Brother BAS-411 User manual

SERVICE

MANUAL

FOR

BAS

-4

11

BAS-415

SINGLE HEAD ELECTRONIC EMBROIDERY

MACHINE

I

· ·

.

~

-

From the library of: Superior Sewing Machine & Supply LLC

CONTENTS

(

PART

NAMES )

·.

· · · · · · · · · · · · · · · · · · ·· · · · · · · · · · ·· · · · · · · ·· · ·· · · · · · · · ·· · · · ·· · · · · · · · · · · · · · · · 1

( MECHANICALDESCRIPTIONS ) · · · · · · ·· · · · · · · ·· · · · · · · ·· · · · · · ·· · · ·· · · · · · · · · · · ·· · · · · · · · 3

[I] .upper

shaft

mechanism . .. . . •. . . . . .. . . . . . . . . . . ••. . . . . .. . •. . . . . . . . . .•. . •• . . •. .. . . . . . . . . . 3

00

Lower

shaft

and

rotary

hook

mechanism . . . . . . •••••. . . . . .. . . . . . . . . •. .. ••. . ••. . . . . . . •. . . . 4

00

Thread

trimmer

mechanism . •. . . . . . . . . . •. . . . . .. . . . . . . .. . . . . . . . . . . .. . . . . .•. . . . . . ••••••. • 5

[j]

Thread

wiper

mechanism . •. . •. . . . . . . . . . . . . .•. •. . . . . . . . . . . . . . . . . . .•••••. ••. •.. . . . . . •. . . 6

[§] Needle

bar

flip-up

mechanism . . ••. . . . . . . . . . .. . . . . . . . . . . .. . . . . . . . . .. . . •.. . . . . . . . . •••. ••. 7

[§] Pickermechanism •. . . . . . . . . . . . . . . . . . . . . . . . . . .•. ••. . . . . . .•. . . . . . . •. •. . ••. •. . . . . . •. . . . . . 8

[1]

Drive, (X)

feed

mechanism . . . . . . . . . . . . . . . . . . . .. . . . . . . . . .. . •••. . . . •. . . •. . . . . . . . . . . . . . . •. 9

[I]

Drive, (Y)

feed

mechanism . . . . . . . . . . . . . . . . . . . .•. •. . . . . . . . . . .. . . . . •. •. . •. . . .. . . . . . . . ••. 10

( STANDARDADJUSTMENT ) · · · · · ·· · · · · · · · · · · ·· · ·

·.

· · · · ·· · · · · · ·· · · · · ·· · · · · · · ·· · · · · · · · ·

11

[I]

Adjusting

needle

bar

height

...•..............••......

~

. . . . .. . . . ••. . . . . . . . •. .•••••••••

11

~

Adjusting

timing

of

needleand

rotary

hook

. . •. . . ••. . . . . .. . . . . . . . . . .. . . . . . . . . . . •. ••••. • 13

00

Adjusting

cloth

presser

height

. . . . . .. . . . . . . . . . . . . . . . .. . . . . . . . . . . . .•. •. . . . . . . . .. . . . . . . •. 13

[j]

Adjusting

knife

and

fixed

knife

. •. . . . . . . . . . . . . ••. . . . . . .. . . . . . . . .. •.. . . . . . . . . . . . . . . . . . . . 14

[§]

Adjusting

picker . . . . . . . . . . . . . . . . . . . . . . . •. .. . . . . . . . . .. . . . . . . •. . . . .. . . . . . . . . . . . . . ••• •. . 15

[§]

Adjusting

the

thread

wiper

. . . . . . . . . . . . . . . . . . . .. . . . . . . . .. •. . . . . . . .•. . . . . . . . .•. . . . . . . •• 16

[1]

Adjusting

wire

tension

.....•.................•........................••...•.•...••••

17

1.

X-

feed

wire

. . . . . . . . . . . . . . . . . . . . . . . . . . . .. •. . . . . . .. . . •.. . . . . •.. . . . . . . . . . . . •. •••••. 17

2.

