BROCK® MEYER® Walkways and Ladders

MFH1968-5B 3

Ladder-and-Cage Installation Basics, Horizontal Tower ....................................................................... 13-14

Outside Ladder Sections • Ladder Splice .................................................................................... 13-14

Cage Hoop Halves ..............................................................................................................................14

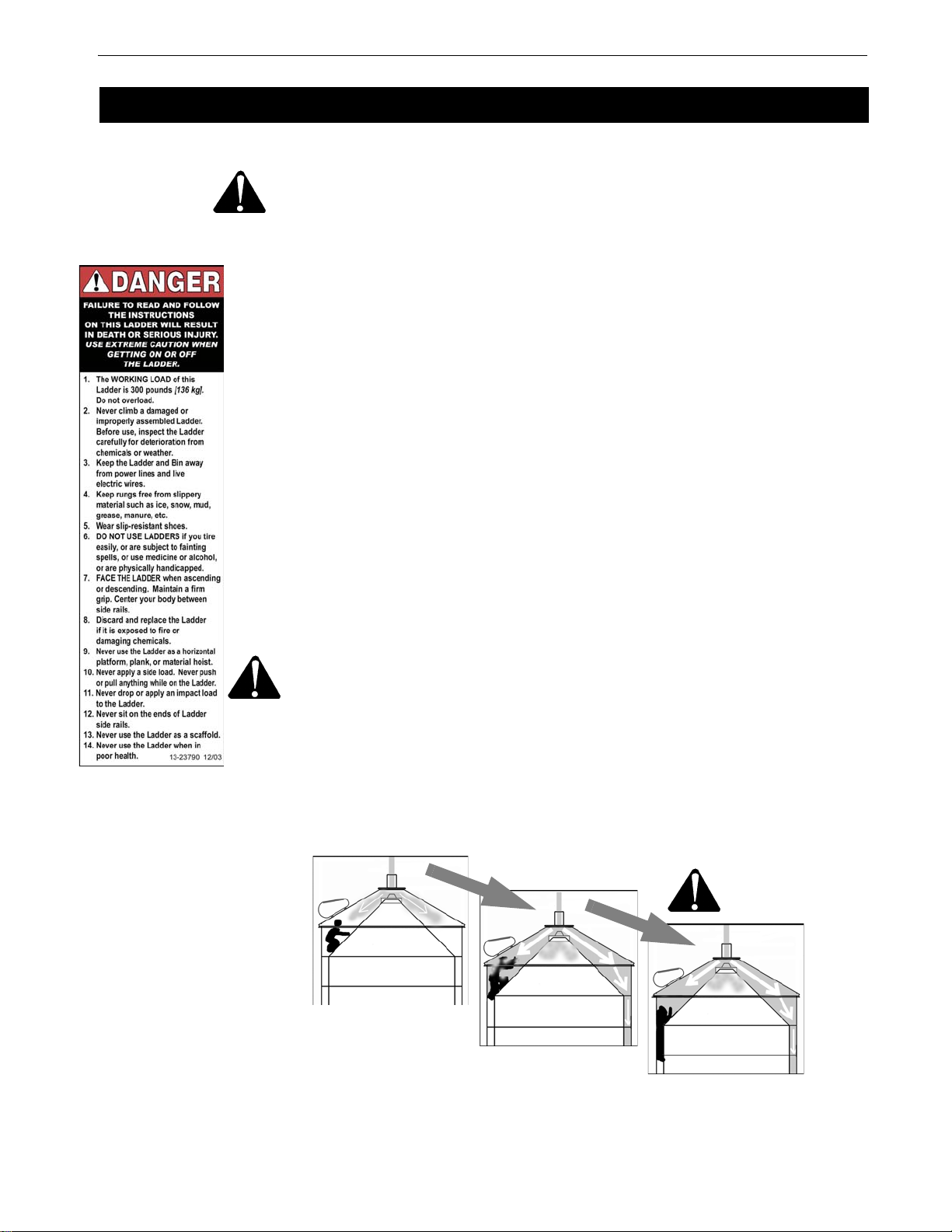

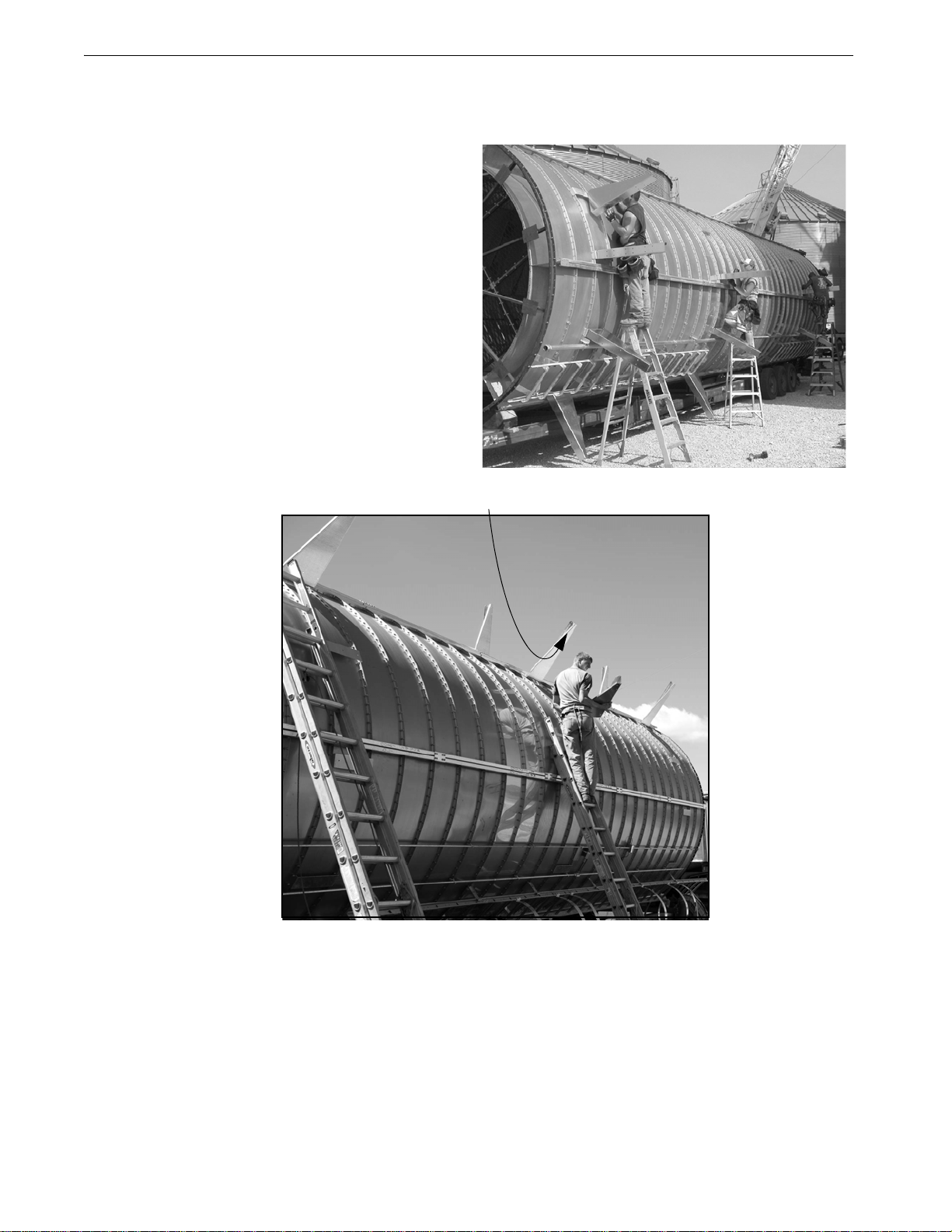

Lift the Tower to “First Stage” to Work Underneath ................................................................................15

