8www.bromic.com

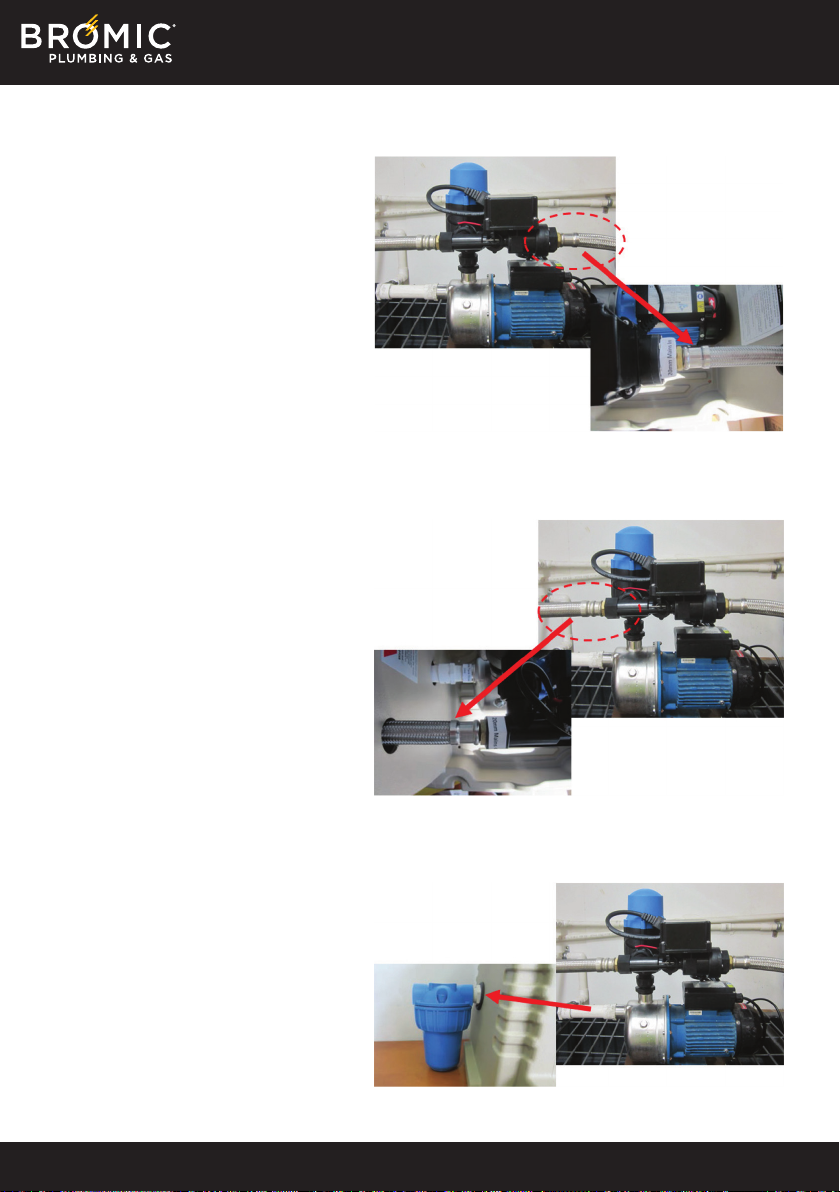

Please note the

inlet filter must

be purchased

separately.

