AUTEC ALM-6040FL Guide

en/TA-11-ALM-6040/10040FL pag.: 1

USER /

INSTALATION

MANUAL

4-POST HD ISSUED 26-05-04

ALM-6040FL

ALM-10040FL

AUTEC Hefbruggen bv

Industrieterrein IJsselveld, Vlasakker 11, 3417 XT MONTFOORT, The Netherlands

Tel: +31 348 477000 Fax: +31 348 475104 Internet: www.autec.nl - E-mail: [email protected]

=ELECTRO-MECHANICAL FOUR POST LIFT

en/TA-11-ALM-6040/10040FL pag.: 2

USER /

INSTALATION

MANUAL

4-POST HD ISSUED 26-05-04

ALM-6040FL

ALM-10040FL

AUTEC Hefbruggen bv

Industrieterrein IJsselveld, Vlasakker 11, 3417 XT MONTFOORT, The Netherlands

Tel: +31 348 477000 Fax: +31 348 475104 Internet: www.autec.nl - E-mail: [email protected]

Disclaimer Of Warranties And Limitations Of Liabilities

Whilst the staff of Autec - SUN / VLT Equipment have taken due care in the preparation of this manual nothing

contained herein modifies or alters in any way the standard terms and conditions of the Autec purchase, lease

or rental agreement under the terms of which the Equipment to which this manual relates was acquired or

increases in any way Autec - SUN / VLT Equipment liability to the customer or to third parties.

To The Reader

Whilst every effort has been made to ensure that the information contained in this manual is correct, complete

and up-to date Autec - SUN / VLT Equipment reserves the right to change any part of this document at any

time without prior notice

BEFORE OPERATING THIS UNIT, PLEASE READ THIS MANUAL

CAREFULLY, PAYING EXTRA ATTENTION TO THE SAFETY WARNINGS

AND PRECAUTIONS.

Copyright © Autec - SUN / VLT Equipment

Autec - SUN / VLT Equipment

A division of AUTEC Carlifts bv

Industrieterrein IJsselveld

Vlasakker 11

3417 XT Montfoort

The Netherlands

Tel : 31-(0)348 477000

Fax: 31-(0)348 475104

http://www.autec.nl

en/TA-11-ALM-6040/10040FL pag.: 3

USER /

INSTALATION

MANUAL

4-POST HD ISSUED 26-05-04

ALM-6040FL

ALM-10040FL

AUTEC Hefbruggen bv

Industrieterrein IJsselveld, Vlasakker 11, 3417 XT MONTFOORT, The Netherlands

Tel: +31 348 477000 Fax: +31 348 475104 Internet: www.autec.nl - E-mail: [email protected]

CONTENTS PAG

1. GENERAL INFORMATION 05

1.1 lntroduction 05

1.2 Use of this manual 05

1.3 Contained in this manual 05

1.4 Safety 05

2SAFETY PRECAUTIONS 06

2.1 Safety Notice 06

2.2 General 06

2.3 General Warnings 06

2.4 The weight of the vehicle 08

2.5 Pictograms on lift 08

3SAFETY DEVICES 09

3.1 General precautions 09

3.2 "Dead man" system 10

3.3 Safety device in the presence of obstacles 10

3.4 Mechanical block 10

3.2 Risk of damage due to electricity 11

3.3 Risk and protective media 11

3.4 Hazards associated with lifting of a vehicle 11

3.5 Risk for persons 11

3.5.1 Risk for the operator. 11

3.5.2 Risk for personnel. 12

3.5.3 Risk for impact. 12

3.5.4 Risk for sliding out. 13

3.5.5 Risk for electrocution. 13

3.5.6 Risk due to insufficient lighting. 13

3.5.7 Risk of use/maintenance. 13

3.6 Suitability for usa. 13

4PACKING, TRANSPORT AND STORAGE 15

4.1 Lift handling and pre-installation 15

4.2 Lifting and moving the packing 15

4.3 Storage 15

4.3 Opening the crates and boxes 15

4.4 Product Identification 16

4.5 Warranty 16

4.6 Servicing 16

4.7 Technical Specification 16

5DESCRIPTION OF THE LIFT 18

5.1 Commands 18

6. CHECKING THE MINIMUM REQUIREMENTS FOR THE PLACE OF INSTALLATION 20

en/TA-11-ALM-6040/10040FL pag.: 4

USER /

INSTALATION

MANUAL

4-POST HD ISSUED 26-05-04

ALM-6040FL

ALM-10040FL

AUTEC Hefbruggen bv

Industrieterrein IJsselveld, Vlasakker 11, 3417 XT MONTFOORT, The Netherlands

Tel: +31 348 477000 Fax: +31 348 475104 Internet: www.autec.nl - E-mail: [email protected]

CONTENTS PAG

7. INSTALLATION 20

7.1 Checking the minimum requirements for the place of installation. 20

7.2 Assembling. 21

7.3 Adjustment of the device controlling the wear of the support screw 27

7.4 Obstacle microswitch adjustment 29

8. INSTRUCTIONS FOR USE OF THE LIFT 30

8.1 IMPROPER USE OF THE LIFT 31

8.2 USE OF ACCESSORIES 31

8.3 STAFF TRAINING 31

8.4 IMPORTANT CHECKS TO BE MADE 31

9. MAINTENANCE INSTRUCTIONS 32

9.1 Motor chains 32

9.2 Containers at post base 32

9.3 Gear boxes 33

9.4 Angular transmissions 33

9.5 Checking the wear on the load-bearing support screws 33

10 PROBLEMS 35

11. STORAGE 35

11.1 SCRAPPING 35

12 ELECTRICAL INSTALLATION 36

13 CONFORMITY 37

en/TA-11-ALM-6040/10040FL pag.: 5

USER /

INSTALATION

MANUAL

4-POST HD ISSUED 26-05-04

ALM-6040FL

ALM-10040FL

AUTEC Hefbruggen bv

Industrieterrein IJsselveld, Vlasakker 11, 3417 XT MONTFOORT, The Netherlands

Tel: +31 348 477000 Fax: +31 348 475104 Internet: www.autec.nl - E-mail: [email protected]

1. GENERAL INFORMATION

1.1 lntroduction

Arrangements for the installation of the lift must be made with the manufacturers or suppliers rep-

resentative.

The lift has been designed and manufactured to the highest standards to give many years of reliable

and safe operation if used and maintained in accordance with the safety, operational and mainte-

nance instructions contained in this manual.

1.2 Use of this manual

This manual is intended for use by workshop technicians in charge of the lift (operators) and routine

maintenance technicians (maintenance operators). The operating instructions are considered to be

an integral part of the machine and must remain with it for the whole of its useful life.

Read every section of this manual carefully before operating the lift since it contains important

information concerning the:

=safety of people

=safety of the lift

=safety of lifted vehicles

GTHE COMPANY IS NOT LIABLE FOR ANY POSSIBLE PROBLEMS, DAMAGE OR ACCIDENTS

ARISING FROM FAILURE TO FOLLOW THE INSTRUCTIONS.

1.3 Contained in this manual

The following is recommended for the proper use of this manual:

=keep the manual in an easily accessible place near the lift;

=keep the manual in an area protected from damp;

=use this manual properly without damaging it

=do not make changes to the manual; changes and updates may only be made by the

manufacturer;

This manual is an integral part of the lift and should be given to the new owner if and when the lift is resold.

1.4 Safety

Every effort has been made to make this lift as safe as possible however, as with all lifting Equipment, it is

important that safe working practices are followed.

General safety information is to be found in the chapter "Safety Precautions" and specific safety warnings and

cautions are printed where applicable this throughout the text. All personnel working with or in the vicinity of

this lift must be familiar with the warnings and cautions contained in this manual.

en/TA-11-ALM-6040/10040FL pag.: 6

USER /

INSTALATION

MANUAL

4-POST HD ISSUED 26-05-04

ALM-6040FL

ALM-10040FL

AUTEC Hefbruggen bv

Industrieterrein IJsselveld, Vlasakker 11, 3417 XT MONTFOORT, The Netherlands

Tel: +31 348 477000 Fax: +31 348 475104 Internet: www.autec.nl - E-mail: [email protected]

2SAFETY PRECAUTIONS

2.1 Safety Notice

GFOR YOUR SAFETY, READ THIS MANUAL AND THE SAFETY PRECAUTIONS THOROUGHLY

BEFORE OPERATING THE LIFT.

