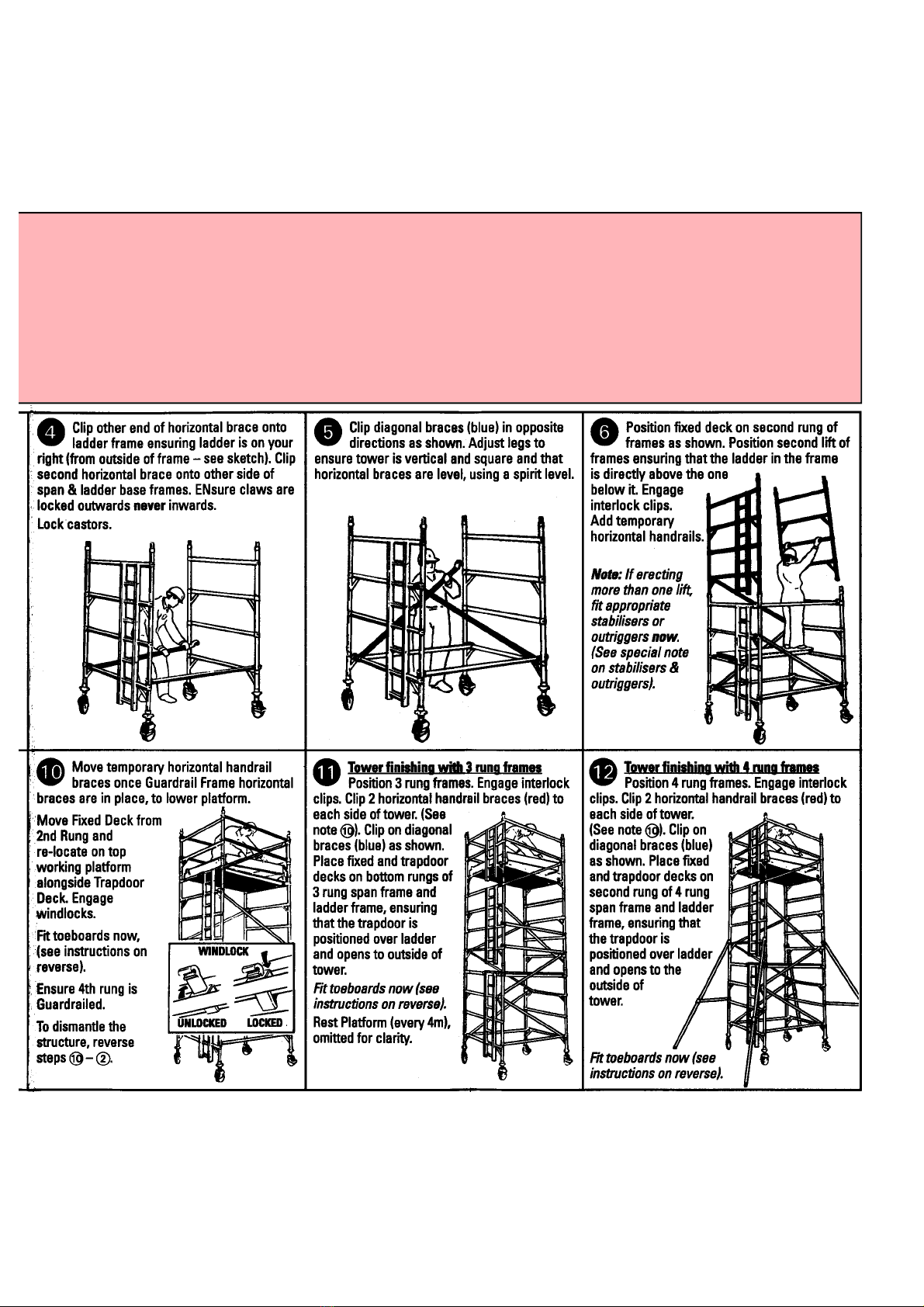

ERECTION

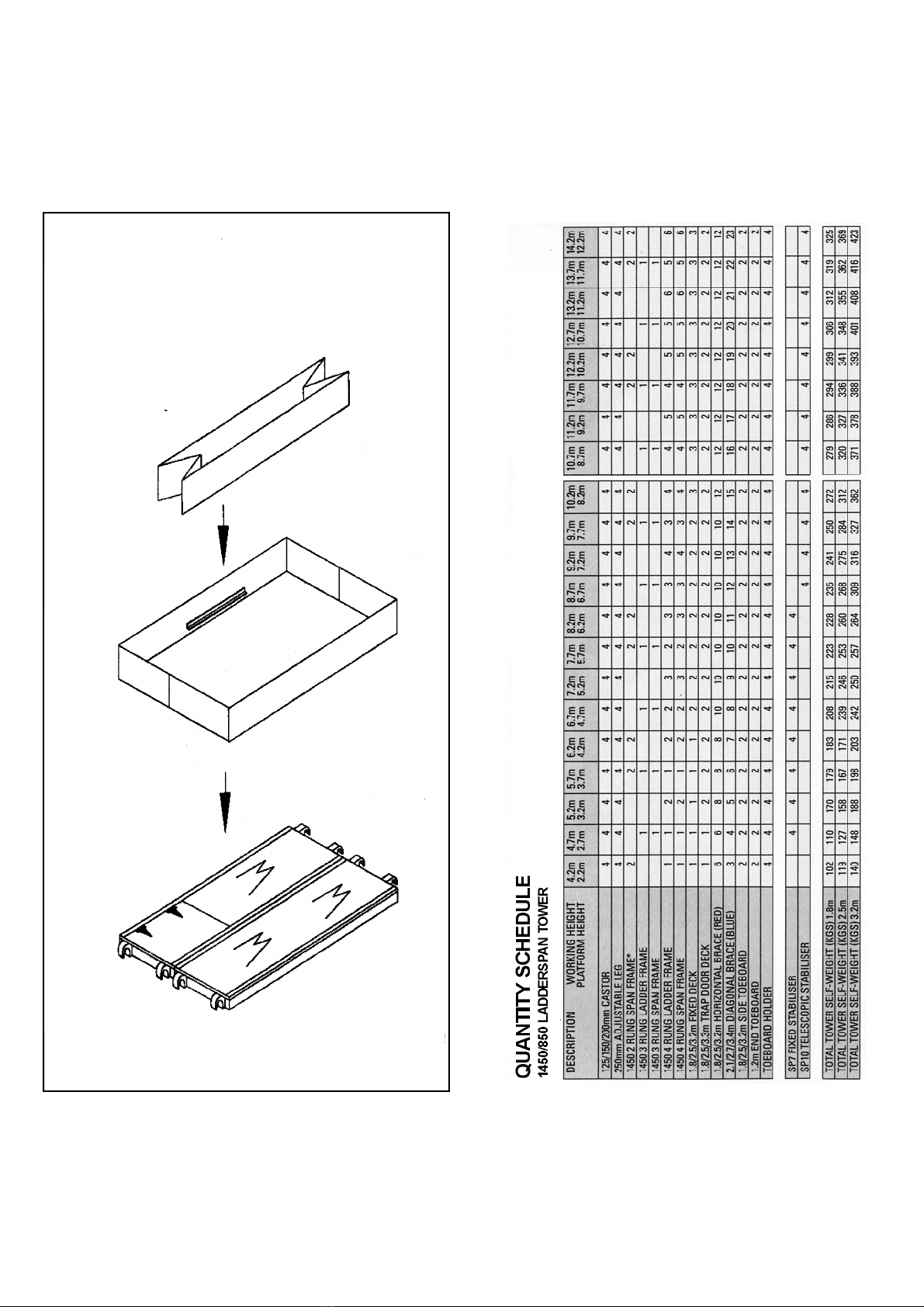

Check that all components are on site and they are

functioning correctly - See Quantity Schedule

Check if the ground on which the mobile access tower is to be

erected and moved, is capable of supporting the tower.

