2

I

IN

ND

DE

EX

X

1-0 INTRODUCTION ...................... 2

1-0-1.

W

ARNINGS

............................................................... 2

1-0-2.

G

ENERAL

I

NFORMATION

A

BO T

T

HE

S

TOVE

. ...... 3

1-0-3.

S

PACING

F

ROM

C

OMB STIBLES

. ............................ 3

1-0-4.

F

IREG ARDING

. ................................................ 3

1-0-5.

W

ARNING

. ............................................................... 3

1-0-6.

D

OOR

G

LASS

. ........................................................... 3

1-0-7.

F

ASTENING

D

OWN

. ................................................ 3

2-0 OUTLINE OF CHIMNEY PROBLEMS . 3

2-0-1.

D

OWNDRA GHTING

......................................... 4

2-0-2.

A

TMOSPHERIC CONDITIONS

. .......................... 4

2-0-3.

S

MMARY

O

F

C

HIMNEY

P

ROBLEMS

................ 4

2-0-4.

M

IN

C

HIMNEY

H

EIGHT

F

OR

H

IGH

F

IRE

. .............. 4

2-0-5.

M

INIM M

H

EIGHT

F

OR

L

OW

F

IRE

R

NNING

...... 4

3-0 FUEL SUPPLY PROBLEMS ............. 4

3-0-1.

W

AXING

.................................................................. 4

3-0-2.

C

HANGING

O

IL

P

RESS RE

A

T

T

HE

S

TOVE

. .......... 5

3-0-3.

P

OOR OIL FLOW PROBLEMS

. .................................... 5

3-0-4.

O

IL FEED SET P

. .................................................... 5

3-0-5.

O

IL LINE

................................................................. 5

4-0 HOW IT WORKS ...................... 6

4-9.

T

HE COAL KIT

.............................................................. 6

4-

10.

D

ESCALING CONTROL

.............................................. 6

4-11.

S

TOVE

C

OMPONENTS

................................................ 6

5-0 RUNNING THE STOVE ...............

5-1.

O

IL

C

ONTROL

V

ALVE

D

ETAILS

................................... 7

5-2.

L

IGHTING

. ................................................................... 7

5-3.

S

TOVES WITH BOILERS

.............................................. 7

5-4.

C

ONTROLS ON

S

TOVES WITH BOILERS

..................... 7

6-0 FAULT FINDING ...................... 8

W

ATER

C

ONTAMINATION

.................................................. 8

6-1.

R

ACING

......................................................................... 8

6-2.

F

L E VAC M

.............................................................. 8

6-3.

B

RNER R NS SOOTY

. ................................................ 8

6-8.

O

IL SMELLS

................................................................. 9

6-9.

D

EFLOODING A FLOODED POT

.................................... 9

6-10.

