Installation and Maintenance Instructions

JSE1-0129MAEAD Extruder Clutch

1. INSTALLATION

a. Coupling should be installed with pins/buffers removed.

b. Apply an anti-seize compound to the gearbox input shaft.

c. Slide gearbox coupling half (1-23) onto gearbox shaft.

d. Slide motor hub onto shaft.

e. If interference or press fit is specified, heat coupling hub per fit

specified before putting hub onto shaft.

f. Bolt Rigid Hub (1-16) to the Module Carrier Plate (1-19). Using qty.

8, M16 x 65 S.H.C.S. (1-2). Torque tighten to 130 lb ft.

g. Dial indicate coupling Misalignment tolerance: Angular .004”,

Radial .003”. If misalignment is beyond tolerance, realign.

h. Assemble bolts and Buffers with Buffer Bush (1-10) inside of

Buffer (1-9) and a M16 Washer (1-11) on each side of the buffer.

Re-install 14 capscrews (1-12) with loctite on threads. Torque

tighten to 130 lbs.

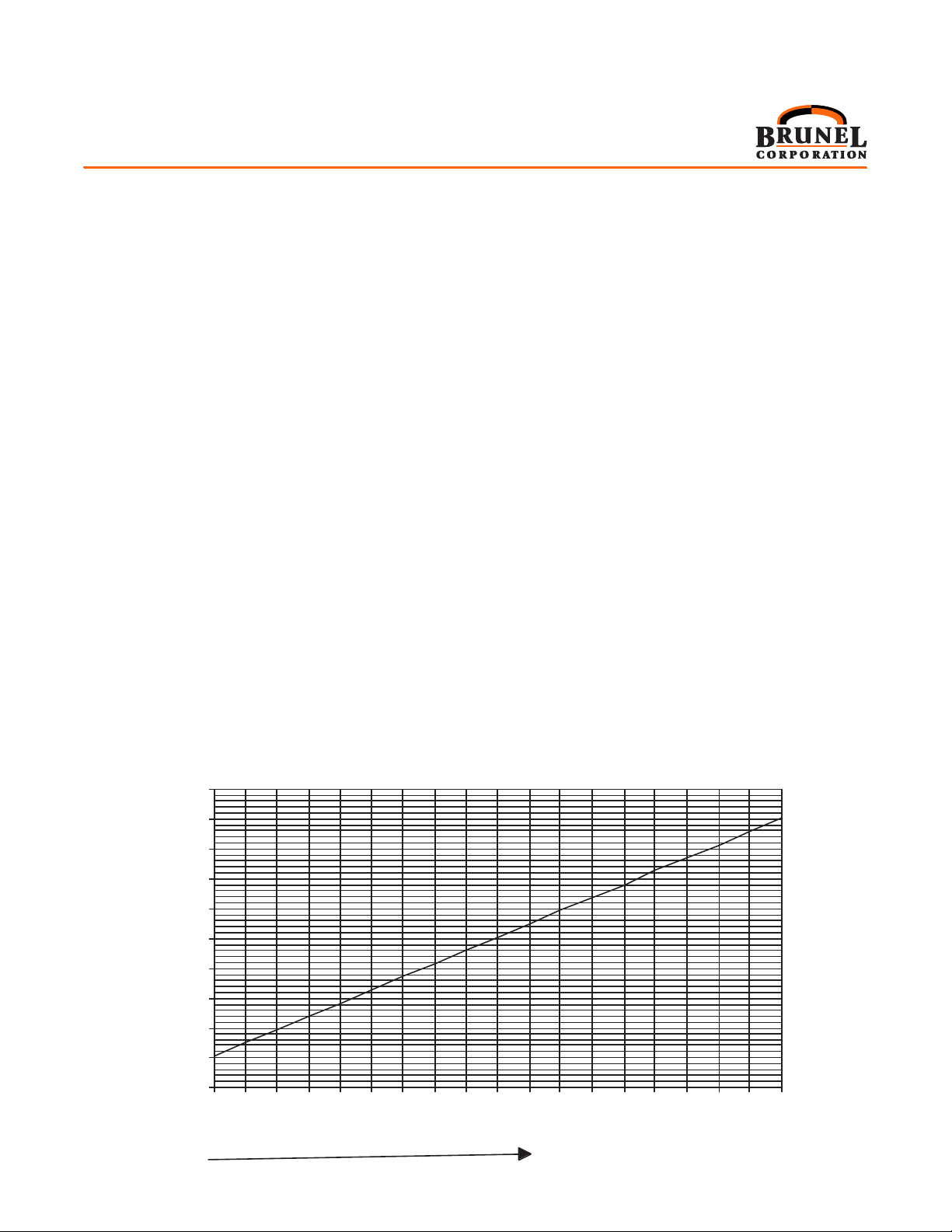

2. TORQUE ADJUSTMENT & INITIAL STARTUP

a. These torque limiters were preset at the factory, no further

adjustment is required at this time.

b. If it is desired to adjust the release torque at a later date, refer to

#5 “Torque Adjustment”.

3. RESETTING

On overload, the Safety Element Ball is displaced and the Module

Carrier Plate disengages from the Detent Pocket Plate. With the

drive at rest (the power off) and the overload cleared, align the two

reset arrows (or grooves) on the Detent Pocket Plate and Module

Carrier Plate by turning the drive motor shaft by hand. After aligning

the match marks strike the safety element plunger shroud with a soft

mallet and the plunger will move back into the safety element 1/4

inch signifying that the unit is engaged.

DISCONNECTING

To manually disconnect the module, turn the disconnecting nut

(2-21) counter clockwise with a wrench until rotation stops. Modules

are now disconnected and torque limiter is free for checking motor

rotation or for greasing bearing and modules. To re-engage module,

turn disconnecting nut (2-21) clockwise until flush with housing nut

(2-7), then strike plunger shroud (2- 12) with a dead blow mallet.

4. GENERAL MAINTENACE

a. Grease 2-3 pumps from a grease gun into Grease Fitting (2-13)

every 3 months. Recommended grease is “Mobil XTC” - (Modules

Only).

b. Safety elements should be disassembled, inspected and

reassembled at least once every 3 years, more frequently where

frequent tripping occurs.

