BSC 615L User manual

Operating Instructions

Before commissioning the machine, read operating instructions

and observe warning and safety instructions.

PLEASE ALSO READ ORIGINAL

BCS INSTRUCTION MANUAL

Crusader Power Scythes

Manufactured by BCS S.p.A.

Models 615L ●615SL ●630

BCS Crusader Power Scythes

Page 2 CPS/MAX/0817

No liability will be accepted for any damage caused to persons or property

through failure to observe the operating and safety instructions.

!

IMPORTANT READ CAREFULLY

Contents

Page 3 Safety

Page 4 Controls - 615L

Page 5 Controls - 615SL

Page 6 Controls - 630

Page 7 Identication & Stickers

Page 9 Setting Up The Scythe Cutter Bar

Page 11 Types of Transmission & Cutter Bars

Page 12 Identifying Controls

Page 13 Instructions for Use

Page 16 Attaching Scythe to Power Unit

Page 17 Operating Hints

Page 18 Starting the Engine

Operation

Page 19 Stopping the Engine

Page 20 Useful Information

Page 21 Maintenance Guide

Page 23 Risk Assessment

Page 24 Troubleshooting

Page 25 Sound & Vibration Levels

Page 26 Spare Parts

Page 27 Manufacturer Information

BCS Crusader Power Scythes

CPS/MAX/0817 Page 3

Safety

ALWAYS read the original manufacturer’s manual rst

ALWAYS start the engine in the open air

DO NOT smoke when refuelling

DO NOT mix OIL with the fuel

ALWAYS stop the engine before making any adjustments, refuelling, moving or

cleaning, or when the unit is unattended

USE ONLY fuel from containers designed for this purpose - refuel outdoors only and

replace the tank cap securely

IN CASE of petrol spillage move the machine away from the area of spillage and

allow the petrol vapours to dissipate before starting the engine

DO NOT remove any safety guards that are tted

DO NOT touch any moving parts or attempt any maintenance whilst the machine is

running - KEEP HANDS AND FEET AWAY

BEFORE starting work clear the work area of any objects that could damage the

machine

DO NOT allow children or anyone uninstructed to operate the machine - KEEP

ANIMALS AWAY

DO NOT use on slopes or banks of more than 20o

ALWAYS wear suitable clothing to give personal protection including footwear that

