3

Table of Contents

Table of contents

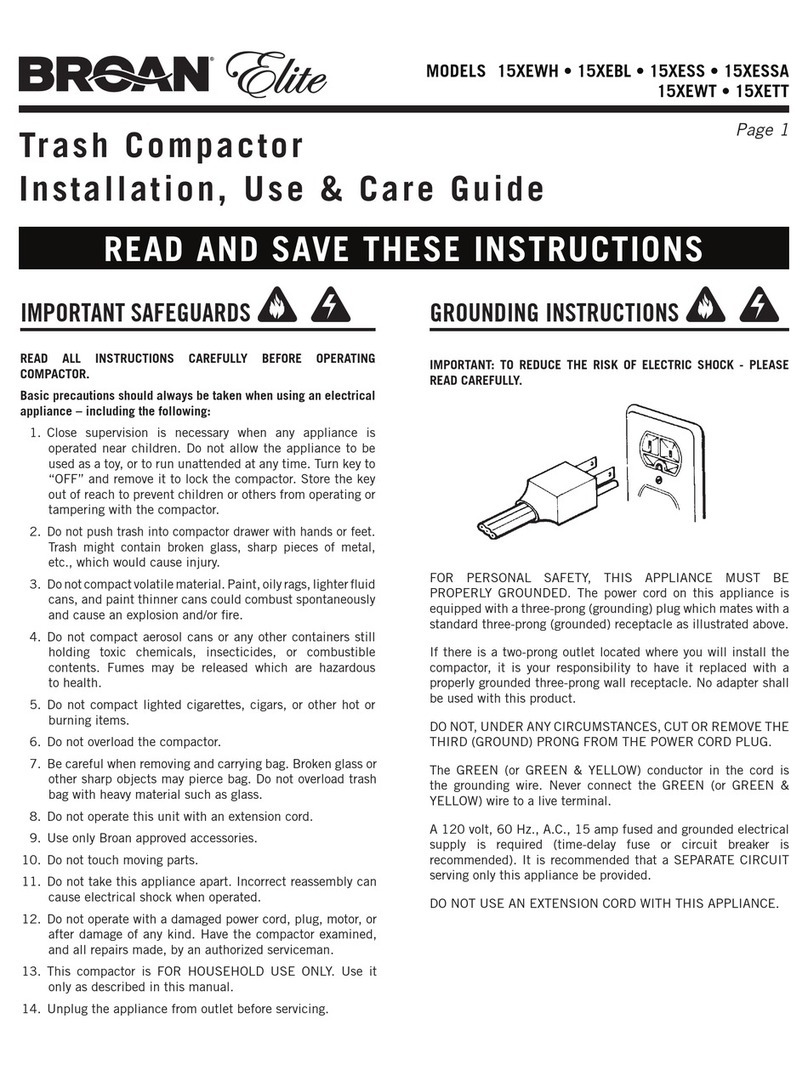

Safe Servicing Practices............................................................ 2

Grounding Instructions.............................................................. 2

