4

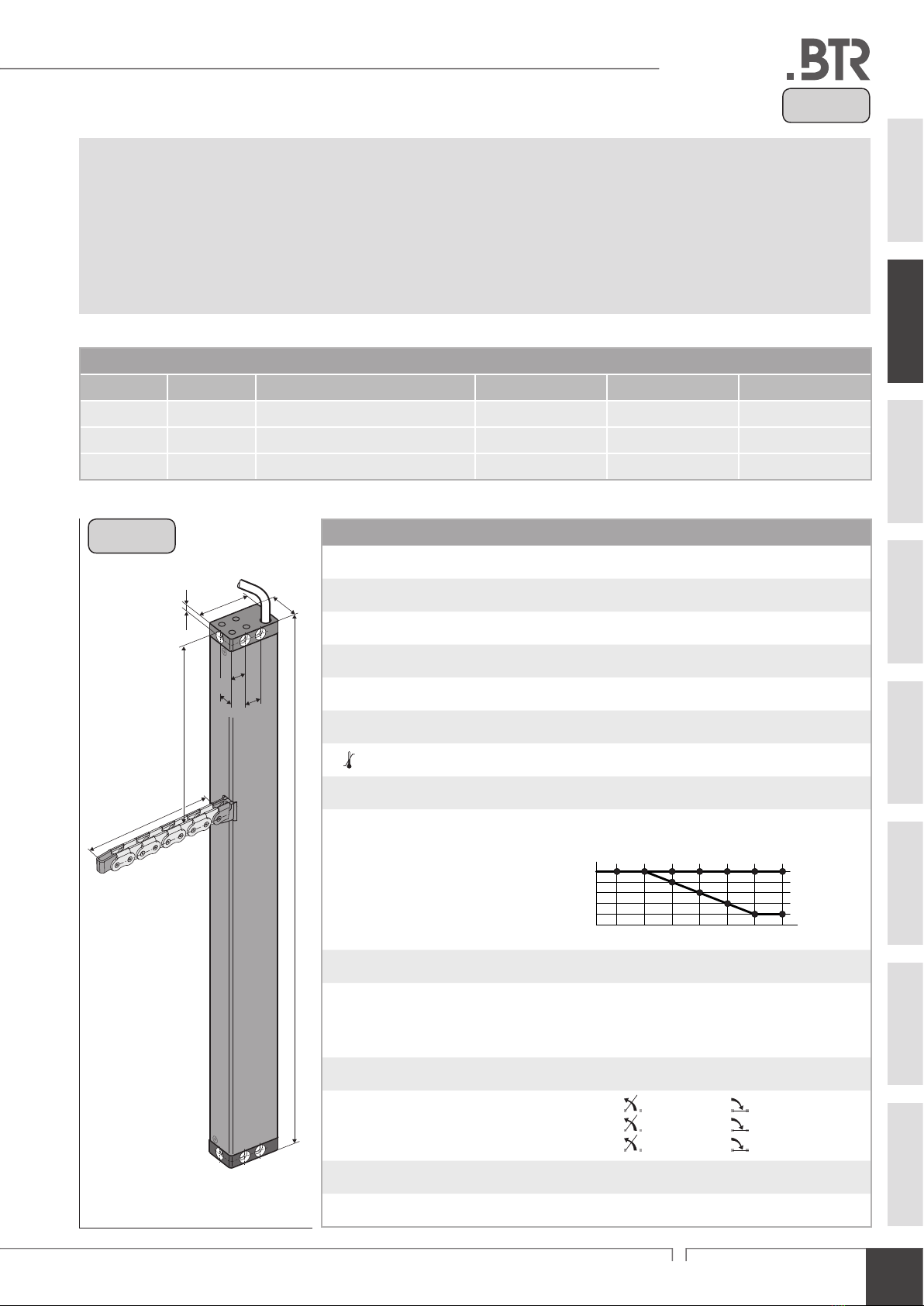

BDC Pro 24 V DC / 230 V DC AC

Preliminary remark

01

By attaching the drive to a movable

element of the window and connecting

it to a power supply a so-called

“power-operated window” is created

which, according to the Machinery

Directive 2006 / 42 / EG, represents a

machine.

Pay attention to possible hazards on

tilting or rotating windows, whose

side closing edges (NSK) are located

at less than 2,5 m installation height

above the oor, under consideration of

the Control Unit and usage!