offers a good grip

AVOID wearing loose garments that may catch in moving parts

KNOW how to stop the machine in an emergency

NEVER interfere with any control settings on the engine

NEVER select reverse gear with your back to a wall or other immovable object

IF A FAULT develops DO NOT attempt any repair - immediately contact the supplier

from whom the machine was obtained

VISUALLY INSPECT the machine before use - ensure all blades, nuts and bolts are

tight and not worn or damaged and replace blades if necessary

KEEP IN MIND the operator is responsible for accidents or hazards occurring to

people or property

BCS Crusader Power Scythes

Page 4 CPS/MAX/0817

Controls

BCS 615L

Forward / Reverse Lever Engine Stop (OPC) Lever

Throttle Lever

Handlebar Offset

Lever

Wheel Speed

Lever

Handlebar Height

Adjustment Lever

PTO Lever

Clutch Lever

Locking Clip

BCS Crusader Power Scythes

CPS/MAX/0817 Page 5

Controls

Forward / Reverse Lever

Throttle Lever

Handlebar Offset

Lever

Wheel Speed

Lever

Handlebar Height

Adjustment Lever

PTO Lever

Clutch Lever

Locking Clip

Differential

Lever

BCS 615SL

Engine Stop (OPC) Lever

BCS Crusader Power Scythes

Page 6 CPS/MAX/0817

Controls Description

Forward /

Reverse

Lever

Engine Stop (OPC) Lever

Throttle Lever

Handlebar

Offset Lever

Wheel Speed Lever

Handlebar Height

Adjustment Lever

Parking Brake

Lever

Clutch Lever

Locking Clip

BCS 630

Differential Lever

Left Steering

Brake Lever

Right Steering

Brake Lever

PTO Lever

BCS Crusader Power Scythes

CPS/MAX/0817 Page 7

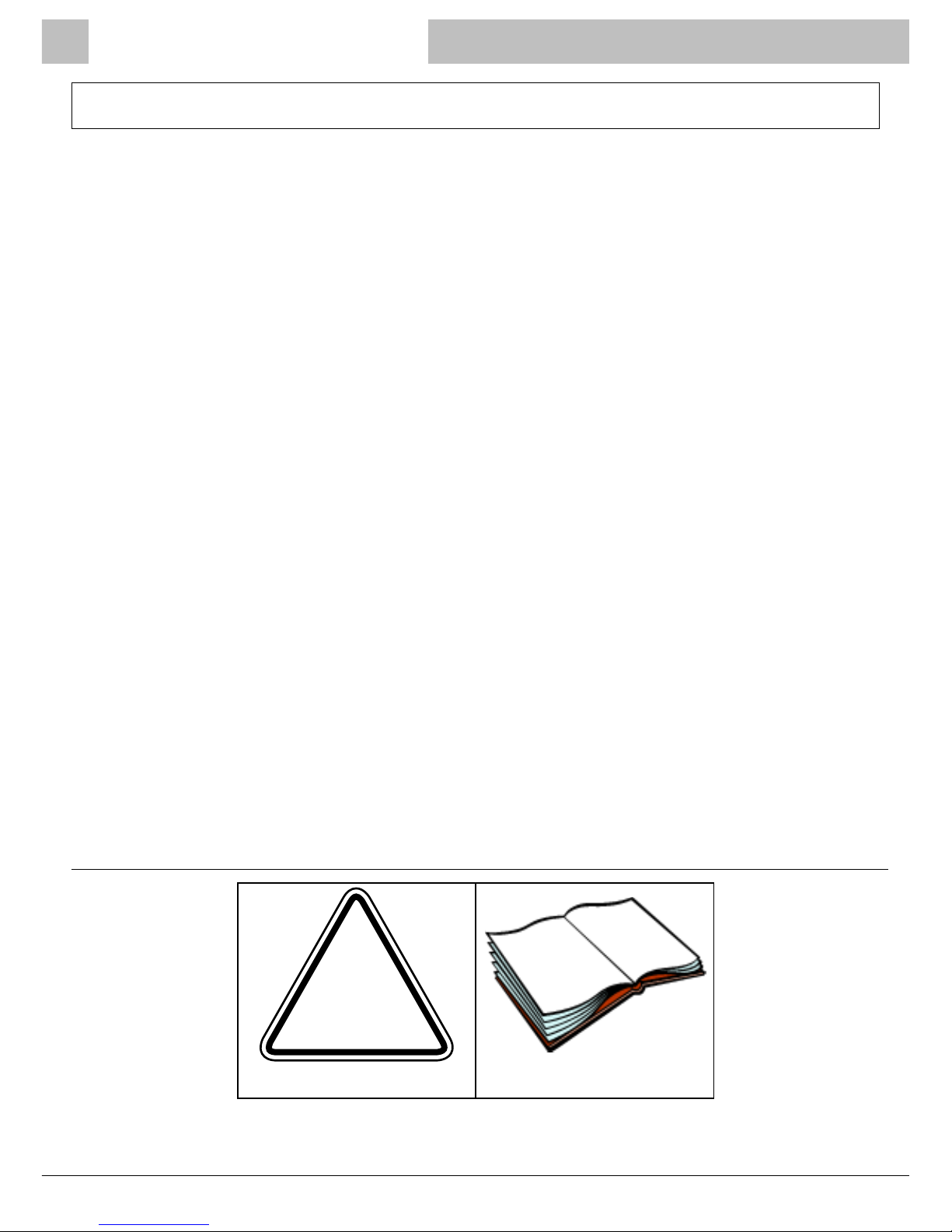

Identication and Stickers

An identication sticker is applied to every machine, as well as product certication in accordance

with the EC Machine Directive (g.2/1).

NOTE: The weight value indicated on the identication plate only refers to the transmission. In

order to obtain the overall weight of the sickle bar, it is necessary to add the weight of the cutter

bar which has been chosen for coupling.

Preservation of the Labels

IMPORTANT! The labels must be kept clean from dust and mud, must always be clearly visible

and legible, and must be replaced if missing or illegible.

If any of the components have to be replaced and they were originally equipped with a safety

label, it is important that the component is returned to its original condition complete with new

labels.

The labels are available as spare parts and can be obtained from your supplier. The part numbers

for each sticker can be found on the parts diagram specic to each machine model, and are

normally also printed on the label.