GTHE LIFT IS INTENDED FOR USE BY PROPERLY TRAINED PERSONNEL ONLY. THE

SAFETY MESSAGES PRESENTED IN THIS MANUAL ARE INTENDED AS REMINDERS TO

TRAINED OPERATORS TO EXERCISE CARE WHEN USING THE UNIT.

2.2 General

The lift is supplied in a safe condition. In order to keep it in a safe condition and to ensure safe

operation of the Equipment, the operating and maintenance instructions contained in this manual

must be followed and the safety warnings & cautions must be observed.

2.3 General Warnings

General Warnings, giving instructions for the prevention of injury to people, are given in the following list.

Further specific warnings are printed where applicable before the appropriate subject.

GBEFORE USING THE LIFT, MAKE SURE THAT THE MAINS POWER SUPPLY CABLE IS

CONNECTED TO A MAINS POWER SUPPLY OUTLET OF THE CORRECT VOLTAGE WITH A

PROTECTIVE EARTH CONTACT. (REFER SERIAL NUMBER PLATE ON THE UNIT FOR MAINS

POWER REQUIRMENTS). VOLTAGES HIGHER THAN SPECIFIED CAN DAMAGE THE UNIT

AND MAKE IT UNSAFE.

G

THE USE OF MAINS POWER SUPPLY EXTENSION CABLES IS NOT RECOMMENDED.

IF ONE HAS TO BE USED, IT SHOULD HAVE CONDUCTORS WITH A DIAMETER OF

AT LEAST 1.5 mm. AND A PROTECTIVE EARTH CONTACT.

GONLY USE FUSES WITH THE FUSE RATING INDICATED NEAR THE FUSE HOLDER.

THE USE OF INCORRECTLY RATED FUSES CAN DAMAGE THE UNIT OR THE POWER CABLE

AND MAKE THESE ITEMS UNSAFE.

GDO NOT OPERATE THE UNIT BEFORE CONTACTING THE SERVICE CENTRE OF THE

MANUFACTURER/SUPPLIER, WHEN THE UNIT:

=SHOWS VISIBLE DAMAGE.

=FAILS TO OPERATE.

=HAS BEEN SUBJECTED TO PROLONGED STORAGE UNDER UNFAVOURABLE CONDITIONS

=HAS BEEN SUBJECTED TO SEVERE TRANSPORTATION STRESSES.

IT IS POSSIBLE THAT THESE CONDITIONS CAN MAKE THE UNIT UNSAFE.

GONLY USE THE LIFT IF YOU ARE QUALIFIED TO WORK WITH IT.

GKEEP PERSONS AND ANIMALS AWAY FROM THE LIFT WHILST IN OPERATION.

GENSURE THAT THE VEHICLE CANNOT MOVE DURING LIFTING. ALWAYS SET THE GEAR

SELECTOR IN NEUTRAL, SET THE PARKING BRAKE AND PLACE WHEEL CHOCKS IN FRONT

AND AT THE REAR OF THE DRIVE WHEELS BEFORE LIFTING A VEHICLE.

en/TA-11-ALM-6040/10040FL pag.: 7

USER /

INSTALATION

MANUAL

4-POST HD ISSUED 26-05-04

ALM-6040FL

ALM-10040FL

AUTEC Hefbruggen bv

Industrieterrein IJsselveld, Vlasakker 11, 3417 XT MONTFOORT, The Netherlands

Tel: +31 348 477000 Fax: +31 348 475104 Internet: www.autec.nl - E-mail: [email protected]

GTHE LIFT HAS BEEN DESIGNED FOR LIFTING VEHICLES AND HOLDING THEM AT ANY

HEIGHT WITHIN THE WORKING PARAMETERS OF THE MACHINE IN AN ENCLOSED ENVI-

RONMENT. ANY OTHER USE IS FORBIDDEN INCLUDING:

=THE WASHING OF VEHICLES;

=THE LIFTING OF PERSONS OR USE AS SCAFFOLDING;

=EXERTING PRESSURE;

=LOADING.

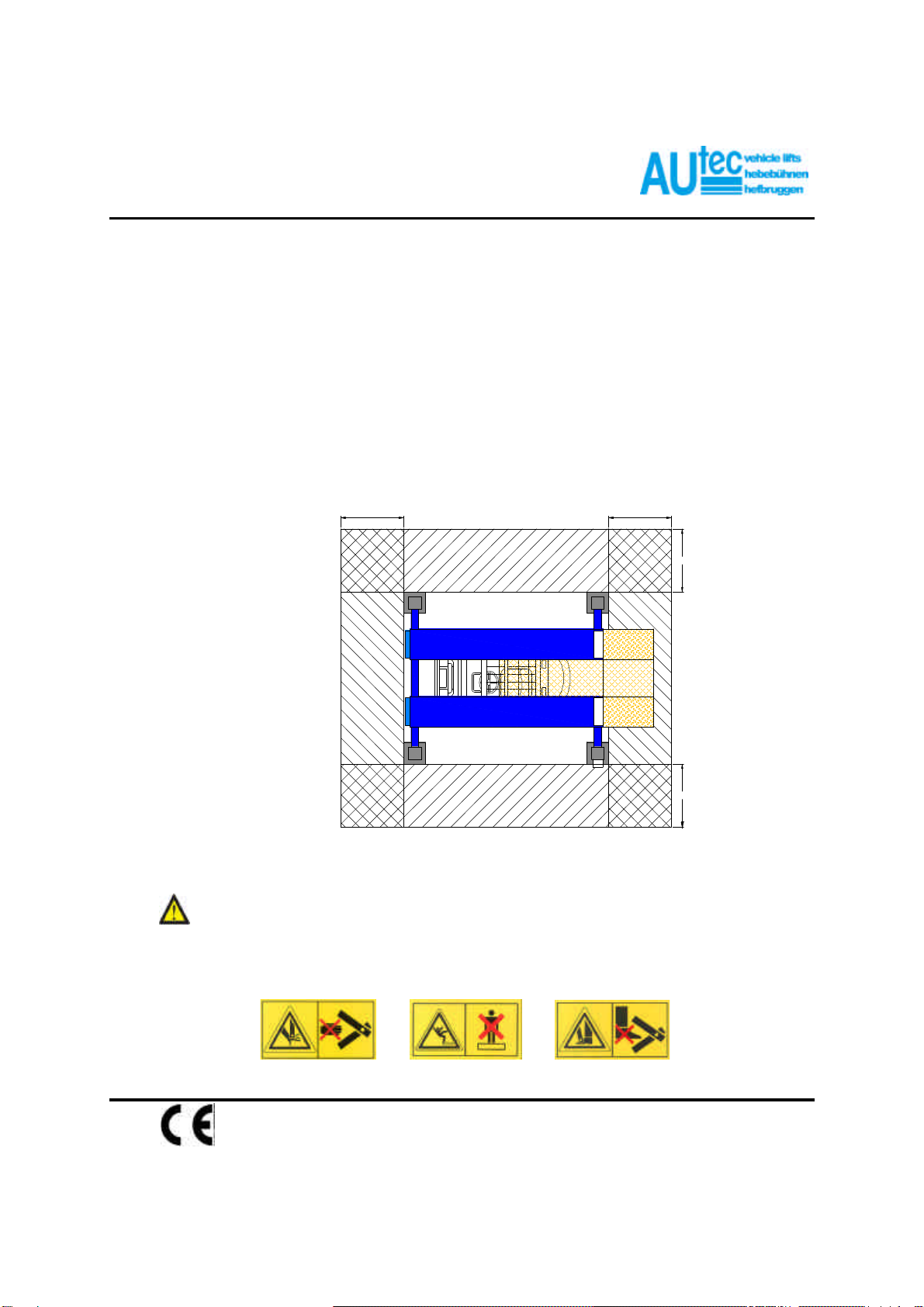

GTHE PRESENCE OF PERSONS INSIDE THE DANGER ZONE (fig. 1) IN THE SAME FIGURE IS

STRICTLY PROHIBITED. THE PRESENCE OF PERSONS BENEATH THE VEHICLE DURING

OPERATIONS IS PERMITTED ONLY WHEN THE VEHICLE IS PARKED IN THE ELEVATED

POSITION.

fig. 1

The safety zone (fig. 1) is to some extend determined by the dimensions of the vehicle to be lifted.

