BRUEL & KJAER 4809 User guide

Other BRUEL & KJAER Measuring Instrument manuals

BRUEL & KJAER

BRUEL & KJAER 2145 Instruction Manual

BRUEL & KJAER

BRUEL & KJAER 2211 User guide

BRUEL & KJAER

BRUEL & KJAER 9737 User manual

BRUEL & KJAER

BRUEL & KJAER 4511-W-006 User manual

BRUEL & KJAER

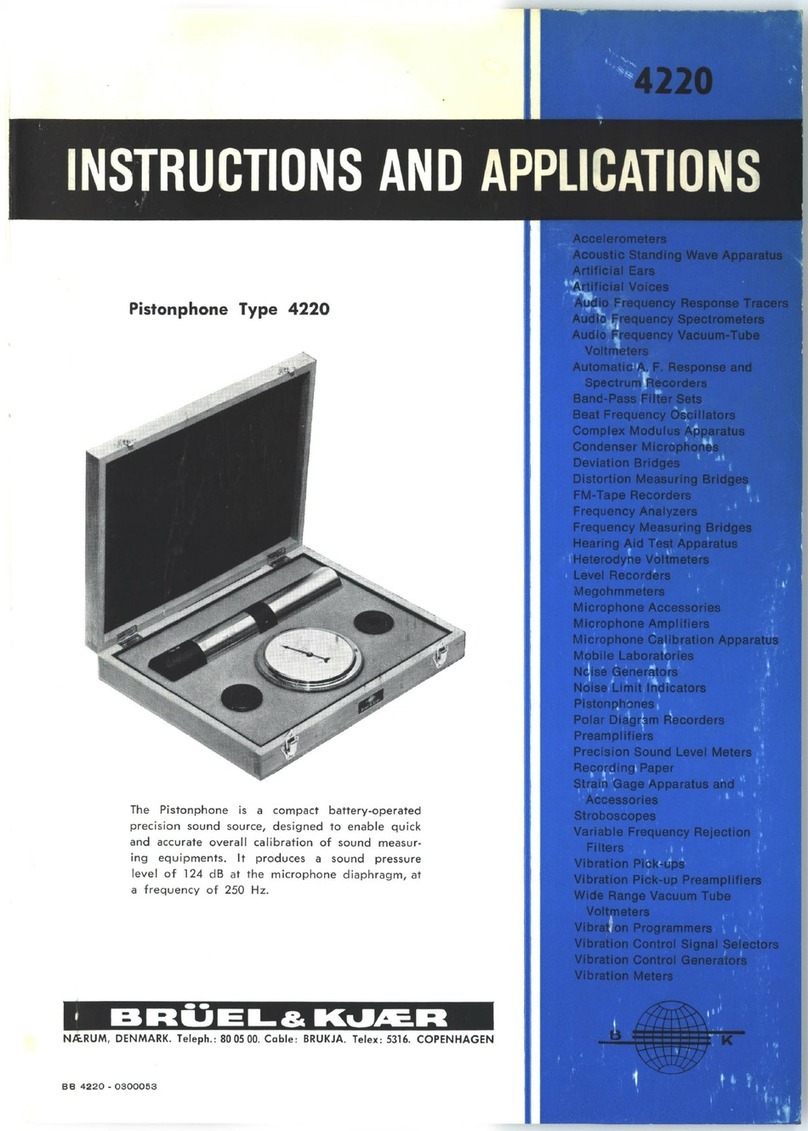

BRUEL & KJAER 4220 User guide

BRUEL & KJAER

BRUEL & KJAER 1019 Operating instructions

BRUEL & KJAER

BRUEL & KJAER LAN-XI Notar BZ-7848-A User manual

BRUEL & KJAER

BRUEL & KJAER UA-1480 Operating and maintenance manual

BRUEL & KJAER

BRUEL & KJAER 7001 User guide

BRUEL & KJAER

BRUEL & KJAER 2976 User manual

BRUEL & KJAER

BRUEL & KJAER 4294 User manual

BRUEL & KJAER

BRUEL & KJAER 2607 User guide

BRUEL & KJAER

BRUEL & KJAER BK Connect 9712-W-FEN User manual

BRUEL & KJAER

BRUEL & KJAER PULSE 7788 Guide

BRUEL & KJAER

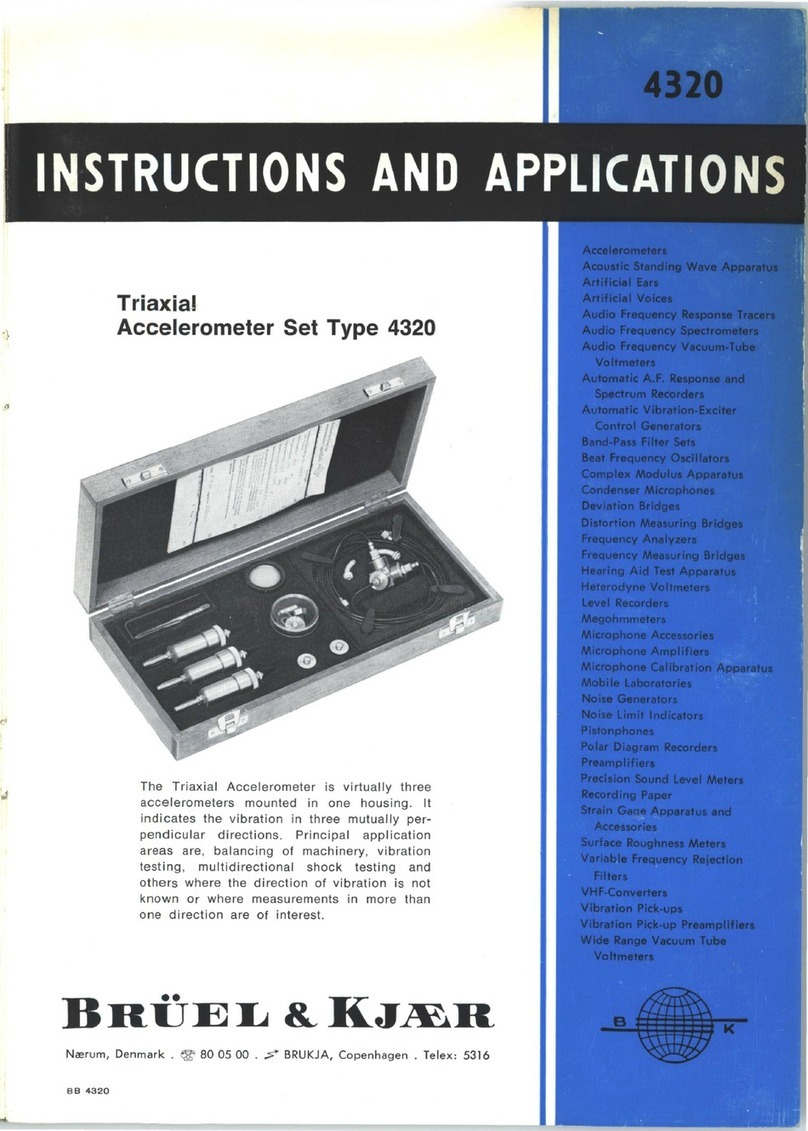

BRUEL & KJAER 4320 User guide

BRUEL & KJAER

BRUEL & KJAER 2225 User manual

