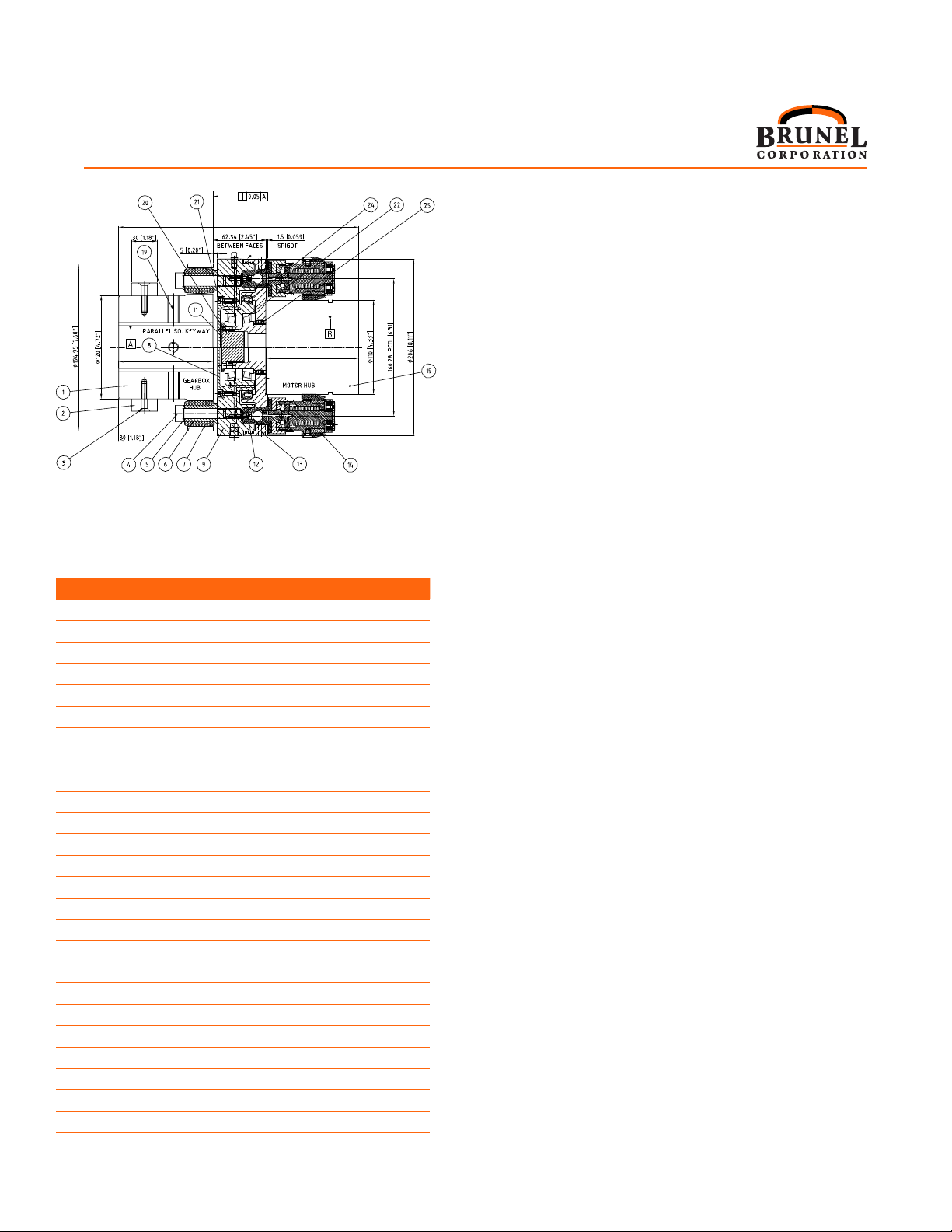

Installation and Maintenance Instructions

JSE.5-0104MAEAD Extruder Clutch

Item Part No. Description Qty.