IT IS POSSIBLE THAT THESE CONDITIONS CAN MAKE THE UNIT UNSAFE.

GONLY USE THE LIFT FOR ITS DESIGNED PURPOSE. THE MANUFACTURER SHALL NOT BE

LIABLE FOR ANY INJURY OR DAMAGE TO PEOPLE, VEHICLES OF ANY OTHER OBJECTS

RESULTING FROM IMPROPER OR UNAUTHORISED USE OF THE LIFT.

1000 1000

1000

1000

GONLY USE THE LIFT FOR ITS DESIGNED PURPOSE. THE MANUFACTURER SHALL NOT BE

LIABLE FOR ANY INJURY OR DAMAGE TO PEOPLE, VEHICLES ORANY OTHER OBJECTS

RESULTING FROM IMPROPER OR UNAUTHORISED USE OF THE LIFT

GFOLLOW ALL APPLICABLE HEALTH REGULATIONS AND SAFETY STANDARDS WHEN

WORKING WITH THE LIFT.

2.4 The weight of the vehicle

The maximum loading capacity is not exceeded.

ALM-6040FL MAX. 6.000 Kg.

ALM-10040FL MAX. 10.000 Kg.

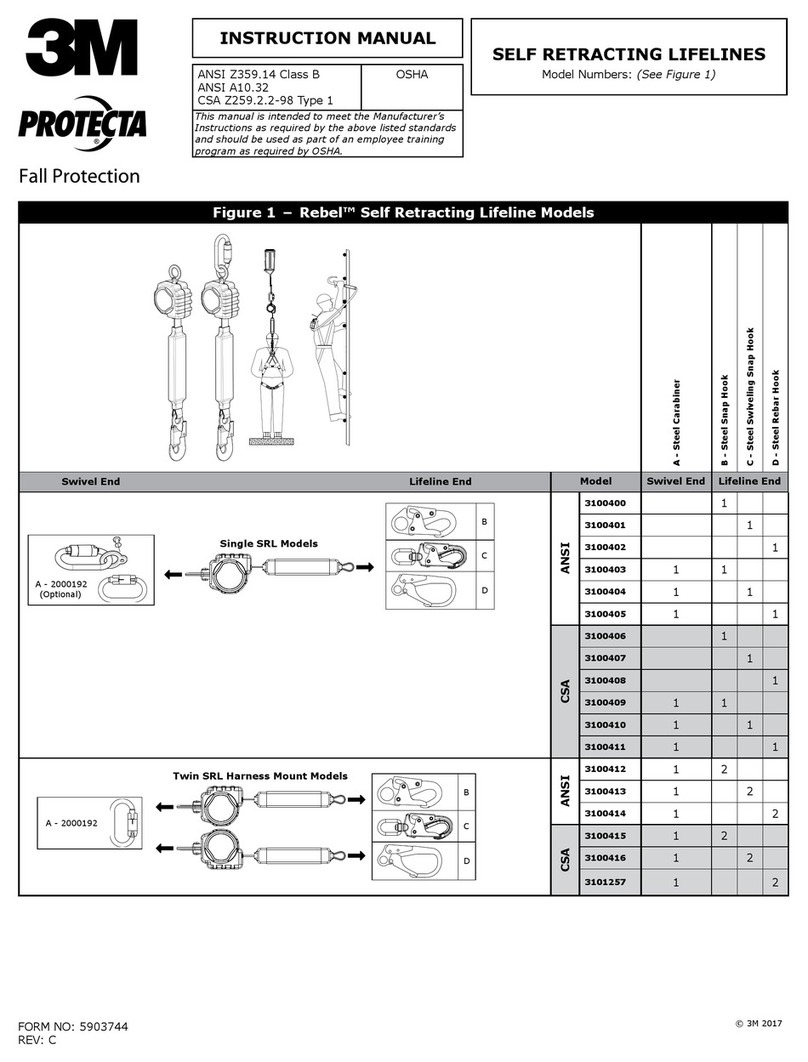

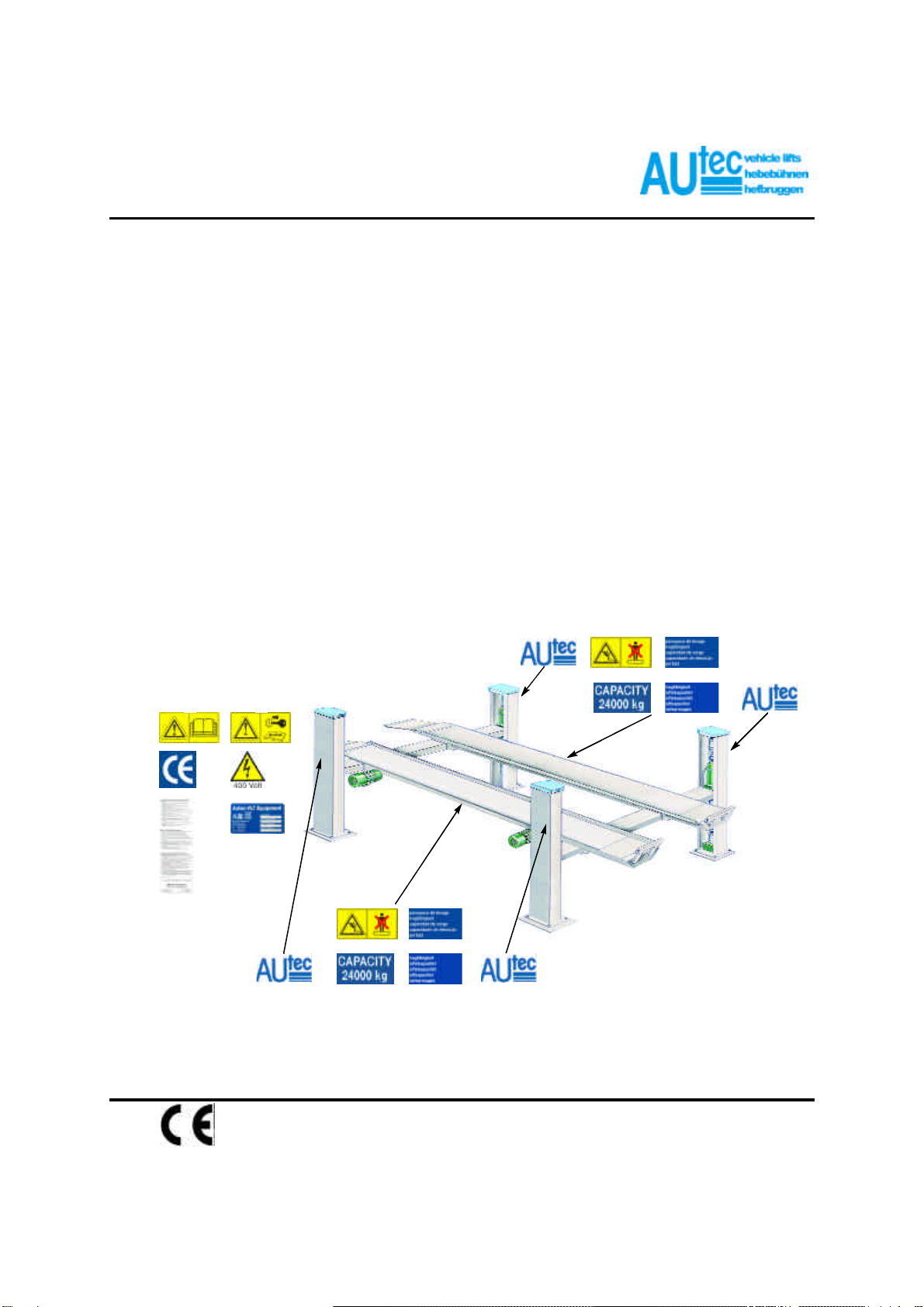

2.5 Pictograms on lift (fig. 2)

IN THE EVENT OF THESE PICTOGRAMS BEING DAMAGED, THEY MUST BE REPLACED BY NEW ONES AVAILABLE

FROM Autec - SUN / VLT Equipment.

