12/22

BSI,

LLC

601

East

64th

Av

enue,

Bldg.

A

,

Denver,

C

o

80229

800.662.9595

[email protected] bsidesigns.com

8

OWNER'S MANUAL & WARRANTY

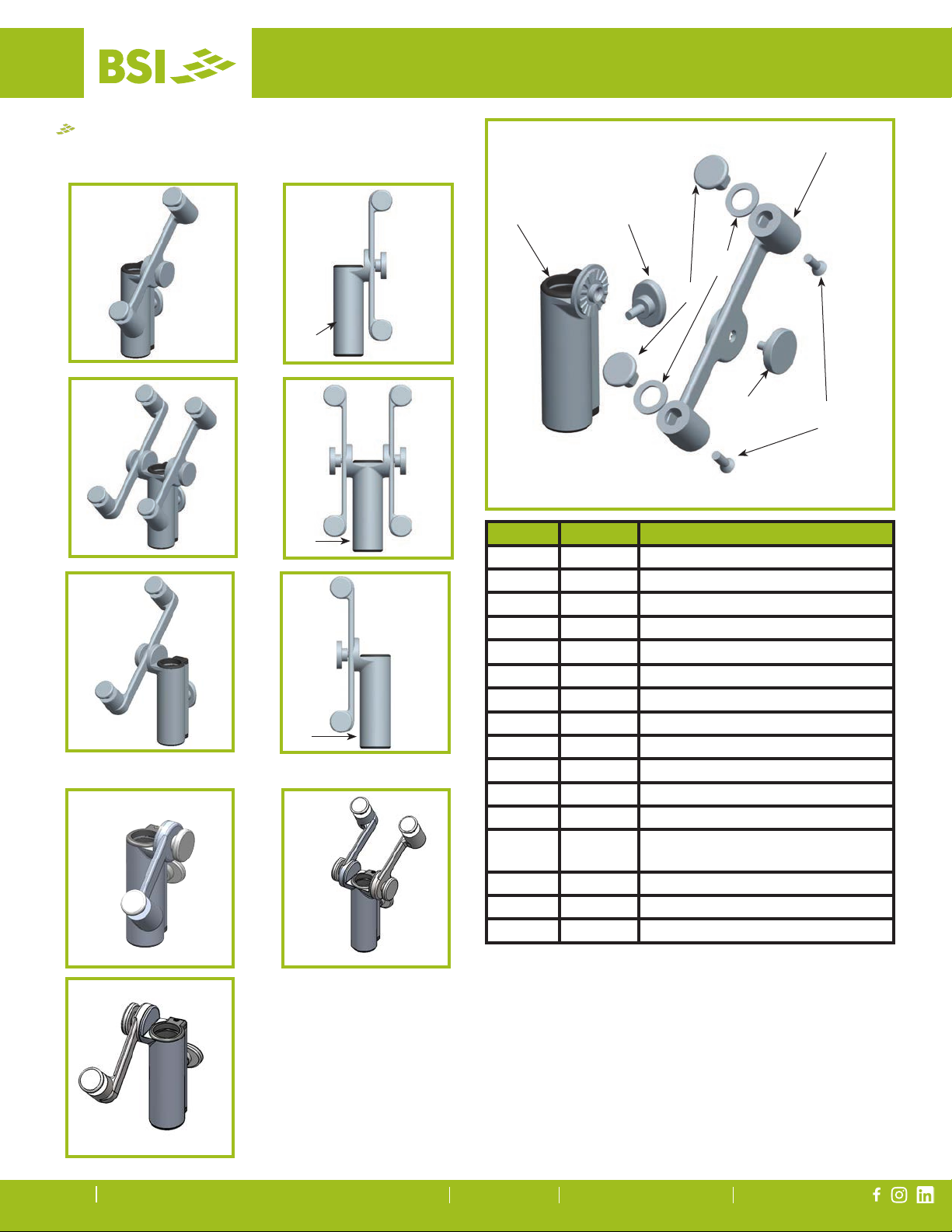

Glass panels can be tilted forward or backwards in 22 .5o increments. The panels (glass and bracket

combination) can be raised or lowered by adjusting the brackets. As detailed in Figure #1 (page 6), the

bracket’s Oval Knob is shown on the Server Side. Oval Knob location varies based on food shield conguration.

The bracket’s Round Knob, which holds the Glass Mounting Clamp in place, always faces the food.

Cleaning your new ZGuard product is key to its long life.

BSI recommends the following for keeping your

product clean:

• Wipe the surface with a clean, damp cloth to

remove ngerprints, dust, etc.

• Spray with a light coating of glass cleaner to

remove grease or other dirt. Use a non-ammonia

cleaner.

• Do not polish ZGuard with any brass polish. Your

ZGuard has a durable nish and will maintain

its nish for years if well maintained. (Polishing

the nish with a polishing agent of any kind will

destroy the coating.)

• Do not scrub the surface with any abrasive

substance such as steel wool, pot scrubbers,

abrasive powders, or similar products, as it will

remove the protective coating.

• If unit is tted with a BSI Stealth warmer, do not

clean the glass or housing when warmer is hot.

Cleaning warmer when hot can cause staining or

damage to warmer nish.

ZGuard food shield systems that are equipped

with a shelf are not intended to withstand

heavy weights. Do not exceed 75lbs. total

weight of all display items across a 36" panel

of 3/8" thick glass.

Food Shield: ZG9500

(glass panel positioned at 90o to post)

Posts & Brackets: Brushed Aluminum

Glass: 36" x 14” (3/8" thick)

Mounting: Above Counter

Time: 24 hours

GLASS AND BRACKET POSITION

CLEANING INSTRUCTIONS

GLASS LIMITATIONS TESTING PARAMETERS

ZGUARD® BRACKET ADJUSTMENT

ZGuard brackets allow you

to adjust the food shield

height and angle of glass.

Referred to as the 'home'

position, bracket and

glass will be in vertical

position.

With the assistance from

a second person, take the

following steps to adjust

your ZGuard.

1. To raise or lower the bracket, loosen the Oval

Knob from the Post Clamp. Slide to new position

and tighten. (See Illustration #1)

2. To adjust angle of the glass, loosen the Round

Knob and then adjust the glass angle to desired

location. (See Illustration #1)

Illustration #1: Bracket and

glass in 'Home' position.

Oval

Knob

Round

Knob