During the erection of the tower it is recommended that a

temporary guardrail brace be employed.

The safe working load is 275 kgs (606 lbs) uniformly distributed -

maximum concentrated load 150 kgs (330 lbs) per deck up to a

maximum of 950 kgs (2100 lbs) per tower (including self weight).

This must not be exceeded

Towers must always be climbed from the inside during assembly

and using the built-in ladder provided during use.

Do not use boxes or step ladders on the platform to gain

additional height.

LIFTING OF EQUIPMENT

Tower components should be

firmly secured by a reliable lifting

material (eg rope), employing a

reliable knot (eg clove hitch), to

ensure safe fatening

STABILISERS/BALLAST

Stabilisers or outriggers and ballast weights shall always be

fitted when specified.

Ballast is used at the base to stabilise towers against

overturning. The QUANTITY SCHEDULE shows the recommended

stabilisation. In circumstances where there is restricted ground

clearance for stabilisers/outriggers, contact your supplier for

advice.

It must be of solid materials (i.e. not water or loose sand) and

should not be positioned to overload individual legs. Ballast

should be secured agains accidental removal, and be

supported on the lowest rung of the bottom frame.

MOVEMENT

The tower should only be moved by manual effort, and only

from the base.

When moving the tower, beware of live electical apparatus,

particularly overhead, plus wires or moving parts of machinery.

No personnel or materials should be on the tower during

movement.

Caution should be exercised when wheeling a tower over

rough, uneven or sloping ground, taking cars to unlock and lock

castors. If stabilisers are fitted, they should be lifted

sufficiently above the ground to clear ground obstructions. The

height of the tower, when being moved, should not exceed

2.5 times the minimum base dimensions, or 6 metres overall

height.

DURING USE

Beware of high winds in exposed, gusty or medium breeze

conditions. We recommend that in wind speeds over 7.7 metres

per second (17 m.p.h.), cease working on tower. If the wind

becomes a strong breeze, expected to reach 11.3 metres per

second (25 m.p.h.), tie the tower to a rigid structure. If the wind

is likely to reach gale force, over 18 metres per second (40m.p.h.)

the tower should be dismantled.

Beware of open ended buildings which can cause funnelling effect.

Do not abuse the equipment, damaged or incorrect components

should never be used.

Raising and lowering components, tools, and/or materials by rope

should be conducted wtihin the tower base. Ensure that the safe

working load of the supporting decks and the tower structure is

not exceeded.

The assembled tower is a working platform and should not be

used as a means of access to other structures.

Beware of horizontal forces (eg power tools) which could

generate instability. Maximum horizontal force 20 kg.