Y

-feed

wire

. . . . . . . . . . . . . . •. . . . . . . . •. . . . . . . . . . . . . . .. . . . . . . . . . . . . •. . . . . .. . . . . •. . . . 18

00

Adjusting

thread

breakage

detect

stud

..........................•.•.....•.•............

19

00

Adjusting

bobbin

winder

...................•.........................................

20

lim

BAS-411·415

test

mode

. . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . .. . . . . . . . . . .••••••. . . . •. . . . . . . . .

21

In]

Adjusting

synchronizer . . . . . . . •. •. . . . . .. . . . . . . . . . . . . .. . . . . . . . . . . . .. . . . . . . . . . . . . . •. . . . . 23

1m

Adjusting

home

position

using

home

position

plate

. . . . . .. . . . . . . . . . •. . . •. . . . . . . . . •. . . . . . 26

lj}

Positioning

over

limit

sensor

...................................•..••..•...............

28

IB1

How

to

adjust

thread

sensor(thread breakage detector) . . . . . . . . . . . . . .. . . . . . . . . . . . •. . . . . . 35

( LUBRICATION ) ·· · · · · · · · · · · · · · · · · · · · · · · · · · · · ·· · · · · · · · · · · · · · · ·· · · ·· · · · · · · · · ·· · · · · · · · · · · 36

[I]

Machine

head . . . . . . . . . . . . . . . . . . . . . . . . •. . . •. . . . . . . . .. . . . . . . . . . . . .•••••. . •. . . . . . . . . . . . 36

~

Feed

guide

mechanism

.......................................•........•..............

38

From the library of: Superior Sewing Machine & Supply LLC

(

REPLACINGANDADJUSTINGPARTS)

· · · ·

··

· · · · · · · · ·· · · ·

··

· · · ·

··

· · · · · · · ·

··

· · · · · · ·

··

39

[I]

Removing and

adjusting

machine head (1) . . . .. . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

~

Removing and

adjusting

machine head (2) .

..

. . . . .

..

.

..

..

. . . . . . .

..

.. . . .

....

..

......

. . . . 40

lm

Removing needle

bar

case

............................................................

41

1!1

Replacing

up

and

down

motion

parts . . . . . . . . . . . .. . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . 42

~

Replacing

jump

solenoid

..............................................................

43

[§]

Attaching

X

wire

.....................................................................

44

[1]

Attaching

Y

wire

.....................................................................

45

(

ELECTRIC

COMPONENTS ) · · · · · ·· · · · · · · · · ·· · · · · · · · · ·· · · · · · · · · · · · ·· · · · · · · ·· · · · · · · · · · 46

[!)

Circuit

board

locations

...•............................................................

46

~

Replacing

circuit

board

...............................................................

47

00

Fuses

...............................................................................

58

(!]

P-ROMS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

~

DIP switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

[§]

Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

[1]

troubleshooting

flowchart

...........................................................

70

BAS-411

..........................................................................

70

BAS-415

..........................................................................

81

00

Harness connectionsand connectors

number

...........................................

92

(

EXPLANATIONOFOPTIONALPARTSINSTALLATION)

·· · · · · · · · ·· · · · · · · · · · · · · · · · · 106

[]]

ML

6511ampset . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . 106

~

Light

marker

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

00

Connecting

optional

parts

with

machine . . . . . .

..

..

. . . . . . .. . . . . .

....

. . . .

..

. .

..

. . . . .

..

. 112

1!1

Bobbin

winder

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

(

TROUBLESHOOTING)·····························································

118

[!) Mechanical

problem

. . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

~ Electrical

problem

. . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

00

List

of

error

messages . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

BAS-411 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . 122

BAS-415 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

BAS-411 KEYBOARD

UN

IT CONTROL

BLOCK

DIAGRAM

BAS-415 KEYBOARD UNITCONTROL

BLOCK

DIAGRAM

BAS-411 CONTROL

BLOCK

DIAGRAM

BAS-41

5 CONTROL

BLOCK

DIAGRAM

.........................................................

.........................................................