BRUEL & KJAER

BRUEL & KJAER PULSE 3560-B Guide

BRUEL & KJAER

BRUEL & KJAER Mediator 2238 User manual

BRUEL & KJAER

BRUEL & KJAER 4448 User manual

BRUEL & KJAER

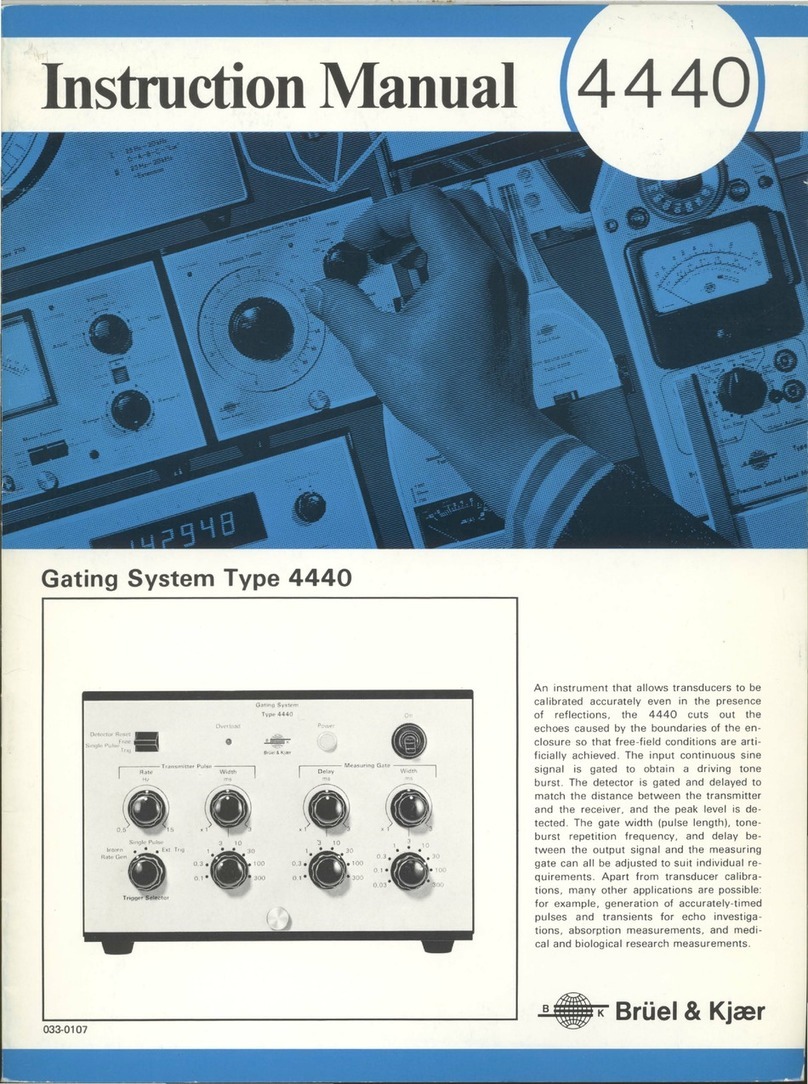

BRUEL & KJAER 4440 User manual

Popular Measuring Instrument manuals by other brands

Powerfix Profi

Powerfix Profi 278296 Operation and safety notes

Test Equipment Depot

Test Equipment Depot GVT-427B user manual

Fieldpiece

Fieldpiece ACH Operator's manual

FLYSURFER

FLYSURFER VIRON3 user manual

GMW

GMW TG uni 1 operating manual

Downeaster

Downeaster Wind & Weather Medallion Series instruction manual

Hanna Instruments

Hanna Instruments HI96725C instruction manual

Nokeval

Nokeval KMR260 quick guide

HOKUYO AUTOMATIC

HOKUYO AUTOMATIC UBG-05LN instruction manual

Fluke

Fluke 96000 Series Operator's manual

Test Products International

Test Products International SP565 user manual

General Sleep

General Sleep Zmachine Insight+ DT-200 Service manual