• Where to locate the stove.

• How to deal with fireplace design.

• Where to locate the oil tank.

• How to get an oil supply to the stove.

• How to fit the chimney.

• How to connect water to the stove.

• How to disconnect and remove the stove,

easily.

The new build situation should be the easiest.

The established boat situation will require careful

attention to the sighting of the stove in relation to

flue positions and existing fittings positions.

In replacement situations it may well be necessary to

blank off the existing through roof flue position and

cut a fresh one to suit the new location.

2. ABOUT THE STOVE

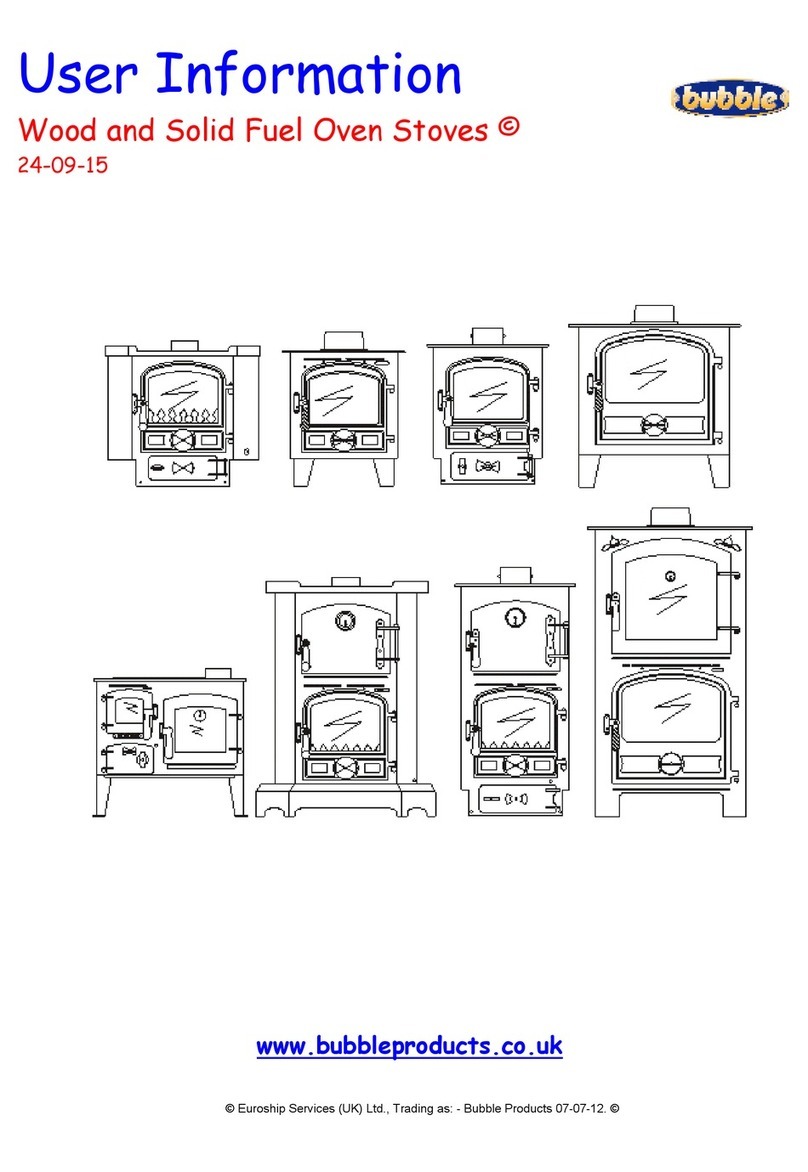

3. The top of the stove can be used for warming and

cooking.

5. Standard deck flanges and traditional chimney

extensions can be used above deck.

6. The stove will provide space or combined space and

water heating.

There are two choices of boiler either a 3 or 9kW and

there are 2 x 1" BSP female sockets for water

connections to be made at the rear of the stove as

required.

8. The boilers are high water content and suitable for

pumped or gravity systems, pressurised or open

vented, provided that the systems are correctly

designed.

3. OPERATING PRINCIPLES.

1. The stove is a space heater, which burns diesel oil in

a controlled manner utilizing a chimney to discharge

the products of combustion.

2. The stove generates heat from burning oil mixed

with air in a vaporizing pot located in the bottom of

the stove.

3. Once lit, oil goes into the pot at a steady and

controlled rate via gravity flow, metered by the OIL

CONTROL VALVE the oil flow can be controlled from

minimum to maximum or any setting in between

determined by where you set the oil flow control knob.

4. Air is sucked into the pot by the natural action of

the negative pressure in the chimney and to allow the

chimney to work correctly it is essential that you have

adequate, unrestricted ventilation into the area where

the stove is situated.

5. The amount of oil that can be successfully burned is

directly proportional to the amount of air that the

chimney can draw into the pot and so to achieve

adequate combustion a balanced and appropriate flow

of both oil and air is required.

4. CONTROLS

The output of the stove is regulated by the amount of

oil allowed to go into it and this function is controlled

by the -:

OIL CONTROL VALVE (O.C.V.), which is situated at

the rear of the stove.

Turning the knob anti clockwise controls the oil flow.

The knob is located at the top rear of the stove and is

calibrated from off position (fully clockwise) through

6 graduations to maximum.

Controls for the stove will vary, depending on which

valve is fitted to it.

Depending upon its intended use the stove could be

fitted with either a ships valve (OCI 252 AY sea

going) or a (Toby DVR inland water) valve.

The control for the sea going ships valve comprises

Oil flow control only. ( OCI 252AY Ships Valve)

For thermostatic control we recommend the use of a

Teddington 90 deg C, KBB remote sensing fire valve,

with the sensing file attached to the hot pipe of the

appliance.

The control for the inland waterways version has

controls which are-:

Oil flow control.

Oil valve trip lever.

For boiler versions of the stove there are two

additional controls.

Thermostat control.

Safety Stat reset control.

The Toby oil control valve used on boiler stoves has a

built in, non electric, modulating thermostat control,

which will put the fire on to low fire when the target

temperature has been achieved.

In addition to this there is also a similar safety stat,

which will shut the burner down, should the water

exceed 80 deg C.

The safety stat re set control is lifted to reset the

valve, should the stat trip. (For details see the

separate booklet on oil valve details supplied with the

stove.)

The Toby valve has to be tripped into action by lifting

the trip lever on the side of the valve.

The flow of oil into the pot can be adjusted via the

knob on top of extension rod rising up from the oil

control valve.

8. With the increased flow of oil, extra heat is

generated, which in turn stimulates the chimney to

work harder and consequently draw more air into the

pot to maintain an adequate fuel air ratio.