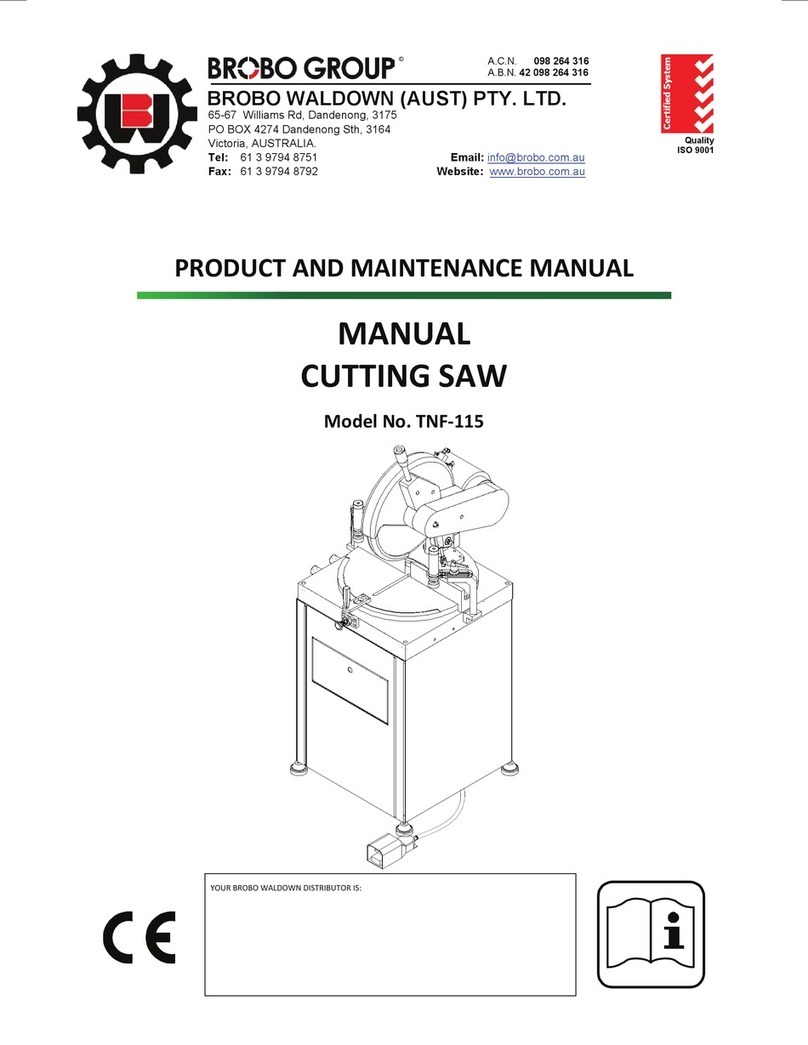

OPERATING MANUAL FOR BROBO GROUP

MANUAL METAL CUTTING SAWS

TECHNICAL SPECIFICATION

CHAPTER 1: Installation of the Machine

1.1 Unpacking and Handling the Machine

1.2 Parts Checklist

1.3 Minimum Requirements

1.4 Anchoring the Saw

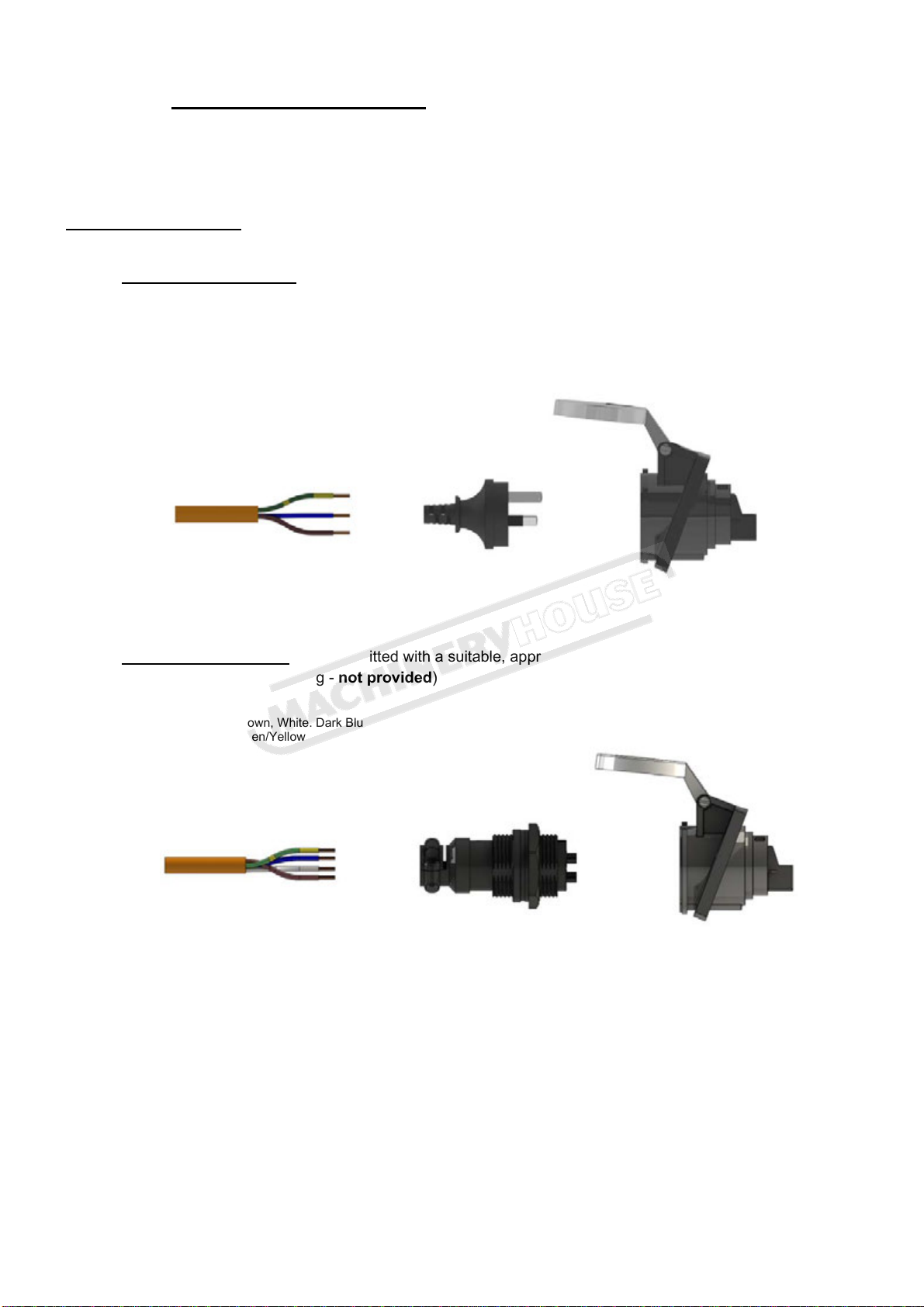

1.5 Connection to Power Source

CHAPTER 2: Safety and Accident Prevention

2.1 Operation of the Machine

2.1.1. Noise Level

2.1.2. Power Supply

2.2 General Requirements

2.3 Advice for the Operator

2.4 Machine Safety Devices

2.4.1. Reference Standards

CHAPTER 3: Main Functions and Operation of the Machine

3.1.1. Cutting Head

3.1.2. Saw Safety Guard

3.1.3. Saw Handle (with ‘Dead Man’ Trigger Switch)

3.1.4. Main power standby & Speed selector switch

3.1.5. Manual Vice Clamp

3.2 Preparation for Operation

3.3 Operation Recommendations

CHAPTER 4: Drawings, Layouts, Assembly and Spare Parts

4.1.1 Assembly Drawing (1 of 3)

4.1.2 Assembly Drawing (2 of 3)

4.1.3 Assembly Drawing (3 of 3)

