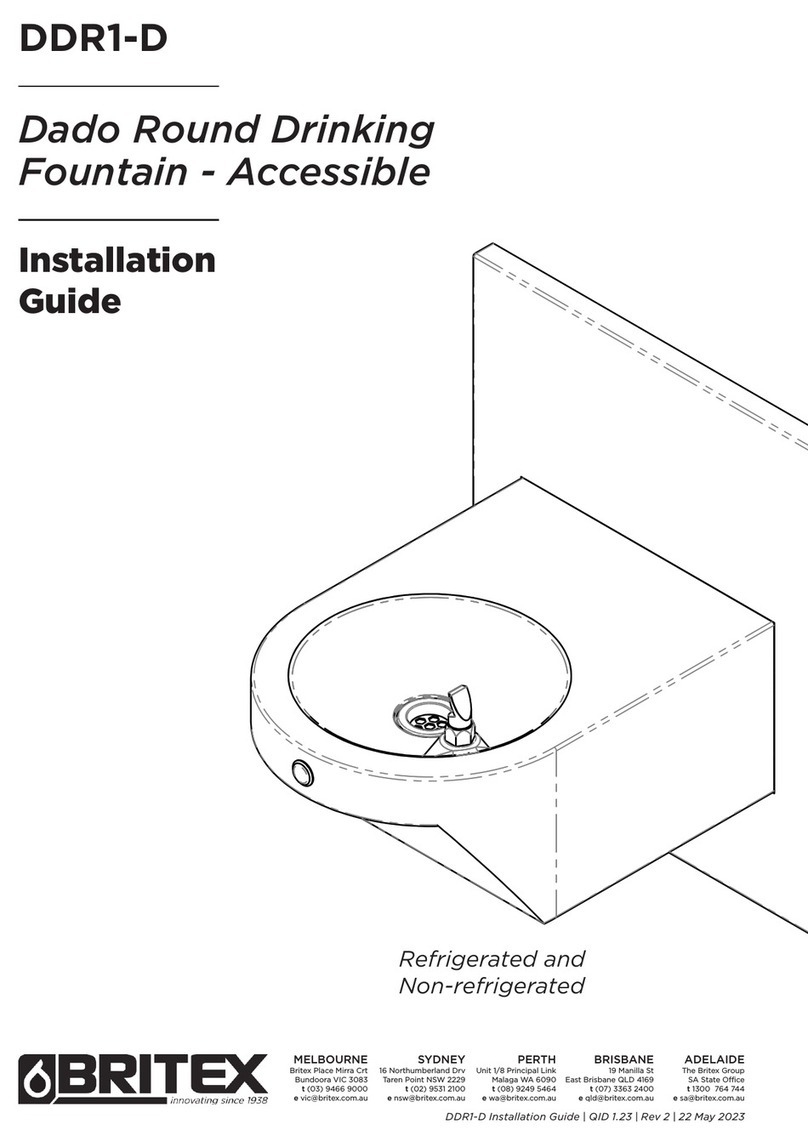

Installation Instructions

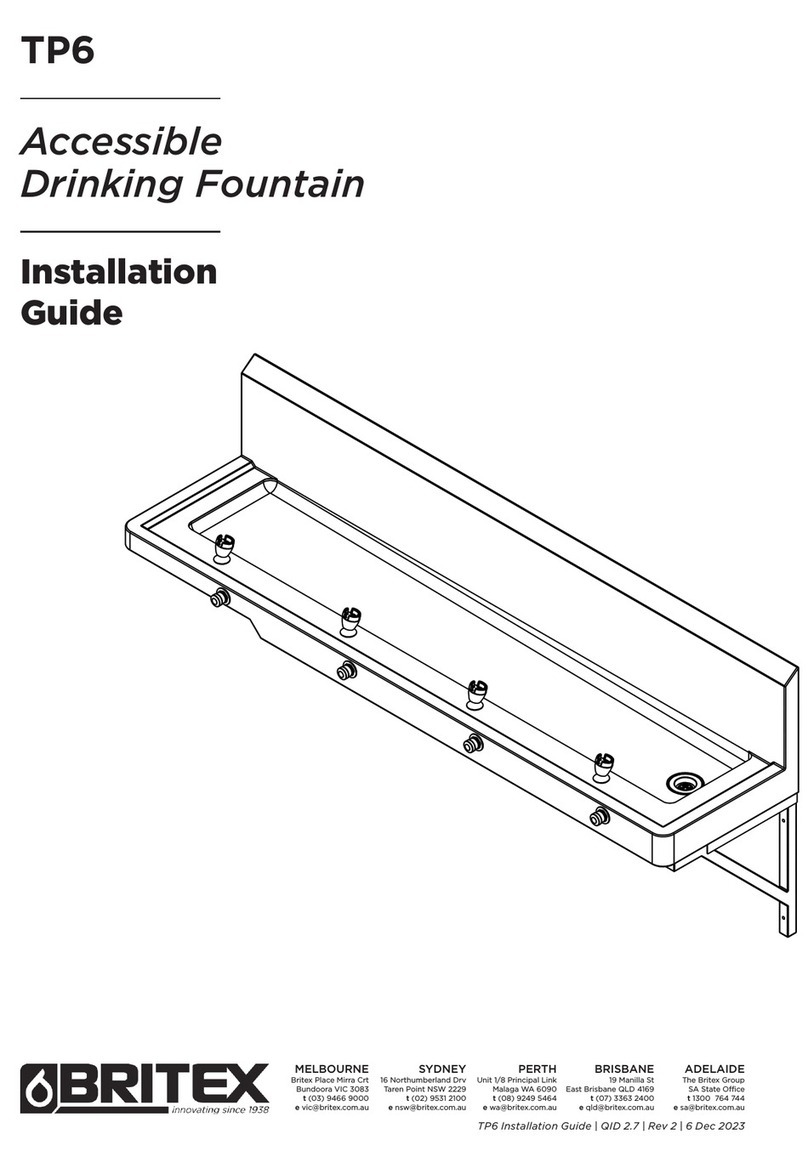

1. Place unit on wall and mark the top to ensure you have the drinking fountain at the

correct height for AS 1428.2, the assessable basin needs to be between 695-700 mm from

the floor to comply.

2. One you have marked the joggle strip location, measure where the bottom strip needs to

be on the wall, then fix both to the wall.

3. Place unit on the top of the joggle strip while holding the bottom of the unit away from

the bottom fixing angle. Ensure you have at least two people assisting in this task.

4. Push the bottom of the unit over the bottom fixing strip and insert the bottom fixing

screws.

