Bucher Automation AG Table of contents

User manual – JMX-15P11-R1A0 iii

Table of contents

1 Introduction................................................................................................................................................. 5

1.1 Information on this document ............................................................................................................. 5

1.2 Typographical conventions................................................................................................................. 5

2 Safety........................................................................................................................................................... 6

2.1 General Information............................................................................................................................ 6

2.2 Purpose .............................................................................................................................................. 6

2.2.1 Intended use.......................................................................................................................... 6

2.2.2 Non-intended use .................................................................................................................. 6

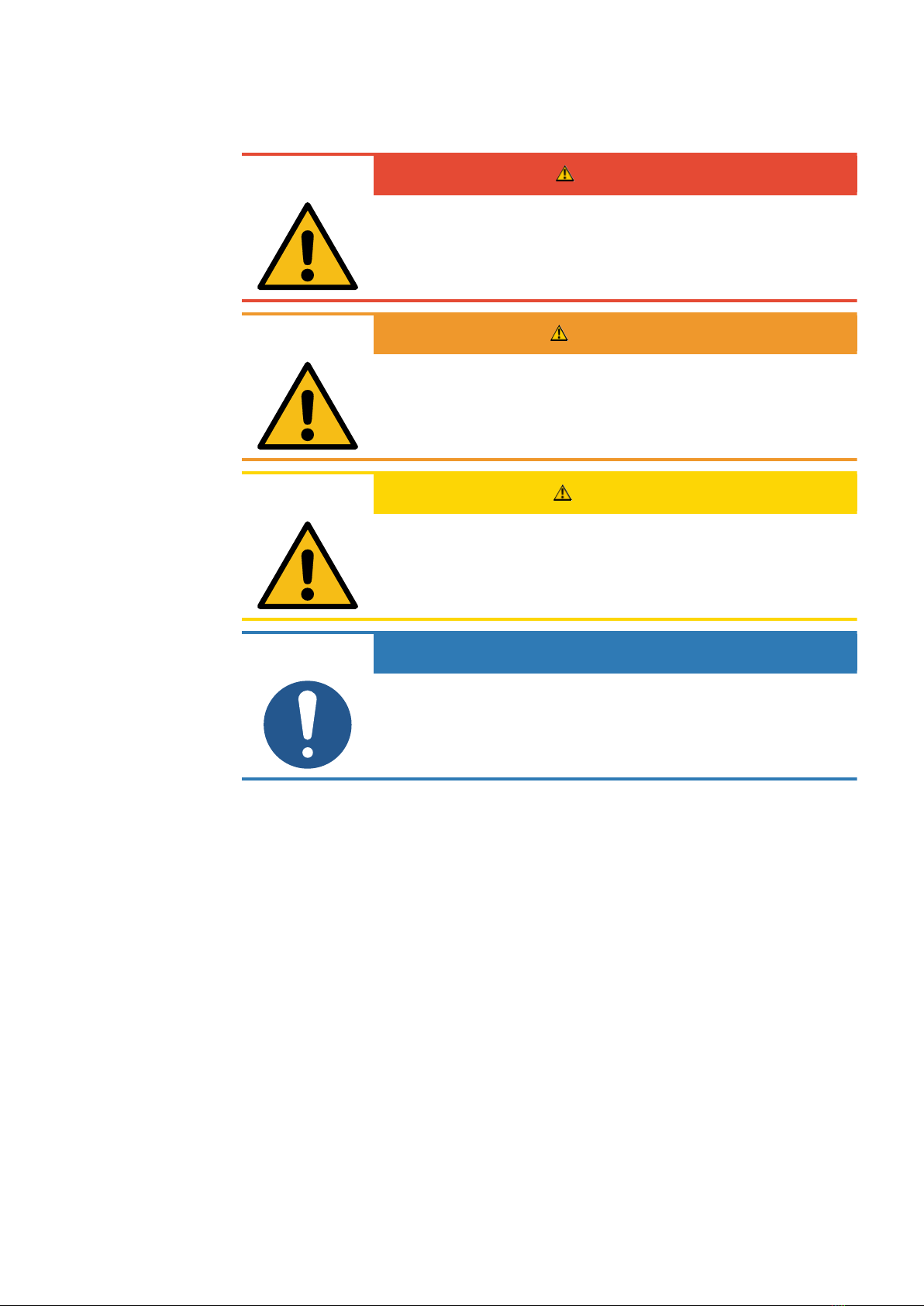

2.3 Warnings used in this document ........................................................................................................ 7