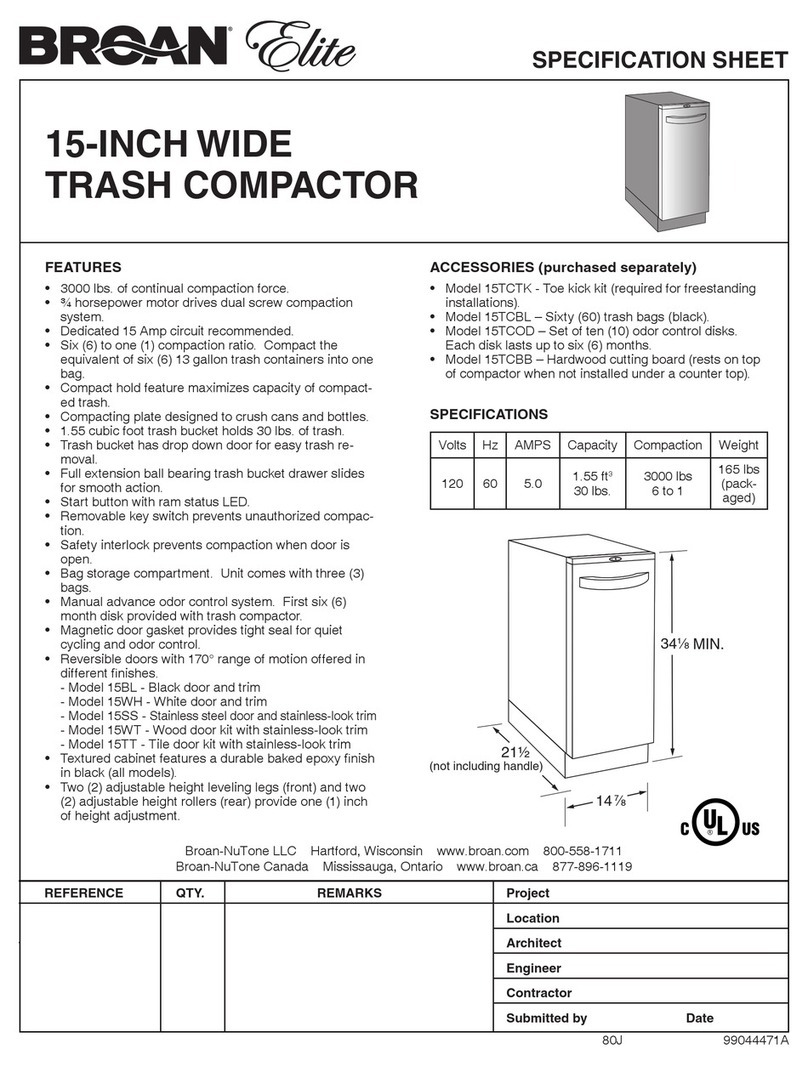

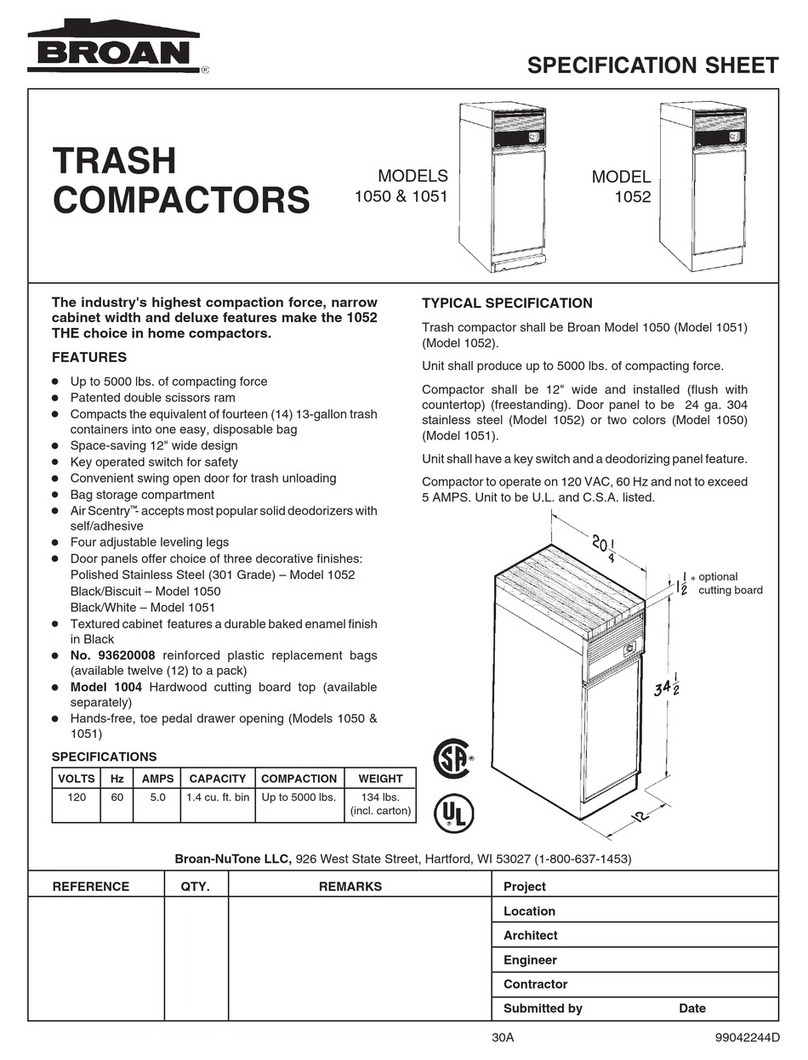

Features....................................................................................... 4