c. Bearings should be re-greased with Mobil SHC220 every 3

months. Add grease with a grease gun into fitting (1-7) and old

grease is purged from grease relief valve (1-18). Recommended

Bearing Grease: Mobil SHC220

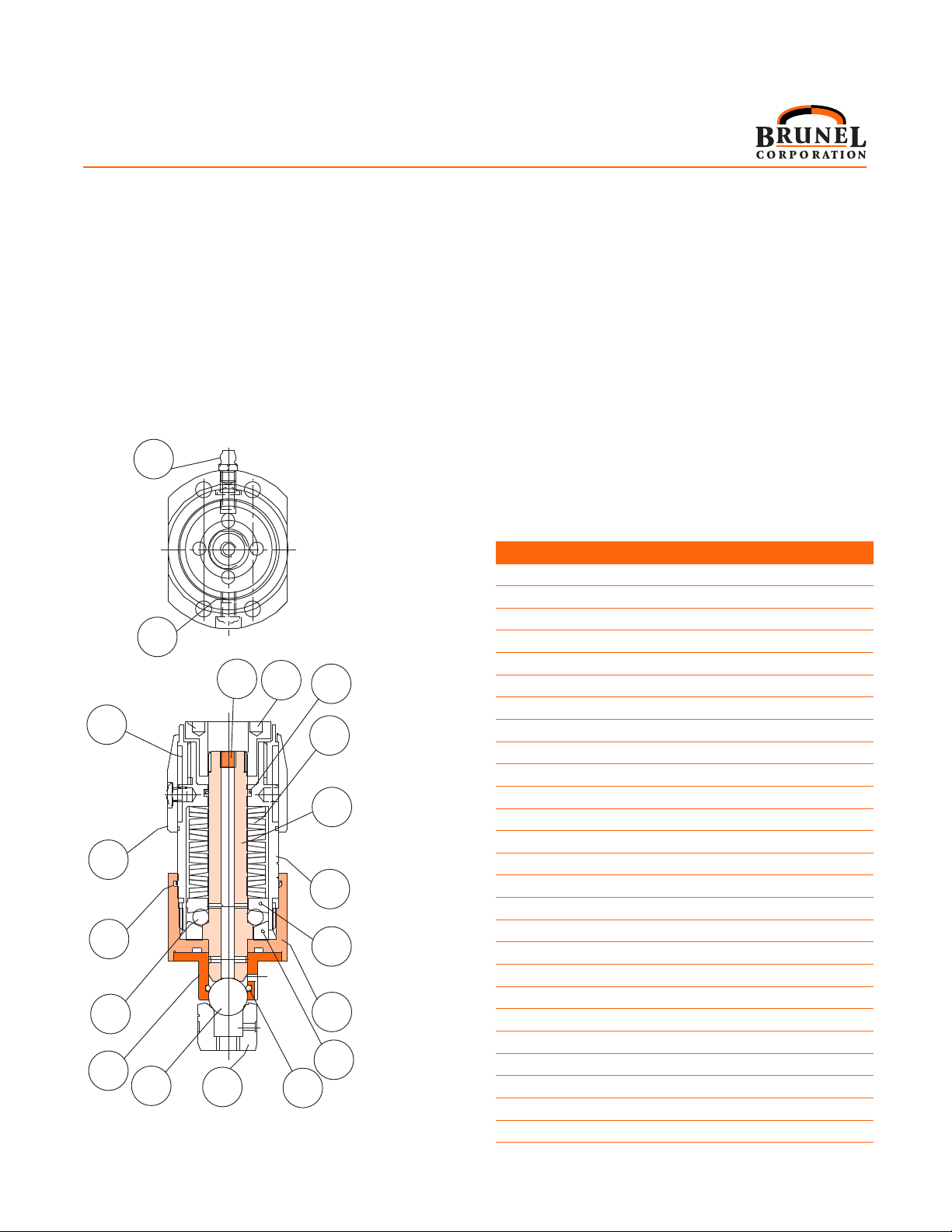

Figure 1

Section view of

Part # JSE1-0129MAEAD

Parts referred to by (Figure # - Part #)

Part No. Description Qty.

1 JSE1 Ext Adj. /Disconnectable 2

2 Capscrew M16 x 65 Skt Hd 8

3 Taper Roller Bearing 2

4 Oilseal 180x150x15 Type R4 1

5 Capscrew M8 x 16 Skt Hd. 1

6 Capscrew M6 x 25 Skt Hd 14

7 Grease Nipple 1

8 JSE1 Thru Hole Fixing Ext. Adj 2

9 Buffer 240 Arnitel, Shore 46D 14

10 Buffer Bush Flanged 240 14

11 Washer M16 Nord-Lock 14

12 Shoulder Bolt 14

13 Grubscrew Mx 3

14 Sensor Segment 2

15 Setscrew M6 x 25 CSK Hd 4

16 Rigid Hub 1

17 Grubscrew 2

18 Pressure Release Valve 1

19 Module Carrier Plate 1

20 Detent Pocket Plate 1

21 Clamp Plate 1

22 Sealing Plate 1

23 Eflex Hub 1

24* Capscrew M6 x 20 Skt Hd 8

25* Blanking Plate 2

26* Flange Blanking Plug 2

27* SE1 Fixing Pack 2

28 Capscrew M6 x 16 SKT HD 6

29 Setscrew M6 x 16 SKT HD IW Point I 4

*Not shown on this view

1