Efficient “Flexible Water Tube” design assures

easy maintenance and low cost operation

All Bryan EB Series boilers offer these operating and performance features

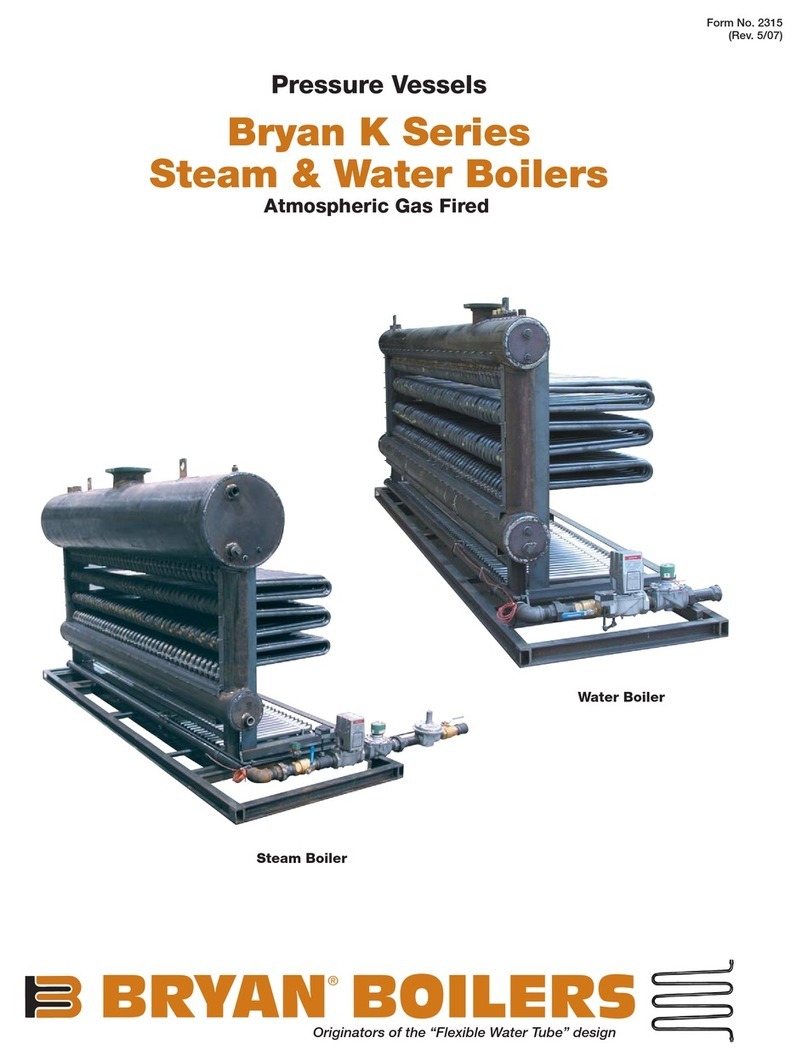

The Bryan Flexible Tube

Bryan’s exclusive “Flexible Tube” design eliminates the

possibility of damage from so-called “thermal shock.”

Tubes are easily removable and replaceable, without

welding or rolling, eliminating long, expensive downtime

should repairs ever be required.

Water cooled furnace

The configuration of the water tubes

provides a water cooled

combustion chamber.

A high percentage of

the heating surface is

exposed to direct ra-

diant heat, increasing

water velocities and heat

transfer.

Large steam drum

The steam drum has gen-

erous water volume and

steam release area. This

design, along with effective drum internal functions,

results in a stable water level and produces extremely

dry steam at all load conditions.

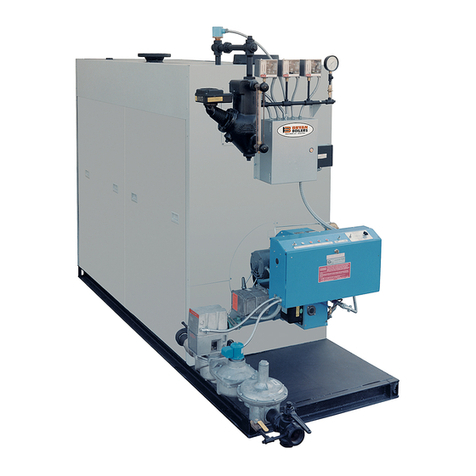

Accessibility of furnace and tube area

One hinged inner panel provides easy and complete

access to furnace and boiler tube area, as well as to

burner head. Other tube side panels are also remov-

able, and all panels are heavily insulated and sealed to

boiler frame. All access is from only one side.

Compact design, minimum floor space

With our compact water tube design, the overall size

of the unit is less than most other types of boilers.

Needing only 32" for tube removal, and on only one

side of the boiler, the EB Series boiler occupies very

little space in the boiler room. This can result in con-

siderable savings in building costs. Pressurized firing

permits minimum sized breaching and vent.