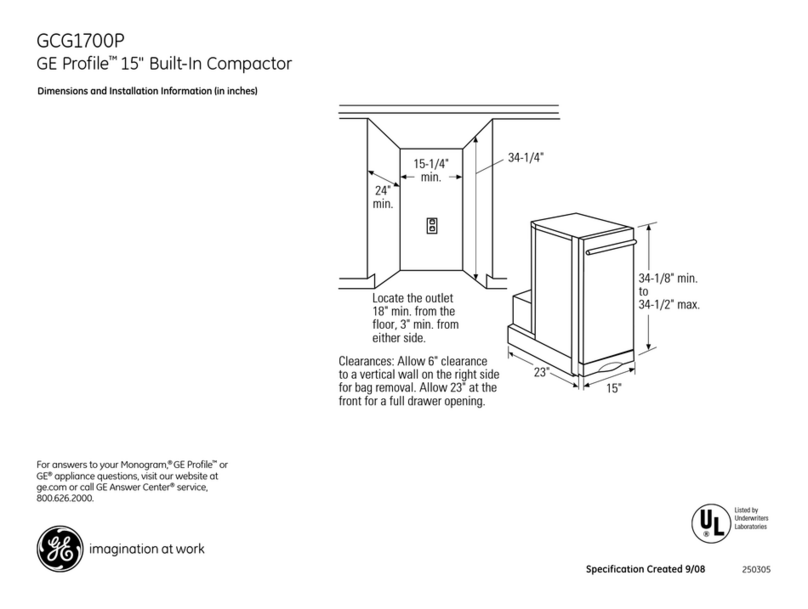

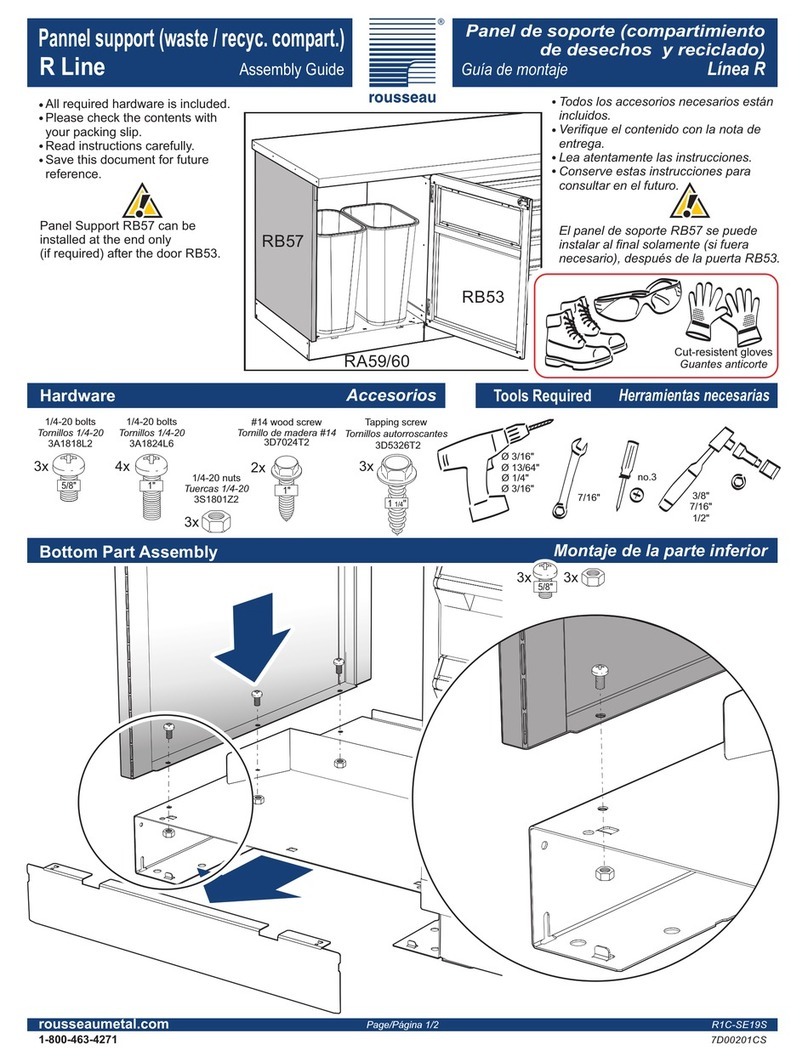

Section A – Installation.............................................................. 5

Free-Standing............................................................................... 5

Built-In Installation ........................................................................ 5

Mounting Straps....................................................................... 5

Under-Counter Opening .......................................................... 5

Cord Clamp ............................................................................. 6

Leveling the Compactor................................................................ 6