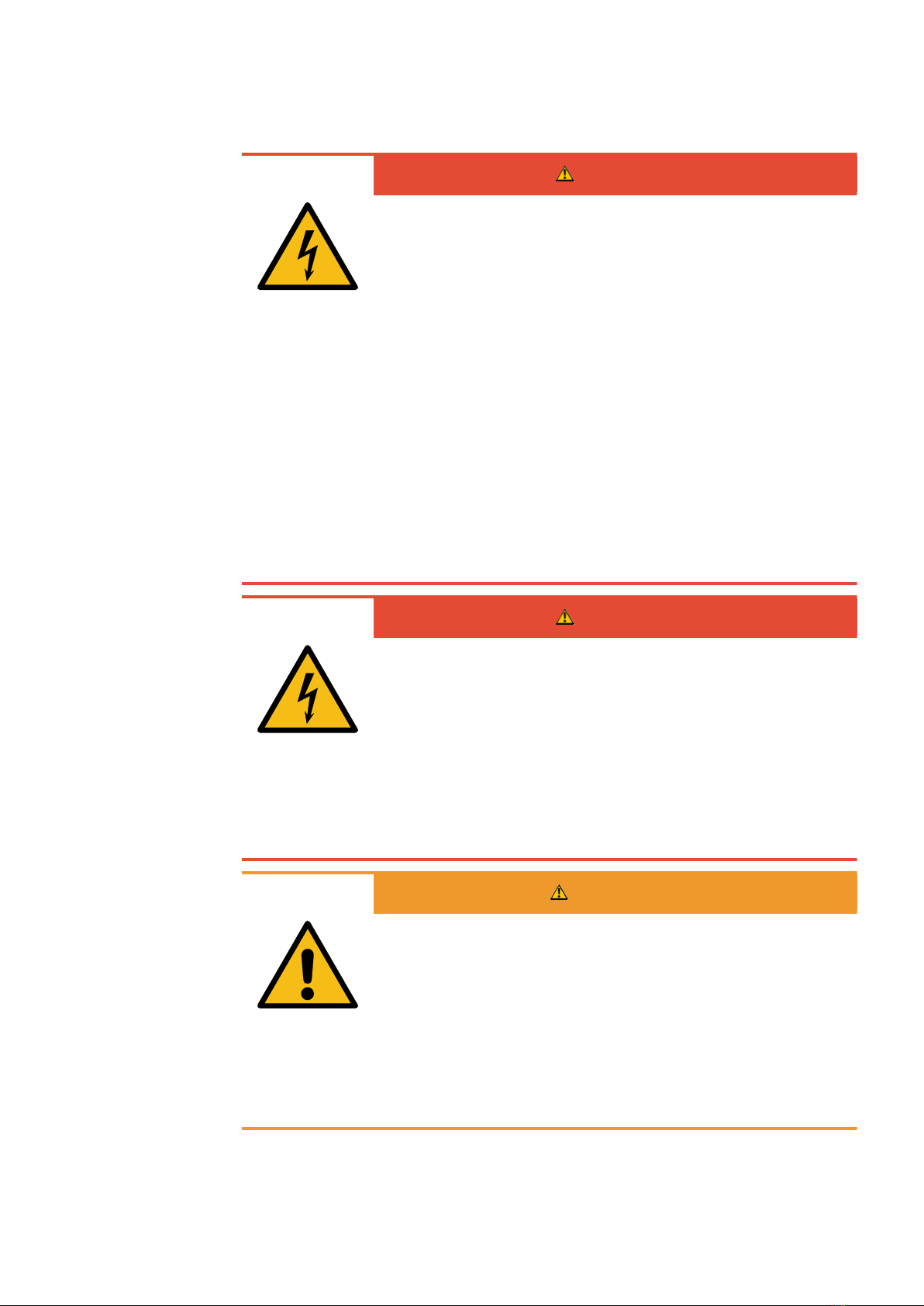

2.4 General safety instructions ................................................................................................................. 8