4.2.1 Electrical Circuit 1PH/ 3PH & 3PH Dual Speed Circuit Diagram

4.2.2 Electrical Circuit 3PH with Dead Man Trigger (DMT)

4.2.3 Diagram For Connection 1PH/3PH Circuit

4.2.4 Component Layout & Electrical Schematic Drawings (3PH)

4.3.1 Cold Saw Main Dimensions

4.3.2 Cold Saw Assembly

4.3.3 Standard Gearbox Assembly

4.3.4 Deadman Trigger Assembly

4.3.5 Standard Manual Vice Assembly

4.3.6 Dual Manual Vice Assembly

CHAPTER 5: Adjustments for the Saw Unit

5.1 Changing the Blade

5.2 Adjusting the Cutting Angle

5.3 Cutting and Feeding Speeds

5.4 Refilling the Lubricator

5.5 Adjusting the Brobolube Unit

5.5.1 Lubricating Oil Precautions – Health Hazard Information

CHAPTER 6: Maintenance and Selection of Consumables

6.1 Role of the Operator

6.2 Maintenance Requirements

6.3 General Maintenance of Functioning Components

CHAPTER 7: Troubleshoot

7.1 Troubleshooting For Blade and Cutting Problems

7.2 General Troubleshooting

APPENDIX

i. Hazard/Risk Assessment

ii. Workplace Health & Safety Policy

Instruction Manual for VS315D (S040)