From the library of: Superior Sewing Machine & Supply LLC

(

Part

names

)

(

BAS-411

)

0 Thread

guide

bar

@ Thread tension dial

@)

Thread take-up

0 Embroidery

hoop

<9

Table plate 6 Operation panel

@)Spool

shaft

(B)

(!) Keyboard assembly

CD

Guard bar

@ Speed dial

4D

Disk drive

-1-

0 Thread take-upcover

@)

Powerswitch

48

Contrastdial

of

liquid

crystal display

From the library of: Superior Sewing Machine & Supply LLC

( ·

BAS-415

)

0 Thread

guide

bar 8 Thread tension dial

@)

Thread take-up

@ Embroidery

hoop

(!) Table

plate

8 Operation panel

@)

Spool

shaft

(B)

tD)

Keyboard assembly

4D

Guard bar

Q) Speed dial

4D

Disk drive

-2-

8 Thread take-upcover

~

Powerswitch

C8

Contrastdial

of

liquid

crystal display

From the library of: Superior Sewing Machine & Supply LLC

(MECHANICAL

DESCRIPTIONS )

lii Upper shaft

mechanism

1)

When

the

pulley 0 rotates

in

the

direction

of

the

arrow,

it

transmits

the

rotation

to

the

uppershaft

8.

The upper.shaft8 then rotates

the

threadtake-updriving

cam

@).

2)

The threadtake-updriving

cam@)

transmits

the

motion

to

the

connecting rod

9.

3)

The

up

and

down

motion

parts

<9,

attached

to

the

main needle bar

0,

move

the

needle bar 8 upand

down.

4)

The needle bar8

is

guided by

the

needle bar

case

@).

-3-

From the library of: Superior Sewing Machine & Supply LLC

~

Lower shaft and rotary hook mechanism

1)

When

the

pulley 0 rotates

in

the

direction

of

the

arrow,

it

transmits

the

rotation

to

the

uppershaft @.

The upper

shaft@

then rotates uppershaftgear(A)@).

2)

Uppershaftgear

(A)@)

transmits

the

movement

to

the

lower

shaftgear0 via the vertical shaft

e.

3)

The

lower

shaftgear 0 transmits

the

rotation

to

the

attached lowershaft

@).

Then

the

rotary hook

6,

attached

to

the

lower

shaft@), rotates in

the

direction

of

thearrow.

NOTE:

In BAS-

411

and 415,

the

rotary hookmakes

two

revolutions

for

each revolution made by

the

pulley.

-4-

From the library of: Superior Sewing Machine & Supply LLC

~

Thread trimmer

mechanism

-------------------

After

the

final stitch, roller shaft (A) 0

moves

into

the

groove

of

the

cam

@,and connecting plate

(B)

@)

~

moves.

Then the knife 0 engages

with

thefixed knife

0,

trimmingthe thread.

-5-

From the library of: Superior Sewing Machine & Supply LLC

II]

Thread

wiper

mechanism

~--------

After

sewing

is

completed,

the

thread guide solenoid 0

moves

the

plate

@in

the direction

of

the

arrow,

and

the

upper thread guide hook

@)

attached

to

the plate @ brings the trimmed thread

to

the

thread

presser.

The thread presser

secures

thetrimmedthread.

-6-

From the library of: Superior Sewing Machine & Supply LLC

[§]

Needle

bar

flip-up

mechanism

~~------

After

receiving

the

set needle bar

flip-up

signal,

cam

gears (A) 8 and

(B)

@)

attached

to

the

pulse

motor

0

are

activated.

The needlebar

flip-up

is

performed

by

the

changecam

9.

-7-

From the library of: Superior Sewing Machine & Supply LLC

[§]

Picker

mechanism

------------

The

picker solenoid 0 functions

at

the

beginning

of

sewing and after thread trimming.

The

picker

@)

attached

to

connecting plate

(A)@

moves inthe direction

of

the bobbin

case

e,then pullsthe upperthread

under

the

material.

Duringthread trimming,

the

picker@) operates

to

keep the needle thread length constant.