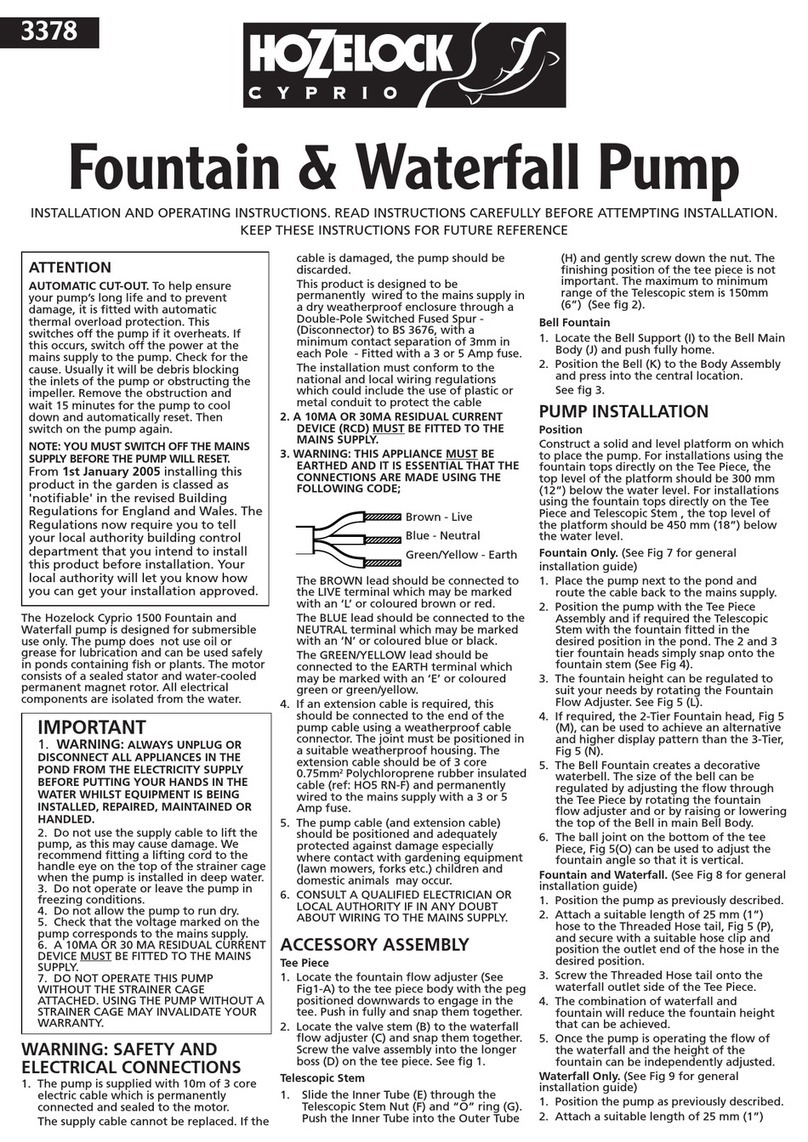

5. Remove the inspection plates on the two basins and plumb up the wastes for all three

units. Connect the basins and bottle filler to the mains pressure, according to the correct

Plumbing Code or Standard.

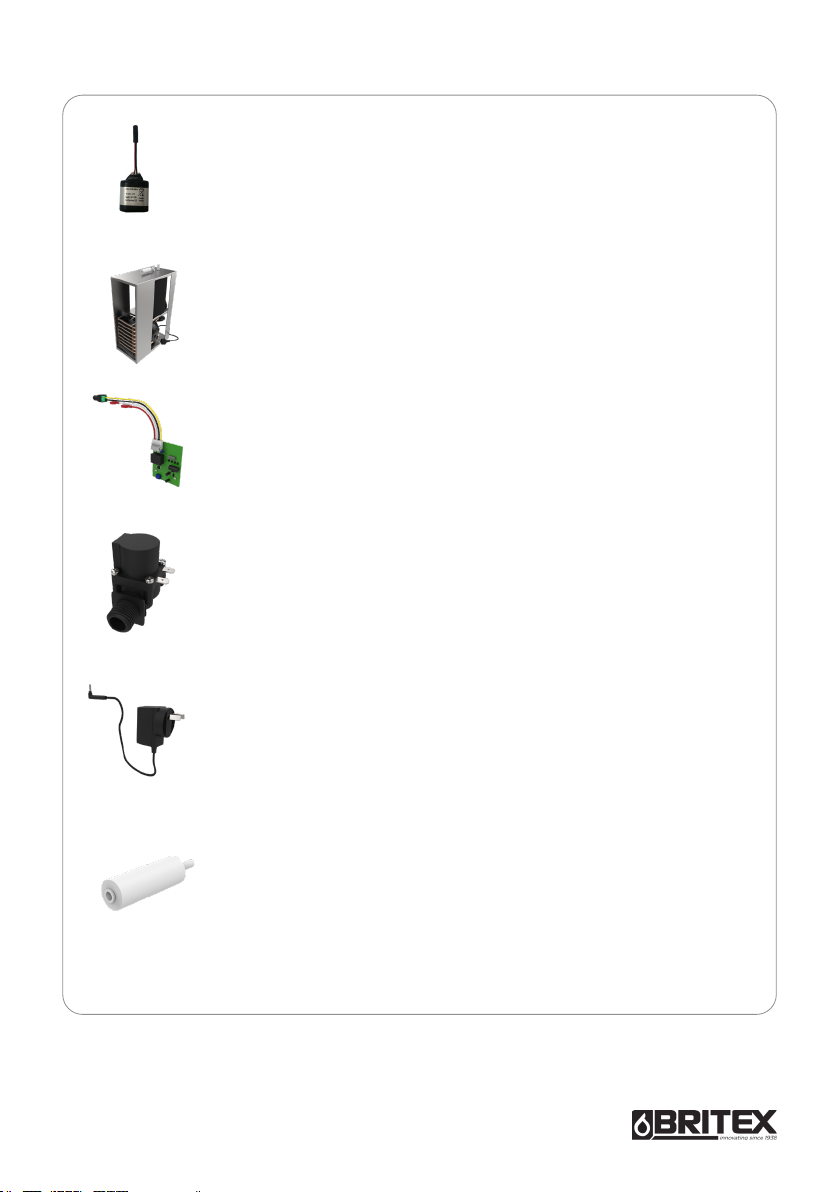

6. Plug in transformer of sensor into the GPO to set up.

7. Once everything is connected, then you need to ensure all the fittings are watertight and

the bottle filler and drinking fountain are working to the desired degree.