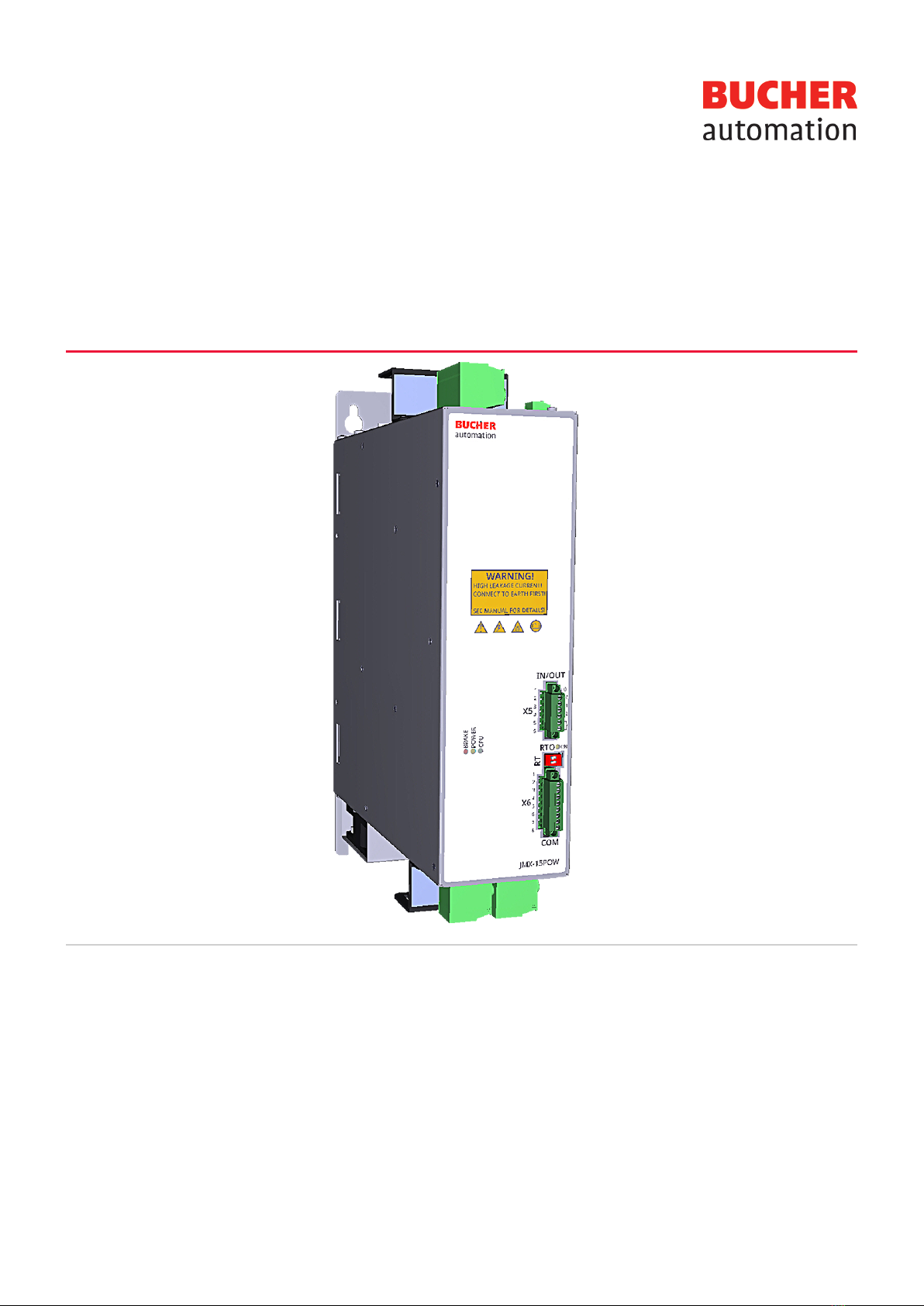

3 Product description.................................................................................................................................... 11

3.1 System overview ................................................................................................................................ 12

3.2 Design ................................................................................................................................................ 13

3.3 Product features ................................................................................................................................. 14

3.4 Status display ..................................................................................................................................... 14

3.4.1 Lighting patterns of the LEDs ................................................................................................ 14

3.4.2 Status display LEDs .............................................................................................................. 15

3.5 Nameplate .......................................................................................................................................... 16

3.6 Scope of delivery ................................................................................................................................ 17

4 Technical data............................................................................................................................................. 18

4.1 Dimensions......................................................................................................................................... 18

4.2 Mechanical specifications................................................................................................................... 19

4.3 Electrical properties ............................................................................................................................ 19

4.4 Torque reduction ................................................................................................................................ 24

4.5 Environmental conditions ................................................................................................................... 25

5 Mechanical installation .............................................................................................................................. 26

5.1 Installing the supply unit ..................................................................................................................... 26

5.2 Dismantling the supply unit................................................................................................................. 27

6 Electrical connection ................................................................................................................................. 28

6.1 Power supply ...................................................................................................................................... 30

6.1.1 Connection of voltage supply and RTO contact .................................................................... 30

6.2 Block diagram..................................................................................................................................... 31

6.3 Test installation................................................................................................................................... 31

6.4 Connection example........................................................................................................................... 33

6.4.1 Line cross-sections................................................................................................................ 34

6.5 Input connection ................................................................................................................................. 34