BR3000-330-2CL,-3CL,-2EN CMM and IPL

Document No. 33-21-57, Rev. A

Page iii

TABLE OF CONTENTS

1.0 SCOPE.................................................................................................................1

1.1 Manufacturer Product Support Information.......................................................1

1.2 How to Use This Manual...................................................................................1

1.3 Warnings, Cautions, and Notes ........................................................................2

1.3.1 WARNING .................................................................................................2

1.3.2 CAUTION...................................................................................................2

1.3.3 Note...........................................................................................................2

1.4 General Safety Precautions..............................................................................2

1.4.1 Electrostatic Discharge..............................................................................2

1.4.2 Modification of Equipment..........................................................................2

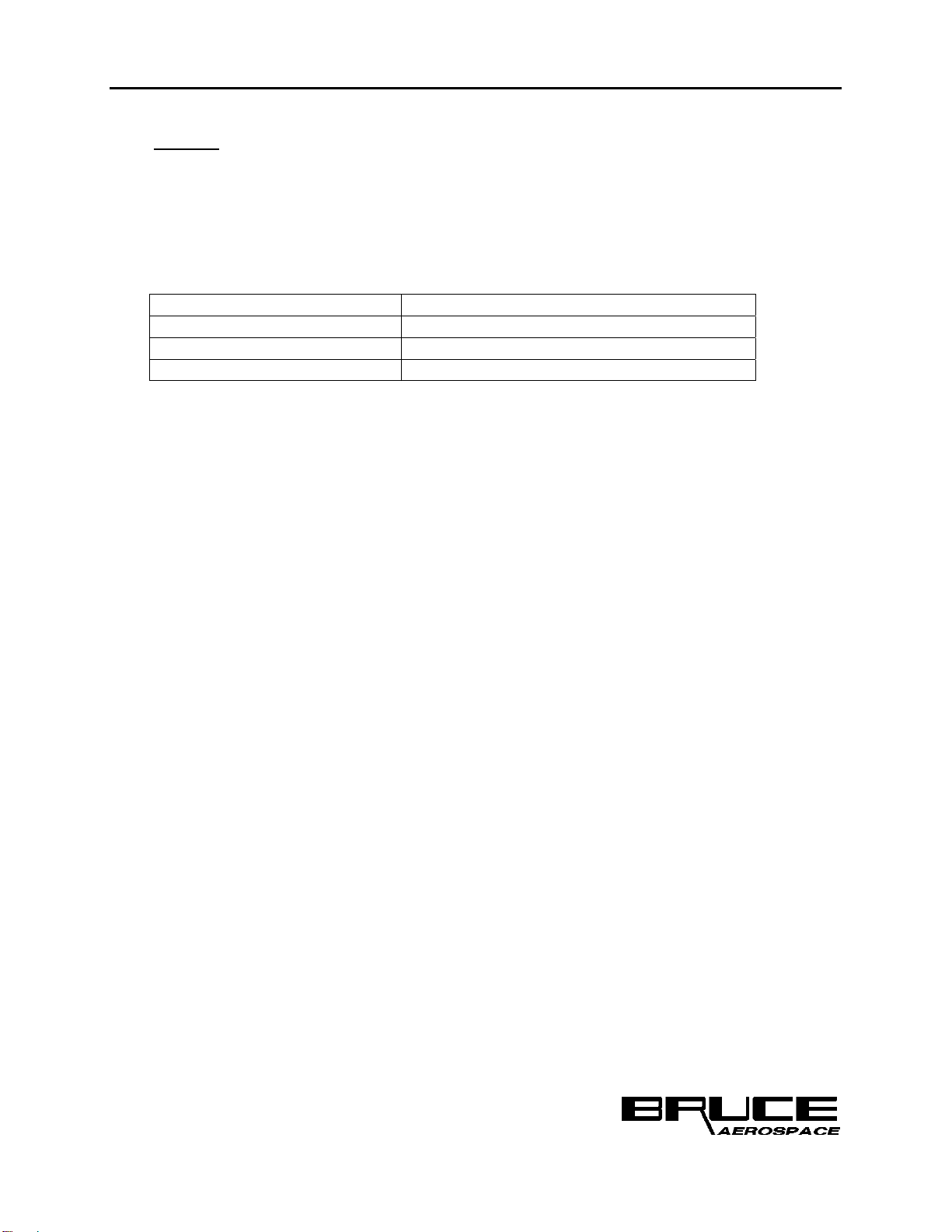

1.5 Abbreviations and Unit Symbols.......................................................................3

2.0 REFERENCE DOCUMENTS ...............................................................................3

2.1 United States Government................................................................................3

2.2 Industry Documents..........................................................................................3

3.0 EQUIPMENT OVERVIEW....................................................................................4

3.1 Unit Descriptions...............................................................................................8

3.1.1 BC1-0212 MLCP........................................................................................8

3.1.2 LCM Units................................................................................................16

