INDEX

1. INTRODUCTION ............................................................................................................................... 2

2. SAFETY APPLICATIONS..................................................................................................................... 3

2.1 DESCRIPTION OF THE SYMBOLS USED IN THE INSTRUCTION ................................................. 3

2.2 SAFETY INSTRUCTIONS ............................................................................................................ 4

3. PRODUCT DESCRIPTION .................................................................................................................. 6

3.1 GENERAL VIEW ........................................................................................................................ 6

3.2 TECHNICAL DESCRIPTION ........................................................................................................ 7

3.3 TECHNICAL FEATURES ............................................................................................................. 7

3.4 CUTTING DIAGRAMM.............................................................................................................. 7

4. INSTALLATION ................................................................................................................................. 8

4.1 TRANSPORTATION INSTRUCTIONS.......................................................................................... 8

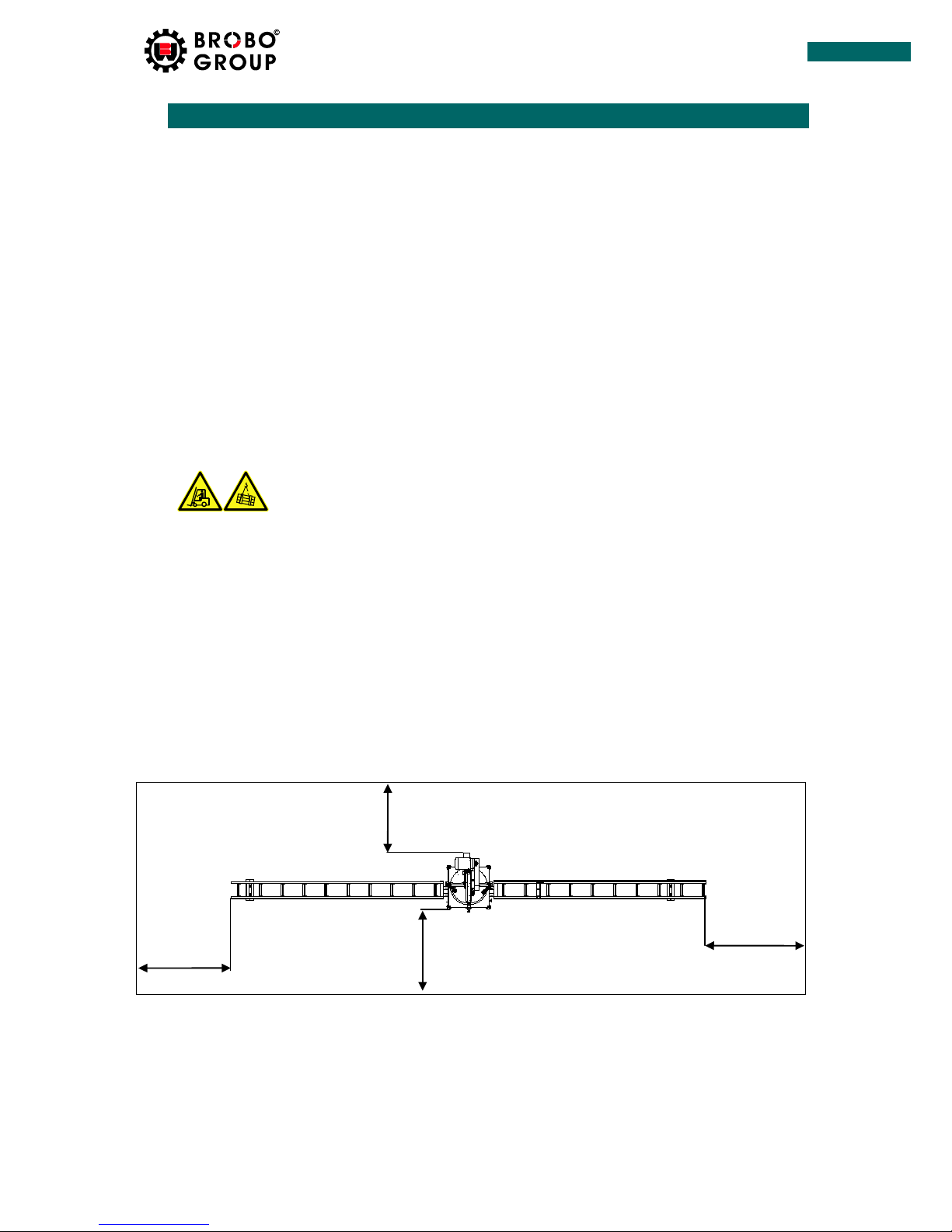

4.2 REQUIRED WORKING AREA ..................................................................................................... 8

4.3 INSTALLATION SETTINGS ......................................................................................................... 9

4.4 FIRST CONNECTION ............................................................................................................... 10

5. PRINCIPLES OF WORK.................................................................................................................... 11

5.1 MAIN SETTINGS ..................................................................................................................... 11

5.1.1 MEASURE CALIBRATION ................................................................................................ 11

5.2 MACHINE CONTROL ELEMENTS ............................................................................................ 11

5.3 OPERATION OF THE MACHINE .............................................................................................. 12

6. MAINTENANCE AND THE LUBRICATION OF THE MACHINE .......................................................... 13

6.1 MAINTENANCE TABLE ........................................................................................................... 13

6.2 MAGNETIC SENSOR ............................................................................................................... 14

6.3 CHANGING THE BLADE .......................................................................................................... 15

7. PNEUMATIC ELEMENTS................................................................................................................. 16

7.1 VALVE AND CYLINDER CONTROL........................................................................................... 16

7.2 COOLING SYSTEM .................................................................................................................. 17

8. TROUBLESHOOTING ...................................................................................................................... 18

8.1 ACTIONS TO BE TAKEN DURING FAILURE.............................................................................. 18

8.2 FAILURE – REASON – SOLUTION TABLE................................................................................. 18

9. CIRCUIT DIAGRAMS ....................................................................................................................... 19

9.1 PNEUMATIC CIRCUIT DIAGRAM ............................................................................................ 19

9.2 ELECTRIC CIRCUIT DIAGRAM ................................................................................................. 20

10. WARRANTY .............................................................................................................................. 22