50 - AdjustmentsAndTroubleshooting

o

Copyrig1

1999

Besam Automated Entrance

Systems. Inc.

'!

Y

be reprinted

witt'out permission.

Trou bleshooti ng

3-26-99

)

SwingmaslerMP US23-o186-ot

FAULT

1_ The door does nol open-motor does not start.

2. Control has power but still no operation.

3. The motor starts but door does not open, or

does not open properly.

4. The door does not open 10 Ihe required

angle.

CHECK

• Is there120 VAC power al control box?

• Is On/Offlhold open switch set to off?

• Is Push Reactivation properly selected?

• Is push plate working (if used)?

• Is motor power absent?

• Are the two fuses on the control blown?

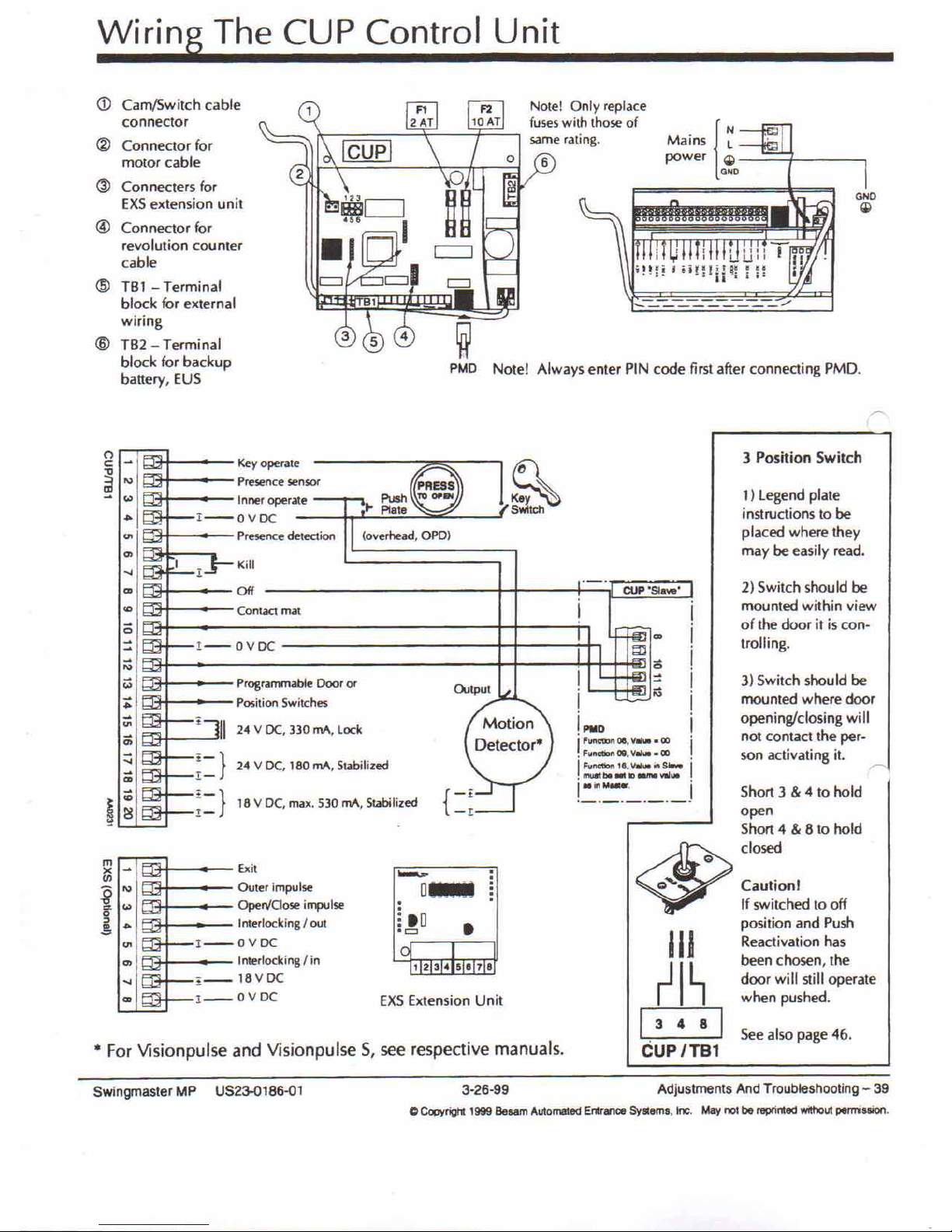

• Do terminals 6 and 7 have jumper in place?

• Is the arm system loose?

• Are the door hinges or arm binding anywherel

• Is there a door strikelelectricl in the system!

• Is spindle rotation correct br arm and door handing?

• Have the settings been checked and do they con-

fonmto the recommended settings in the instructions?

• loose motor coupling.

• Did you program the full open position?

• Is the encoder plugged into the controll

• Isthe encoder, its wiring or the plug damaged?

• loose motor coupling.

• Isthe operator or the mechanical door stop adjusted?

FIX

I

REMEDIES

• Check

I

replace

I

resetmain panel fuseor breaker.

Note: if il repeatedly trips, there is a short.

Check wiring from panel to conlrol for an open circuit.

Note: lhere may be an in-line on/offwall switch.

• Change swilch position to on.

• Select Push Reactivation

• Check push plate connections to control. Check

for proper operation of push plale by using a multi-

meier to check for 0 ohms (when the switch is

pressed) as measured at the control inputs.

• Check the motor cable plug on the control unit.

• Check wilh a multimeter for 0 ohms, and replace

with a fuse of the same rating. Conlinued blowing of

fuses suggests either a short, miswiring or lastly a

bad control unit.

• This kill jumper musl be closed for the control to

operate. If an external kill swilch is wired, tem-

porarily short terminals 6 &7; if the door now

works, fix the external kill swilch and wiring .

• Remove power, close door fully and adjust and

tighten anm per installation inslruclions.

• Correct the binding condition .

• Check wiring and adjust slrike.

• Check the instructions and correct if necessary.

• Connect the PMD and change settings to conform

to recommended settings. NOle that factory replace-

ments are pr"1'rogrammed for th,: SwingmasterIK-A.

• Retighten.

• Set the full open position with the PMD.

• Plug il in to the proper socket.

• Repair or replace as necessary .

• Relighten.

• Readjust.