Note: GPO required for bottle filler and refridgerated version. Drinking Fountain is battery

operated

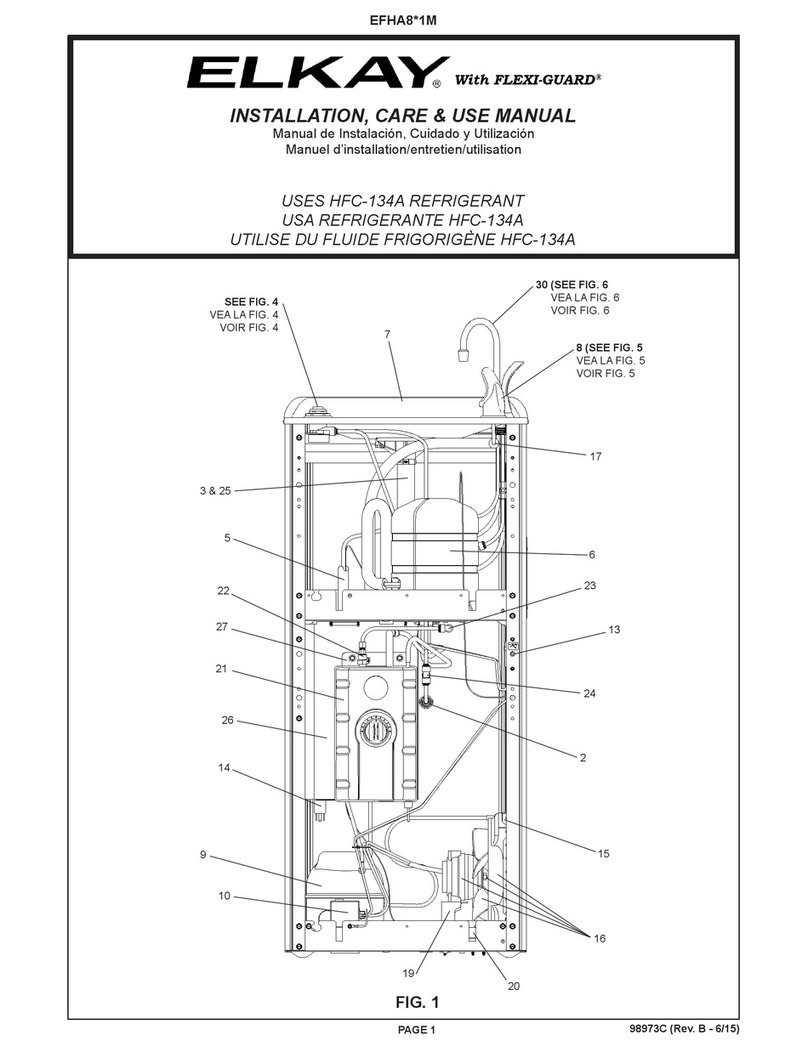

If you have ordered a refrigeration model, then below is the other steps that need to be

carried out.

1. 1. Place the refrigeration unit in the cavity, ensure there is a 10-amp standard power

outlet.

2. This unit to be installed in a cavity not less than 700mm wide. A vent should be installed

adjacent to the fan aperture. The remote unit must have 25mm at front and back of the

unit, the unit can be installed flush against either side wall of the cabinet.

3. Unit is ‘remotely’ located whether that’s in a cupboard space with adequate ventilation

or in a janitorial/services room ideally adjacent to the fountain.

4

PLEASE NOTE:

This unit is preset and locked to flow for 7 seconds and cannot be adjusted.

PLEASE READ: This unit has an automatic 24 hour purge setting (hygiene rinse) to

remove any stagnant water. This will reduce the amount of metals that may leach into the

water from the plumbing system, and assist in minimising the growth of bacteria such as

Legionella. This function is activated at the time the unit is first live (switched on). The unit

will then automatically flush at this time if the unit has been inactive for 24 hours.

PLEASE READ: If this unit is preplumbed with your product please note that it has been

tested and to flow for 7 seconds and will be installed with a blue ring.

PLEASE READ: Ensure all supply lines are flushed thoroughly to remove debris prior to the

installation. Strainers are recommended if debris is an ongoing problem.

DDR2-HFBF & DDR2-R-HFBF Installation Guide | QID 3.9 | Rev 2 | 25 Oct 2023