Allegion (UK) Limited

35 Rocky Lane, Aston, Birmingham B6 5RQ

T: +44 (0) 330 8080 617

DOOR CONTROLS

Overhead Closers

1110

1110.S

DATASHEET DC-003

ISSUE DATE: June 2021

Introduction

Briton 1110 is an industry leading

compact, template adjustable size

EN 2-4 medium duty door closer

suitable for living accommodation

and commercial spaces. Available

with simple trimplate cover or softline

all-over cover to conceal fixings and

adjustment screws.

Certification

CE Marked to EN 1154 (2812-CPR-AD0033)

UKCA Marked to EN 1154 (1121-CPR-UK-AD7580)

Fire tested to EN 1634-1 for use on fire doors up to 2hr timber / 4hr steel [* May be

fitted to fully insulated steel based doorsets or uninsulated steel based doorsets

where the closer is fitted to the fire risk face only].

Certifire Approved (CF388)

Environmental Product Declaration in accordance with ISO 14025 and EN 15803

DoP available at www.britondops.co.uk

Features & Functions

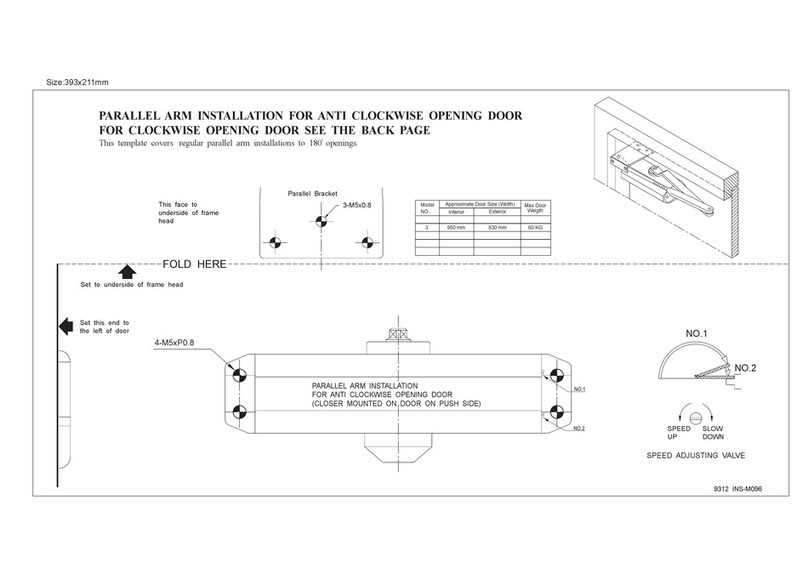

Template adjustable closing

power size EN 2-4 (regular) EN 3

(parallel arm) applications

Certified for door mount, transom

and parallel arm applications

Cast aluminium body

Adjustable closing speed and

latch action

Universal fittings for door mount,

transom and parallel arm mount

Fitting template for quick,

accurate installation

Screw thread armset in forged

steel for additional strength and

durability (supplied with trimplate

variants)

All-over cover variants supplied

with flatform arm pack

Snap joint arm connection for quick

and easy installation and

maintenance

Trimplate option a cost eective

means of concealing fixing and

adjustment screws

Suitable for fire door applications

Optional hold-open armset (not

to be used on fire doors)

Available in a choice of sprayed

finishes and plated cover and arm

options

Options with Softline (S) cover shown in Satin

Stainless Steel finish.

1110.S.SSS

1110.SES

*