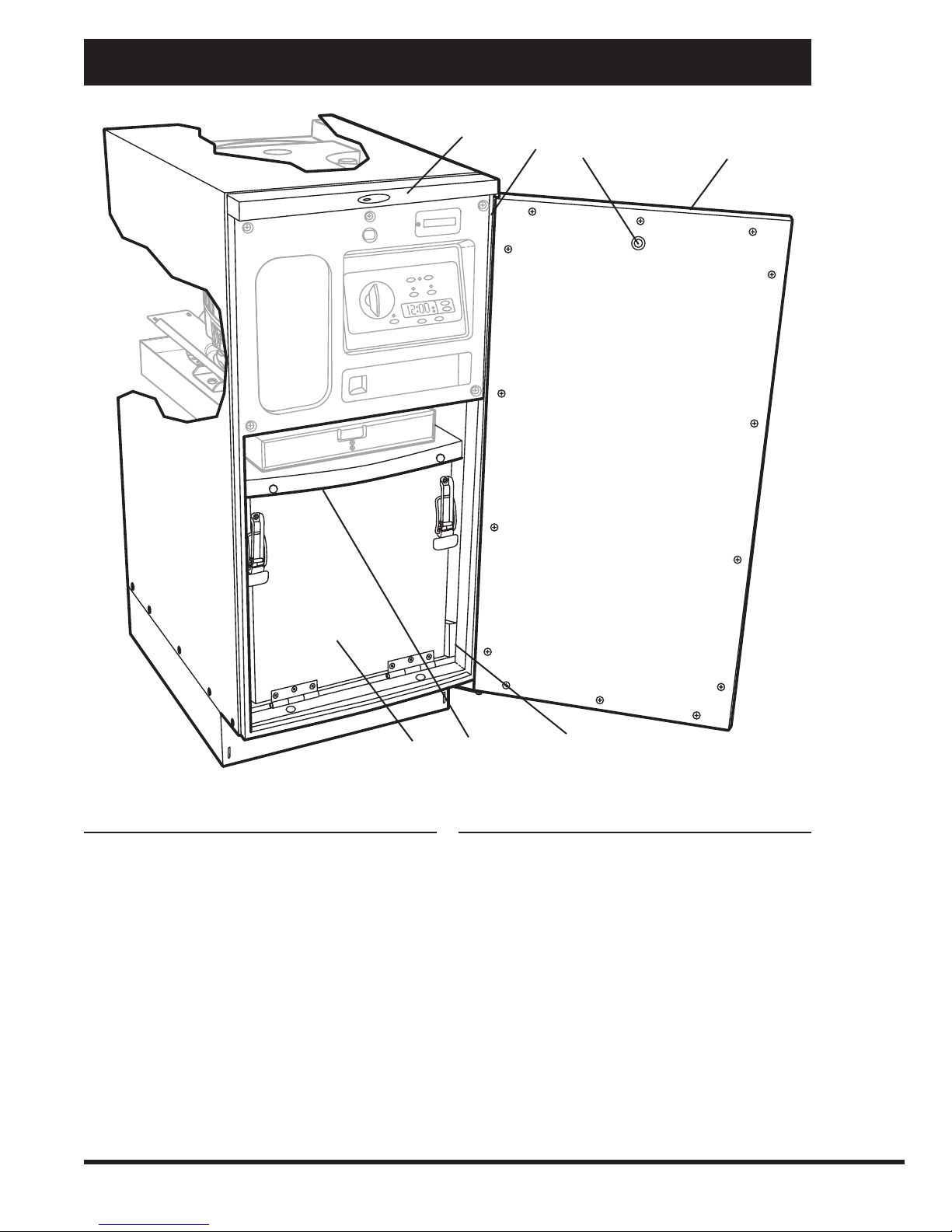

Section B – Cabinet.................................................................... 7

Trash Bucket ................................................................................. 8

Remove ................................................................................... 8

Bucket Handle .............................................................................. 8

Remove and Replace .............................................................. 8

Slide Rails (Cabinet)..................................................................... 9

Remove and Re-install ............................................................ 9

Slide Rails (Bucket) ...................................................................... 9

Remove and Re-install ............................................................ 9

Door Assembly ............................................................................. 10

Remove and Re-install ............................................................ 10

Reverse Door Hinge Position................................................... 11

Safety Interlock Actuator............................................................... 13

Remove and Re-install ............................................................ 13

Gasket Assembly.......................................................................... 14

Remove and Re-install ............................................................ 14

Top Trim Cover Assembly ............................................................. 15

Remove and Re-install ............................................................ 15

Section C – Power Unit Mechanism.......................................... 16

Drive Belt...................................................................................... 17

Remove and Re-install ............................................................ 17

Main Motor.................................................................................... 18

Remove and Replace .............................................................. 18

Complete Power Unit Mechanism................................................. 19

Remove and Re-install ............................................................ 19

Drive Wheels ................................................................................ 19

Remove and Replace .............................................................. 19

Ram Screw Assembly................................................................... 20

Remove and Replace .............................................................. 20

Section D – Electrical Components.......................................... 23

Start Switch .................................................................................. 24

Remove and Replace .............................................................. 24

Access to Components................................................................. 24