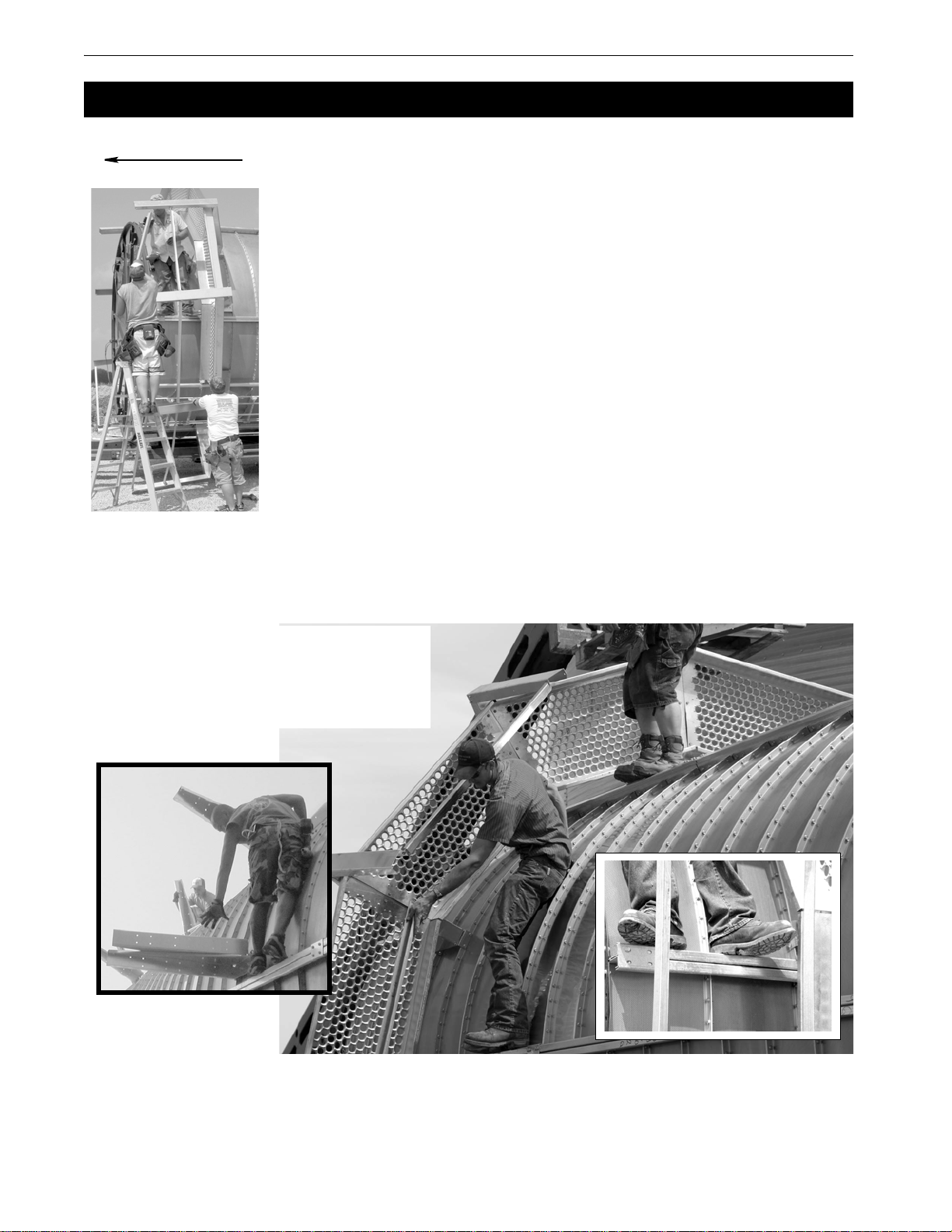

Types of Walkways ...................................................................................................................................... 16-24

Common Parts in Walkways ......................................................................................................................17

Full Walkway (3121-00052).................................................................................................................... 18-19

Partial Walkway (3121-00120), All Models ........................................................................................... 20-21

Eave Platform (3121-00175) Roof Module All Models.......................................................................... 22-23

Eave Platform on the ME1000S - ME1600S ........................................................................................24

Outside Ladder-and-Cage Installation ...................................................................................................... 25-35

Ladder-and-Cage Parts Identification.........................................................................................................25

Top Ladder Extension Through the Eave Platform....................................................................................26

Extension Rail Bracing to the MEYER® Roof .........................................................................................27