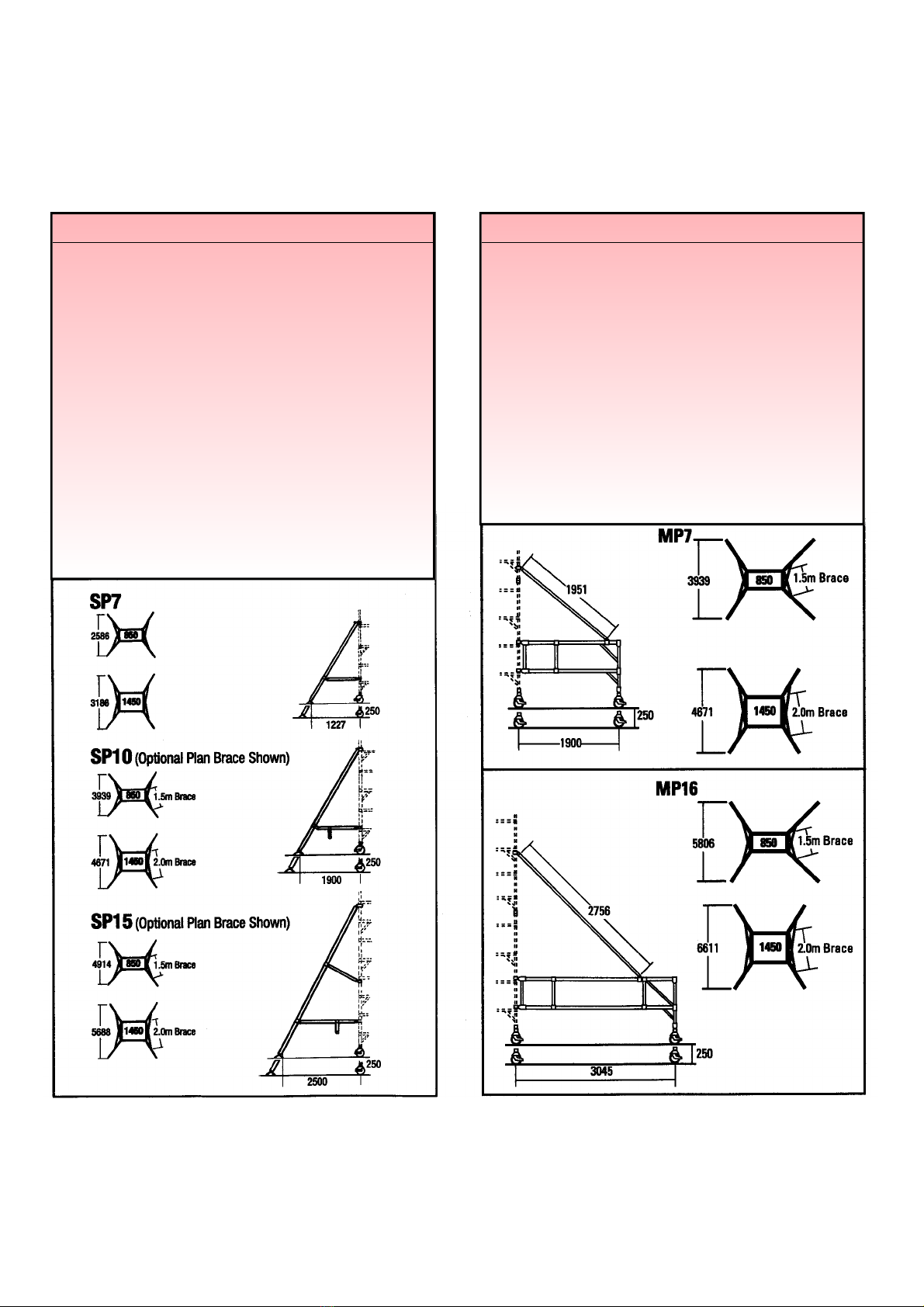

The Stairway towers featuring an inclined staircase access are

for use with personnel frequently carrying tools an/or materials.

mobile towers are nor designed to be suspended - please refer

to your supplier.

TIES

Ties should be used when the tower goes beyond its safe height

beyond the limits of the stabilisers/outriggers or there is a danger

of instability.They should be rigid, two way ties fastened to both

uprights of the frame with load-bearing right angled or swivel

couplers. Only couplers suitable for the 50.8mm dia. tube of the

tower should be used. Ideally ties should secure to either face of

a solid structure or by means of anchorages.

The tie frquency may vary depending on the application, but

they should, at a minimum, be at every 4 metres height.

MAINTENANCE

All components and their parts should be regularly inspected to

identify damage, particularly to welds. Lost or broken parts should

be replaced, and any tubing with indentations greater than 5mm

should be put to one side for manufacture repair.Adjustable leg

threads should be cleaned and lightly lubricated to keep them

free running.

Wind Beaufort Beaufort Speed in Speed in

Description Scale No. m.p.h. m/sec.

Medium Breeze Raises dust and loose 4 8-12 4-6

paper, twigs snap off.

Strong Breeze Large branches in motion, 6 25-31 11-14

telegraph wires whistle.

Gale Force Walking is difficult 8 39-46 17-21

•

•

•

•

•

•

•

•

••

•

•

•

•

•

•

•

•

•

•

•

•

USAGE ADVICE FOR ALL TOWER VARIATIONS