1OB904-09 7OB901-ENSKA

3OB904-10 8OB901-DFSP

4OB904 9OB901-24000

5OB905-EDNL 10 OB904-08

6OB903-002 11 OB901-4000

Control unit.

en/TA-11-ALM-6040/10040FL pag.: 8

ISSUED 26-05-04

ALM-6040FL

ALM-10040FL

AUTEC Hefbruggen bv

Industrieterrein IJsselveld, Vlasakker 11, 3417 XT MONTFOORT, The Netherlands

Tel: +31 348 477000 Fax: +31 348 475104 Internet: www.autec.nl - E-mail: [email protected]

11

10 7

9 8

2 1

4 3

5 6

11

11

11

fig. 2

USER /

INSTALATION

MANUAL

4-POST HD

10 7

9 8

en/TA-11-ALM-6040/10040FL pag.: 9

USER /

INSTALATION

MANUAL

4-POST HD ISSUED 26-05-04

ALM-6040FL

ALM-10040FL

AUTEC Hefbruggen bv

Industrieterrein IJsselveld, Vlasakker 11, 3417 XT MONTFOORT, The Netherlands

Tel: +31 348 477000 Fax: +31 348 475104 Internet: www.autec.nl - E-mail: [email protected]

3. SAFETY DEVICES

WARNING:

The lift is designed and constructed to lift vehicles and to hold them in a certain position

in a covered working place. Any other form of use is not permitted. In short, the lift is

not suitable for the following purposes:

=Washing and spraying exersises.

=To be used as a device for applying force.

=To be used as a goods lift.

=To be used as a jack or for lifting vehicles for changing wheels.

The manufacturer hereby refuses any claims for damages arising in connection with injury to

persons or damage to vehicle or other property caused due to incorrect and/or unauthorised use of the lift.

During lifting- and lowering movements, the operator must be within the zone of operation (1), as shown in

fig. 1. The presence of any person in the safety zone (2) is strictly forbidden. The presence of persons under

the vehicle is only permitted if the vehicle is parked and locked in the lifted position.

GUSE THE LIFT ONLY IF ALL THE SAFETY ARRANGEMENTS ARE WORKING PROPERLY. IF

THESE RULES ARE NOT FOLLOWED, SERIOUS INJURY COULD BE CAUSED TO PERSONS AS

WELL AS IRREPARAIBLE DAMAGE TO THE LIFT AND THE VEHICLE ON THE LIFT.

3.1 General precautions:

=The operator is bound to follow the regulations which apply in the country in which these lifts are installed.

In addition, the operator must :

=Always work in the operators area as designated in the manual.

=Never remove the protective guards or dismantle or shut down the mechanical, electrical or other types of

safety arrangements.

=Read the safety regulations relating to the lift and take cognisance of the safety information provided in this

manual.

The following terms have been used in this manual to describe the various types of risk :

DANGER: there is a direct possibility of danger which could lead to serious injury or death.

WARNING:this indicates situations and/or actions which are unsafe and could lead to injuries of various

types except death.

CAUTION:this indicates situations and/or actions, which are unsafe and could lead to light injuries to

persons and/or damage to the lift, the vehicle or other properties.

en/TA-11-ALM-6040/10040FL pag.: 10

USER /

INSTALATION

MANUAL

4-POST HD ISSUED 26-05-04

ALM-6040FL

ALM-10040FL

AUTEC Hefbruggen bv

Industrieterrein IJsselveld, Vlasakker 11, 3417 XT MONTFOORT, The Netherlands

Tel: +31 348 477000 Fax: +31 348 475104 Internet: www.autec.nl - E-mail: [email protected]

3.2 "Dead man" system

The lift is equipped with a system which only operates in the presence of the operator: push-button controlled

rise or descent movements are immediately halted when these buttons are released.

3.3 Safety device in the presence of obstacles

If, during lift descent, an obstacle which resistance is greater than the weight of the moving element, a special

limit switch is activated, causing the lift to halt in any working condition. When the lift is at a halt, the only pos-

sible command is the rise command which enables the obstacle to be removed, followed by the descent com-

mando.

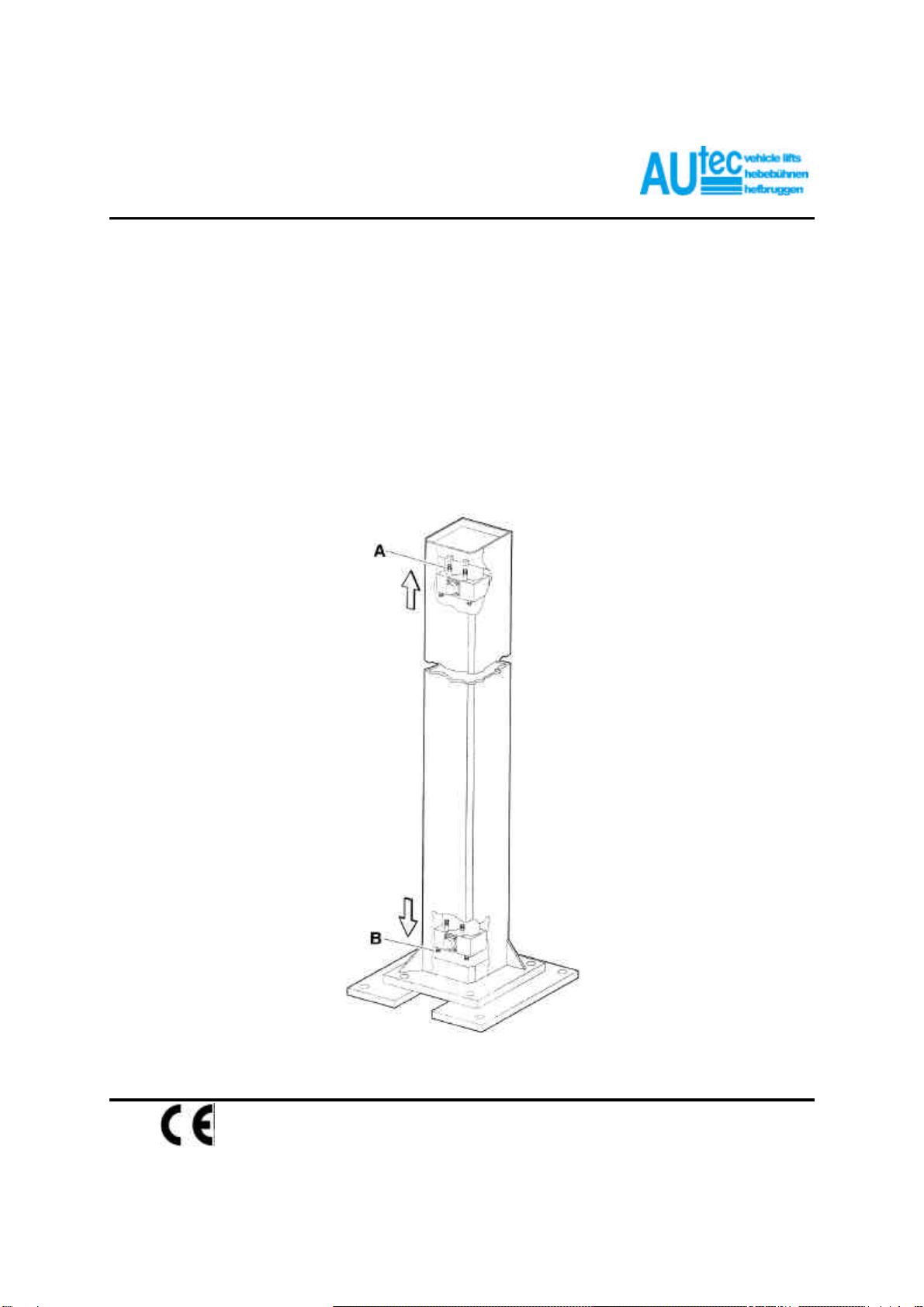

3.4 Mechanical block

This is activated if the rise/descent limit switches do not work.