-8-

From the library of: Superior Sewing Machine & Supply LLC

[1]

Drive, (X) feed mechanism

1)

Pinion gear

(B)

@ attached

to

the X-pulse motor 0 rotates, then transmits the rotation

to

idle gear (A)

@).

2)

When idlegear(A)@) rotates, the (X) wire

CD

reeled inthewire drum

(X)

e moves

the

carriage & in

the

direction

of

the

X-axis

(left

e right) via

the

pulley

<9.

-9-

From the library of: Superior Sewing Machine & Supply LLC

[II.

Drive, (Y) feed

mechanism

1)

Pinion gear(B)@

of

theY-pulse motor0 rotates, thentransmitsthe rotation

to

idlegear

(A)@).

2) When idlegear (A) @)rotates, the

(Y)

wires @)(left) and (right) reeled in

the

wire drums

(Y)

8 on

the

right

and the

left

move the carriage

fi

in the direction

of

theY-axis (backwards e forwards) via the

pulley8.

-10-

From the library of: Superior Sewing Machine & Supply LLC

c

STANDARD

ADJUSTMENT

)

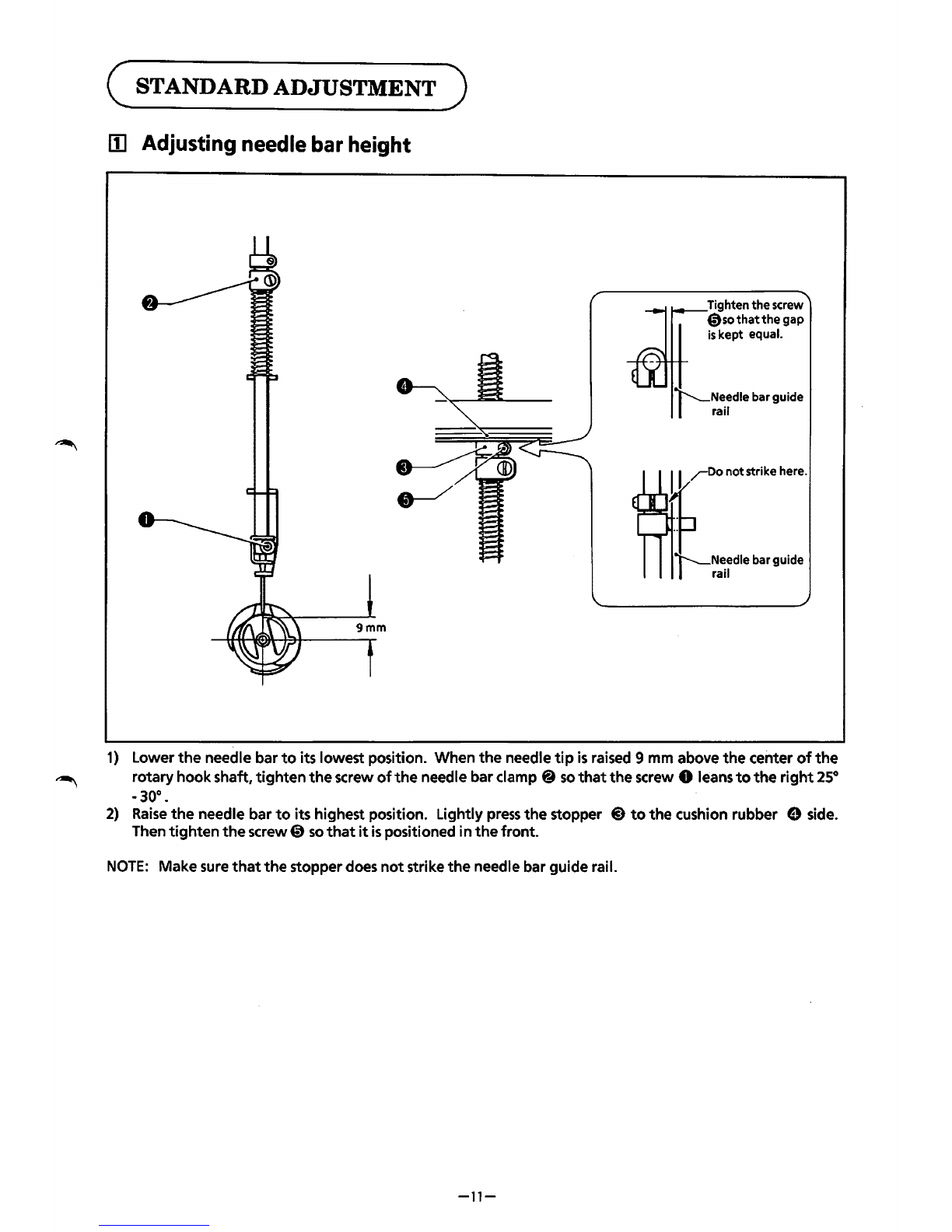

lii

Adjusting

needle

bar

height

Tightenthescrew

0so

that

the

gap

is

kept equal.

1)

Lower

the

needle bar

to

its lowest position. When

the

needle

tip

is

raised 9 mm above

the

center

of

the

~

rotaryhookshaft,

tighten

the

screw

of

the

needle barclamp @

so

that

the

screw 0 leans

to

the

right

25°

-30°.

2)

Raise

the

needle bar

to

its highest position. Lightly

press

the

stopper

@)

to

the

cushion rubber 9 side.

Then

tighten

the

screw0

so

that

it

is

positioned in

the

front.

NOTE:

Make sure

that

the

stopperdoes

not

strike

the

needle bar guide rail.

-11-

From the library of: Superior Sewing Machine & Supply LLC

When using

the

gauge (optional)

Gauge

1)

Loosen

thescrew 0 and remove

the

rotary

hook@

from the lowershaft.

2)

Insertthe gauge (option)

into

the lowershaft.

3)

Loosen

the

screw e

of

the

needle bar clamp

@).

Turn

the

pulley until the needle

tip

lightlycontacts