g.2/1

1 3 2

4 6 7 5

1. Brand

2. Manufacturer

3. Model

4. Minimum Power Required

5. Weight (see note above)

6. Identication Number of

Production Year

7. Serial Number

BCS Crusader Power Scythes

Page 8 CPS/MAX/0817

Identication and Stickers

1

1

2

4

3

2

4

3

58057724

58040548

58057769

BCS Crusader Power Scythes

CPS/MAX/0817 Page 9

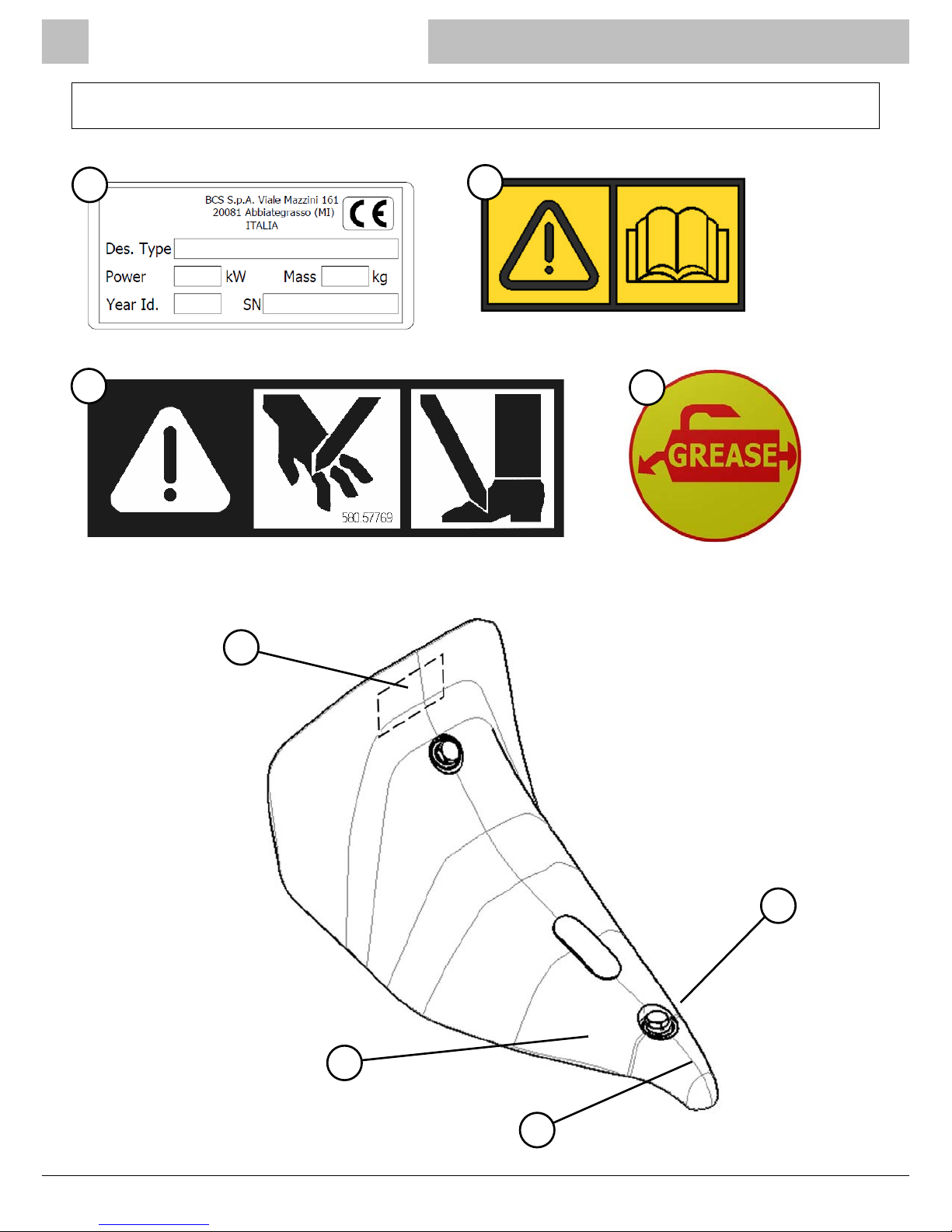

Setting Up The Scythe Cutter Bar

What the Machine is Designed For

The scythe cutter bar is designed for mowing grass and

pastures by cutting stems at the base.

This is achieved by coupling the gearbox or transmission

(power unit) to the cutter bar attachment which consists of

the cutting blades.

Opening the Boxes

The scythe attachment is delivered in two boxes, one

containing the transmission and the other containing the

cutter bar.

These should be moved either with a forklift truck or carried

by at least two people. Open the boxes starting from the lid,

and remove the accessories.

Preliminary Checks

Check that the machine is in good condition and has not

been damaged in transit, then proceed with assembly as

indicated in the following points.