It is activated during rise (A) and descent (B) after 5 mm runover of the operation point of the limit switch.

Adjust if necessary using the relative adjustment devices.

en/TA-11-ALM-6040/10040FL pag.: 11

USER /

INSTALATION

MANUAL

4-POST HD ISSUED 26-05-04

ALM-6040FL

ALM-10040FL

AUTEC Hefbruggen bv

Industrieterrein IJsselveld, Vlasakker 11, 3417 XT MONTFOORT, The Netherlands

Tel: +31 348 477000 Fax: +31 348 475104 Internet: www.autec.nl - E-mail: [email protected]

3.2 Risk of damage due to electricity

Special safety arrangements have been made on the lift in places where the risks are very high.

3.3 Risk and protective media

The risks to which the operator is exposed when the vehicle is in a raised position, together with the protective

media which have been installed, in order to limit the possible dangers.

3.4 Hazards associated with lifting of a vehicle

The following provisions have been made to avoid damage from excessive weight:

1. Cable break security: in each column a safety bar (catch bar) has been fitted parallel to the cable, which in

the event of the cable breaking will automatically support the raised section

2. Microswitches: microswitches have been fitted to the ends of the crossbeams to control the cable voltage.

Should the voltage to the cable be interrupted, by for example impact with an obstacle during lowering, the

lifting bridge will stop its descent.

3. Leakage and breakage protection: a pipe-breakage valve has been fitted in the cylinder head that will, in

the event of pipe breakage, reduce the rate of descenting of the tracks.

4. Accoustic signal: the lifting bridge will during its descent produce an accoustic signal.

5. Lifting bridge locking: next to the catch bar in each column a locking mechanism has been installed.

This consists of a strip in which grooves have been cut at regular intervals and with them slide locks that

are shot into them by a spring when the raising/lowering button is released.

6. Roll-on and roll-off protection: there is on the front end of the tracks roll-off protection, on the rear side at

the point of entry these are automatically elevated upon lifting.

7. Thermal protection: the electric motor is fitted with thermal protection, which guards the motor from over

heating.

3.5 Risk for persons

This paragraph describes the risks to which the operator or any other person near the working area where the

lift is in operation, in case the lift is not used in the appropriate manner.

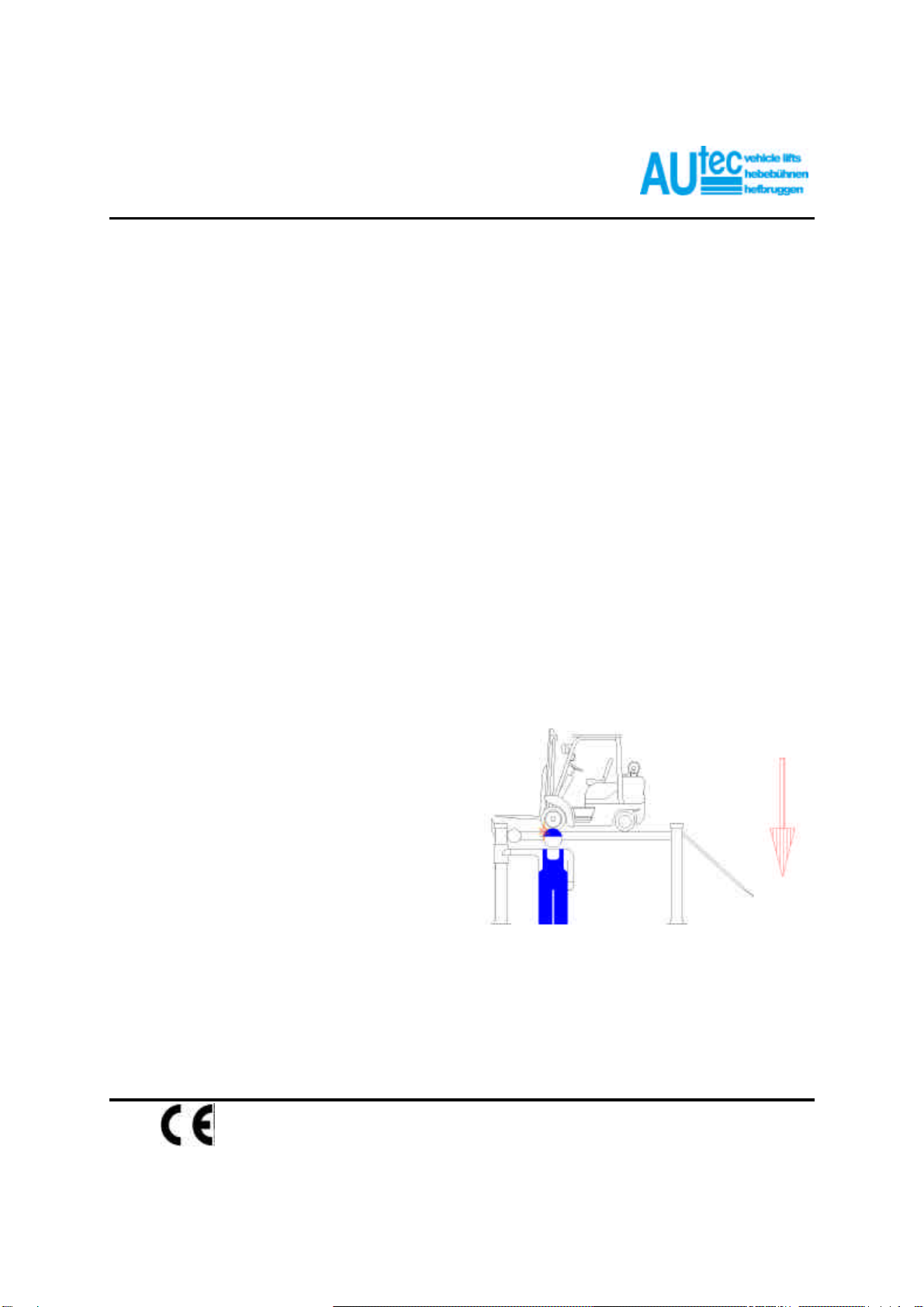

3.5.1 Risk for the operator.

This risk arises in cases where the operator is not

standing at the appointed place at the control

cabinet; when the lift with the vehicle is being low-

ered, it is not permissible for the operator to stand

below the descending system and its load to any

extent. It is imperative that the

operator must be standing in the operating zone

during the lifting and lowering operation. (fig. 3)

fig. 3

en/TA-11-ALM-6040/10040FL pag.: 12

USER /

INSTALATION

MANUAL

4-POST HD ISSUED 26-05-04

ALM-6040FL

ALM-10040FL

AUTEC Hefbruggen bv

Industrieterrein IJsselveld, Vlasakker 11, 3417 XT MONTFOORT, The Netherlands

Tel: +31 348 477000 Fax: +31 348 475104 Internet: www.autec.nl - E-mail: [email protected]

3.5.2 Risk for personnel

When the lift with the vehicle is

moving downwards, it is not per-

mitted for any of the personnel to

enter the room or walk under the

(downwards) moving parts of the

lift.(fig. 4)

The operator should not start the

motion of the lift until he has

assured himself that there are no

persons within the danger zone. fig. 4

3.5.3 Risk for impact

Caused by parts of the lift or the

vehicle that are positioned at head

height. When, due to operational

reasons, the lift is immobilised at

relatively low elevations ( less than

1.75 m from the ground) personnel

must be careful to avoid impact

with parts of the machine not

marked with special hazard

colouring. (fig. 5) fig. 5

Never enter the vehicle or start the

motor when the vehicle is on the lift

(fig.6)

fig. 6

Never rest any fittings or other

objects against the platform

and never place such objects

under the platform when it has

a load mounted on it, since this

can impede the lowering opera-

tions and may cause the vehicle

to fall off the platform (fig. 7)

fig. 7

en/TA-11-ALM-6040/10040FL pag.: 13

USER /

INSTALATION

MANUAL

4-POST HD ISSUED 26-05-04

ALM-6040FL

ALM-10040FL

AUTEC Hefbruggen bv

Industrieterrein IJsselveld, Vlasakker 11, 3417 XT MONTFOORT, The Netherlands

Tel: +31 348 477000 Fax: +31 348 475104 Internet: www.autec.nl - E-mail: [email protected]

3.5.4 Risk for sliding out.

This risk can be overcome by

avoiding the spillage of oil or

grease in the area surroun-

ding the lift (fig. 8).