the

gauge

at

its lowestposition.

NOTE:

Do

not

use

the

flat

part

of

the

gauge

at

thistime.

4)

Tighten

the

screw 9

of

the

needle bar

clamp@)

firmly.

-12-

From the library of: Superior Sewing Machine & Supply LLC

~ Adjusting timing

of

needle and rotary hook

1/

I I

I

I I

I I

I I

: I

1)

Selectthefirstneedlebar

0.

\

I

I

I

I

I I

I I

I I

2)

Remove

the

two

screws and

the

needle plate@.

Aprrox.1 mm

2.5mm

3)

When

the

needle bar

is

raised

2.5

mm

(201°)

above its lowest position (180°), loosen

the

screw 0

of

the

rotary hook

@),

and adjust

so

that

the

needle meets

the

rotary hook point. Then, temporarily

tighten

the

two

stopscrews.

At

thistime,

the

needle barheightshould be about 1mm. {Figure A) .

4)

As

for

other needle bars,

if

the

gap between

the

needle and rotary hook

point

is

0.01

-

0.2

mm,

tighten

the

3screws

of

the

rotary hook.

~

Adjusting cloth presser height

Cutand insert.

Adjust

the

cloth presser 0

height

with

the

cushion rubber

@).

The cloth presser 0 heightshould be raised 1

-

1.5

mm

from

the

needle plate @

at

the

cloth presser's lowest position. {Asheet

of

the

cushion rubber

is

0.5

mmthick.)

~13-

From the library of: Superior Sewing Machine & Supply LLC

(j] Adjusting knife

and

fixed knife

1.

Attaching fixed knife

1)

Attach

the

fixed knife

so

that

the

attached part parallels

the

rotary hook

base.

The movable knife

broadens

at

part®.

Makesure

the

fixed knife doesn'tcontact

it

at

thispart.

2.

Knife timing

1)

While pushing

the

cam

lever 0 up

with

a finger, rotate

the

pulley @ in

the

direction

of

the

arrow.

When

the

knife

@)

begins

to

move,

the

pulley

will

become harder

to

turn.

At

thistime,tighten

the

screw

of

the

24 Jgear eI

fix

the

cam

CD

by hand

so

it

does

not

rotate, and

turn

the

pulley.