1 JSE.5-0018-1 Plunger 1

2 JSE.5-0018-2 Outer thrust race 1

3 JSE.5-0018-3 Balls (5 mm) 9

4 JSE.5-0018-4 Inner thrust race 1

5 JSE.5-0018-5 Disc spring 20

6* JSE.5-0018-6 M5 x 25 SHCS 4

7 JSE.5-0018-7 Housing nut 1

8 JSE.5-0018-8 Bushing 1

9 JSE.5-0015-9 Detent ball 12mm 1

10 JSE.5-0015-10 Detent pocket (blind hole) 1

11 JSE.5-0018-11 Housing 1

12

13 JSE.5-0018-13 Grease tting - 6mm 1

14 JSE.5-0018-14 “O” Ring housing 1

15* JSE.5-0018-15 M4 x 15 SHCS 1

16 JSE.5-0018-16 Shim Pack 4

17

18* JSE.5-0018-18 Locking pellet 1

19 JSE.5-0018-19 “O” Ring - bushing 1

20 JSE.5-0018-20 Security screw 2

21 JSE.5-0018-21 Security cover 1

22 JSE.5-0018-22 “O”-Ring (Adjusting Nut) 1

23 JSE.5-0018-23 Jacking nut 1

24 JSE.5-0018-24 End cap 1

25 JSE.5-0018-25 Plunger cap 1

26 JSE.5-0018-26

Setscrew M5 x 10 2LG C Sunk HD

2

* Not shown on this view

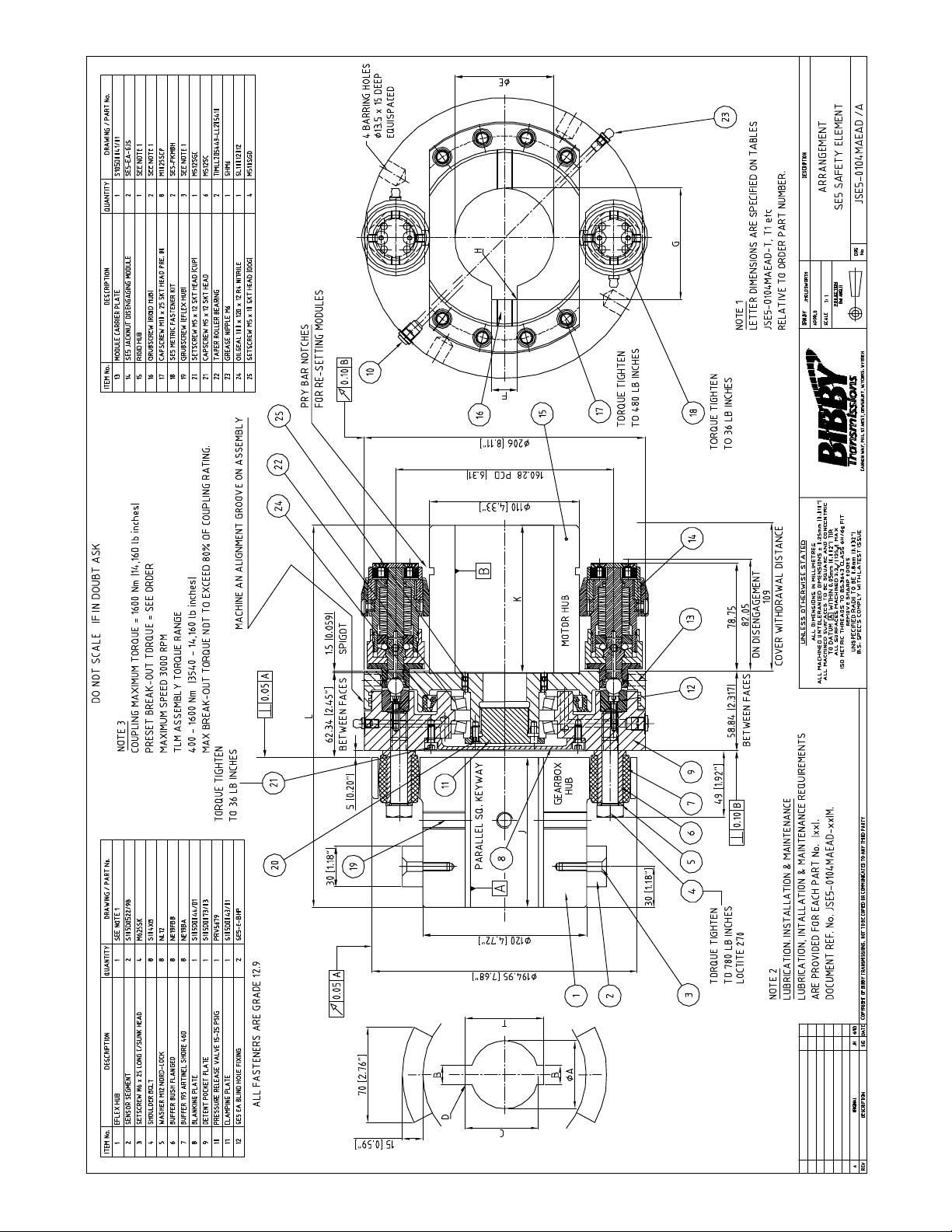

6. TORQUE ADJUSTMENT

a. To adjust torque at the job site: Prior to setting Safety Elements

which are new or which have been re-assembled, the desired

release torque for the torque limiter must be known. On

the graph labeled “JSE.5-0104AEA Setting Curve” (Page 3)

read the desired release torque on left. Follow across until

that point meets the setting curve and then follow down to

the required setting for each Safety Element. The numbers

at the bottom of the graph refers to the number of setting

marks on the housing of the Safety Element as measured

from “zero”. Zero varies slightly on each Safety Element

and must be determined independently prior to setting.

b. In order to determine “zero” and set each Safety Element:

1) Remove security screws (2-20) using special

tool and take off Nut Shield. (2-21)

2) Release Set Screw (2-20) using special tool.

3) Turn housing nut (2-7) counter-clockwise using socket

until spring force is removed and the housing nut is free

to turn by hand. Now turn the housing by hand clockwise

and determine the point at which resistance is rst

felt as the springs become engaged. This is the “zero

point”. The number of setting marks required from the

Setting Chart must be counted from this “zero point”.