Apart from that, any oil

spillage which may occur

should be thoroughly removed

from the spot immediately.

Fig. 8

3.5.5 Risk for electrocution.

Never spray water steam, sol-

vents or paint in the area imme-

diately surrounding the platform

and the control cabinet (fig.9)

fig.9

3.5.6 Risk due to insufficient lighting

The area surrounding the lift must be properly lighted according to the legal requirements applicable in the place

of installation.

3.5.7 Risk of use/maintenance

Autec uses material of the highest quality in its lift. These must be used according to the standard specified, and

maintenance must be carried out regularly.

3.6 Suitability for use.

This product has been manufactured in compliance with the European Directive 89/392. On the

basis of article 4.1.2.3 of this Directive, the coefficients used tor the tests are as follows:

1.10 for the dynamic test.

1.25 for the statie test.

These tests must be performed by specialist staff.

Any unauthorized modifications or tampering with the equipment release the manufac-

turer of responsibility for the damages caused by or related to the above men-

tioned acts.

The removal of or tempering with safety devices constitutes an infringement of

European Safety Regulations.

en/TA-11-ALM-6040/10040FL pag.: 14

USER /

INSTALATION

MANUAL

4-POST HD ISSUED 26-05-04

ALM-6040FL

ALM-10040FL

AUTEC Hefbruggen bv

Industrieterrein IJsselveld, Vlasakker 11, 3417 XT MONTFOORT, The Netherlands

Tel: +31 348 477000 Fax: +31 348 475104 Internet: www.autec.nl - E-mail: [email protected]

Place the vehicle in the centre of the footboards.

en/TA-11-ALM-6040/10040FL pag.: 15

USER /

INSTALATION

MANUAL

4-POST HD ISSUED 26-05-04

ALM-6040FL

ALM-10040FL

AUTEC Hefbruggen bv

Industrieterrein IJsselveld, Vlasakker 11, 3417 XT MONTFOORT, The Netherlands

Tel: +31 348 477000 Fax: +31 348 475104 Internet: www.autec.nl - E-mail: [email protected]

4. PACKING, TRANSPORT AND STORAGE

Every action involving the operation, transportation or unpacking of the equipment may only be done by trained

personnel who have a proper knowledge of the lift, and who are familiar with the contents of this operating

manual.

fig. 10

4.1 Lifting and moving the packing

The boxes must be lifted and moved with the help of a fork lift truck or a crane.

The equipment chosen must be capable of lifting and moving the equipment safely, keeping in mind the dimen-

sions of the vehicle, the weight, the centre of gravity and protection of fragile parts.

4.2 Storage

The packed lift must always the placed in a covered area at a temperature between -10 oC and + 40 oC and may

not be exposed to direct sunlight.

4.3 Opening the crates and boxes

Check whether the machine hase been damaged during transportation, and whether all the components as

mentioned in the packing list are physically present.

=avoid sudden bolts and tugs, be careful of uneven surfaces, bumps etc...;

=be extremely careful of exposed parts: obstacles, difficult through ways, etc...;

=wear suitable and protective clothing;

=after having removed the various packings, place them in special waste collecting areas which are inaccessi-

ble to children and animals where they will then be disposed of;

=on arrival, check that the packing has not been opened and, once unpacked check that nothing has been

damaged.

en/TA-11-ALM-6040/10040FL pag.: 16

USER /

INSTALATION

MANUAL

4-POST HD ISSUED 26-05-04

ALM-6040FL

ALM-10040FL

AUTEC Hefbruggen bv

Industrieterrein IJsselveld, Vlasakker 11, 3417 XT MONTFOORT, The Netherlands

Tel: +31 348 477000 Fax: +31 348 475104 Internet: www.autec.nl - E-mail: [email protected]

4.4 Product Identification

The identification data of the machine are shown in the label placed on the frame of the machine (fig. 11) and

indicated in the declaration of conformity. Use this data both to order spare parts and when getting in touch with

the manufacturer.

fig. 11

THE REMOVAL OF THIS LABEL IS STRICTLY FORBIDDEN.

Machines may be updated or slightly modified in appearance and, as a consequence, may present features

different from those shown without prejudice to what is described on it.

4.5 Warranty

The warranty is valid for a period of 12 months starting from the date of the invoice.

The warranty will be automatically invalidated if unauthorised modifications to the machine or parts there of are

carried out. The Manufacturer's authorised personnel must verify defects in workmanship or materials.

4.6 Servicing

For all servicing and maintenance operations not specified or shown in these instructions, contact the Dealer

where the machine was purchased or the Manufacturer's Commercial Department.

4.7 Technical Specification

X

ALM-6040FL ALM-10040FL

Capacity 6.000 kg 10.000 kg

Lifting time 70 s 80 s

Descent time 70 s 80 s

Noise level 70 dB (A) / 1 m 70 dB (A) / 1 m

Working temp. 0 °C / + 45 °C 0 °C / + 45 °C

Working envir. Indoor Indoor

Motor power 2 X 3 kW 2 X 3 kW

Electr. Supply 400 V / 50 Hz / 3 ph 400 V / 50 Hz / 3 ph

Color RAL 5015 RAL 5015

CE number 390-150X-0028-02-95 390-150X-0029-02-95

Notified body Bureau Veritas Bureau Veritas

en/TA-11-ALM-6040/10040FL pag.: 17

USER /

INSTALATION

MANUAL

4-POST HD ISSUED 26-05-04

ALM-6040FL

ALM-10040FL

AUTEC Hefbruggen bv

Industrieterrein IJsselveld, Vlasakker 11, 3417 XT MONTFOORT, The Netherlands

Tel: +31 348 477000 Fax: +31 348 475104 Internet: www.autec.nl - E-mail: [email protected]