3.1.3 BC1-0216 CAN Bus Terminator...............................................................26

4.0 BR3000 MLS SYSTEM OPERATION ................................................................28

4.1 BR3000-330-2CL & -3CL MLS System Operation..........................................28

4.1.1 MLS System Power-Up Procedure..........................................................28

4.1.2 Power-Up Procedure ...............................................................................28

4.1.3 MLS System Reset..................................................................................31

4.1.4 SCENARIO EXECUTION........................................................................32

4.1.5 Test Function...........................................................................................33

4.2 DECOMPRESSION OVERRIDE ....................................................................34

4.3 SCENARIO RE-PROGRAMMING..................................................................34

5.0 MAINTENANCE .................................................................................................35

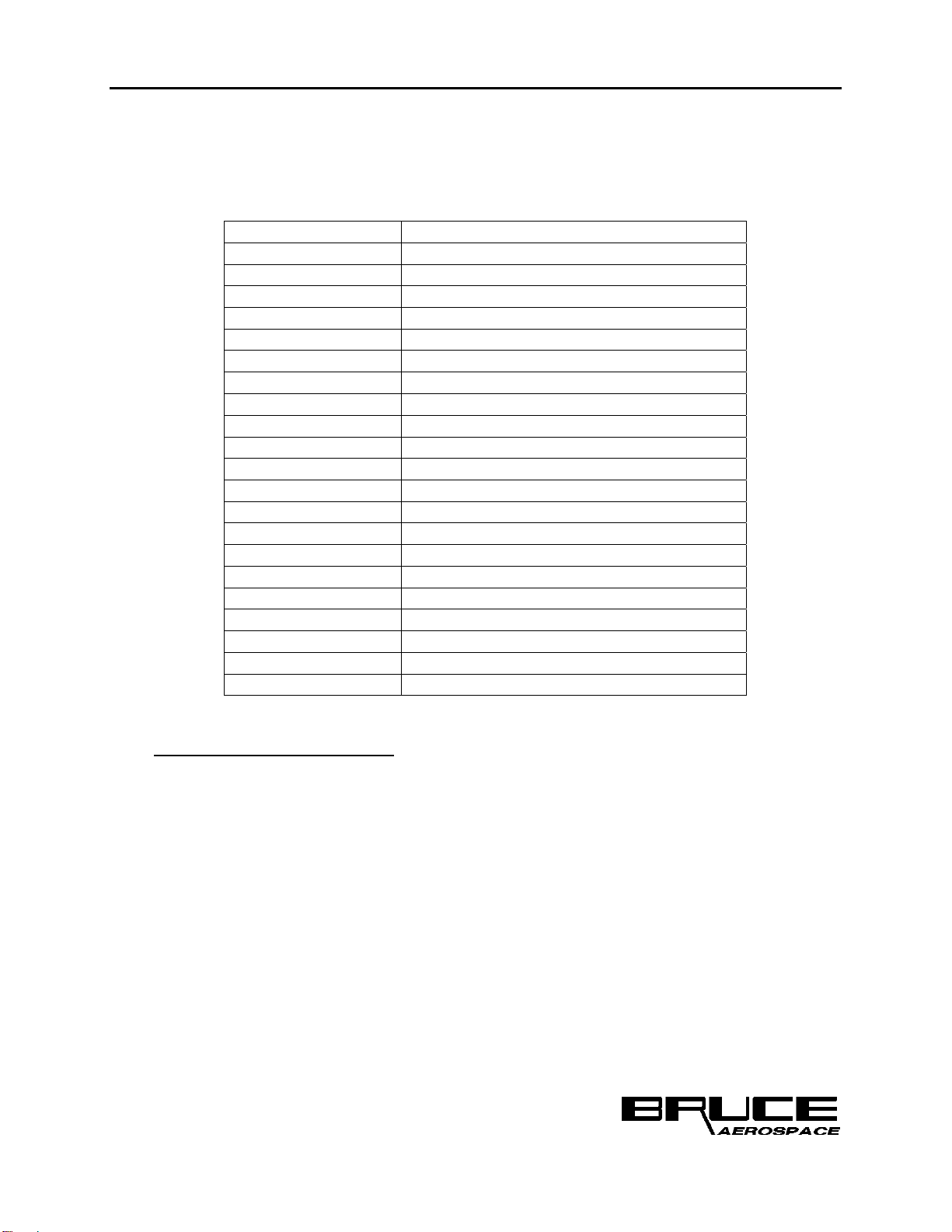

5.1 Vendor Codes.................................................................................................35

5.2 Outline and Mounting Information...................................................................36

5.3 BR3000 MLS Unit Identification......................................................................36

5.4 Wiring Information...........................................................................................36

5.5 Scheduled Maintenance..................................................................................38

5.5.1 Daily Check..............................................................................................38

5.5.2 Tools and Equipment, Daily Check..........................................................38

5.6 BR3000 MLS LRU Testing and Fault Isolation................................................39