2130B

2130BD

General Maintenance

Door controls

In research, Allegion has identified

that 95% of all problems associated

with overhead door closers can

be attributed directly to errors in

installation rather than problems with

the door closer itself. If the door is not

closing properly into the frame you

should first disconnect the door closer

(disconnect the arm(s)) and determine

that there is not an underlying problem

with the door, frame or any smoke /

draft seals that might be fitted.

PLEASE NOTE:

The power of the door closer should

not be used to overcome problems

associated with the door or other

items of hardware fitted to it.

Under no circumstances should the

closer body be dismantled.

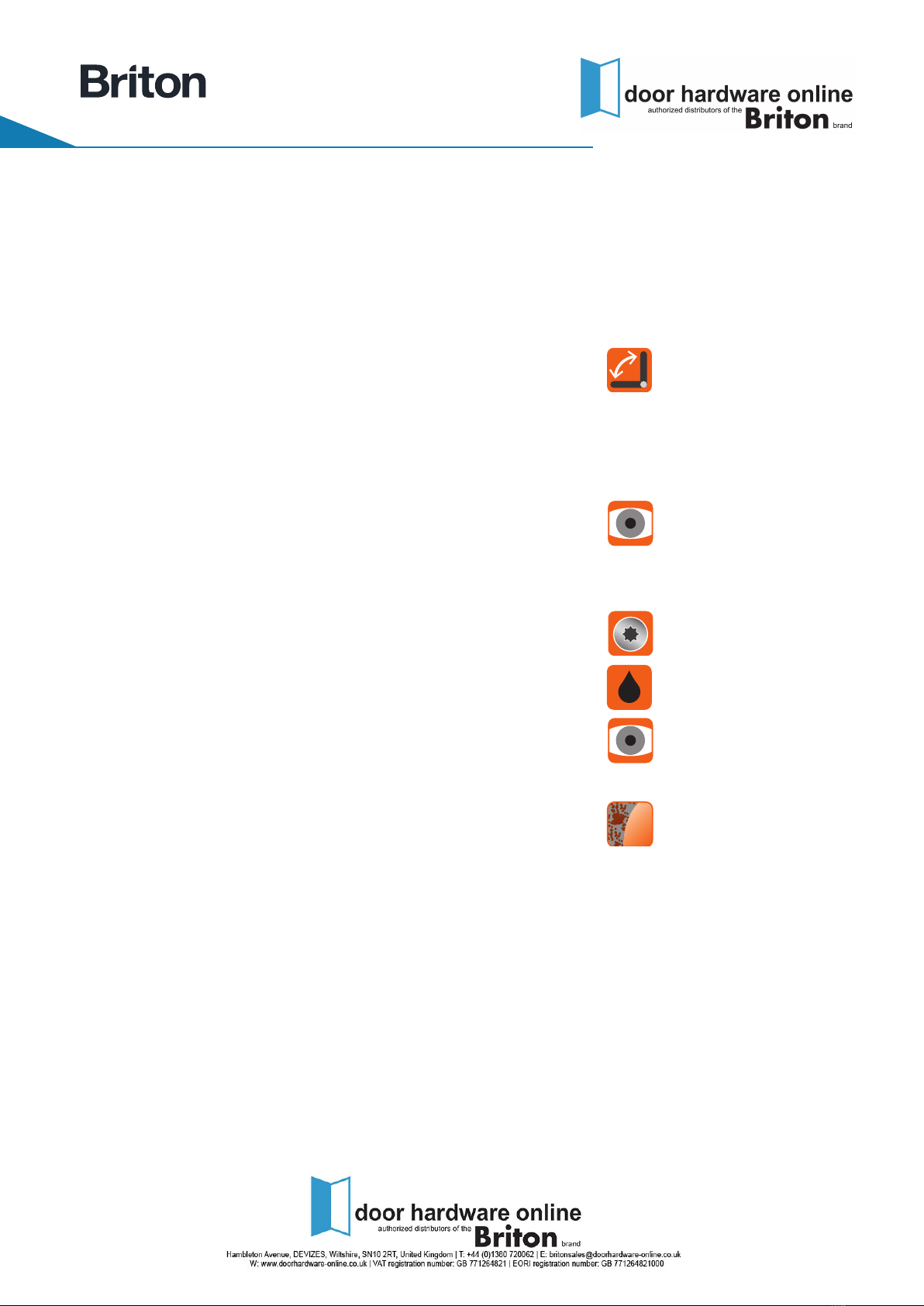

Types of maintenance

Much of the routine maintenance recommended consists of a combination of

visual and mechanical checks, cleaning and lubrication. Look out for the icons

opposite which provide a ‘quick glance’ reminder of the maintenance required.

Visual checks

Primarily making a visual check on the product and surrounding

door/frame looking for wear, damage, and general condition.

Functional checks

Consists of checking that the product operates properly ensuring

the door can fully close without any binding or undue force

required. Check that any seals or weatherstripping do not inhibit

correct operation of the door

Check fixings

Fixings need to be checked regularly and tightened when

necessary. Check that no projection of fixings prevents the door

from swinging freely.

Lubricating

Some products will benefit from periodic lubrication using a light

machine oil or as instructed.

Cleaning

Build up of grease, dust and harmful chemicals should be removed

to prevent corrosion and maintain the product finish.