2

SAFETY CONSIDERATIONS

Installation and servicing of this equipment can be hazardous due to

mechanical and electrical components. Only trained and qualified

personnel should install, repair, or service this equipment.

Untrained personnel can perform basic maintenance functions such

as cleaning and replacing air filters. All other operations must be

performed by trained service personnel. When working on this

equipment, observe precautions in the literature, on tags, and on la-

bels attached to or shipped with the unit and other safety precautions

that may apply.

Follow all safety codes. Installation must be in compliance with lo-

cal and national building codes. Wear safety glasses, protective

clothing, and work gloves. Have fire extinguisher available. Read

these instructions thoroughly and follow all warnings or cautions

included in literature and attached to the unit.

Recognize safety information. This is the safety--alert symbol !

!

When you see this symbol on the unitand in instructions or manuals,

be alert to the potential for personal injury.

Understand these signal words: DANGER, WARNING, and CAU-

TION. These words are used with the safety--alert symbol. DAN-

GER identifies the most serious hazards which will result in severe

personal injury or death. WARNING signifies hazards which could

result in personal injury or death. CAUTION is used to identify un-

safe practices which may result in minor personal injury or product

and property damage.NOTE isused to highlight suggestionswhich

will result in enhanced installation, reliability, or operation.

Note: Installer: This manual should be left with the equipment user.

FIRE, EXPLOSION HAZARD

Failure to follow this warning could result in death, personal

injury and/or property damage.

Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

WARNING

!

FIRE, EXPLOSION, ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury,

death or property damage.

Do not use this unit if any part has been underwater.

Immediately call a qualified service technician to inspect the

unit and to replace any part of the control system which has

been underwater.

!WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury

or death.

Before performing recommended maintenance, be sure the

main power switch to unit is turned off.

!WARNING

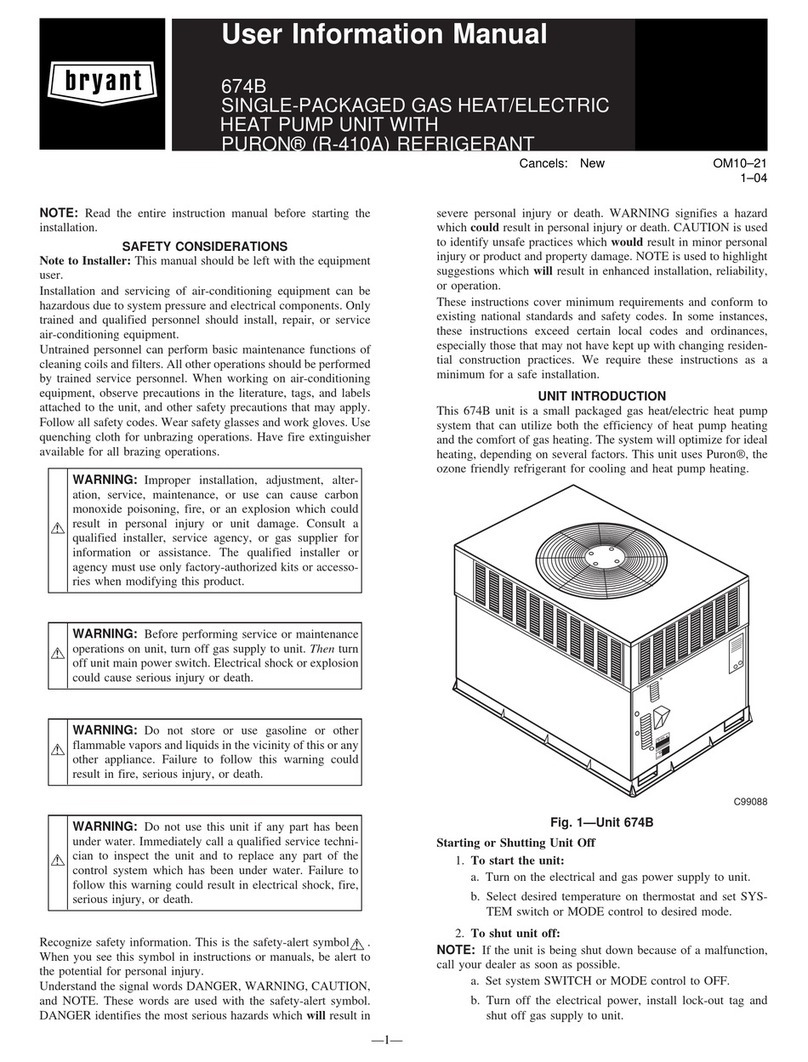

OPERATING YOUR UNIT

The operation of your heat pump system is controlled by the Evolu-

tiontUser Interface (UI). You may adjust the temperature manual-

ly through the UI or program the UI for automatic control. See UI

manual for detailed instructions.

To better protect your investment and to eliminate unnecessary ser-

vice calls, familiarize yourself with the following facts:

1. During heating, increasing the desired temperature setting

more than 2°F may cause the supplemental heaters to be

turned on for a short period of time to satisfy the demand.

Needless use of the supplementary heat reduces potential

energy savings.

2. Ice or frost tends to form on the coil during winter heating

operation. Your unit is designed to automatically melt the

ice. When in this defrost cycle, it is normal for steam or

fog to rise from the outdoor unit, and for water to drain

from the outside of unit. Do not be alarmed!

To start the unit:

1. Turn on the electrical power supply to unit.

2. Set MODE control to desired mode and the User Interface

for automatic control.

To shut off unit:

Note: If the unit is being shut down because of a malfunction, call

your dealer as soon as possible.

1. Set system MODE control to OFF.

2. Turn off the electrical power supply to unit.

Cooling Mode

With the UIcontrol set to COOL, your unit will run in cooling mode

until the indoor temperature is lowered to the level you have se-

lected. On extremely hot days, your unit will run for longer periods

at a time and have shorter “off” periods than on moderate days.

Heating Mode

With the UI control set to HEAT, your unit will run in heating mode

until the room temperature is raised to the level you have selected.

Of course, your unit will run for longer periods to maintain a com-

fortable environment on cooler days and nights than on moderate

ones.

Supplemental Heat

Your unit is your primary heating source. Your system may also be

equipped with a supplemental heating source such as electric heat.

On cold days and nights, your system will automatically turn on the

supplemental heat, as needed, in order to maintain the level of com-

fort you have selected.

Defrost Mode

When your unit is providing heat to your homeor officeand theout-

door temperature drops below 45°F, moisture may begin to freeze

on the surface of the coil. If allowed to build up, this ice would im-

pede airflow across the coil and reduce the amount of heat absorbed

from the outside air. So, to maintain energy--efficient operation,

your unit has an automatic defrost mode.

The defrost mode starts at a preset time interval of 30 minutes, al-

though, it may be reset to 60, 90 or 120 minutes. Defrost will start

at the preset time only if the ice is sufficient to interfere with normal

heating operation.

After the ice is melted from the coil, or after a maximum of 10 min-

utes in defrost mode,the unit automatically switches back to normal

heating operation.

Do not be alarmed if steam or fog appears at the outdoor unit during

defrost mode. Water vapor from the melting ice may condense into

a mist in the cold outside air.

During certain weather conditions such as heavy snow and freezing

rain it is not uncommon for ice to build up on the unit grille. This is