Remove Cabinet Cover............................................................ 24

Re-install Cabinet Cover.......................................................... 26

Control Panel Assembly ............................................................... 27

Remove and Re-install ............................................................ 27

Display Module Assembly............................................................. 28

Remove and Re-install ............................................................ 28

Power Supply Board ..................................................................... 28

Remove and Re-install ............................................................ 28

Control Board ............................................................................... 29

Remove and Re-install ............................................................ 29

Key Switch.................................................................................... 30

Remove and Replace .............................................................. 30

Interlock Switch Assembly............................................................ 30

Remove and Re-install ............................................................ 30

Upper Limit Switch Assembly....................................................... 31

Remove and Replace .............................................................. 31

Lower Limit Switch........................................................................ 31

Remove and Replace .............................................................. 31

Motor Centrifugal Switch Assembly.............................................. 32

Remove and Replace .............................................................. 32

Motor Capacitor............................................................................ 32

Test, Remove and Replace...................................................... 32

Odor Disk Gear Motor .................................................................. 34

Remove and Replace .............................................................. 34

Power Cable ................................................................................. 35

Remove and Replace .............................................................. 35

Section E – Troubleshooting

Troubleshooting Table ................................................................... 36

Section F – Specifications

Specifications Table ...................................................................... 39

Section G – Diagrams and Parts Lists

Wiring Schematic ......................................................................... 40

Drawing and Parts List – Doors ................................................... 41

Drawing and Parts List – Cabinet ................................................ 42

Drawing and Parts List – Mechanism .......................................... 43