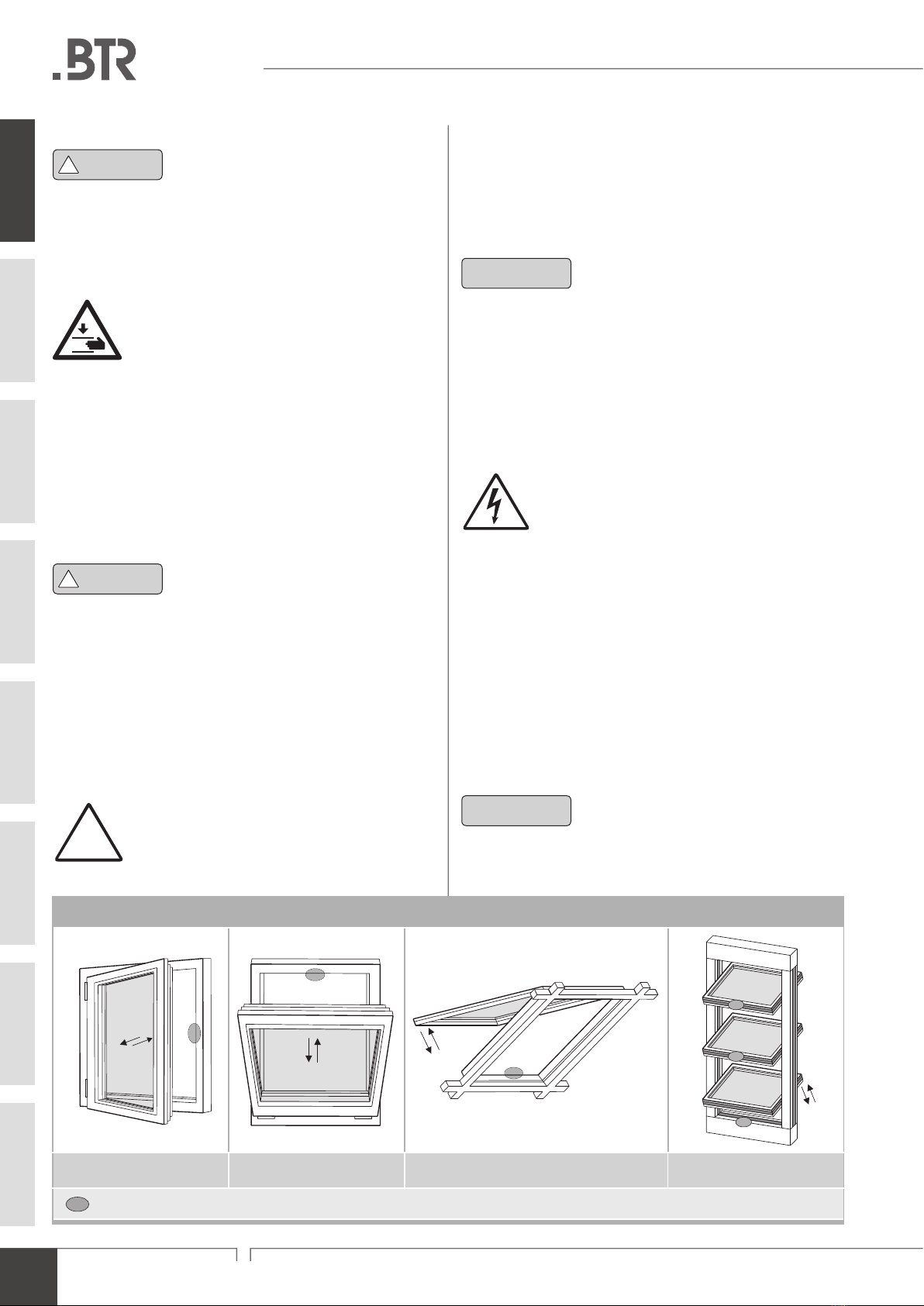

Area of application / Scope of application

This drive is intended for the electromotive opening and

closing of windows in facade or roof areas.

The main task of this product, in combination with

a window and a suitable external control unit, is to

evacuate hot smoke and combustion gases in case

of re, to safe human lives and protect material

assets. Furthermore, with the electromotive operated

window and a suitable external control unit, the natural

ventilation of the building can be ensured.

Intended use

The drive is intended for stationary installation and

electrical connection at the window as part of a building.

The drive is in combination with an external Control Unit

(e.g. from Btr) released for its proper use at a power-

operated window for the following use:

• Application for natural ventilation

with an installation height of the drive and

the bottom side of casement of at least 2,5 m above

the oor, or

with an opening width at the HSK of the driven

part of < 200 mm by a simultaneous speed of

< 15 mm/s at the HSK in closing direction.

• Application as NSHEV (natural smoke and heat

exhaust ventilator(s) in accordance with EN12101-2

without dual purpose for ventilation.

The need for a risk assessment at the installation site

due to the reasonably foreseeable misuse.

A risk assessment in accordance with the Machinery

Directive 2006 / 42 / EG for the usage of the power-

operated window for natural ventilation is absolutely

necessary under the following conditions:

• the installation height of the drive and lower edge

of casement < 2,5 m above the oor

and one of the following conditions:

• the opening width at the HSK is > 200 mm, or

• the closing speed at the HSK is > 15 mm/s, or

• the opening speed at the HSK is > 50 mm/s, or

• the closing force at the HSK is > 150 N

The following ow chart can be applied, which also includes

the protective measures in accordance with EN 60335-2-

103/2016-05.

We as manufacturers are well aware of our duties and

responsibilities regarding the development, manufactu-

ring and placing of safe window drives on the market and

consistently implement them. Ultimately, however, we have

no direct inuence on the usage of our drives. Therefore,

as a precaution, we point out the following:

• The constructor or his agent (architect, specialist

planner) are obligated to evaluate the

hazards to persons, outgoing from the usage,

installation position, opening parameters and from the

external Control Unit of the power operated window,

already in the planning phase and to establish

necessary protective measures.

• The constructor / manufacturer of the machine

“power-operated window” must implement the

planned protective measures at the installation site

or, if not yet established, determine them by it´s

own responsibility and detect or minimize possible

remaining risks.

Snow load on roof windows for SHEV-systems

Example calculation

Establish snow loading based on national standards /directives

(in Germany according to DIN 1055-5)

total weight = FG + snow load

total weight = (40 kg + 60 kg) = 100 kg

Example:

snow load = 60 kg

(Casement area x

Typical snow load)

Example: FG = 40 kg