The

rotary hook

bladeshould be in

the

center

of

the rotaryhooksupporter@).

2)

Tighten

the

screw

of

the

24 J gear e

so

there

is

no backlash

of

the

cam

in

the

direction

of

the

lower

shaft. While pushing

the

cam

lever 0 up

with

a finger, rotate

the

pulley @again. When

the

knife

@)

begins

to

move,

the

blade in

the

rotary hookshould be in

the

center

of

the

rotaryhooksupporter

@).

3.

Knife position

Loosen

the

screw & and adjust

the

knife

@)

position

so

that

its end projects 1 mm beyond

the

fixed

knife'stip.

After

threadtrimming,

the

knifeshould be in this position.

If

the

knife does

not

stop

at

the

stop position,

the

uppershaft

will

be locked and

it

cannot make one

full

revolution. In

that

case,

move

the

knife

to

the

stop position byhand.

4.

Knife and fixed knife

1)

With

a marker, color

the

back

of

the

knife

@)

and engage

it

with

thefixed knife

@)

manually.

Check

that

the

colored portion

is

shaved equally.

This

shows properknifeengagement.

2)

If

the

engagement

is

wrong, loosen

the

screw

@)

of

the

fixed knife

@)

and adjust

the

inclination

with

the

lower

set screw

CD).

NOTE:

The inclination

of

the

fixed knife @)should

be

adjusted

with

the

two

top

screws

@)

and

the

bottomsetscrew

CD).

NOTE:

This

is

fineadjustment. Adjust carefully.

-14-

~-

From the library of: Superior Sewing Machine & Supply LLC

1§1

Adjusting

picker

FigureA

1)

Insert

the

bobbin

case

0 containing

the

bobbin

into

the

rotaryhookand set

the

picker@ position.

2)

Leave

the

solenoid arm

@)

pushed

to

the

needle bar side, then

tighten

connecting plate (A) e

with

the

screw0.

3)

Adjust

the

picker @

so

that

there

is

no

looseness and

so

that

it

functions lightly. Then

tighten

the

picker

bracket(!)

with

the

screw

8.

4)

Adjust

the

gap between

the

point

of

the

pickerand

the

bobbin

to

1

-1.5

mm.

Leave

the

solenoid arm

@)

pushed

to

the

pulleyside (thesolenoid operation position), thentighten

the

screw@).

5)

Adjust

the

picker position

so

that

it

is

bisected by

the

bobbin

case

spring

(see

figureA).

-15-

From the library of: Superior Sewing Machine & Supply LLC

[§]

Adjusting

the

thread wiper

1)

With

a finger, move

the

solenoid arm 0 in

the

direction

of

the

arrow.

Loosen

the

two

screws @ then

adjust

the

upperthread guide

hook@

so

that

it

movesslightly.

2)

Adjust

the

upperthread guide hook @

so

that

itscut part

is

located

at

the

center

of

the

needle hole.

-16-

From the library of: Superior Sewing Machine & Supply LLC

111

Adjusting

wire

tension

1.

X-feed wire

0 1.5 kg

Using a 1.5 kg

torque

wrench

or

a similar

tool,

push

at

the

location marked by

the

arrow

and adjust

so

there

is

a deflection

of

approximately

14

mm.

How

to

adjust

1)

Remove

the

seven screws 0 and

the

two

covers

(LR,

LL)@.

2)

Loosen

the

two

screws 0

of

both

hook

(LX)

@)

and hook

(RX)

0.

3)

There are

two

stoppers (U)

(S)

on

the

right

and

the

left

sides.

Turning them clockwise

will

increase

the

tension and

turning

them counterclockwise

will

decrease

the

tension.

4) When

the

tension

is

proper,

tighten

screw

0.

5)

After

tightening

screw

0,

firmly

retighten stoppers

(U)

(S)

so

there

is

no

looseness.

-17-

From the library of: Superior Sewing Machine & Supply LLC

Other manuals for BAS-411

3

This manual suits for next models

1

Table of contents

Other Brother PDA manuals