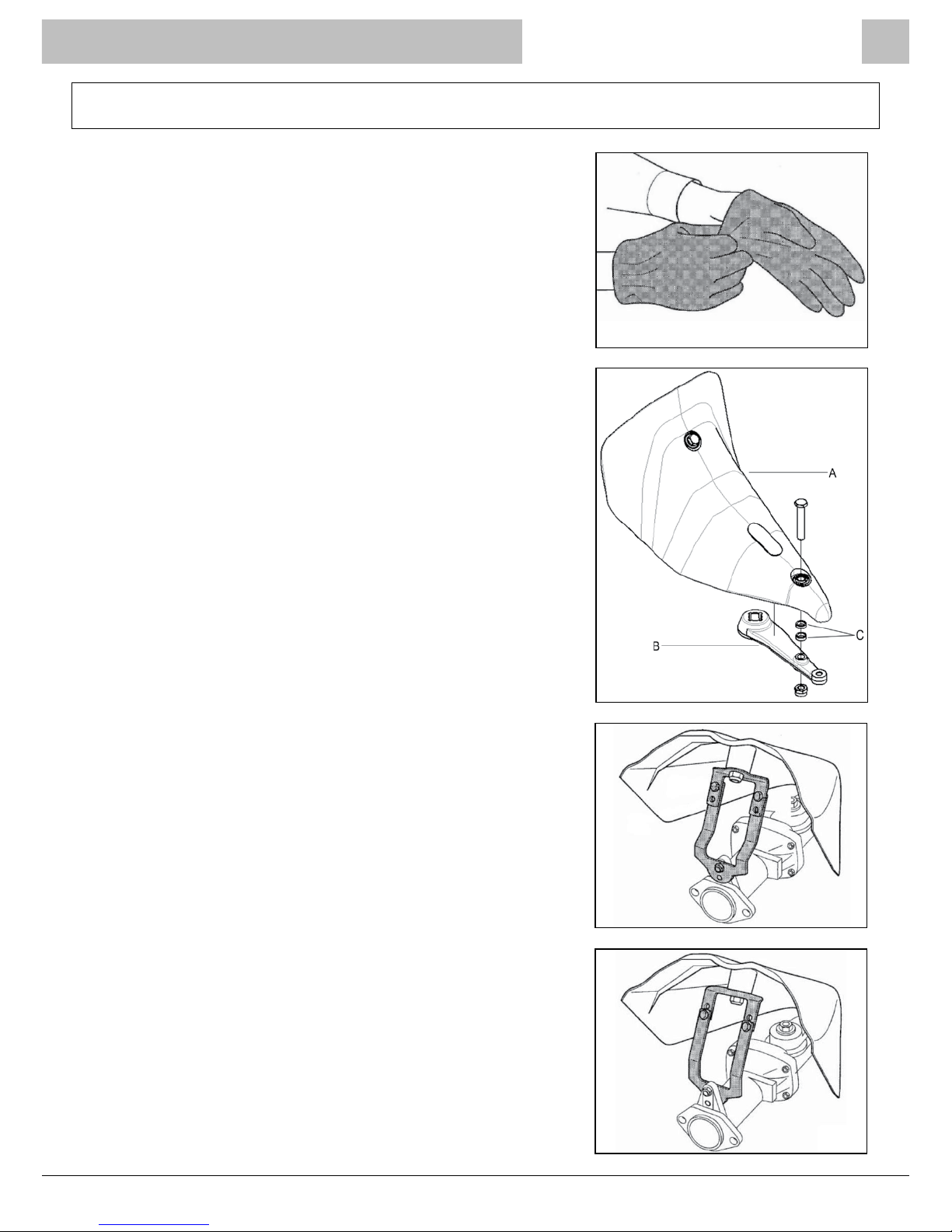

WARNING! Protective gloves must be worn for all assembly

operations, repair and use (g.4/1).

Gearbox Assembly

Fix the protection cover A to crank B as shown in g.4/2.

NB: For dry transmission and short oil bath transmissions two

C spacers must be used, for long oil bath transmissions only

one C spacer is required, and for DUPLEX transmissions no

spacers are required.

Fix the rear side of the protection cover A to the transmission,

as shown in g.4/3 and g.4/4, according to the type of

transmission and gearbox.

g.4/1

g.4/2

g.4/3

g.4/4

BCS Crusader Power Scythes

Page 10 CPS/MAX/0817

Setting Up The Scythe Cutter Bar

Fixing Cutter Bar to Transmission

Lay the cutter bar at and remove the two nuts A and related

washers (g.4/5).

Move the transmission closer to the cutter bar making sure

that the pivot is correctly lodged, then mount the cutter bar

B to control panel A using the two nuts and washers (g.4/6)

and tighten securely.

NB: For the assembly of the DUPLEX bars (with a double

crank mechanism), ensure both pins F and G t into their

housings (g.4/7), then proceed as described above.

IF A HIGH CUT IS NECESSARY: Install the cutting height

adjustment slides (skids) C on the cutter bar using the bolts

provided (g.4/8).

g.4/5

g.4/6

g.4/7

g.4/8

This manual suits for next models

2

Table of contents