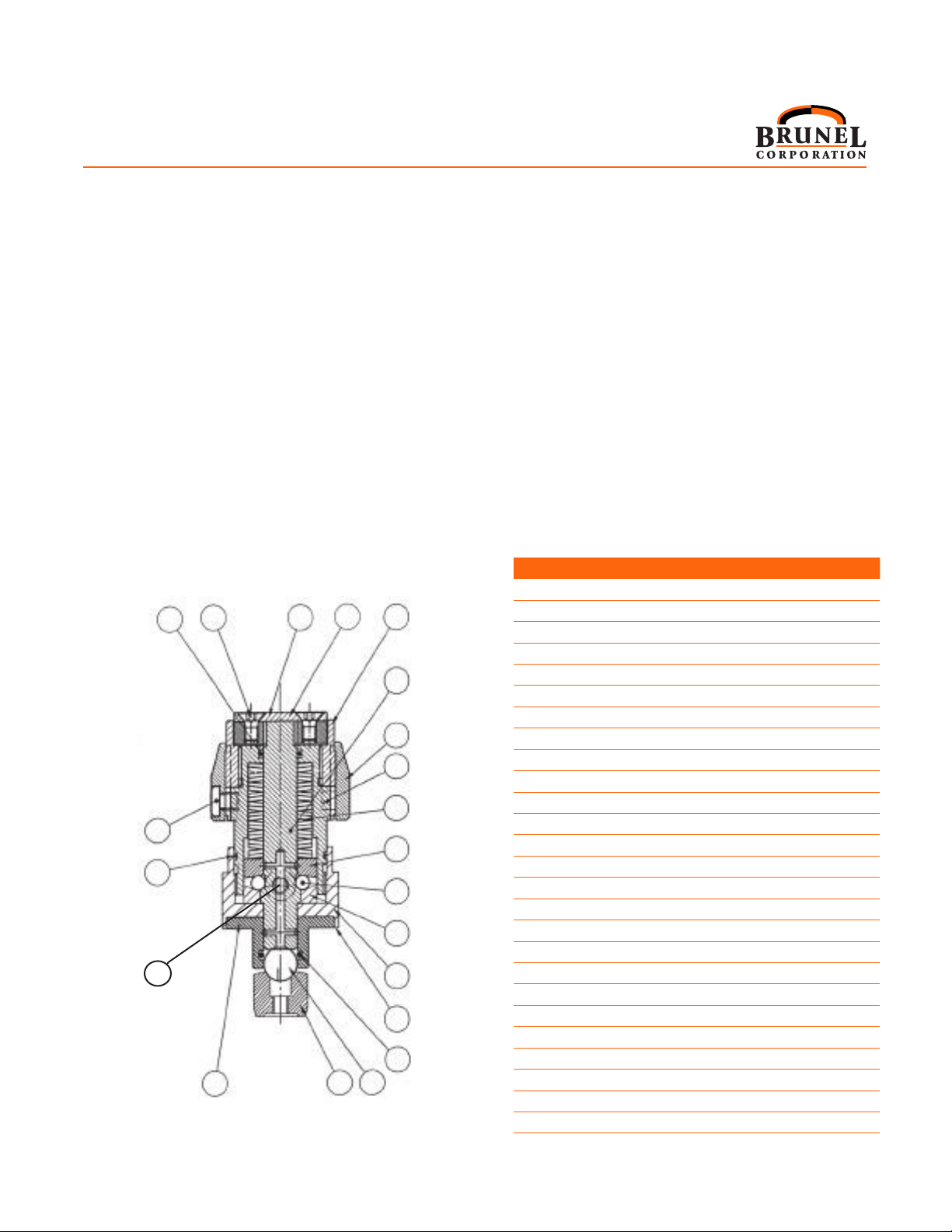

14 26 25 24 23

1

21

7

5

2

20

22

810 9

19

16

11

4

3

13

4) Using box or open end wrench, turn housing nut until the

required number of setting marks from “zero” are obtained.

5) Turn Set Screw (2-20) until tight. Re-install

Nut Shield using security screws.

6) Repeat steps 1 through 6 for each Safety Element.

7. METHOD OF PRELOADING EACH SAFETY

ELEMENT (BLIND HOLE DETENT)

Safety Elements must be preloaded anytime they are

mounted onto assembly. If mounting the Safety Element (1-

12) prior to preloading follow steps (a) thru (e). If preloading

a mounted Safety Element (1-14), start with step (e).

a. Grease and insert the Detent Pocket (2-10) into the Detent Pocket

Plate (1-9). Fix with SHCS.

b .Grease the bushing (2-8) complete with “O” ring (2-19) and install

over the greased plunger (2-1). Install the greased ball (2-9) in the

hole in the Module Carrier Plate (1-13).

c. Insert the Safety Element assembly (1-14) into the Module Carrier

Plate (1-13) and using feeler gauge, determine shim thickness

required between Housing (2-11) and Module Carrier Plate (1-13).

Figure 2

Section View of

Part # JSE.5-0018

Safety Element

Parts referred to by (Figure # - Part #)

2