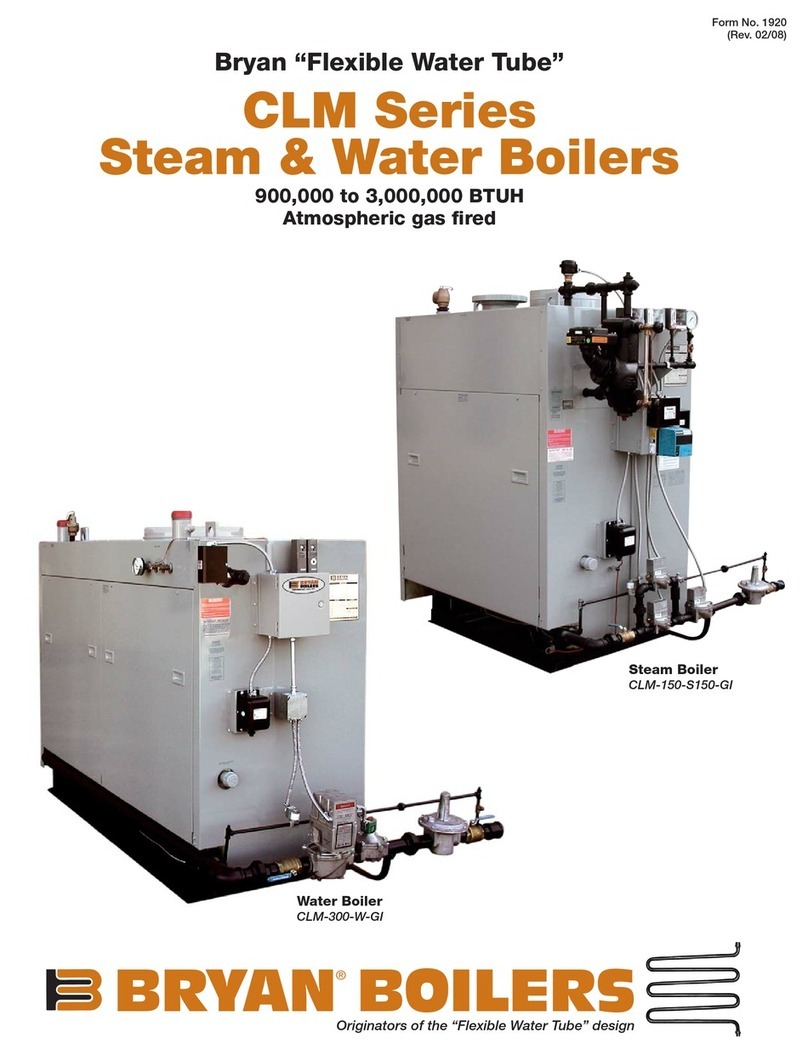

Water Boiler

Combination thermometer and alti-

tude gauge, ASME Code rated boiler

relief valve, water temperature control

(240°F max std.), high limit control,

probe LWCO.

Steam Boiler

Combination low water cutoff and

pump control, auxiliary low water cut-

off, high limit pressure control, ASME-

rated safety valve, water glass set.

Straight gas fired unit

Electronic combustion safety control,

automatic operating gas valve, safety

gas valve, pilot solenoid valve, pilot

ignition assembly, main manual gas

shut-off valve, pilot cock, pilot and

main gas pressure regulators, air safety

switch, control panel, all controls

installed and wired.

Multi-pass flue gas travel

High velocity four-pass flue gas travel is obtained by a

unique baffling system. This contributes to maximum

fire side heat transfer and overall boiler efficiency.

Thermal blend water return

Bryan’s unique “thermal blend” return blends cold or

cooler return water with warmer boiler water blending

it to design operating temperatures. An injector tube

directs the “mixed” water flow through the downcomer to

the lower header and heating surfaces at a temperature

above possible condensing conditions. This reduces the

possibility of “cold spots” and damage from corrosive

condensation.

Positive internal circulation

Each pass of the Bryan

water tube slopes up-

ward. This configuration,

along with the large

volume down-comer

water legs, provides the

extremely rapid natural

thermal internal circu-

lation, promoting both

high efficiency of heat

transfer and uniform

temperature throughout

the boiler. Eliminating

stress damage caused

by unequal temperature dis-

tribution is especially important

for heating systems, particularly where

intermittent or continuous low temperature water

returns may be encountered.

OPTIONAL EQUIPMENT,

EXTRA COST

1. Manual reset high limit control

2. Manual reset low water cutoff

3. Auxiliary low water cutoff

(standard on steam boilers)

4. Combination low water cutoff

and feeder

5. Alarm bells or horns

6. CSD-1, FM, GE-GAP or other

insurance approved control

systems

7. Indicating lights, as desired

8. Lead-lag systems for two or

more boilers with or without

outdoor reset control

9. Draft control system

When ordering, please specify:

1. Boiler size

2. Supply and return tempera-

tures required

3. Boiler relief valve setting

4. Type of fuel: natural, LP, or

other gas and/or No. 2 oil

5. If gas, type, BTU content,

specific gravity and pressure

available

6. Electric power voltage, phase

and frequency

7. Optional extra equipment or

construction

8. Special approvals required

(UL, CSD-1, FM, or GE-GAP)

9. Altitude

Bryan EB Series Boilers Standard and Optional Equipment

STANDARD EQUIPMENT FURNISHED

Straight oil fired unit

Electronic combustion safety control,

oil valve, oil ignition transformer,

two-stage fuel unit — spark ignition

(EB75 & 100)/gas pilot (EB 125-240),

oil nozzle assembly, control panel, all

controls installed and wired.

Combination gas-oil unit

Electronic combustion safety control,

automatic motorized gas valve, safety

gas valve, pilot solenoid valve, pilot

ignition assembly, main manual gas

shut-off valve, pilot cock, pilot and

main gas pressure regulators, air

safety switch, manual fuel selector

switch, oil valve, gas pilot, two-

stage fuel unit, oil nozzle assembly,

control panel, all controls installed

and wired.

Water

Boiler

Steam

Boiler