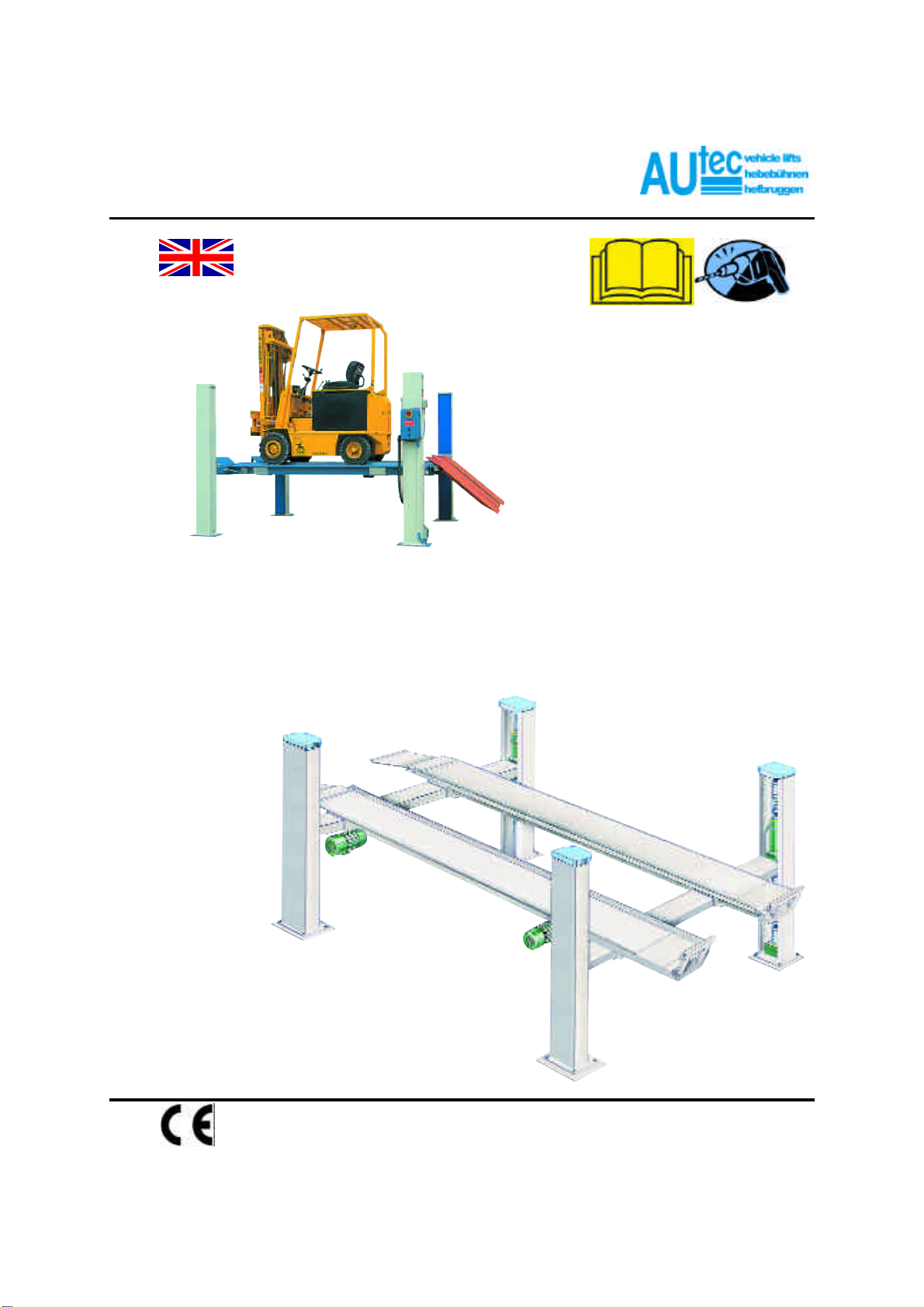

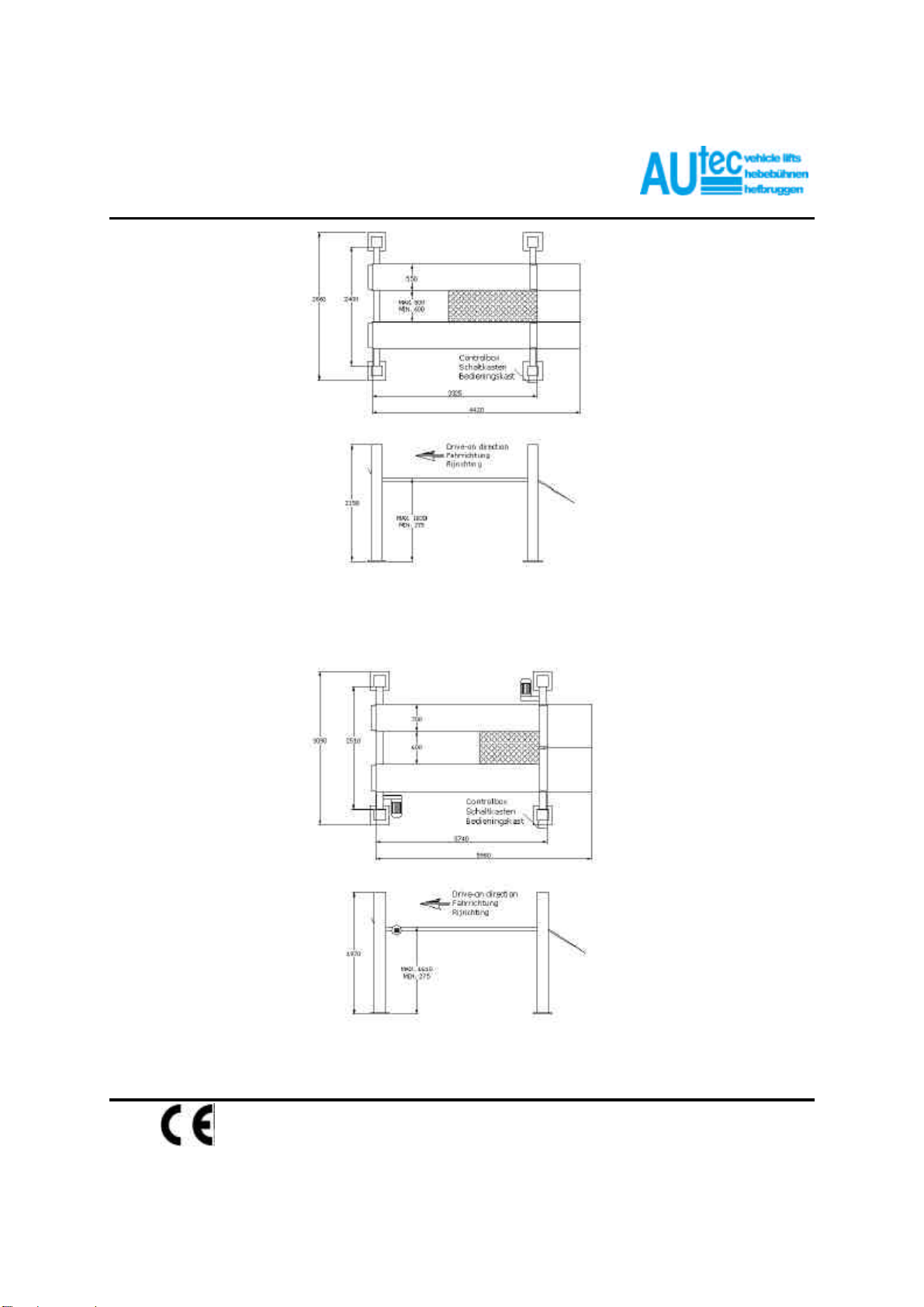

ALM-6040FL

ALM-10040FL

en/TA-11-ALM-6040/10040FL pag.: 18

USER /

INSTALATION

MANUAL

4-POST HD ISSUED 26-05-04

ALM-6040FL

ALM-10040FL

AUTEC Hefbruggen bv

Industrieterrein IJsselveld, Vlasakker 11, 3417 XT MONTFOORT, The Netherlands

Tel: +31 348 477000 Fax: +31 348 475104 Internet: www.autec.nl - E-mail: [email protected]