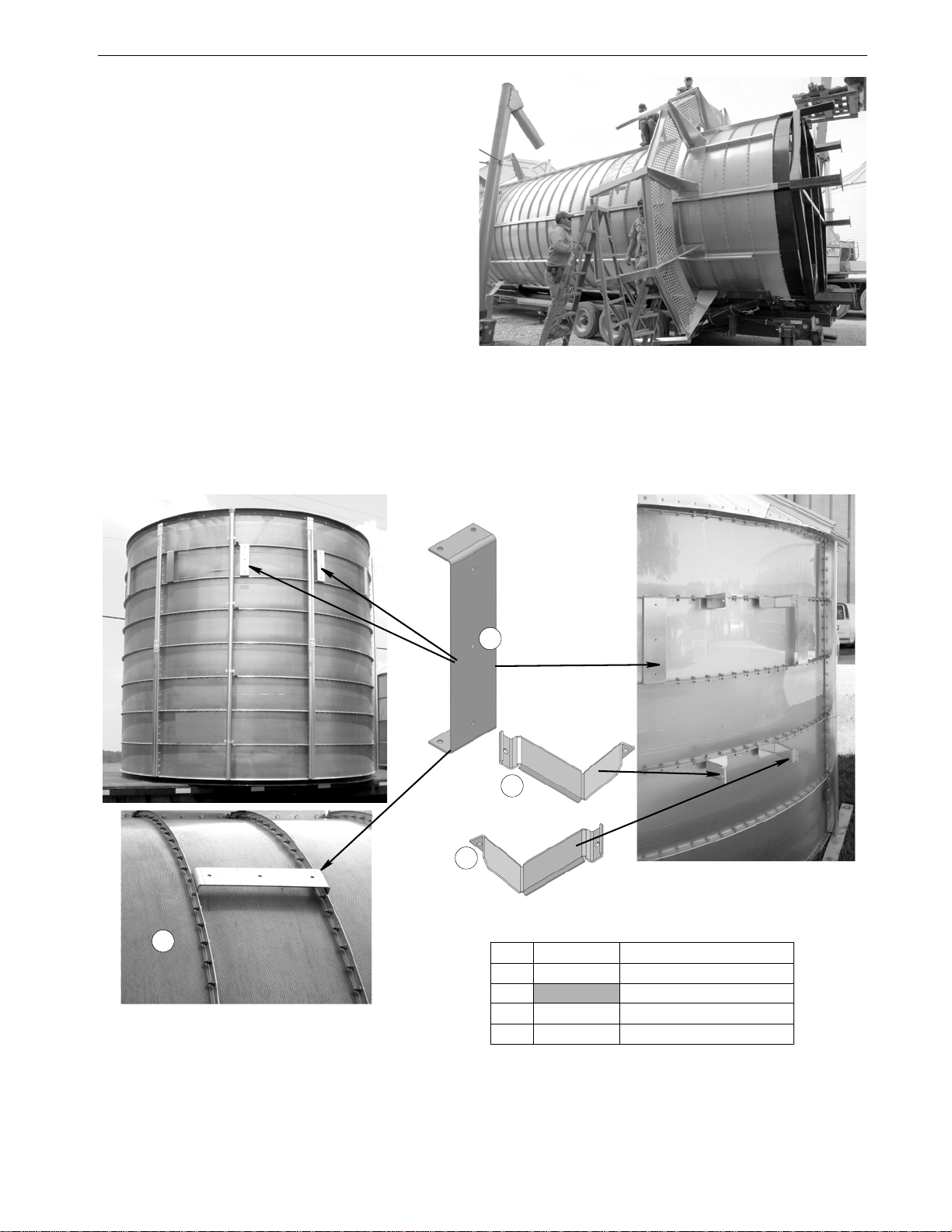

Outside Ladder Brackets to the Tower.................................................................................................... 28-29

Ladder-and-Cage Sections....................................................................................................................... 30-31

Hoop Halves .......................................................................................................................................30

Cage Channels ......................................................................................................................................31

Bottom Flared Cage Section ....................................................................................................................32

Outside Bottom Ladder (May Be Pre-Installed).........................................................................................33

Locking Ladder Door Assembly 9-41037............................................................................................... 34-35

Tie-Back Installation ............................................................................................................................35

Diagrams: Outside Walkways and Ladder-and-Cage ............................................................................. 36-55

Outside Ladder-and-Cage Packages...........................................................................................................36

Outside Ladder Package Kit Numbers Chart..............................................................................................37

ME1000S with 1 Level Catwalk (3121-00084)..........................................................................................38

ME1200S with 1 Level Catwalk (3121-00085) ......................................................................................39

ME1200S with 2 or 3 Level Catwalks (3121-00163)................................................................................40

ME1400S with 1 Level Catwalk (3121-00165 .........................................................................................41

ME1400S with 2 or 3 Level Catwalks (3121-00166)................................................................................42

ME1600S with 1 Level Catwalk (3121-00087) ........................................................................................43

ME1600S with 2 or 3 Level Catwalks (3121-00112)................................................................................44

ME1800S with 2 Level Catwalks (3121-00088).......................................................................................45

ME1800S with 3 Level Catwalks (3121-00179).......................................................................................46

ME2000S with 2 Level Catwalks (3121-00089) ......................................................................................47

ME2000S with 3 Level Catwalks (3121-00113).......................................................................................48

ME2000S with 4 Level Catwalks (3121-00185).......................................................................................49

ME2400S with 3 or 4 Level Catwalks (3121-00091)................................................................................50

ME2400S with 5 Level Catwalks (3121-00043).......................................................................................51

ME2650S with 3 Level Catwalks (3121-00176).......................................................................................52

ME2650S with 4 Level Catwalks (3121-00178).......................................................................................53

ME2650S with 4 Level Catwalks (3121-00184).......................................................................................54

Inside Ladder Installations ......................................................................................................................... 55-57

Inside Ladder Sections................................................................................................................................55

Internal Service Platform Ladder Access...................................................................................................56

Top Inside Ladder Sections........................................................................................................................57

Pre-Installed Inside Ladder Sections..........................................................................................................57

Diagrams: Inside Ladders .......................................................................................................................... 58-66

Inside Ladder Package Kit Numbers Chart................................................................................................58

ME1000S ...................................................................................................................................................59

ME1200S ................................................................................................................................................60

ME1400S ...................................................................................................................................................61

ME1600S .................................................................................................................................................62

ME1800S ...................................................................................................................................................63

ME2000S ...................................................................................................................................................64

ME2400S ...................................................................................................................................................65

ME2650S ...................................................................................................................................................66