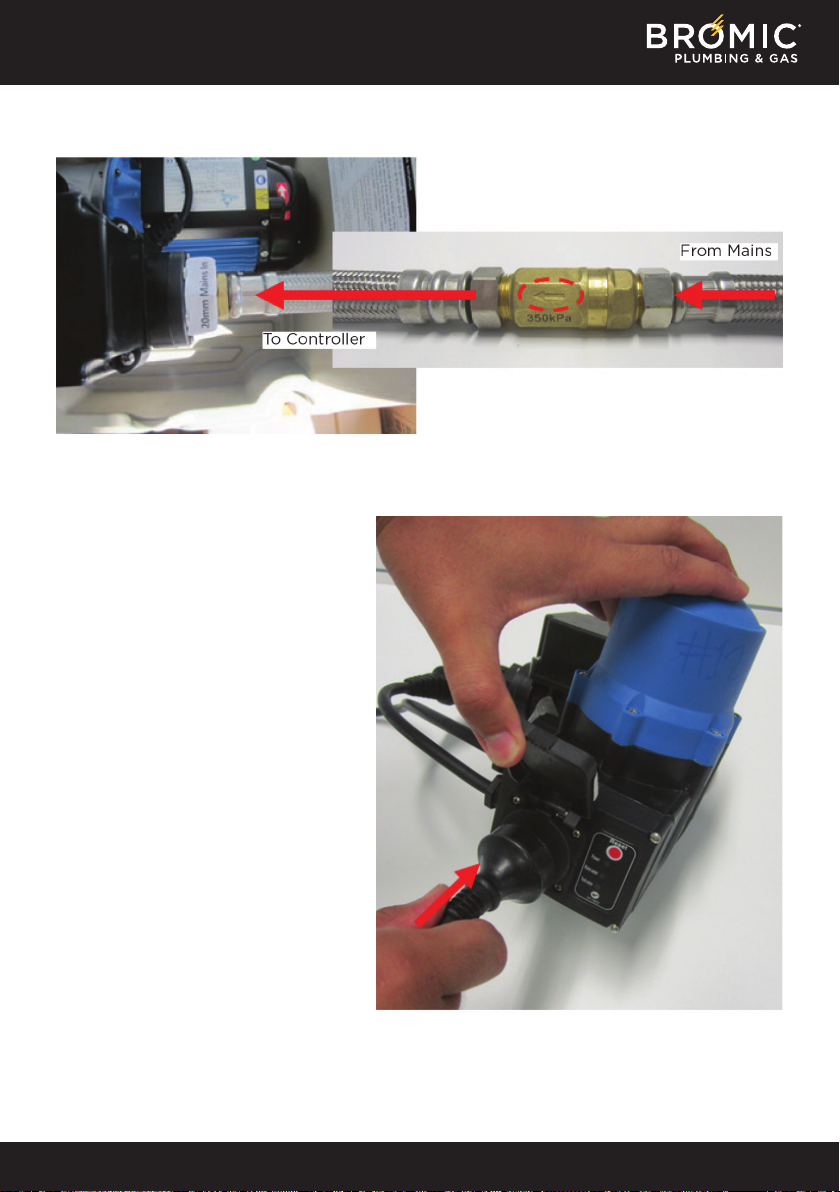

Pressure

Limiting

Valve Isolation

Valve

Isolation

Valve

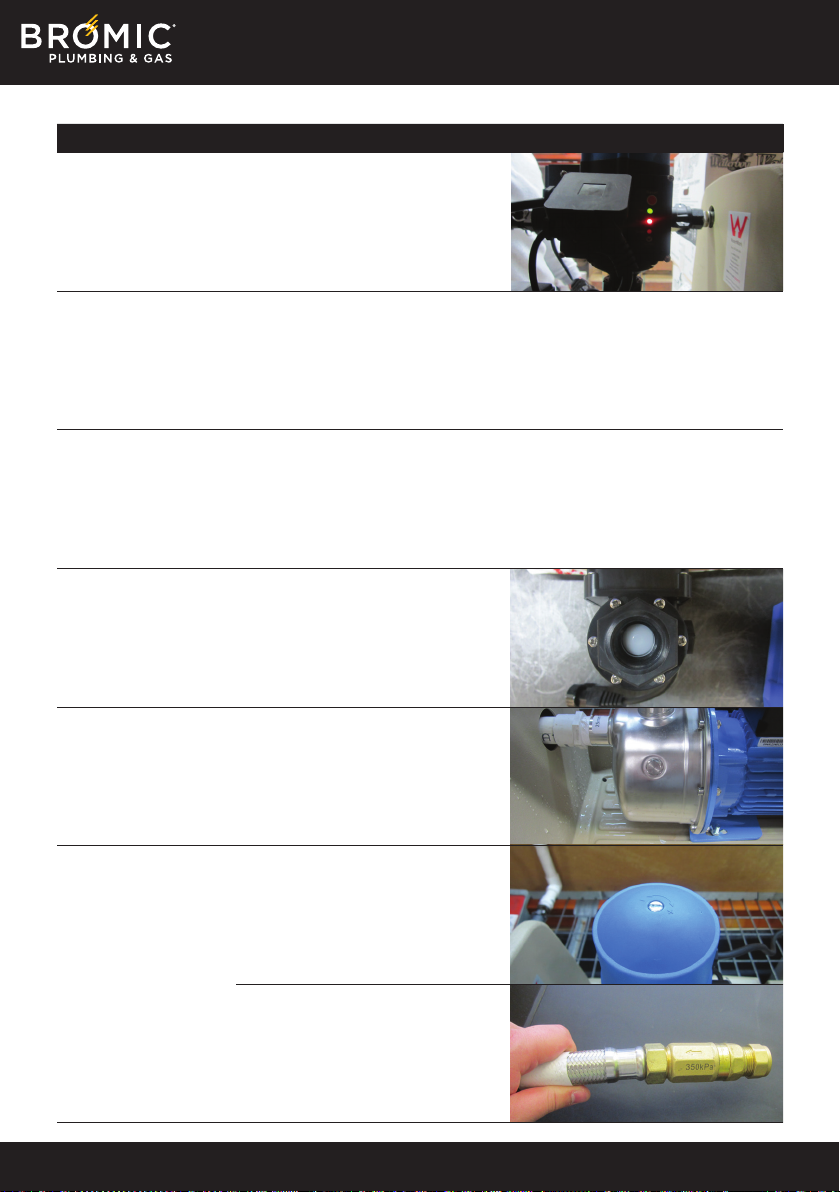

OPERATION AND MAINTENANCE

Priming of Pump

1. Fill tank to a level above the draw o point

2. Turn on the water supply from the tank.

3. Prime the pump by removing the priming

point from the top of pump chamber and

allowing the tank water to fill the pump

chamber, or by filling the pump chamber

with water from an external supply. Once

this is done refit the Priming point.

4. Turn on the power supply (at power point)

which will start the pump, this will run until

the air in the system is pressurized.

5. At this stage turn on the Mains water

supply

Installation Tips:

• The Waterboy Wizard is designed to be

installed at ground level along side tank.

Although the cover is waterproof, the

system should ideally be installed in a

covered area.

• Make sure the water inside the tank is clean

(it may be necessary to flush out pipes also)

• Do not use the system for any other

purpose other than what is specified in this

manual.

• Locate system in a place that will not be

subject to freezing – water freezing inside

the wateryboy unit will damage the system.

OPERATION

Before you start:

1. Make sure pump is primed (see

commissioning procedure Page 4)

2. Waterboy Wizard is designed to handle

clean water, do not use the system to

supply bore water, dam water, grey water,

storm water or recycled water.

3. Ensure wiring, plumbing and the system

are not accessible by children or pets

Filling your tank:

Should it not be possible to fill the tank to

the required level the system may be

connected to the supply and outlet

connections, the mains water can then be

turned on but the power to the unit should

not be connected until there is sucient

water in the tank and the pump primed as

per the Commissioning Procedure.

We recommend you do not run the pump

without water - please turn pump o until

tank has replenished with sucient water.

You will need to prime the pump.