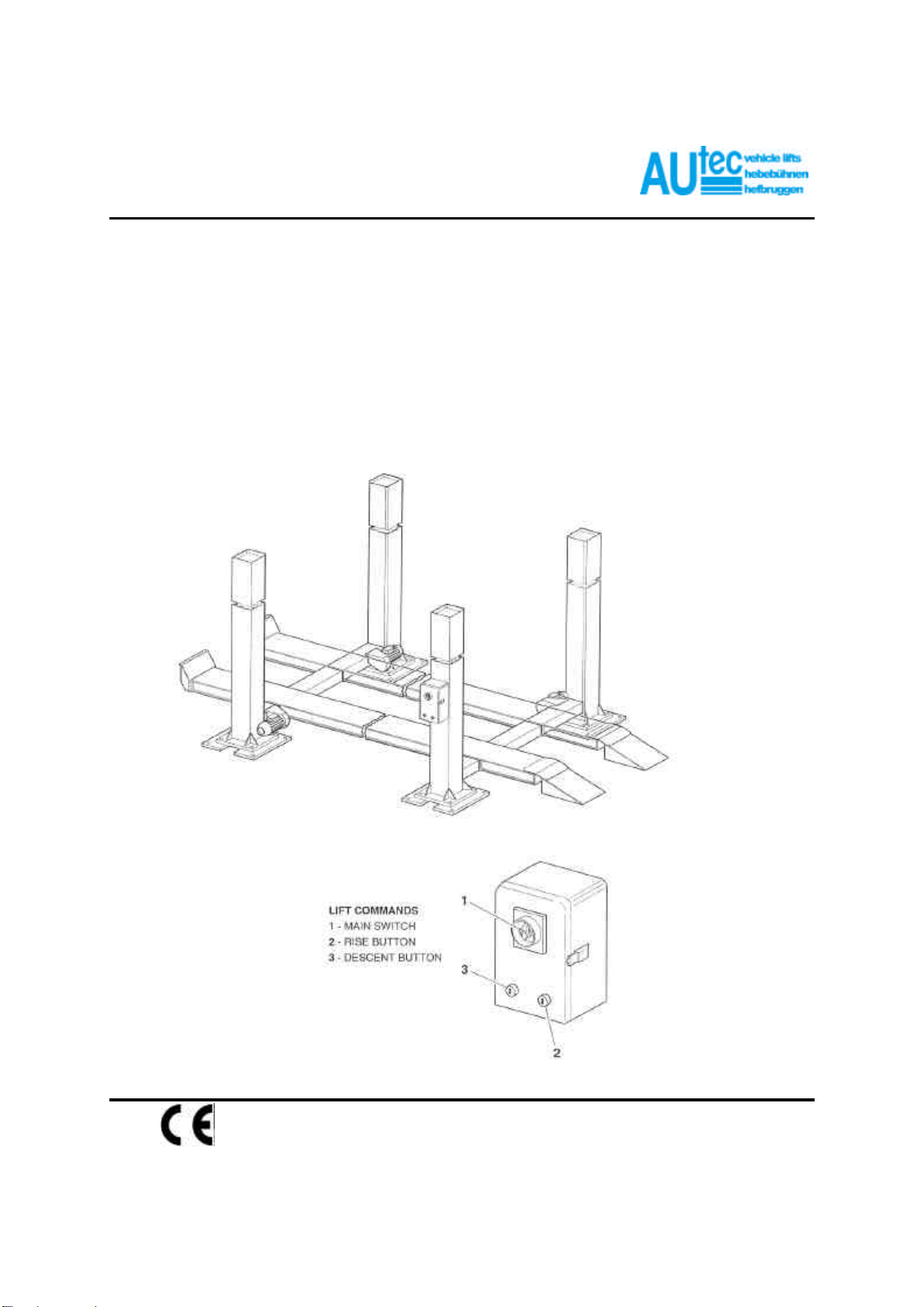

5. DESCRIPTION OF THE LIFT

LIFT Electromechanical four post lift.

Main technical specifications:

=platforms with overhang at both sides for easy motor extraction

=mechanical synchronisation of movements

=irreversible lifting mechanism

=possibility of driving on/down from both sides

5.1 Commands

Command cabinet containing: the hydraulic control box, mains switch, lift rise button, lift descent button and lift

in lockout indicator light.

en/TA-11-ALM-6040/10040FL pag.: 19

USER /

INSTALATION

MANUAL

4-POST HD ISSUED 26-05-04

ALM-6040FL

ALM-10040FL

AUTEC Hefbruggen bv

Industrieterrein IJsselveld, Vlasakker 11, 3417 XT MONTFOORT, The Netherlands

Tel: +31 348 477000 Fax: +31 348 475104 Internet: www.autec.nl - E-mail: [email protected]

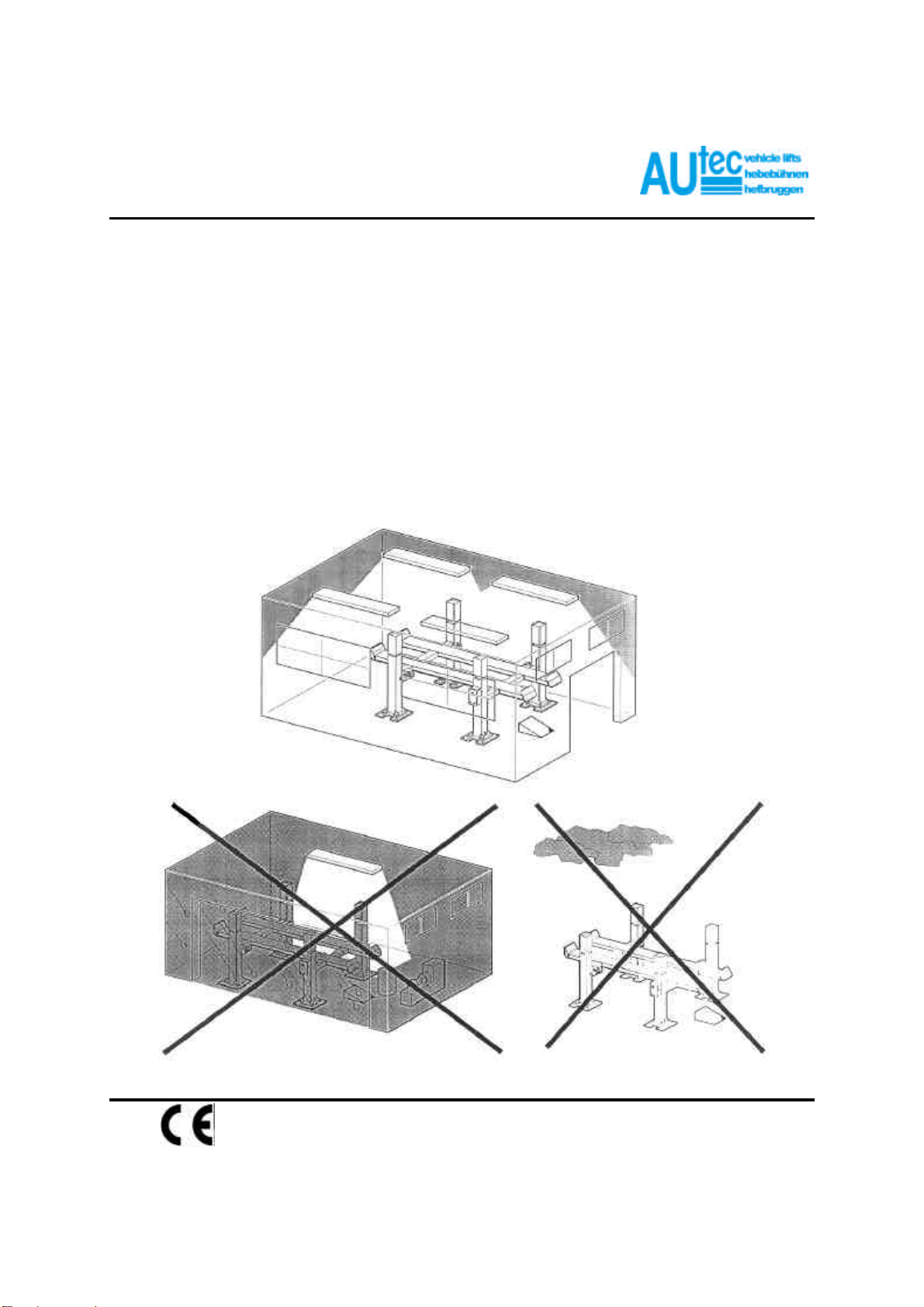

6. CHECKING THE MINIMUM REQUIREMENTS FOR THE PLACE OF

INSTALLATION

Check that the area in which the machine has to be installed has the tollowing characteristics:

=enough light (without strong or dazzling lighting).

=the area is not exposed to bad weather.

=the area is adequately ventilated.

=an unpolluted environment.

=sound levels are below the prescribed standards required by law

=no dangerous movements are caused in the area by either machines being operated.

=the area in which the machine is installed does not stock explosive, corrosive and/or toxic material.

=the installation layout should be selected so that the operator can see all the equipment and the surrounding

area from the operating position. The operator must prevent unauthorised persons and potentially

dangerous objects from entering this area.

All installation work concerning connections made to external power supplies (particularly electrical) should

be done by professionally qualified staff.

Installation must be done by authorised staff following specific instructions where present in this manual: if

in doubt, please consult authorised service centres or Autec technical services department.

en/TA-11-ALM-6040/10040FL pag.: 20

USER /

INSTALATION

MANUAL

4-POST HD ISSUED 26-05-04

ALM-6040FL

ALM-10040FL

AUTEC Hefbruggen bv

Industrieterrein IJsselveld, Vlasakker 11, 3417 XT MONTFOORT, The Netherlands

Tel: +31 348 477000 Fax: +31 348 475104 Internet: www.autec.nl - E-mail: [email protected]

7. INSTALLATION

7.1 Preparing the assembling area.

The lift must be placed on an even, compact, resistant floor. If the floor does not meet these requirements,

construct 4 concrete bases (fig. 3) which must be cast at least a week before assembling the lift.

(N.B. Concrete should be R'bk 250 dass or higher with suitable reinforcement).

fig. 12

Cement base measuresMaximum capacity on every post

Cement base measures

This manual suits for next models

1

Table of contents

Other AUTEC Lifting System manuals