O

IL LEAKS

.................................................................. 9

.0 ROUTINE MAINTENANCE............ 9

8-0 WARRANTY ............................ 9

1-0 INTRODUCTION

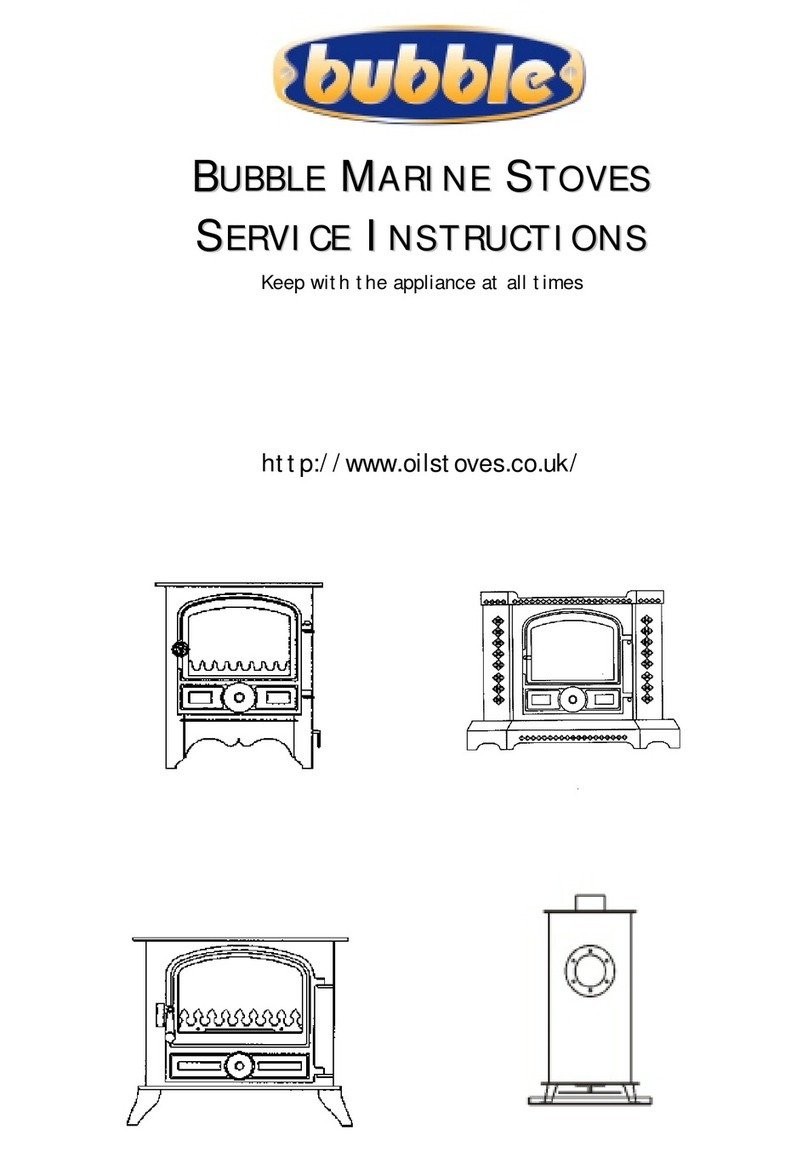

1. As its name implies, the Corner Bubble has been

designed to fit into confined spaces.

2. A great deal of effort has gone into the

development of this stove and it has been

specifically designed for the narrow boat user.

3. The triangular shape allows the stove to be

fitted with minimal use of space, allowing easy

access past it, better integration with internal

decor and designed as an integral part of the boat,

not just another add on.

4. The triangular base acts as a built in drip tray

and positioning device to allow adequate clearances

for air to circulate around the heater panels and

convert heat into the boat.

5. The top of the stove can be used for warming and

cooking.

6. The stove can also be supplied with or without a

coal kit.

7. Standard deck flanges and traditional chimney

extensions can used above deck providing a suitable

anti downdraught terminal is fitted.

8. The dry stove will provide space heating via

convection together with limited cooking facilities

on the top plate.

8a. The boiler version will provide the same with the

addition of hot water and central heating.

9. We have found from our now extensive

experience of existing installations that in most

cases, existing Bubble 1 users only have to run their

stoves on the lowest setting, even through the very

coldest of weather.

With this in mind and the increasing cost of oil, we

have designed the corner bubble using a more

economical burner which will run at 4ccs (.24 of a

litre per hour) on minimum firing rate and 10ccs (.6

of a litre per hour) on maximum firing rate equating

to a consumption per 24 hours continuous running of

5.76 litres low fire and 14.4 litres high fire.

10. The stove incorporates a combustion air

restrictor (C.A.R.) as opposed to the more

traditional swinging barometric damper and also

features a front mounted oil control valve with easy

access to the control knob.

1-0-1.

W

ARNINGS

1. Never try to relight a hot stove; wait until it has

cooled down, hot oil vapour is explosive.

2. Never try to light a flooded pot, when attempting

to light a stove make sure that the pot is not

flooded with oil, by looking into the base of the

burner.

If it is flooded remove the excess oil as per

instructions in the fault finding section.